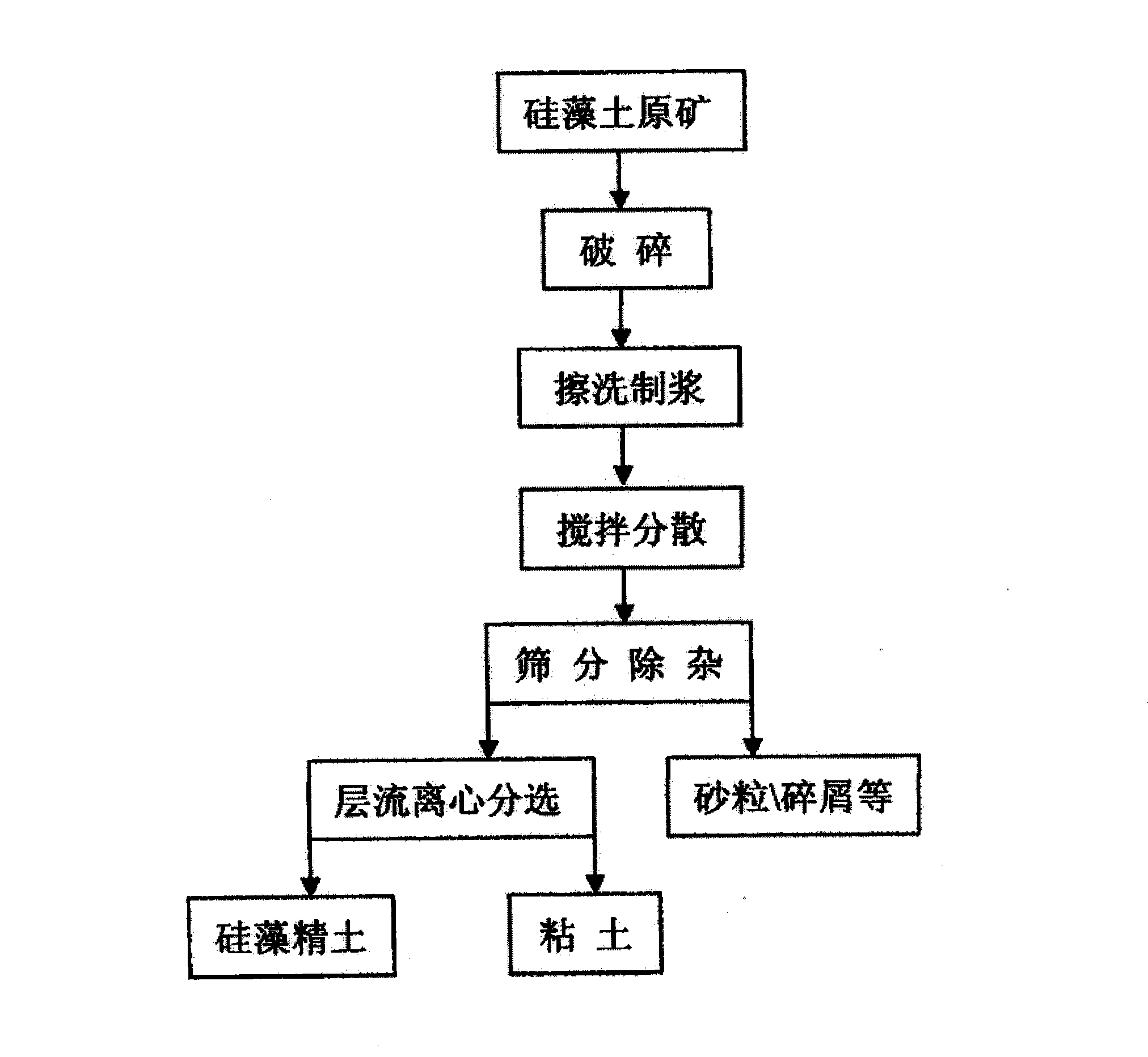

Laminar centrifugal beneficiation method for diatomite ores

A technology of diatomite ore and ore dressing method, which is applied in the direction of centrifuges with rotating drums, centrifuges, chemical instruments and methods, etc., which can solve the problem of affecting the separation accuracy and recovery rate of diatomite and affecting the safety of separation It can solve the problems of safety, reliability, and high speed, and achieve the effect of high sorting efficiency and precision, small footprint, and good quality of fine soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

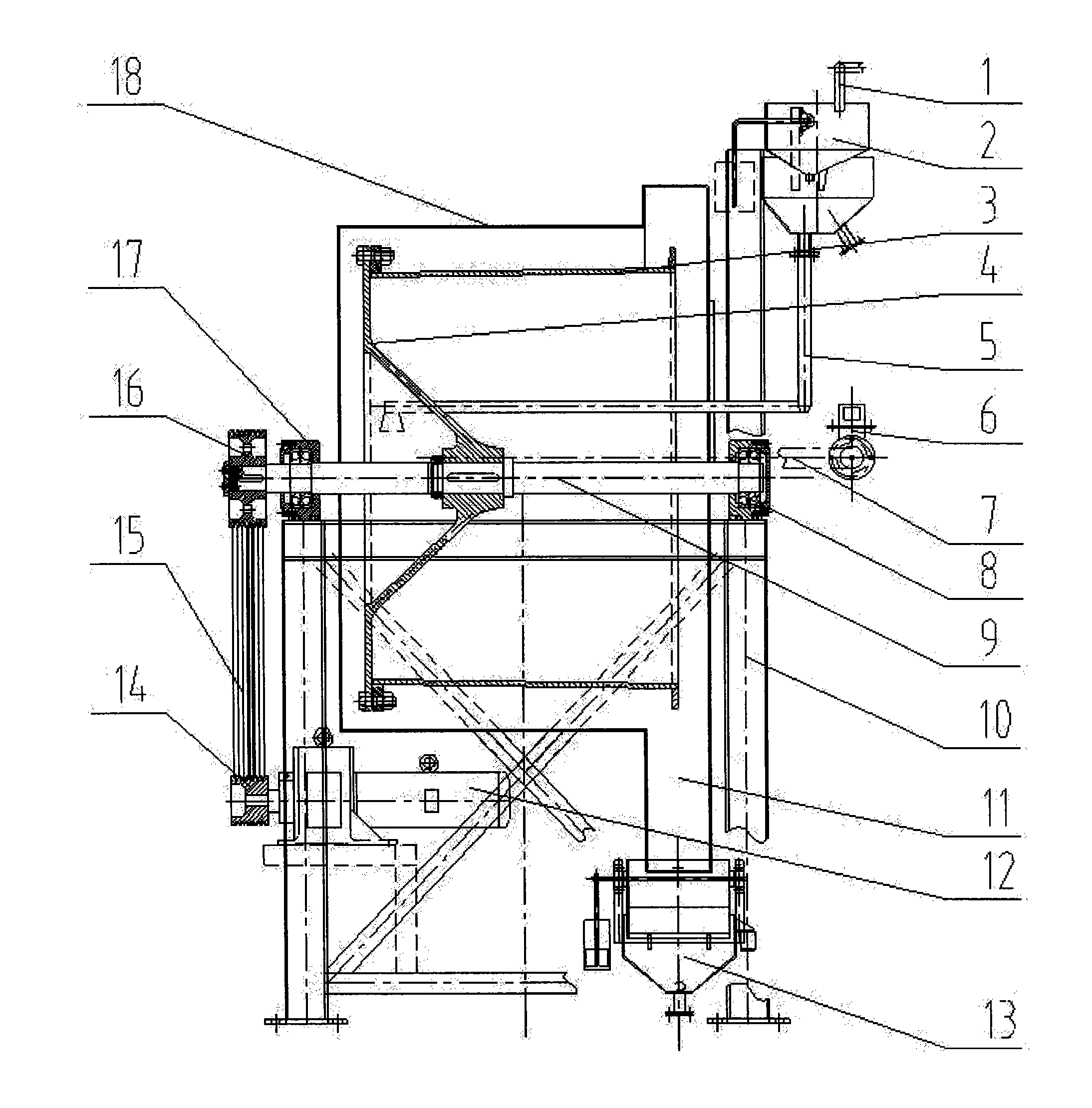

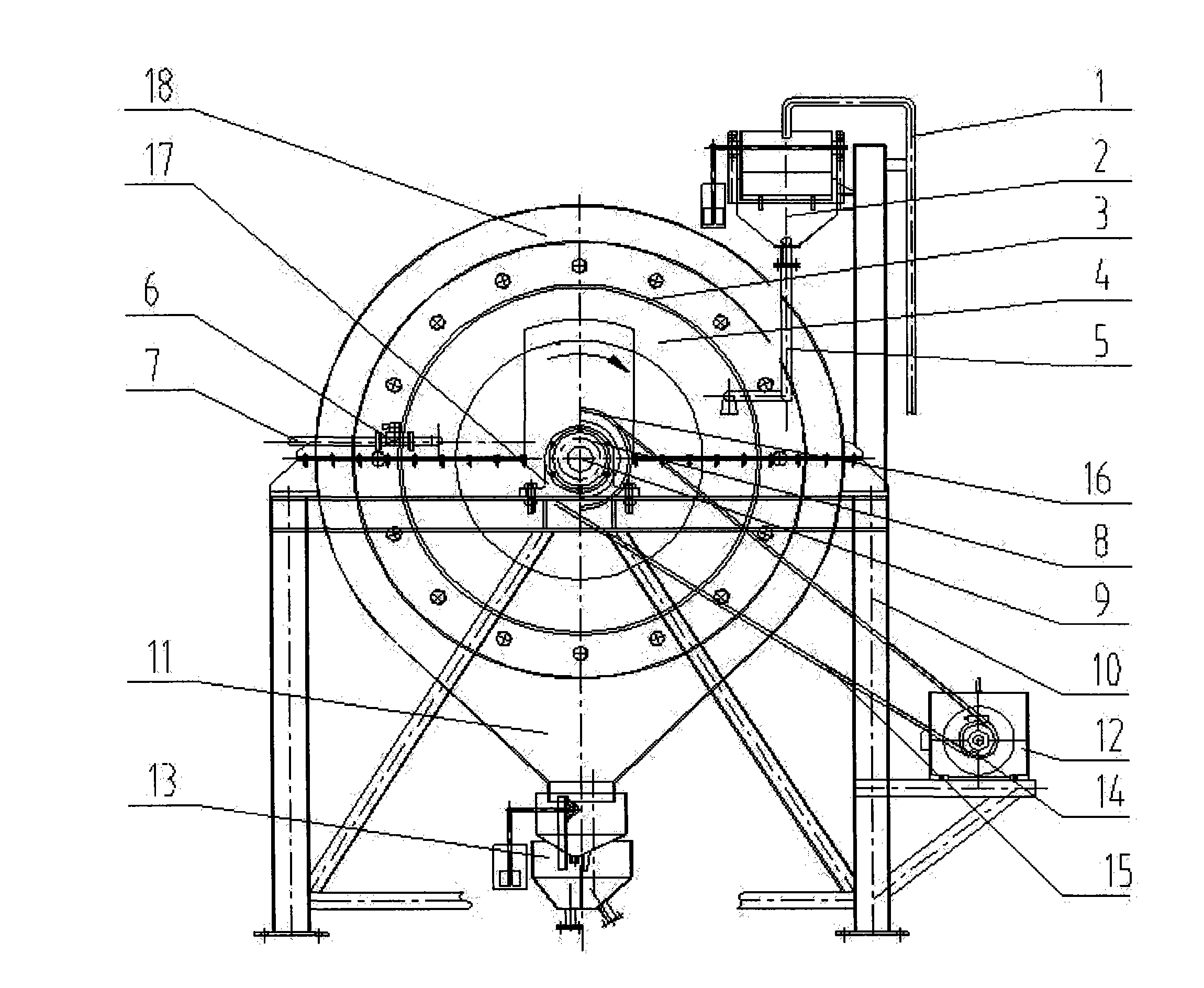

[0045] Embodiment one: with 24kg (water content 55%) SiO 2 Diatomite ore with a content of 78.46% and a diatomite content of about 76% is added with 12L of water, added to a ZCX-0.08×2 double-slot scrubbing machine for scrubbing, and the pH of the pulp is adjusted to 9 with sodium hydroxide, and the scrubbing time is 15 minutes; the scrubbed pulp enters Add 44L of water and 380g of sodium pyrophosphate to the mixing tank to disperse while stirring; the dispersed pulp is sieved with a 200-mesh rotary vibrating sieve to separate impurities such as sand and debris, and then fed into Φ500 (imported) / Φ520 (Export) × 600 laminar flow centrifugal concentrator to separate clay and diatomite, centrifugal separation factor 548, feeding time 90s, diatomite (sediment) washing time 30s, intermittent 5s; filter and dry to obtain diatoms 9.11kg of fine soil (moisture content 6%).

Embodiment 2

[0046] Embodiment two: with 24kg (water content 55%) SiO 2 Diatomite ore with a content of 78.46% and a diatomite content of about 76% is added with 12L of water, added to a ZCX-0.08×2 double-slot scrubbing machine for scrubbing, and the pH of the pulp is adjusted to 9 with sodium hydroxide, and the scrubbing time is 15 minutes; the scrubbed pulp enters Add 44L of water and 380g of sodium pyrophosphate to the mixing tank to disperse while stirring; the dispersed pulp is sieved with a 200-mesh rotary vibrating sieve to separate impurities such as sand and debris, and then fed into Φ500 (imported) / Φ520 (Export) × 600 laminar flow centrifugal concentrator to separate clay and diatomite, centrifugal separation factor 402, feeding time 90s, diatomite (sediment) washing time 30s, intermittent 5s; filter and dry to obtain diatoms 9.01kg of fine soil (moisture content 6%).

Embodiment 3

[0047] Embodiment three: with 24kg (water content 55%) SiO 2 Diatomite ore with a content of 78.46% and a diatomite content of about 76% is added with 12L of water, added to a ZCX-0.08×2 double-slot scrubbing machine for scrubbing, and the pH of the pulp is adjusted to 9 with sodium hydroxide, and the scrubbing time is 15 minutes; the scrubbed pulp enters Add 44L of water and 380g of sodium pyrophosphate to the mixing tank to disperse while stirring; the dispersed pulp is sieved with a 200-mesh rotary vibrating sieve to separate impurities such as sand and debris, and then fed into Φ500 (imported) / Φ520 (Export) × 600 laminar flow centrifugal concentrator to separate clay and diatomite, centrifugal separation factor 308, feeding time 90s, diatomite (sediment) washing time 30s, intermittent 5s; filter and dry to obtain diatoms Refined soil 8.95kg (moisture content 6%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com