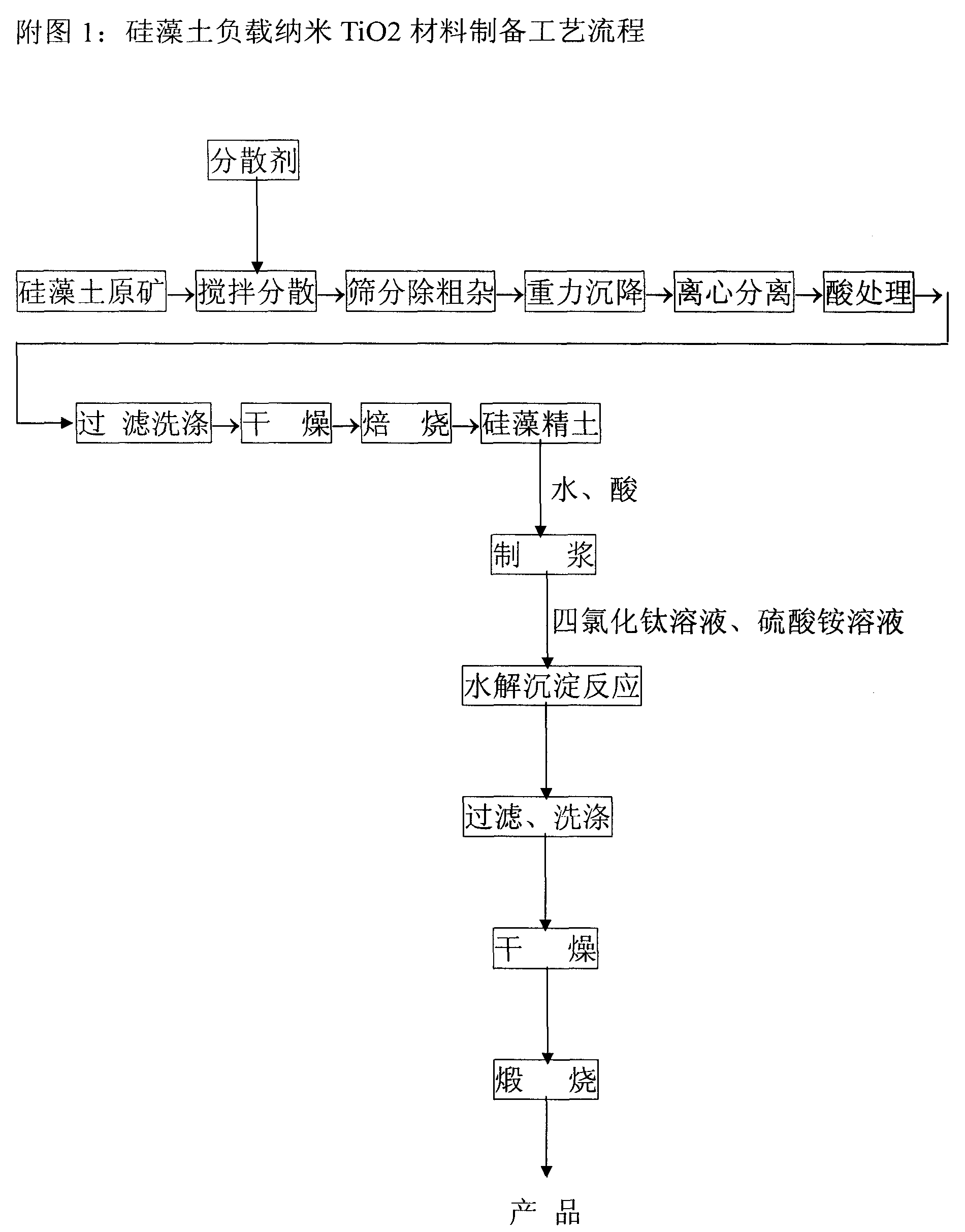

Method for producing tripolite loading nano-TIO2 material capable of being used for water and air purification

An air purification and diatomite technology, which is applied in the field of preparation of diatomite-supported nano-TiO2 materials, can solve the problems of high production cost, influence on photocatalyst, influence on the effect of photocatalyst, etc., and achieves low production cost, environmental friendliness, good quality The effect of photocatalysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]Take 1000g of diatomite ore, add 1500mL of water, 5g of sodium hydroxide, and 3g of sodium pyrophosphate, stir and disperse with a laboratory mixer for 20 minutes, then add 1500mL of water, use a 50-mesh sieve to separate impurities such as grass roots and bark; sieve the pulp in a plastic basin After medium gravity sedimentation for 4 minutes, suck it out with a siphon and separate the sucked ore pulp with a sedimentation centrifuge for 6 minutes; then take out the centrifuged precipitate product, put it into a three-necked flask, add 1200L of 65% sulfuric acid solution, stir at 95°C for 4 hours, and then filter. Washing; the filter cake was dried at 105°C and baked in a muffle furnace at 450°C for 2h.

[0033] Take 100g of the dried selected diatomite, add 3000mL of water, adjust the pH to 2 with hydrochloric acid, stir and disperse, add 200mL of the prepared titanium tetrachloride solution with a concentration of 2.9mol / L, and then evenly add the concentration of 1.49m...

Embodiment 2

[0035] Take 1000g of diatomite ore, add 1500mL of water, 6g of sodium hydroxide, and 4g of sodium pyrophosphate, stir and scrub with a laboratory scrubber for 30 minutes, then add 2000mL of water, and use a 50-mesh sieve to separate impurities such as grass roots and bark; After gravity settling in the basin for 5 minutes, suck it out with a siphon and separate the sucked ore pulp with a sedimentation centrifuge for 7 minutes; then take out the centrifuged precipitate product, put it into a three-necked flask, add 1100L of 72% sulfuric acid solution, stir at 100°C for 3 hours, and then filter 1. Washing; the filter cake was dried at 105° C. and baked at 400° C. for 2.5 hours in a muffle furnace.

[0036] Take 500g of dried selected diatomite, add 15000mL of water, adjust the pH to 2 with hydrochloric acid, stir and disperse, add 1000mL of titanium tetrachloride solution with a concentration of 2.9mol / L, and then evenly add the concentration of 1.49mol / L 2300ml of ammonium sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com