Phosphate adsorbent capable of being repeatedly used and preparation method thereof

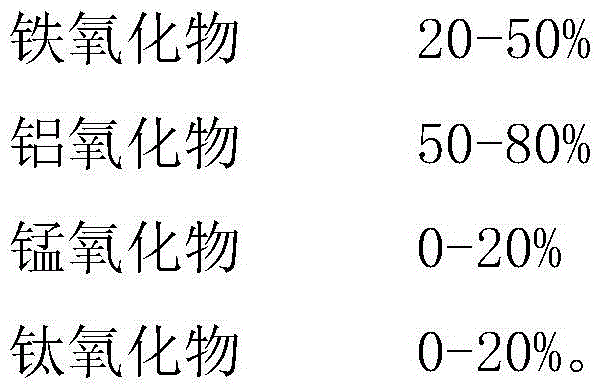

A phosphate adsorbent and adsorbent technology, applied in silicate, chemical instruments and methods, adsorbed water/sewage treatment, etc., can solve the problems of increasing sludge volume, lack of phosphate removal technology, and increasing total environmental load. , to achieve the effect of simple preparation method, strong operability and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1), preparation of porous carrier:

[0032] Mix 50g of silicon oxide (or aluminum oxide, or manganese oxide, or zeolite, or activated carbon, or diatomaceous earth, or several combinations), 5g of glass powder, and 5g of kaolin to form a porous carrier precursor; The carrier precursor was sintered at a temperature of 800° C. for 6 hours to form a porous carrier, ready for use.

[0033] (2), the preparation of metal ion mixed solution:

[0034] The titanium sulfate of 35g, the ferric chloride of 30g and the aluminum sulfate of 350g and the water of 1000g and the right amount of sulfuric acid are uniformly mixed, form the metal ion mixed solution;

[0035] (3), soak the porous carrier in the mixed solution of metal ions, and let it stand for 22 hours to form a reusable phosphate adsorbent precursor;

[0036] (4) Air-dry the reusable phosphate adsorbent precursor for 20 hours, and then dry it at 250°C for 8 hours.

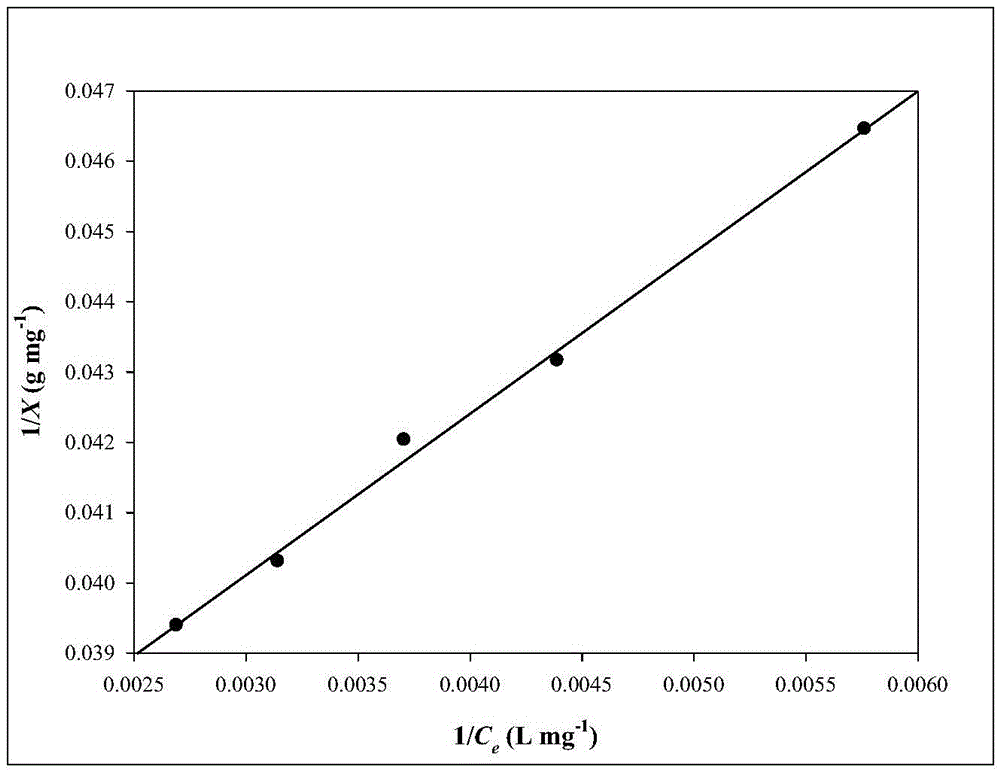

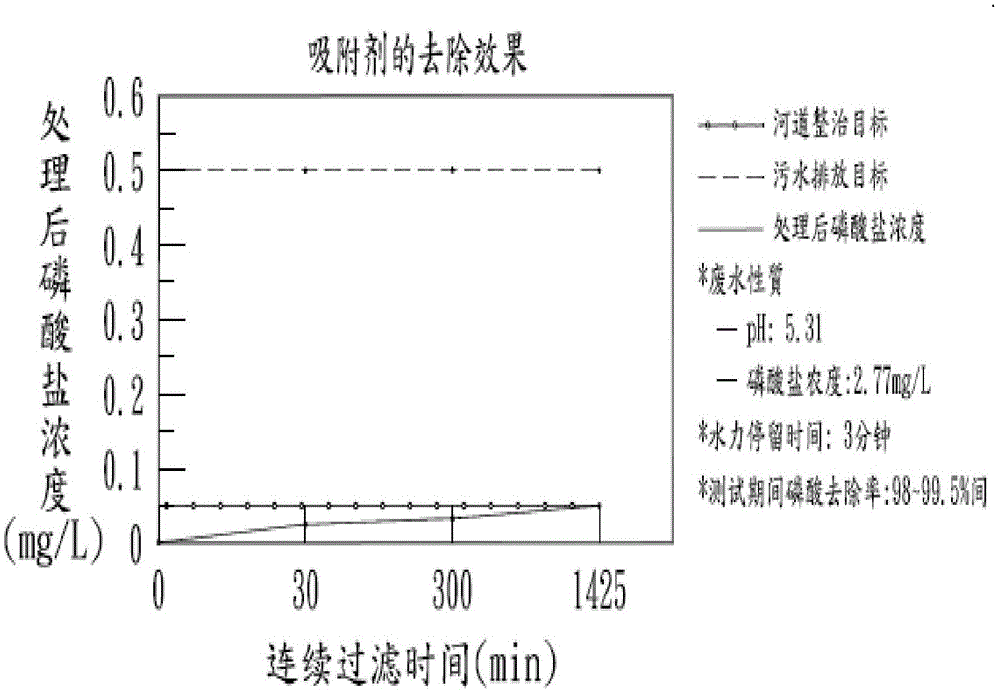

[0037] The reusable phosphate adsorbent prepared in t...

Embodiment 2

[0039] (1), preparation of porous carrier:

[0040] Mix 50g of silica (or alumina, or manganese oxide, or zeolite, or diatomaceous earth or a combination of several), 10g of adhesive glass powder and 5g of kaolin; Sintering at high temperature for 5 hours to form a porous carrier, ready for use.

[0041] (2), the preparation of metal ion mixed solution:

[0042] The manganese hydroxide of 15g, the titanium sulfate of 20g, the ferric chloride of 30g and the aluminum sulfate of 350g and the water of 1000g and the right amount of sulfuric acid are uniformly mixed, form metal ion mixed solution;

[0043] (3), immerse the porous carrier in the mixed solution of metal ions, and let it stand for 24 hours to form a reusable phosphate adsorbent precursor;

[0044] (4) Air-dry the reusable phosphate adsorbent precursor for 24 hours, then dry it at 300°C for 6 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com