Composite ionic adsorption material and preparation method thereof

An ion adsorption and composite technology, applied in the field of materials, can solve the problems of difficult regeneration of activated carbon, limitation of adsorption effect, increase of treatment cost, etc., and achieve the effect of abundant reserves, enhanced ion exchange capacity and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

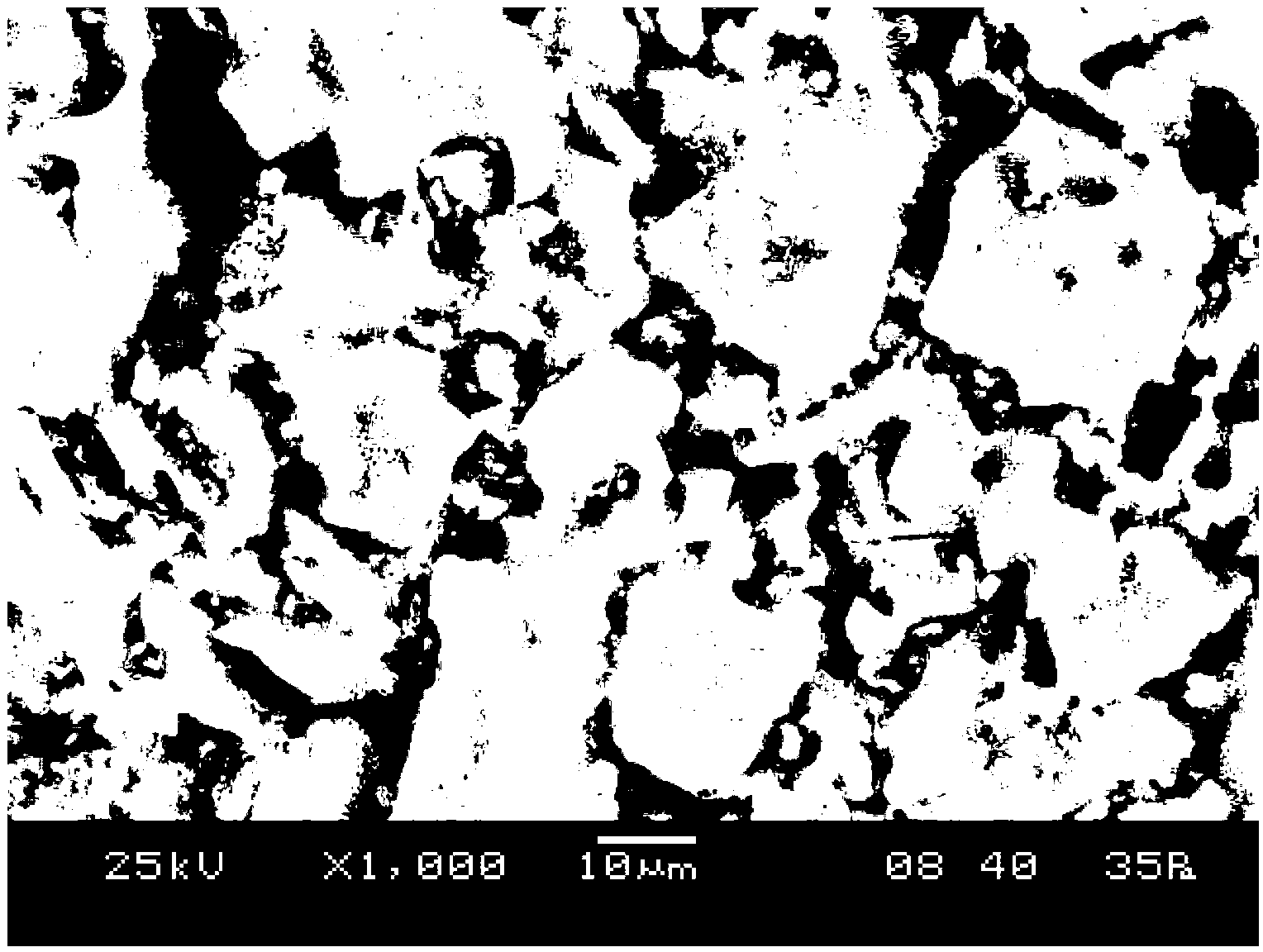

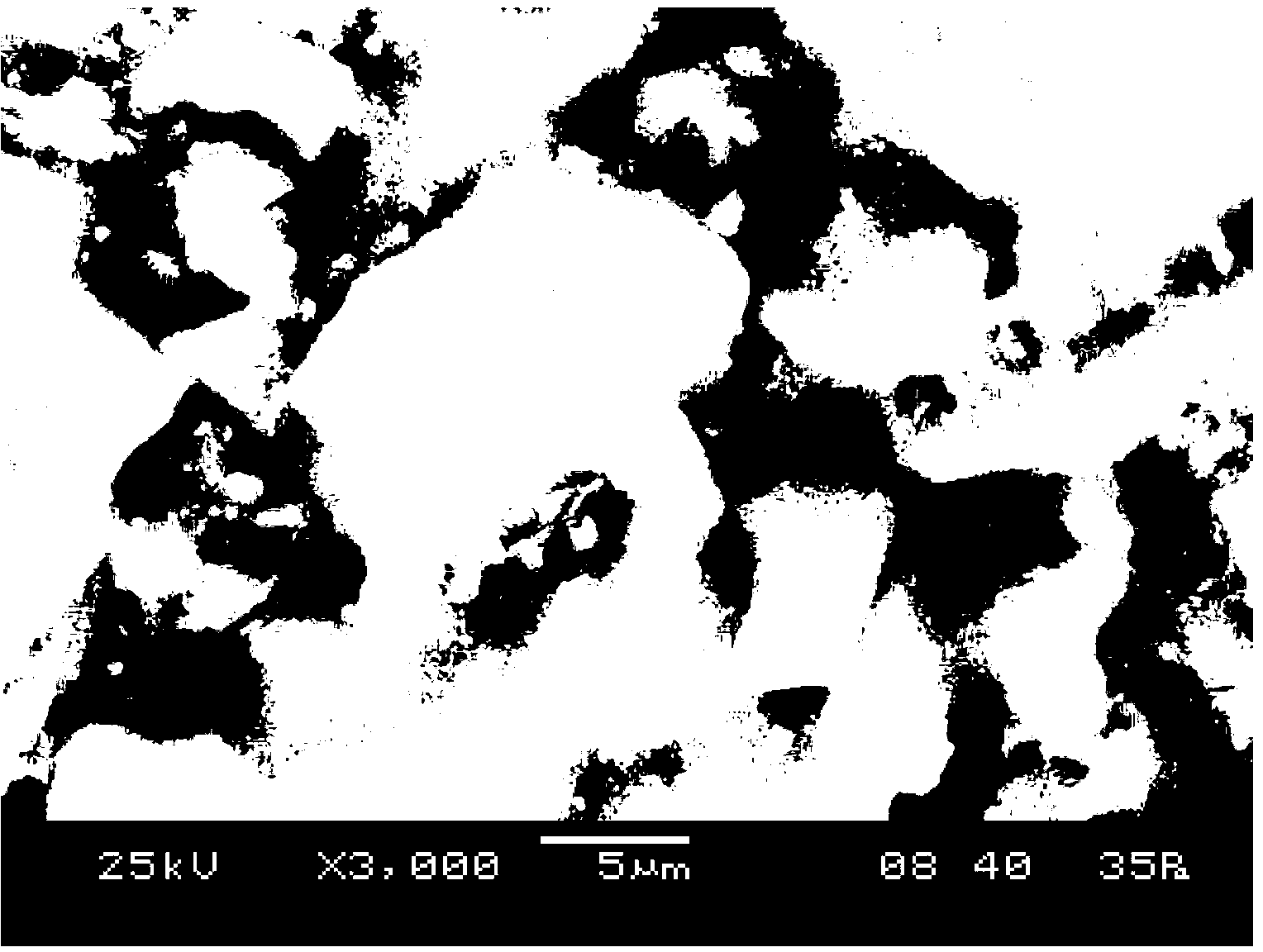

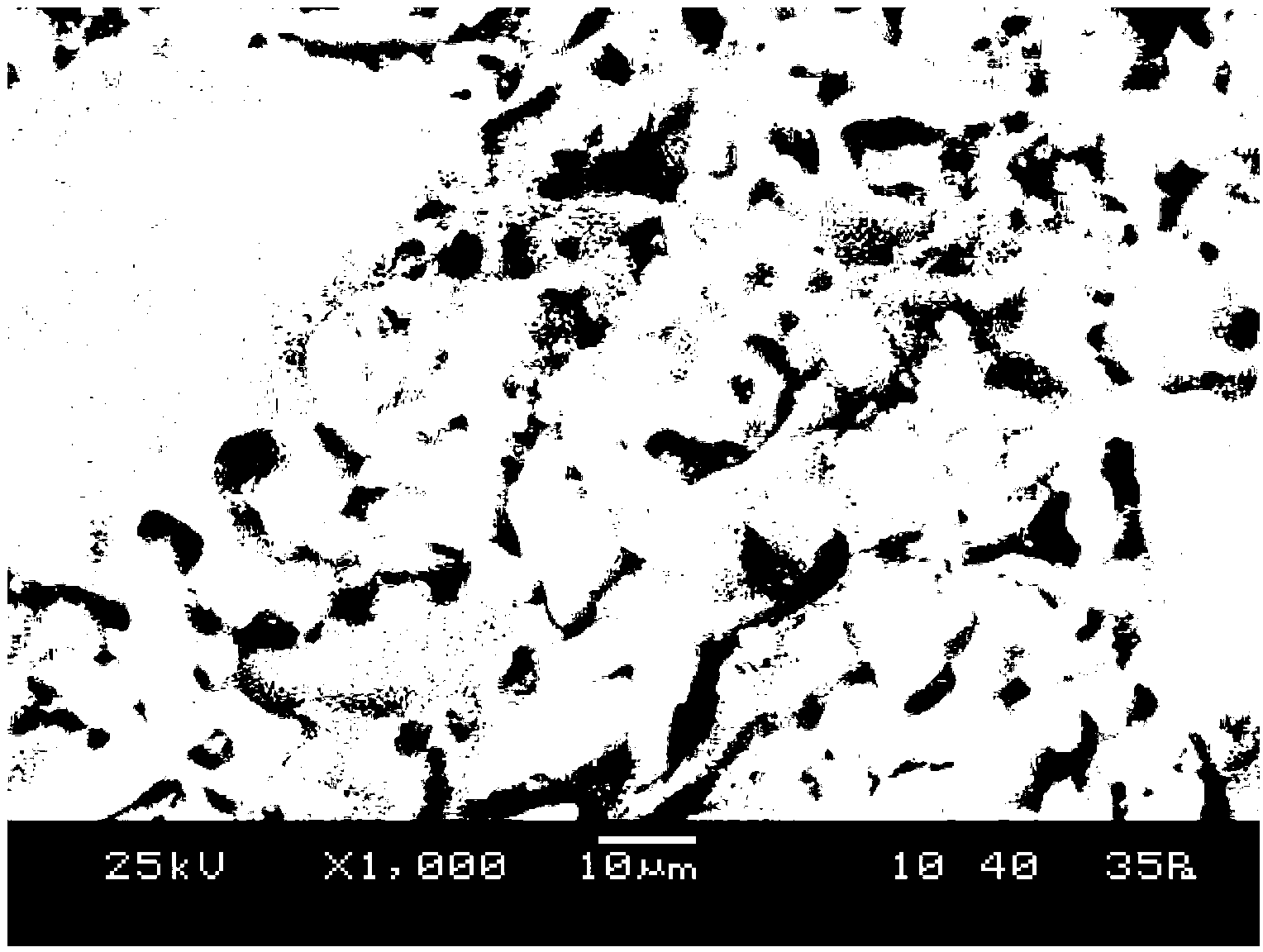

Image

Examples

Embodiment 1

[0035] A method for preparing a composite ion-adsorbing material, comprising the following steps:

[0036] In the first step, natural zeolite, medical stone and diatomite are respectively processed into 180-mesh fine powder;

[0037] In the second step, the above two fine powders of zeolite and medical stone are respectively modified in a water bath with 0.8mol / L 70°C NaCl solution, and the water bath time is 2.5 hours. 25mL of NaCl solution; then wash and filter with water respectively, and dry at 110°C for 2 hours after washing and filtering; obtain modified zeolite fine powder and modified medical stone fine powder for later use;

[0038] The third step is to take 80 parts of modified zeolite fine powder, 15 parts of modified medical stone fine powder, 10 parts of diatomite fine powder, 6 parts of 200 mesh activated carbon powder, and 2 parts of soluble starch, mix well, and add a certain amount of water Blend into a puree and set aside;

[0039]The fourth step is to shot...

Embodiment 2

[0043] A method for preparing a composite ion-adsorbing material, comprising the following steps:

[0044] In the first step, natural zeolite, medical stone and diatomite are respectively processed into 190-mesh fine powder;

[0045] In the second step, the above two fine powders of zeolite and medical stone are respectively modified in a water bath with 0.9mol / L 70°C NaCl solution, and the water bath time is 2.5 hours. 25mL of the above solution; then rinse and filter with water respectively, and dry at 110°C for 2 hours after rinsing and filtration; obtain modified zeolite fine powder and modified medical stone fine powder for later use;

[0046] The third step is to take 80 parts of modified zeolite fine powder, 10 parts of modified medical stone fine powder, 15 parts of diatomite fine powder, 6 parts of 200 mesh activated carbon powder, and 2 parts of soluble starch, mix well, and add a certain amount of water Blend into a puree and set aside;

[0047] The fourth step is...

Embodiment 3

[0051] A method for preparing a composite ion-adsorbing material, comprising the following steps:

[0052] In the first step, natural zeolite, medical stone and diatomite are respectively processed into 200 mesh fine powder;

[0053] In the second step, the above two fine powders of zeolite and medical stone are respectively modified in a water bath with 1.0mol / L 75°C NaCl solution, and the water bath time is 2.5 hours. 25mL of the above solution; then rinse and filter with water respectively, and dry at 110°C for 2 hours after rinsing and filtration; obtain modified zeolite fine powder and modified medical stone fine powder for later use;

[0054] The third step is to take 85 parts of modified zeolite fine powder, 10 parts of modified medical stone fine powder, 10 parts of diatomite fine powder, 6 parts of 200 mesh activated carbon powder, and 2 parts of soluble starch, mix well, and add a certain amount of water Blend into a puree and set aside;

[0055] The fourth step is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com