Preparation method for diatomite loaded birnessite type manganese dioxide

A technology of birnessite and manganese dioxide, applied in chemical instruments and methods, separation methods, and other chemical processes, can solve problems such as secondary pollution, inability to decompose formaldehyde, and long-term doubts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

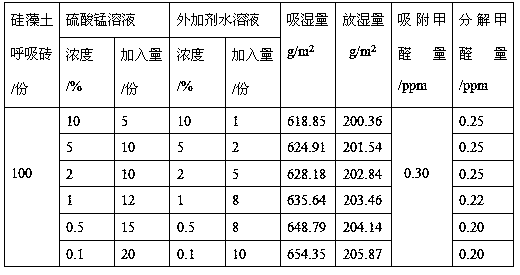

[0013] Potassium permanganate is prepared into an aqueous solution with a concentration of 0.1-10.0%, and the admixture is prepared into an aqueous solution with a concentration of 0.1-10.0%. After stirring the aqueous solution of potassium permanganate and the admixture evenly, the powdered diatom Soil is soaked in the mixed aqueous solution of potassium permanganate and additive, and dried at 60-150 DEG C to prepare birnessite-type manganese dioxide loaded diatomite. Under the condition that the relative air humidity is 50%, its formula and effect are as shown in Table 1:

[0014] Table 1 Preparation and effect of diatomite loaded birnessite-type manganese dioxide

[0015]

Embodiment 7-12

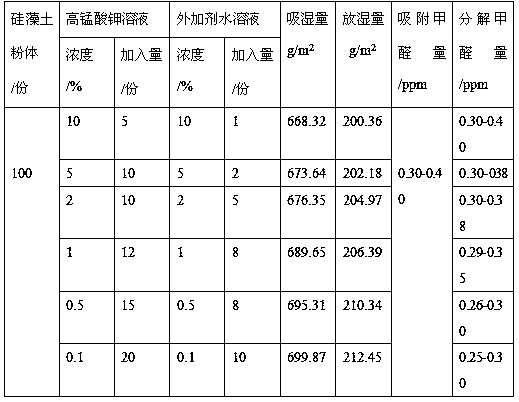

[0017] Manganese sulfate is formulated into an aqueous solution with a concentration of 0.1-10.0%, and the admixture is prepared into an aqueous solution with a concentration of 0.1-10.0%. After stirring the aqueous solution of birnessite-type manganese dioxide evenly, the diatomite breathing brick is immersed in the mixed aqueous solution of manganese sulfate and admixture, and dried at 60-150°C to prepare diatomite loaded with birnessite-type manganese dioxide. . Under the condition that the relative air humidity is 50%, its formula and effect are as shown in Table 2:

[0018] Table 2 Preparation and effect of diatomite loaded birnessite-type manganese dioxide

[0019]

Embodiment 13-18

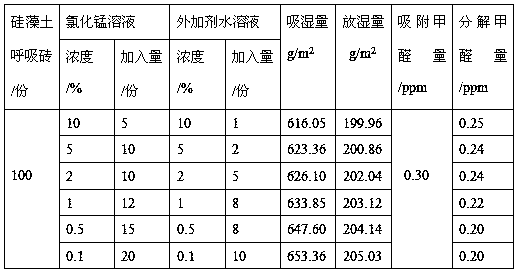

[0021] Manganese sulfate is prepared into an aqueous solution with a concentration of 0.1-10.0%, and the admixture is prepared into an aqueous solution with a concentration of 0.1-10.0%. After the aqueous solution of manganese sulfate and the admixture are stirred evenly, the diatomite breathing brick is soaked in sulfuric acid In the mixed aqueous solution of manganese and admixture (the admixture contains 0.1-0.5% potassium permanganate), after drying at 60-150°C and annealing at 100-300°C, the loaded birnessite-type manganese dioxide is prepared diatomaceous earth. Under the condition that the relative air humidity is 50%, its formula and effect are as shown in Table 3:

[0022] Table 3 The formula and effect of preparing diatomite loaded with birnessite-type manganese dioxide

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com