Patents

Literature

51 results about "Chemistry radiation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

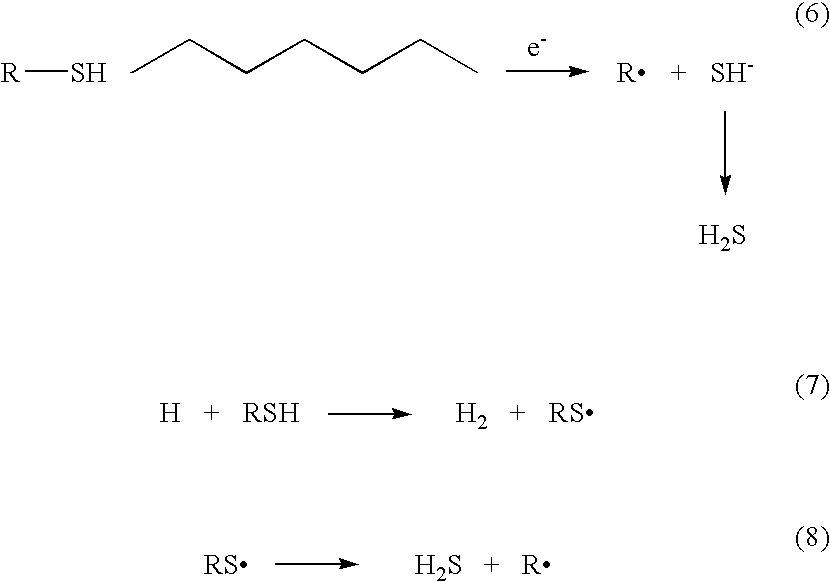

Radiation chemistry is a subdivision of nuclear chemistry which is the study of the chemical effects of radiation on matter; this is very different from radiochemistry as no radioactivity needs to be present in the material which is being chemically changed by the radiation.

Method for preparing graphene-based titanium dioxide composite photocatalyst by radiation of electron beams

ActiveCN101658786AWrappedPromote growthWater/sewage treatment by irradiationWater contaminantsTitanium tetrafluorideRadiation chemistry

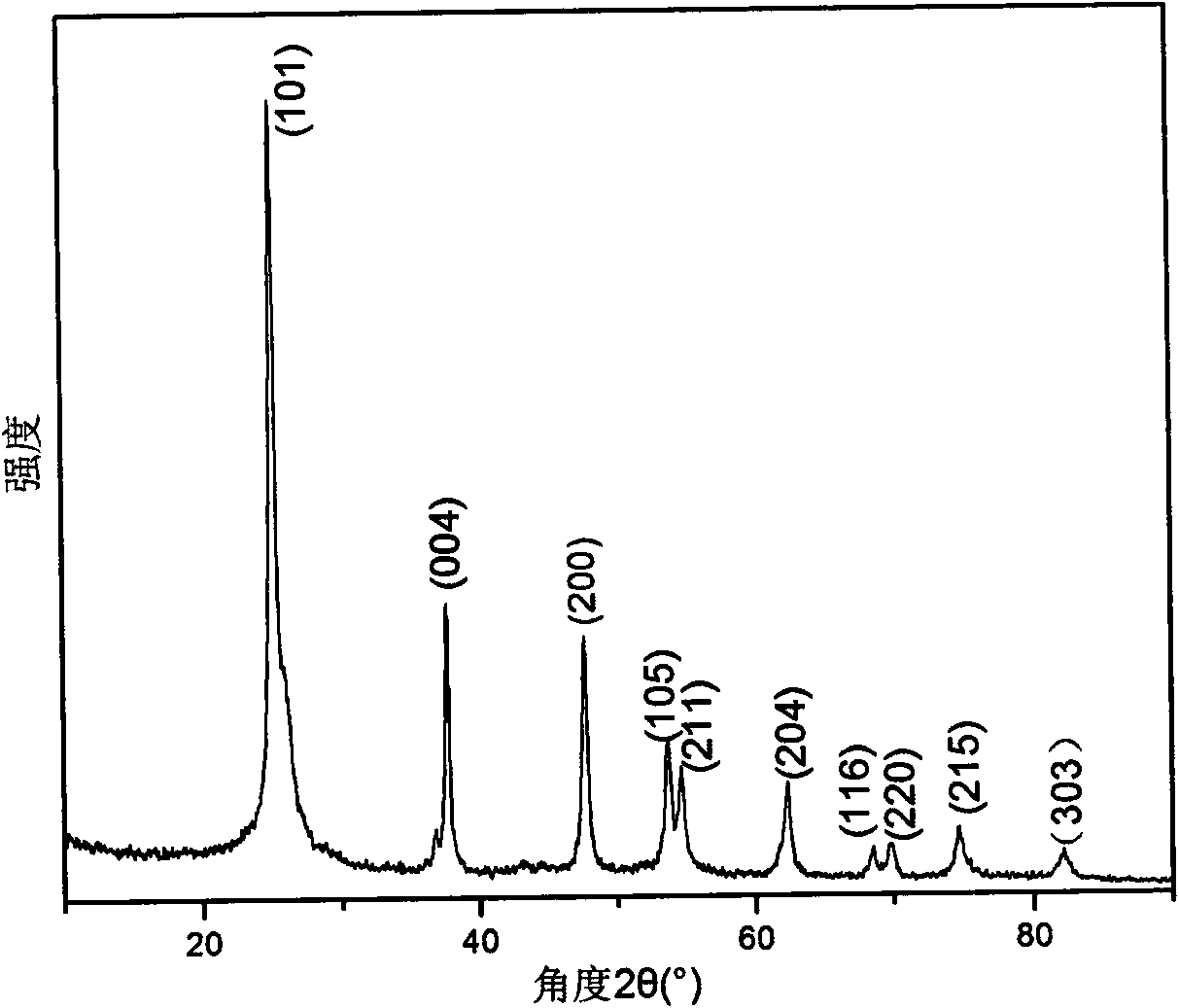

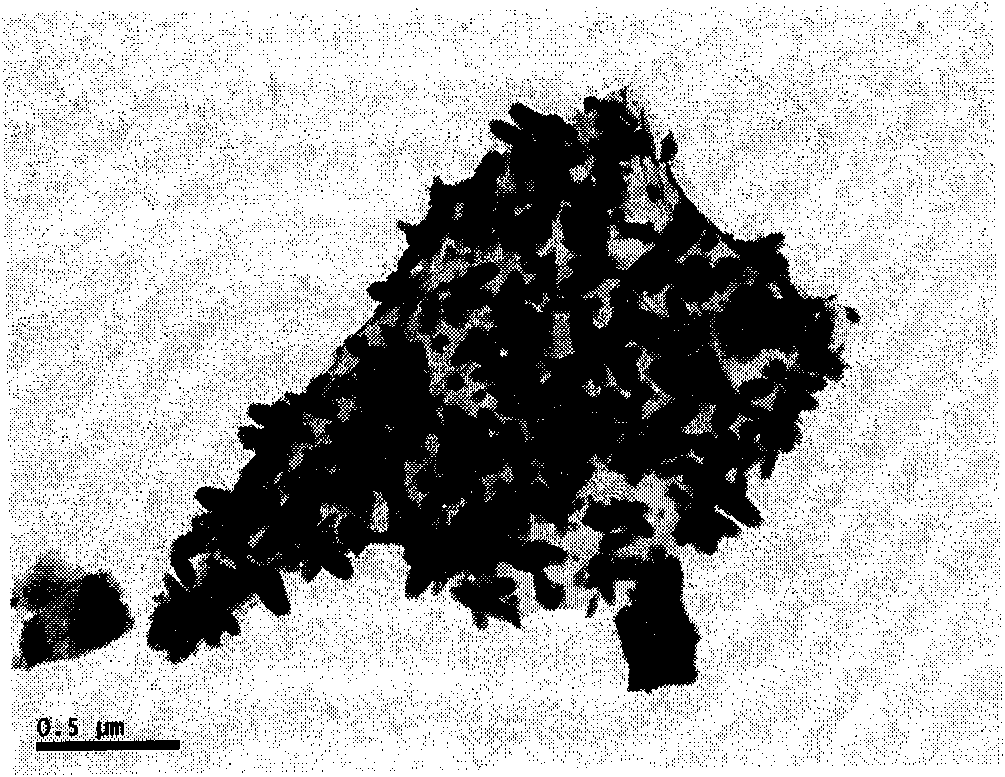

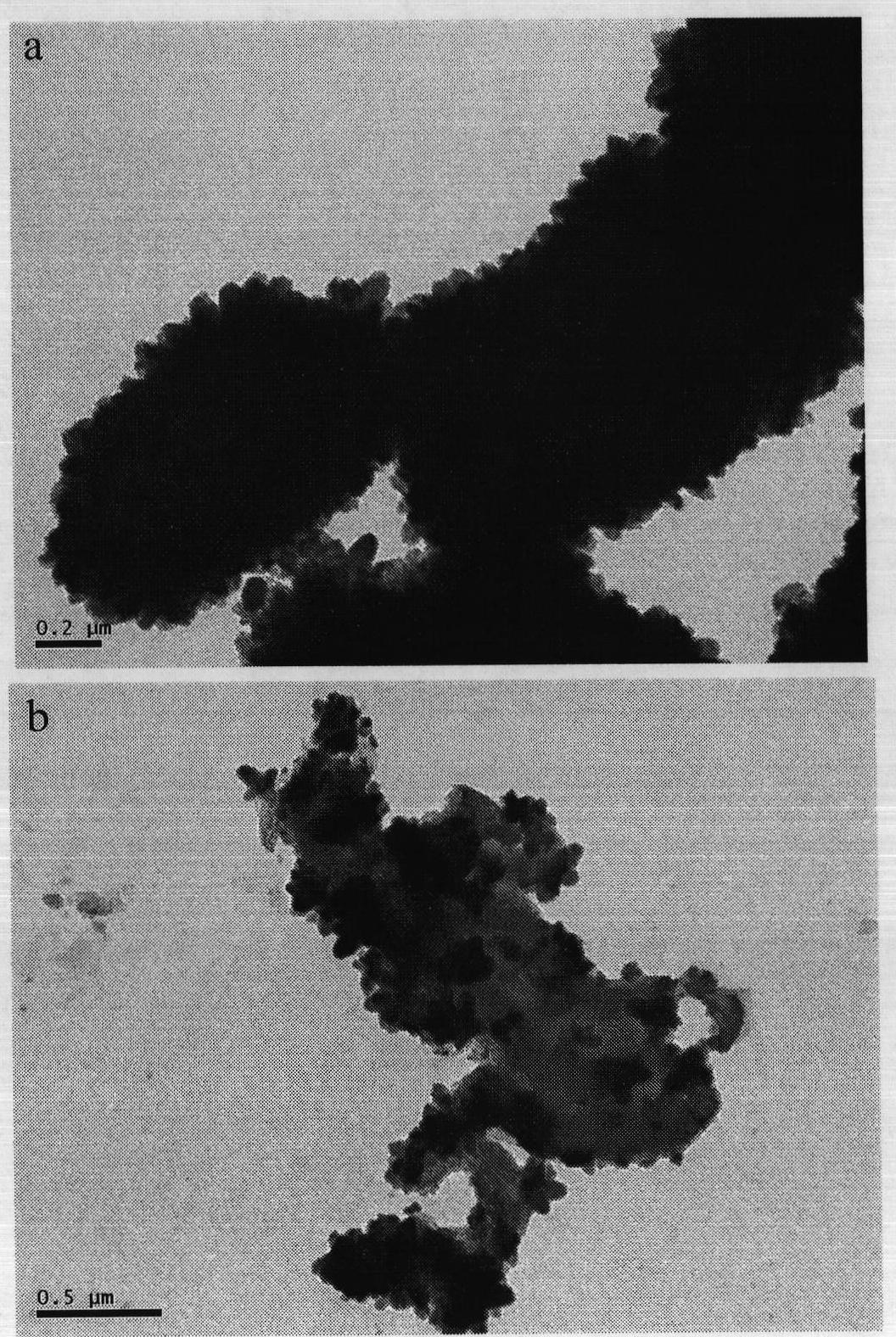

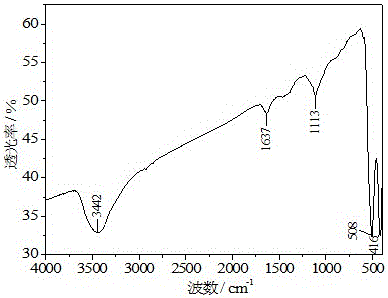

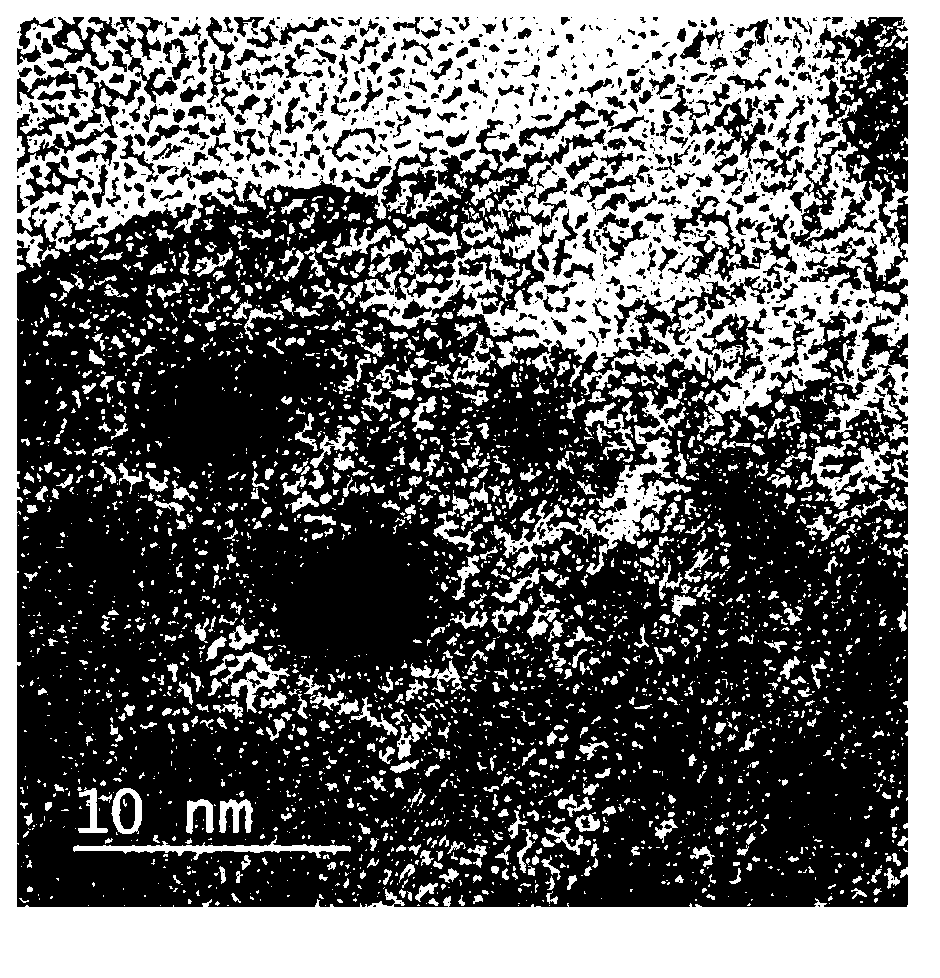

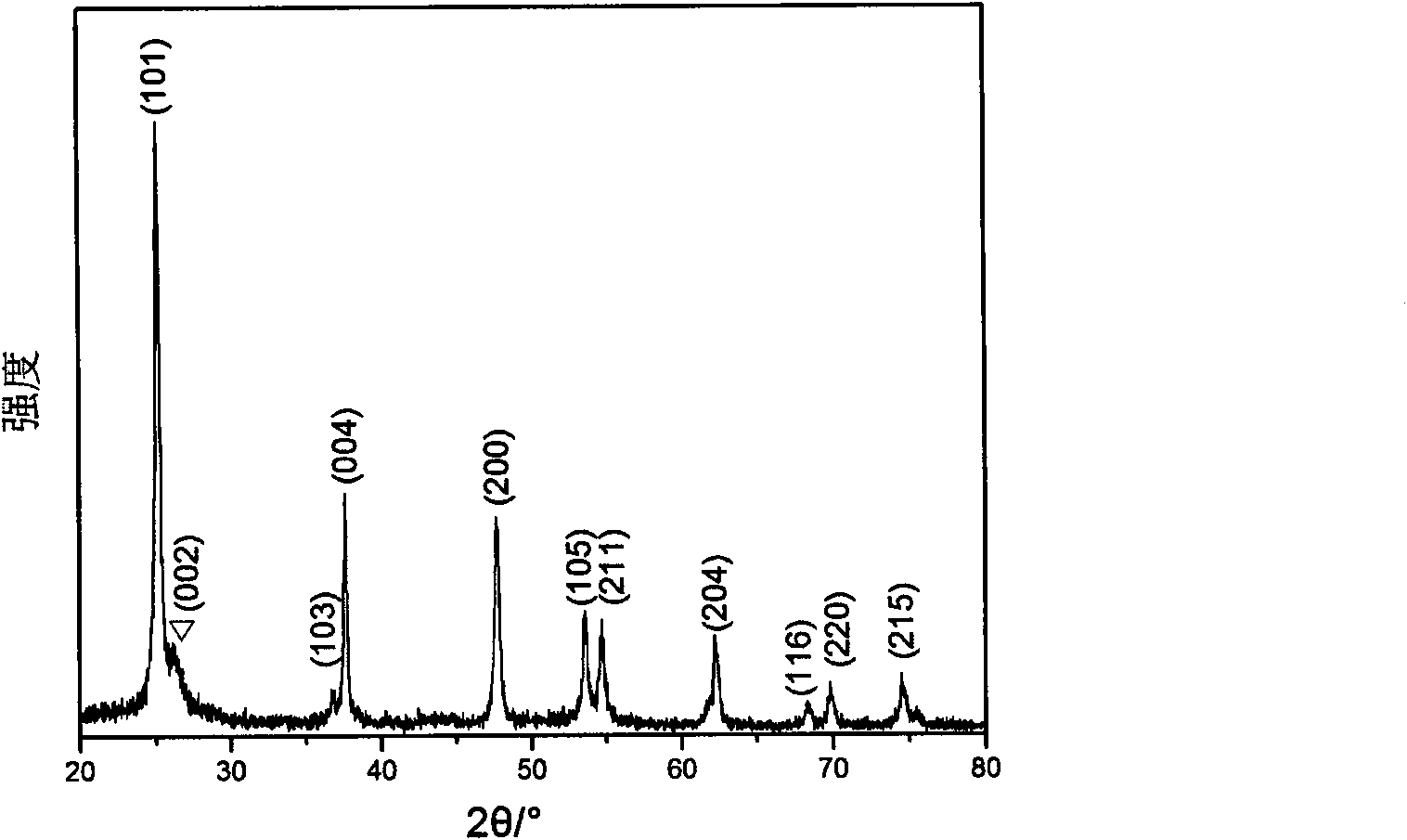

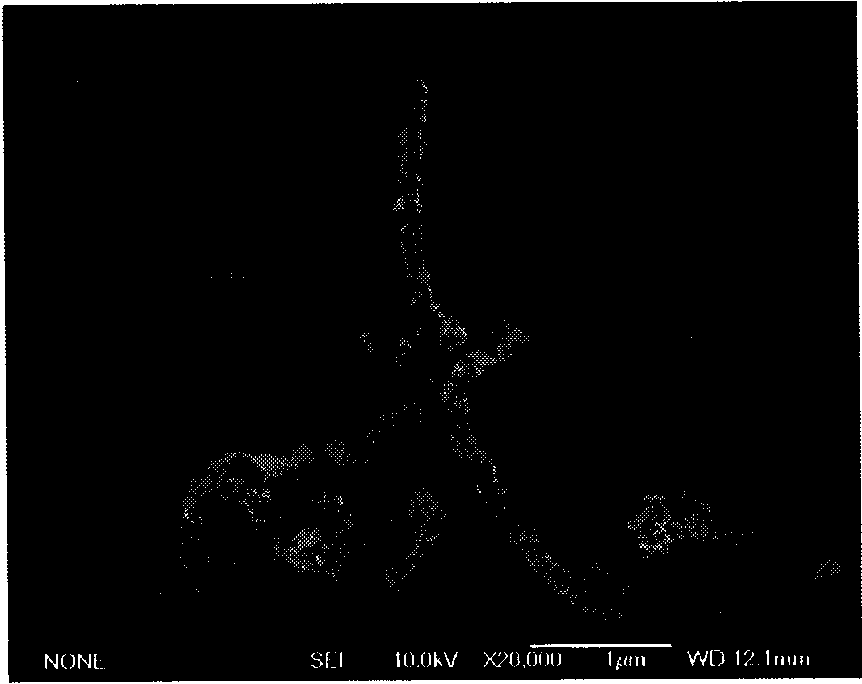

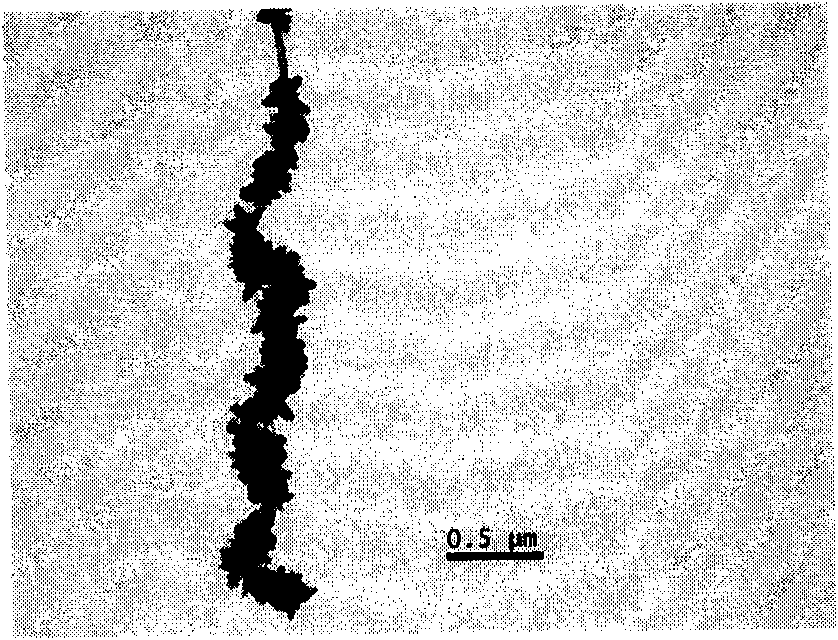

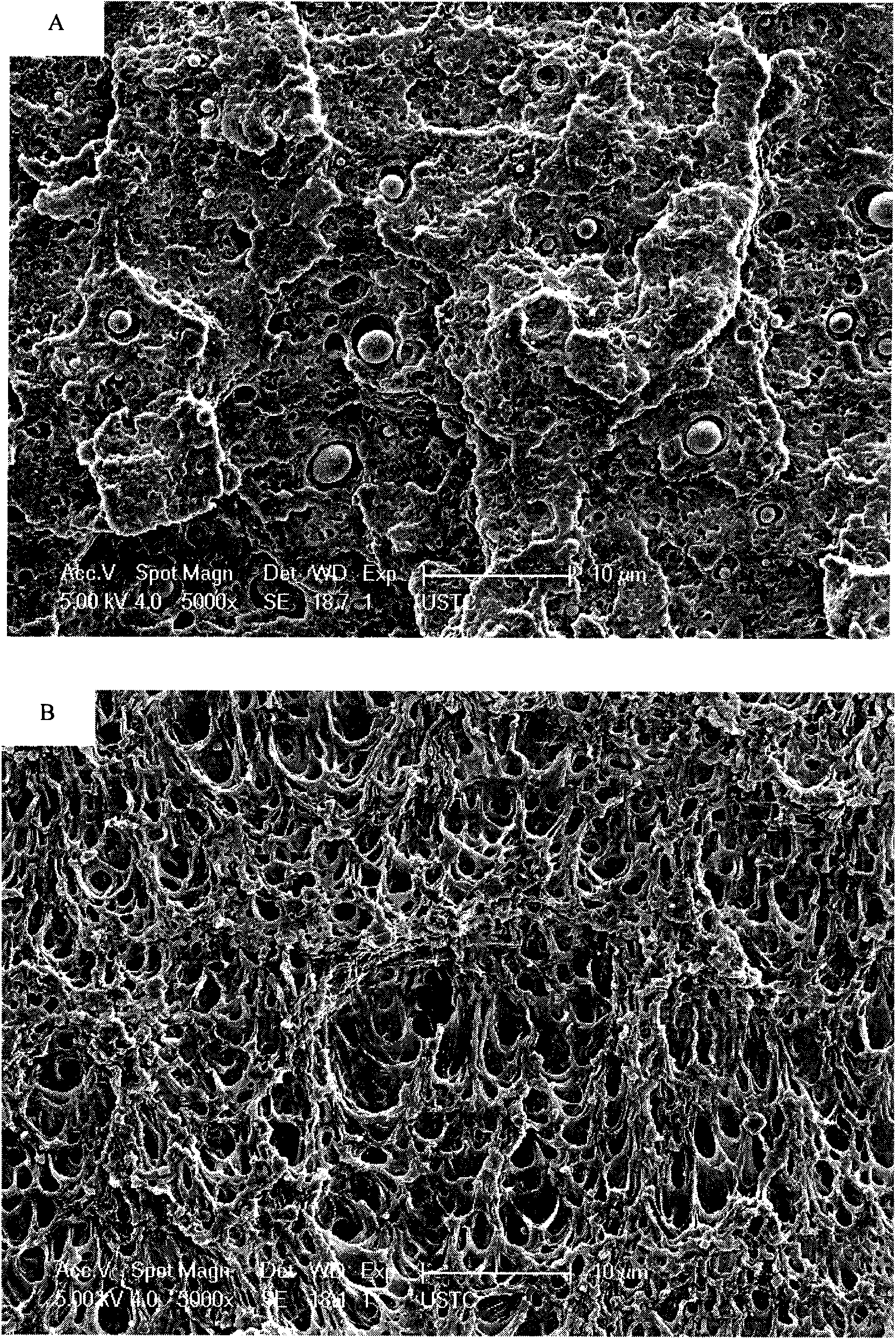

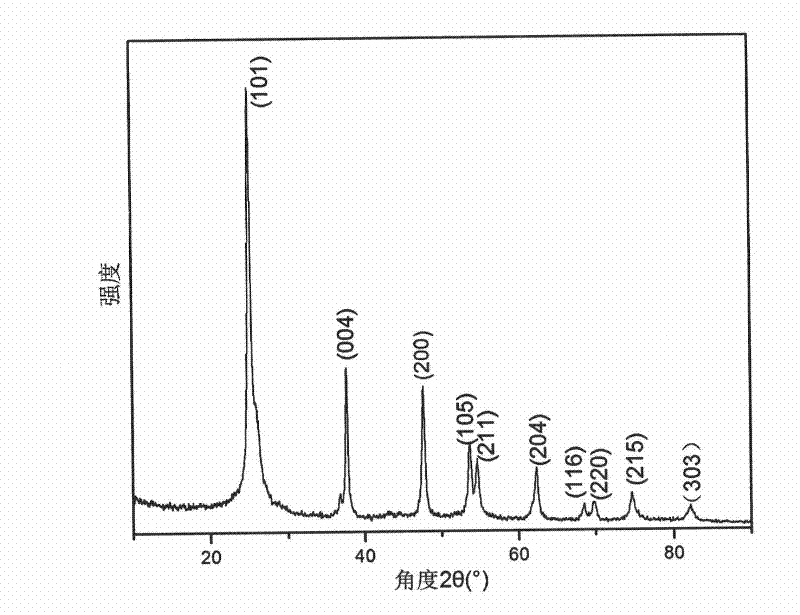

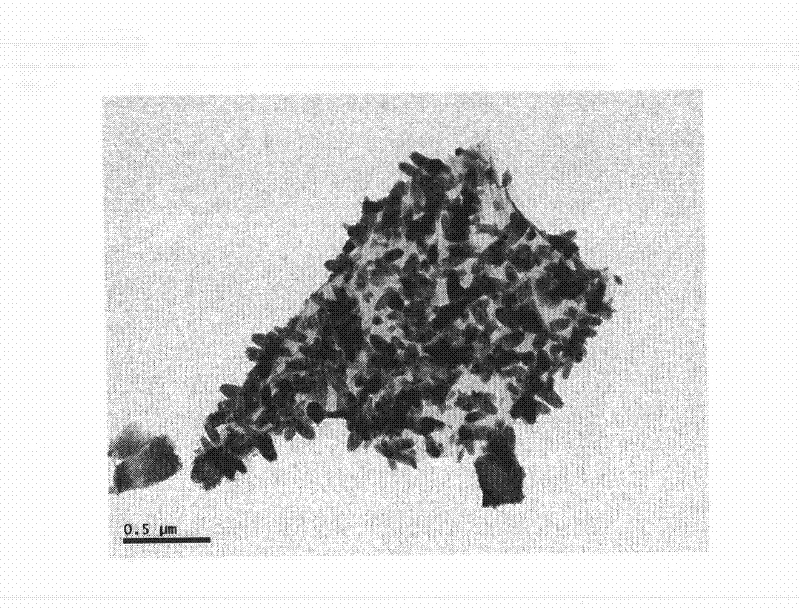

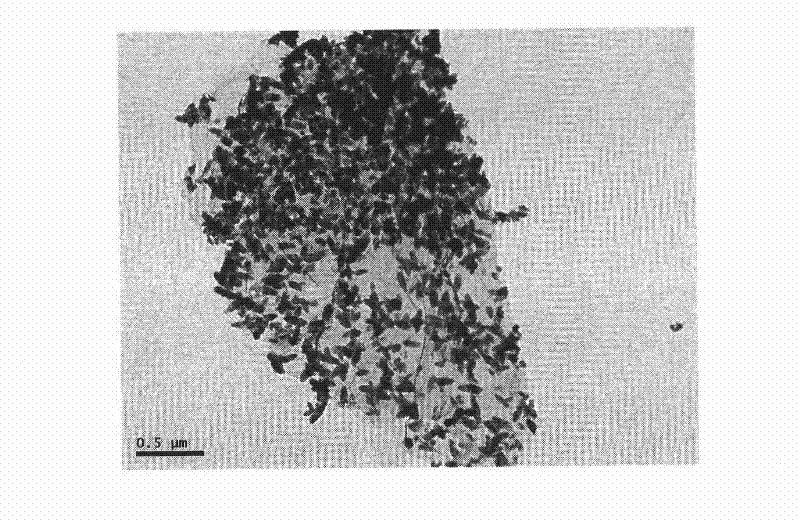

The invention relates to a method for preparing a graphene-based titanium dioxide composite photocatalyst by radiation of electron beams, belonging to the technical fields of radiation chemistry and photocatalyst preparation. The method comprises the following steps: firstly, preparing graphene by the prior art, then adding the graphene powder into a titanium tetrafluoride solution, and dispersingthe graphene powder with ultrasonic waves to obtain a suspension; then putting the suspension in an electron beam generating device to be radiated by a certain dose of electron beams, the irradiationdose of which is 70-280KGy; after sealing, putting the suspension in an oven of 60 DEG C for reaction for 20 hours; and finally, obtaining the graphene-based titanium dioxide composite photocatalystby washing and drying. The inspection proves that the graphene-based titanium dioxide composite photocatalyst prepared by the method of the invention has higher photocatalytic activity. In addition, by inspecting with a transmission electron microscope (TEM), titanium dioxide crystals which are densely and evenly loaded on the graphene matrix can be seen.

Owner:安徽省通源环境节能股份有限公司

Chemically resistant radiation attenuation barrier

ActiveUS20050191918A1Enhance layeringProtective equipmentSynthetic resin layered productsManufacturing technologyRadiation attenuation

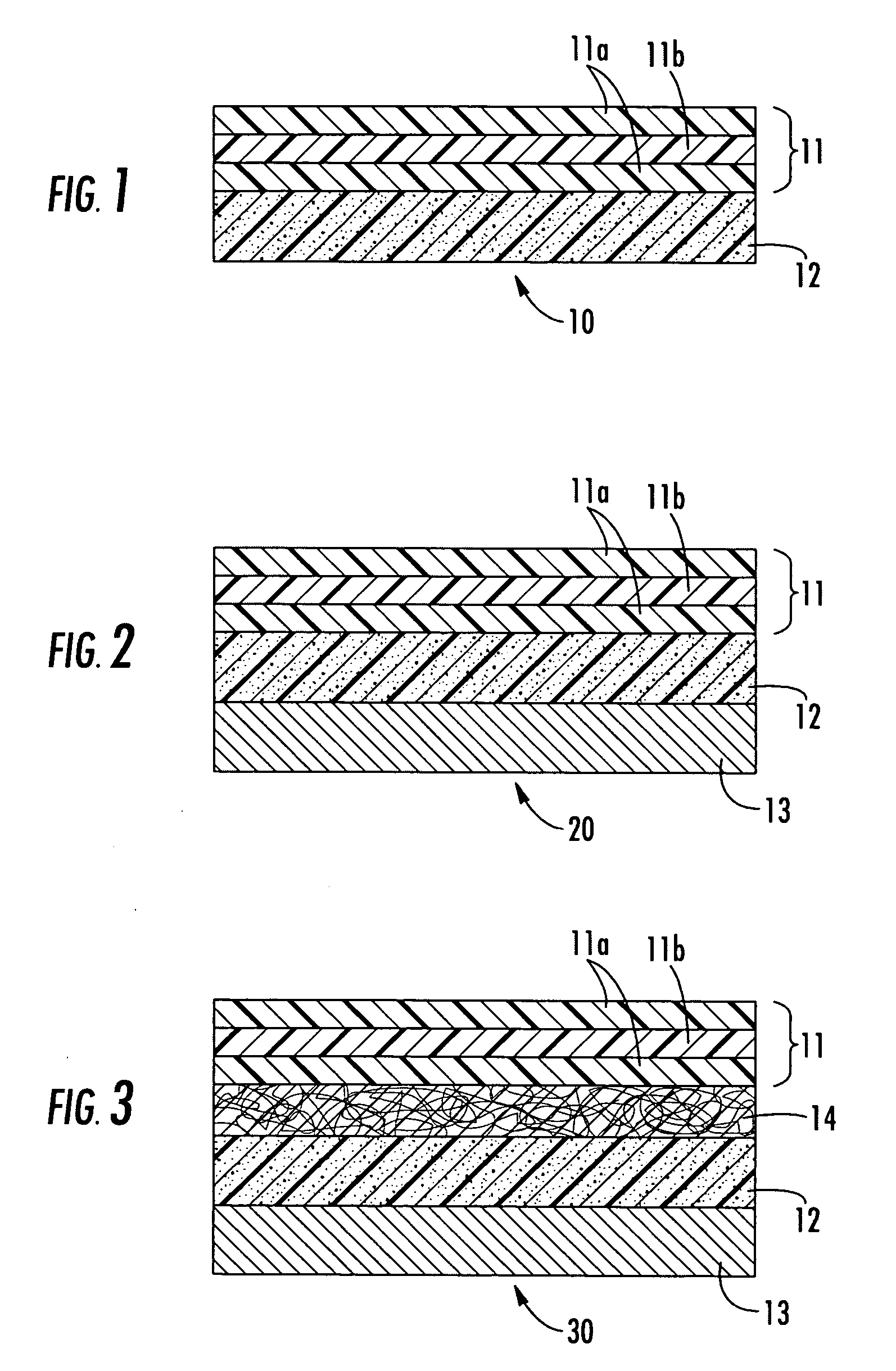

A unique and novel multi-functional composite fabric and fabrication process for use during chemical, biological, radiological and nuclear countermeasure (CBRNC) events is disclosed. The composite fabric combines the performance characteristics of chemically resistant films and radiation attenuating polymer matrices. The composite fabric offers universal protection against a wide range of military chemical agents, toxic industrial chemicals and materials (TICS and TIMS), biological agents, as well as certain ionizing and non-ionizing forms of radiation. The composite fabric is heat sealable and can be fabricated utilizing hermetically seal seams, and has application in protective clothing and equipment, indoor and outdoor covers, containment systems, bags, drapes, gowns, remains pouches, etc.

Owner:MERIDIAN RES & DEV

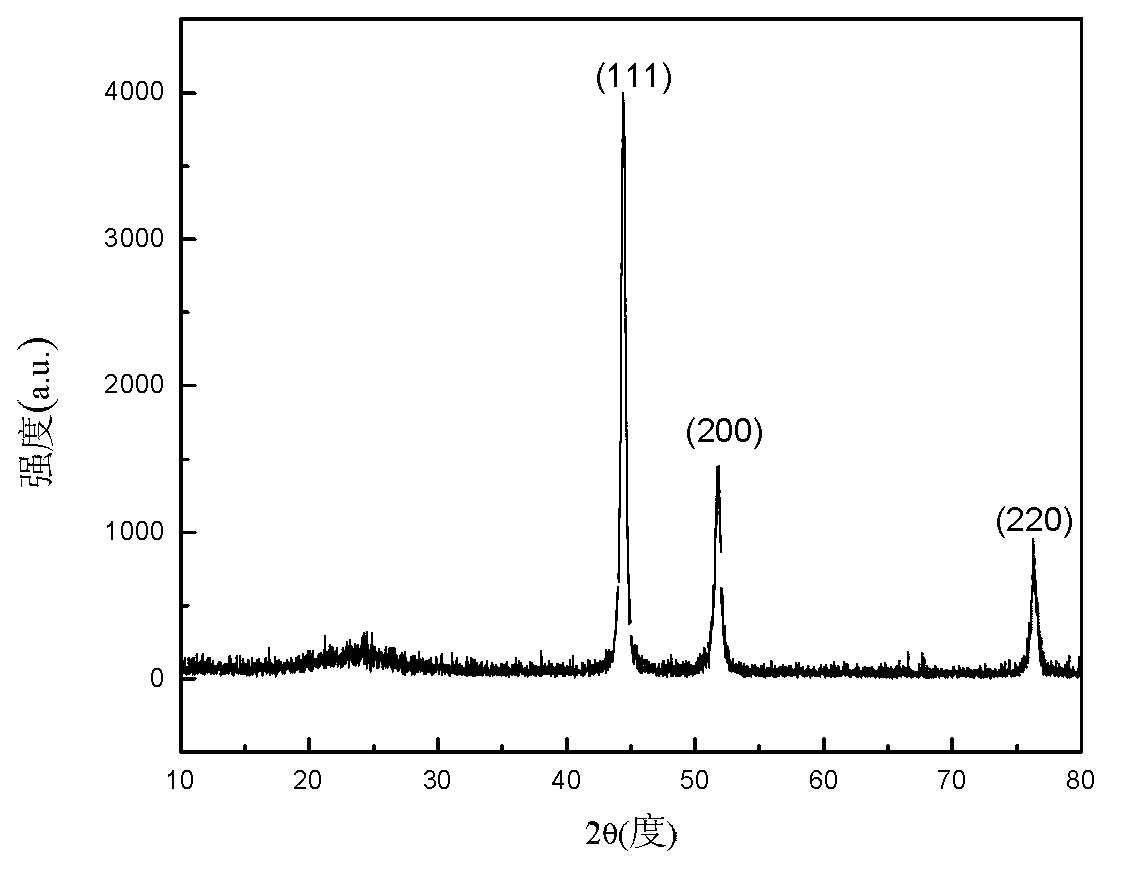

Method for manufacturing nano-silver

The present invention is nano silver preparing process and belongs to the field of nano material preparing technology in radiochemistry. The technological process includes adopting silver nitrate as silver source, isopropanol as oxidant clearer in water solution, hydrophilic suitable for PVA for controlling the crystal kernel growth speed and grain size and electronic accelerator to produce electron beam for irradiation treatment; washing irradiated solution, centrifugal separation and stoving to obtain black nano silver powder. The present invention has simple technological process, short production period, no pollution and high safety, and the prepared nano silver grain is spherical, homogeneous in size and good in dispersivity.

Owner:SHANGHAI UNIV

Method for preparing titanium dioxide/mesoporous carbon composite photocatalyst by electron beam irradiation

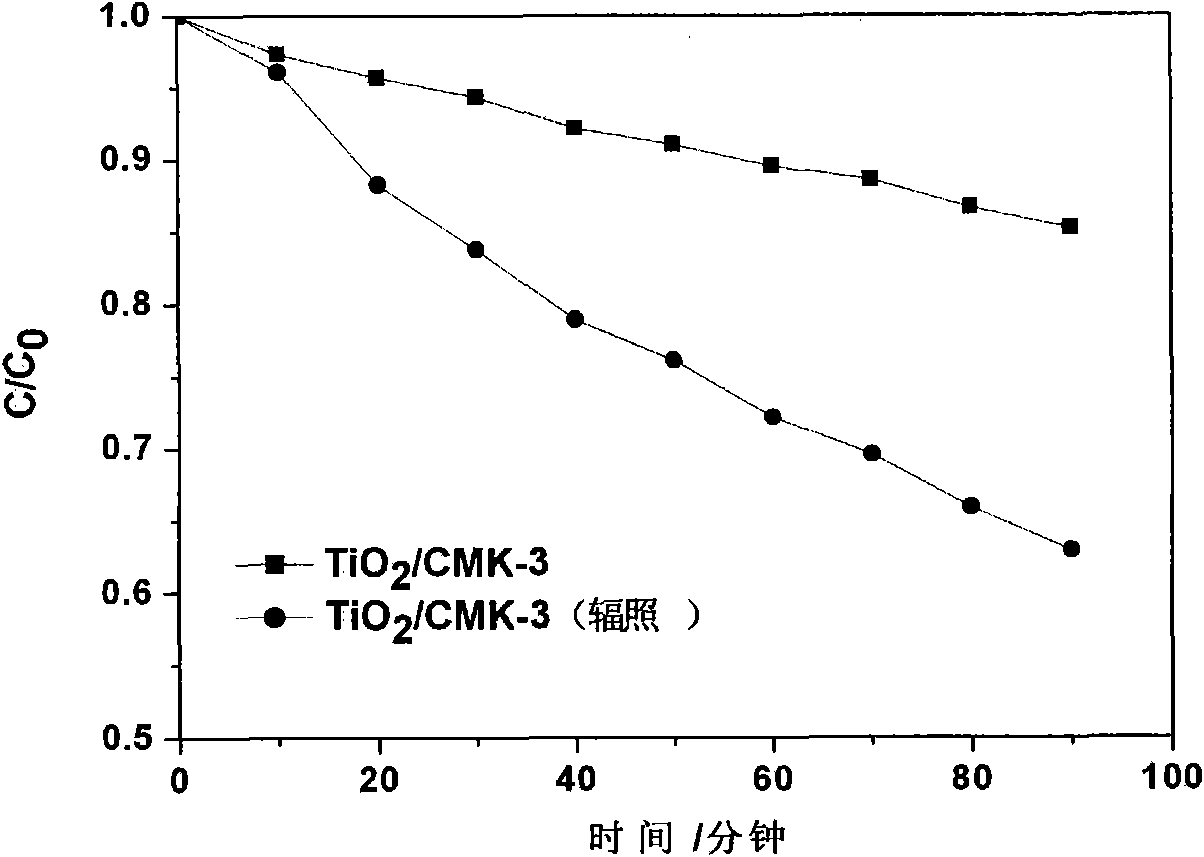

InactiveCN101829555AImprove photocatalytic performanceEasy to operateWater/sewage treatment by irradiationCatalyst activation/preparationRadiation chemistryMesoporous carbon

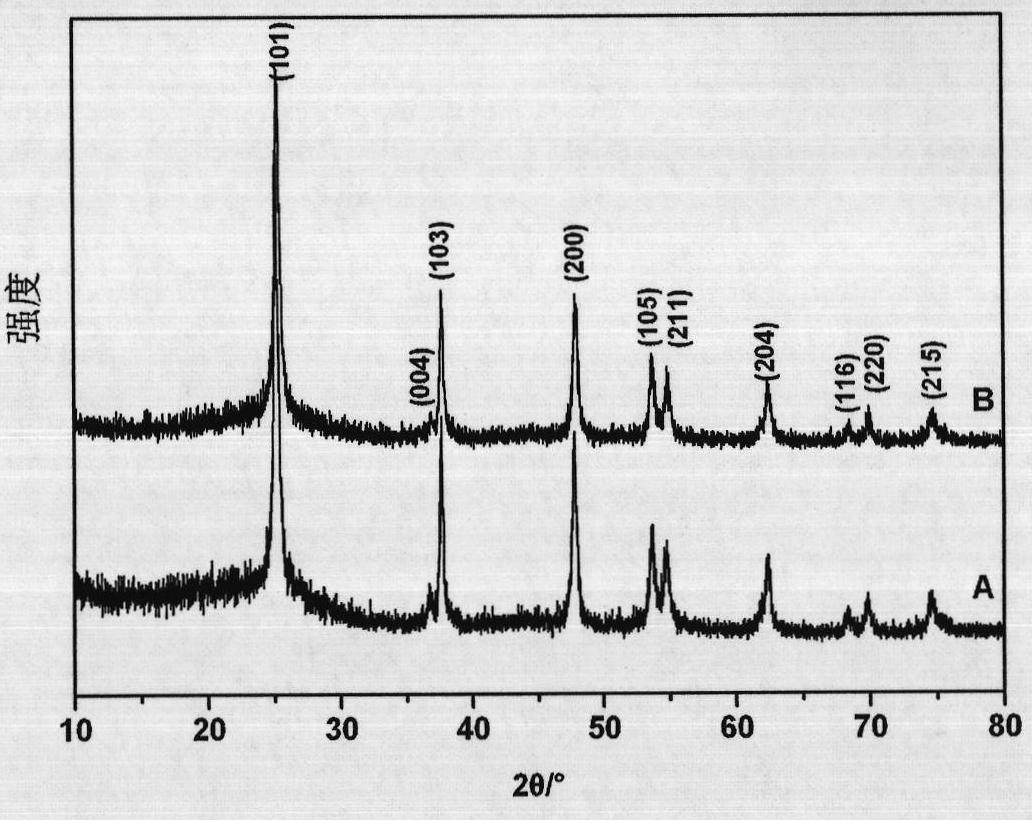

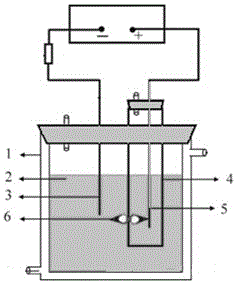

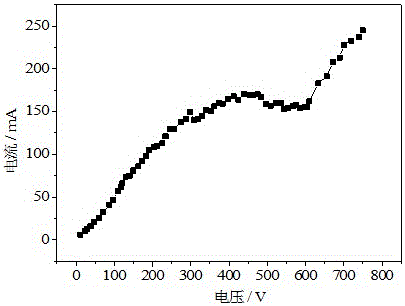

The invention relates to a method for preparing titanium dioxide / mesoporous carbon composite photocatalyst by electron beam irradiation, belonging to the technical field of radiation chemistry and photocatalyst preparation technology. The preparation method mainly comprises the following steps of: firstly, adding mesoporous carbon CMK-3 into TiF4 solution, uniformly mixing by ultrasound, pouring the solution into a self encapsulation, irradiating under an 2.5MeV and 40mA electronic accelerator with the irradiation dose of 140-700Kgy, wherein the mass ratio of the mesoporous carbon and the carbon tetrafluoride is 0.17, i.e. CMK-3: TiF4=0.17; secondly, putting the solution after irradiation into an oven to react for 20h under the temperature of 60 DEG C; and thirdly, washing and drying to finally obtain obtaining TiO2 / CMK-3 composite photocatalyst. A product has favorable the photocatalysis performance.

Owner:SHANGHAI UNIV

Method for manufacturing nanometer iron

The invention relates to an iron super-micro particle preparation technique, belongs to radiation chemical nanometer material production technique. The technique of the invention is that: nanometer material preparation: obtain iron hydroxide colloid solution by using iron sulfate as raw material and ammonia liquor as precipitant; control the crystal core accumulating speed and the particle size by hydrophilic surface-activator polyvinyl alcohol with isopropyl alcohol as free radical scavenger and in radiation chemistry principles; develop the radiation chemical reaction by the bunch of electrons generated by industrial electron accelerator; the radiated solution produces nanometer triple iron quadoxide which deoxidated with high purity hydrogen to obtain nanometer iron powder. The advantages of the invention are that: simple technical processes, short production cycle, non-pollution, the obtained particles are of uniform diameter and finely divided. The nanometer iron produced in above ways is of higher satiating hard magnetism and coercive force which is applicable on high intensity magnetic recording material..

Owner:SHANGHAI UNIV

Method for manufacturing nano-sized Fe3O4

The present invention is preparing process of nano ferroferric oxide or superfine ferroferric oxide particle, and belongs to the field of nano material preparing technology in radiochemistry. The radiochemical process adopts ferric trichloride as iron particle source, ammonia water as precipitant, IPA as oxidizing free clearing agent in aqua, hydrophilic surfactant PVA for controlling crystal kernel growing speed and particle size, and electron accelerator to produce electron beam for irradiation treatment, and the solution after being irradiated is washed, centrifugally separated and stoved to obtain black nano ferroferric oxide powder. The present invention has simple technological process, short production period, no pollution, and high safety. The prepared nano ferroferric oxide has very low magnetic saturation strength and very small coercive force and is one excellent kind of supermagnetic material and soft magnetic material.

Owner:SHANGHAI UNIV

Method for preparing nano zinc oxide by using liquid diaphragm discharge plasma

InactiveCN106006715AMild conditionsEasy to controlMaterial nanotechnologyZinc oxides/hydroxidesShock waveDispersity

The invention provides a method for preparing nano zinc oxide by using liquid diaphragm discharge plasma. The method produces the nano zinc oxide by using zinc plates as an anode and a cathode and Na2SO4 solution as electrolyte, irradiating the zinc plate of the anode with liquid diaphragm discharge plasma, and electrochemically sacrificing the zinc plate of the anode. By using the principle of radiation chemistry, transient high temperature and local high pressure are produced in liquid with light and shock wave, and high-activity particles are also produced to initiate chemical reactions, enabling the reactions such as oxidation, reduction, decomposition and hydrolysis to prepare nanoparticles; the nano zinc oxide synthesized herein has good dispersity, low aggregating degree and uniform particle size distribution and has a promising application prospect in terms of catalysis, optics, magnetics, mechanics and the like; products are easy to separate, high in purity and free of pollution; in addition, the method has the advantages of mild conditions, controllable process, simple equipment, good operation convenience, low cost and the like and is applicable to industrial production.

Owner:天雄健新材料有限公司

Process for preparing nano cadmium sulfide

The present invention relates to the preparation process of nanometer cadmium sulfide, and belongs to the field of radiochemical nanometer material preparing technology. The preparation process includes the following steps: compounding water solution of cadmium chloride and water solution of sodium thiosulfate; mixing to form mixed reaction solution with cadmium chloride in the concentration of 0.05-0.20 mol / L and sodium thiosulfate in the concentration of 0.125-0.50 mol / L; adding surfactant PVA and free radical -OH eliminating agent isopropanol in the amount of 15-30 ml / 100ml; irradiating the mixture solution with electron beam an electron accelerator produces in the dosage of 100-350 KGY; separating the irradiated reaction suspension centrifugally, washing the precipitate for several times, and vacuum drying at 60 deg.c for 6-8 hr to prepare lemon-yellow nanometer cadmium sulfide powder of average size 20 nm.

Owner:SHANGHAI UNIV

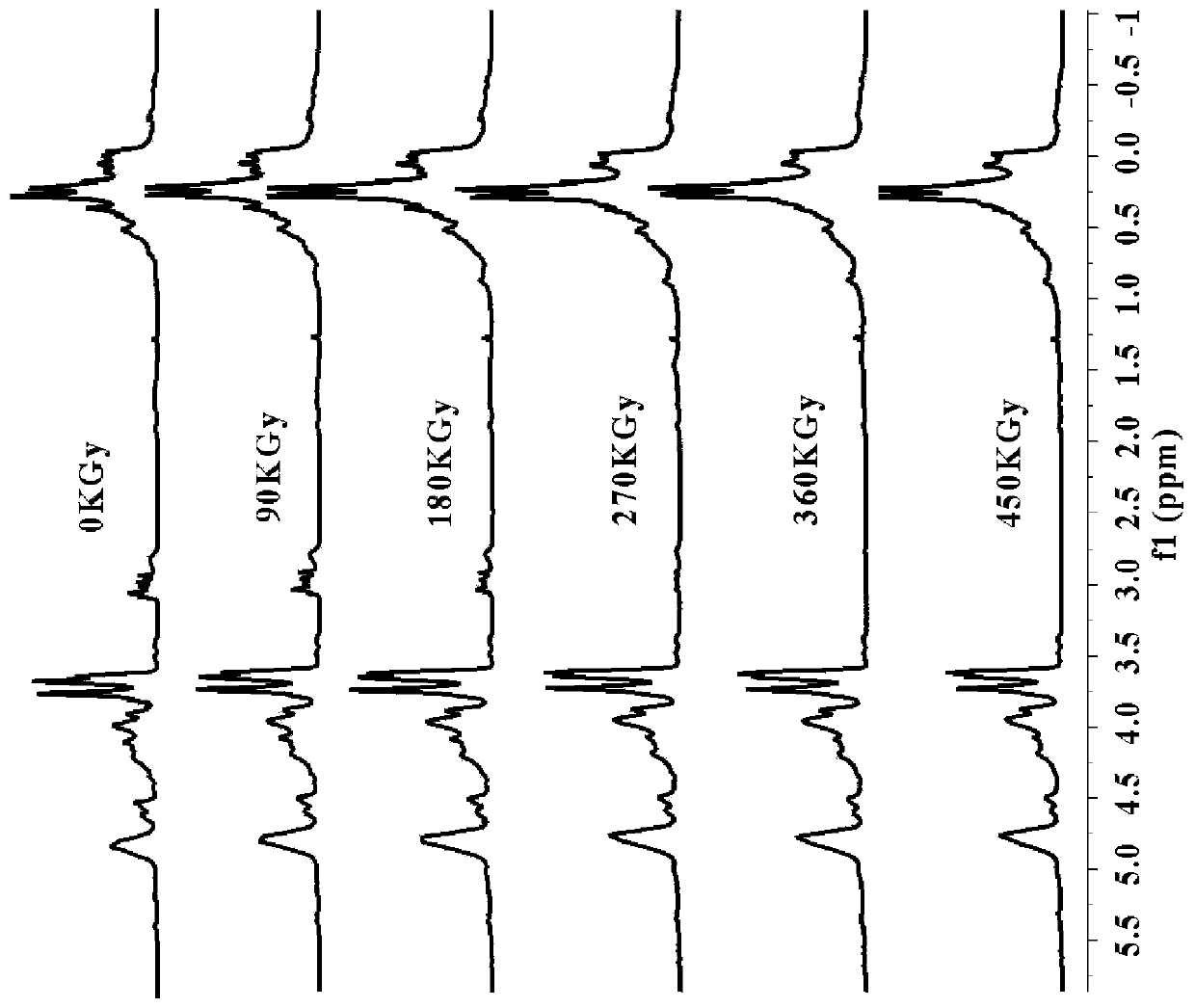

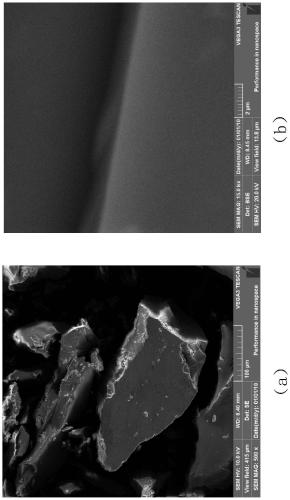

Method for preparing graphene/nickel nanocomposite material by utilizing gamma ray

ActiveCN103011151ASuitable for quantitative productionMild reaction conditionsMaterial nanotechnologyGrapheneRadiation chemistryGamma ray

The invention discloses a method for preparing a graphene / nickel nanocomposite material by utilizing a gamma ray, belongs to the field of crossing of the nanocomposite material and radiation chemistry, and in particular relates to a method for preparing the graphene / nickel nanocomposite material by utilizing the gamma ray. The problem that the graphene-nickel nanocomposite material prepared by the conventional method is high in cost and severely damages the environment is solved. The method comprises the following steps of: 1, preparing oxidized graphite; 2, preparing mixed solution; 3, reacting under the irradiation of the gamma ray to obtain a product; and 4, centrifugally separating, cleaning and drying the product to obtain the graphene / nickel nanocomposite material. The method is applied to the field of preparation of the graphene / nickel nanocomposite material.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

Process for preparing nano zinc sulfide

The present invention relates to the preparation process of nanometer zinc sulfide, and belongs to the field of radiochemical nanometer material preparing technology. The preparation process includes the following steps: compounding water solution of zinc sulfate and water solution of sodium thiosulfate; mixing to form mixed reaction solution with zinc sulfate in the concentration of 0.12-0.20 mol / L and sodium thiosulfate in the concentration of 0.25-0.50 mol / L; adding surfactant polyglycol or sodium dodecyl sulfate and free radical -OH eliminating agent isopropanol in the amount of 15-20 ml / 100ml; irradiating the mixture solution with electron beam an electron accelerator produces in the dosage of 250-300 KGY; separating the irradiated reaction suspension centrifugally, washing the precipitate with N2 inflated distilled water and absolute ethanol alcohol for several times, and vacuum drying at 60 deg.c for 6-8 hr to prepare white nanometer zinc sulfide powder of average size 20 nm.

Owner:SHANGHAI UNIV

Method for preparing polyimides microporous separation membrane

InactiveCN101053786AImprove filtration efficiencySimple processSemi-permeable membranesRadiation chemistryPolyimide membrane

The invention relates to a method for irradiating the dosage polyimide micropore separating membrane using electron beam, and to the technology field of radiation chemistry and macromolecule membrane treatment. The method of the invention uses the polyimide membrane synthesized by polymerizing various of monomers as the main membrane material, on which metalform with micropore pattern is covered, and irradiates by high energy electron beam product by regular electron accelerator; the irradiation dose is 600-1200KGy; and then it is immerged into the mixed comprising H2SO4 and K2Cr2O7, wherein the concentration of H2SO4 solution is 6-10 mol / L, and the concentration of K2Cr2O7 solution is 0.1-0.3 mol / L; etching is done under the temperature of 60-90 degree C for 5-10 hours; lastly, clean and dry to get the macromolecule polyimide micropore separating membrane with the pattern arranged clear and neat and consistent aperture.

Owner:SHANGHAI UNIV

Method for manufacturing nano-zinc oxide

InactiveCN1557716ASimple processShorten the production cycleZinc oxides/hydroxidesPolyvinyl alcoholZno nanoparticles

The present invention is preparing process of nano zinc oxide or superfine zinc oxide particle, and belongs to the field of nano material preparing technology in radiochemistry. The radiochemical process adopts zinc sulfate as zinc particle source, ammonia water as precipitant, IPA as oxidizing free clearing agent in aqua, hydrophilic surfactant PVA for controlling crystal kernel growing speed and particle size, and electron accelerator to produce electron beam for irradiation treatment, and the solution after being irradiated is washed, centrifugally separated and stoved to obtain white fibrous nano zinc oxide powder with high purity. The present invention has simple technological process, short production period, no pollution, and high safety.

Owner:SHANGHAI UNIV

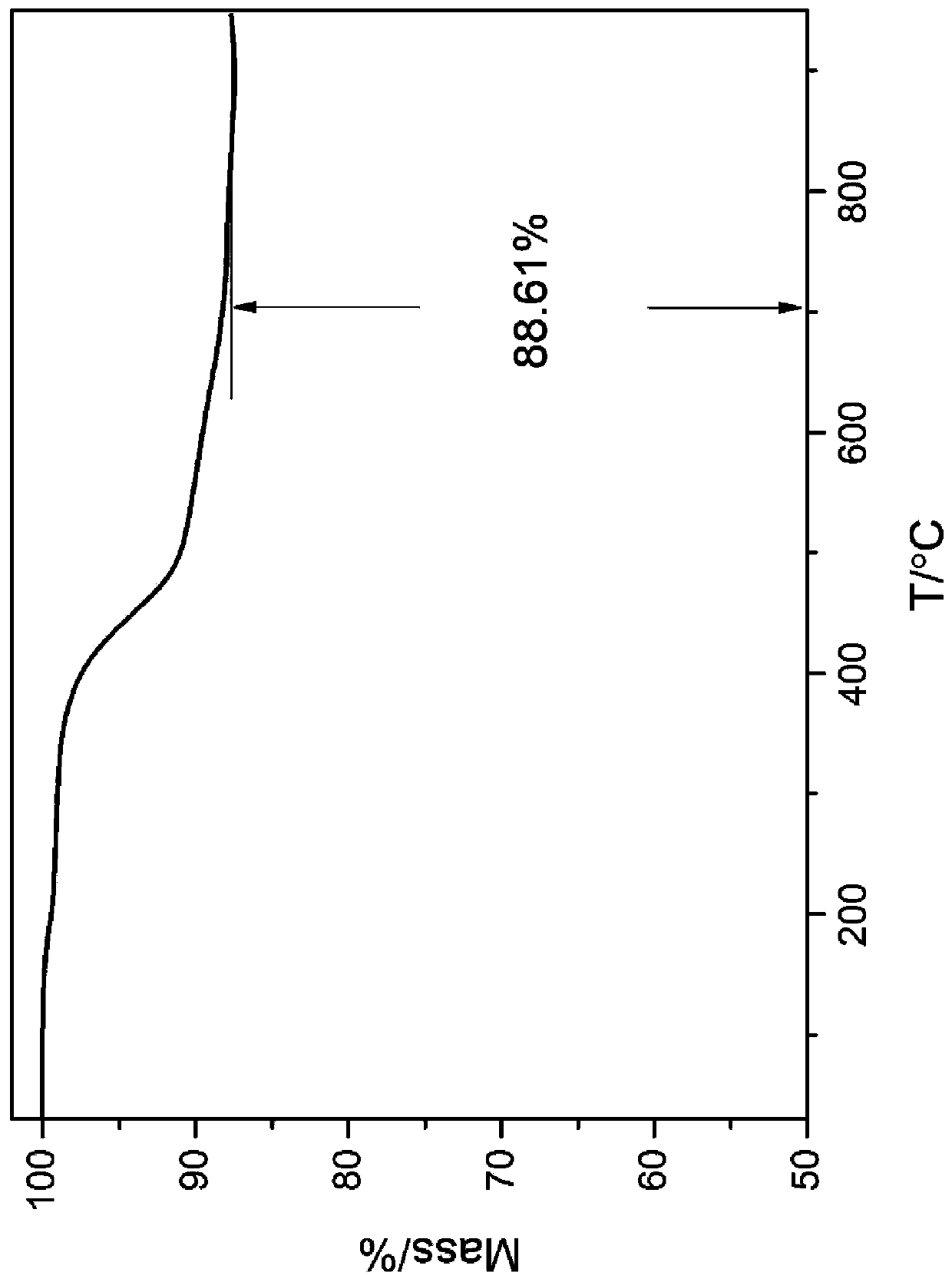

Radiative reduction and curing method of liquid polycarbosilane

The invention provides a radiative reduction and curing method for liquid polycarbosilane, and belongs to the field of macromolecules and the field of inorganic non-metallic ceramics. An electron beamradiation technology is applied to reduction and curing of liquid polycarbosilane, liquid polycarbosilane containing chloromethyl groups is subjected to a radiation chemical reaction under radiationof electron beams, and cross-linking curing of liquid polycarbosilane is realized while chlorine atoms are reduced by hydrogen. The method can be directly applied to a liquid polycarbosilane dipping pyrolysis method for preparing a silicon carbide ceramic material, unsaturated bonds are not required to be introduced into liquid polycarbensilane molecular chains, or a cross-linking agent, a catalyst and an initiating agent are added to a liquid polycarbensilane precursor, curing of liquid polycarbensilane can be realized, so that not only is change of a silicon-carbon ratio of the polymer precursor in a curing process avoided, but also introduction of heteroatoms such as platinum, oxygen and nitrogen are avoided, and the method has the advantages of being simple to operate, easy to controland capable of realizing large-scale production and the like.

Owner:HUBEI UNIV OF SCI & TECH

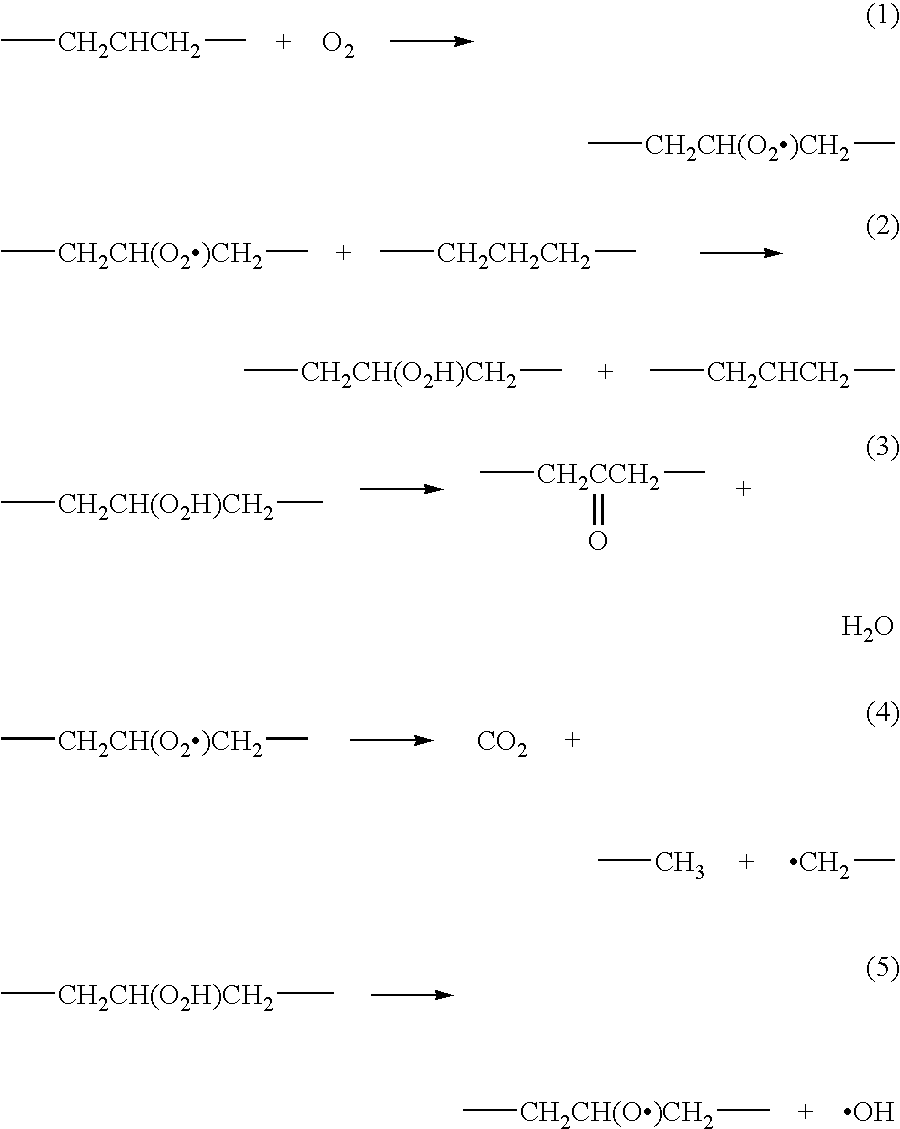

Radiation processing of heavy oils

InactiveUS20090308789A1Maximize roleIncrease productionRefining with oxygen compoundsFluid removalRadiation chemistryPetroleum product

The present invention is drawn to a method of processing heavy paraffinic oils or heavy aromatic oils using radiation chemistry of polyethylene under oxidizing conditions. The process of the invention will result in a chain reaction for oxidative scission as the basis for a radiation processing for heavy paraffinic or aromatic oils. The method of the invention will allow for the cost-efficient and environmentally-friendly processing of heavy oils into lighter petroleum products.

Owner:PETRORADIANT

Method for preparing composite photocatalyst of titanium oxide/multi-wall carbon nano pipe by electron-beam irradiation

InactiveCN101670283AImprove photocatalytic performanceEasy to operateCatalyst activation/preparationTitanium tetrafluorideRadiation chemistry

The invention relates to a method for preparing a composite photocatalyst of a titanium oxide / multi-wall carbon nano pipe by electron-beam irradiation, which belongs to the technical fields of radiation chemistry and the preparation technique of the photocatalyst. The method mainly comprises the following preparation processes: adding a multi-wall carbon nano pipe (MWCNTs) into a titanium fluoride(TiF4) solution, dispersing by ultrasonic and mixing fully and evenly, wherein the mass ratio of the multi-wall carbon nano pipe (MWCNTs) and the titanium fluoride (TiF4), i.e. the MWCNTs:the TiF4 isequal to 0.05-0.15; then, putting the solution in an irradiation area under an electron accelerator and carrying out irradiation processing, wherein the irradiation dose is 280-560KYy; afterwards, moving to the other container, putting into a baking oven after sealing a sealed opening, and reacting for 20 hours at the temperature of 60 DEG C; and afterwards, washing a product, drying and finallypreparing the composite photocatalyst of the titanium oxide / multi-wall carbon nano pipe. The composite photocatalyst obtained by the method has favorable photocatalysis property and better photocatalysis effect.

Owner:SHANGHAI UNIV

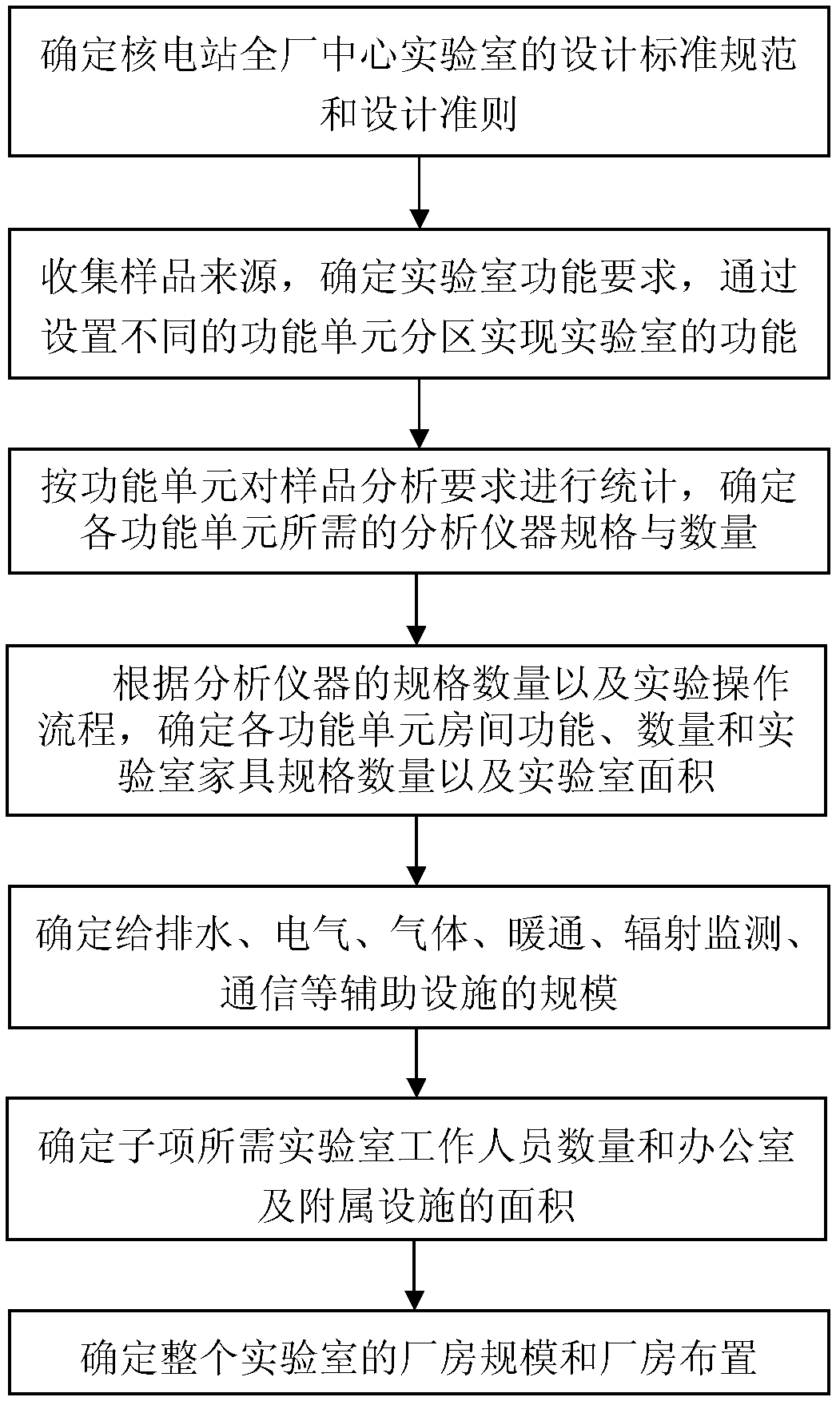

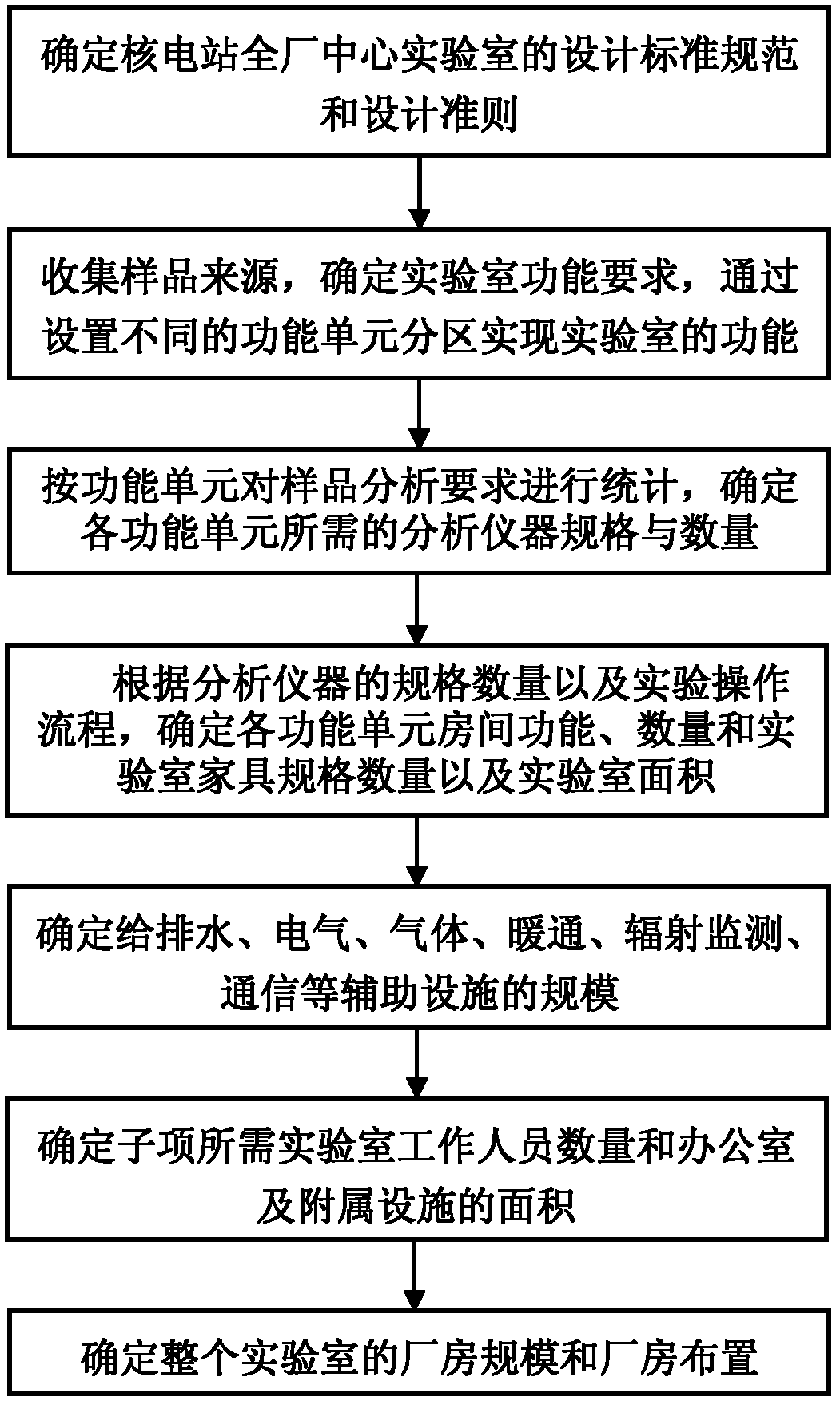

Design method for central laboratory of whole nuclear power station

InactiveCN102644393AReasonable layoutSatisfy the experimental operation processIndustrial buildingsRadiation chemistryDesign standard

The invention belongs to subitem design technology of nuclear power stations, and particularly relates to a design method for a central laboratory of a whole nuclear power station. By means of formulating a design standard specification system and a design criterion which are applicable to the central laboratory of the whole nuclear power station, the design method for the central laboratory of the whole nuclear power station is provided. The design method is a technical method including dividing regions of functional units of the laboratory; determining the specifications and the quantity of experimental analysis instruments; analyzing the scale of workshops of the laboratory; and designing auxiliary facilities of the workshops. On the basis, finished subitem workshop functions, overall arrangement and workshop scale designing can guarantee overall arrangement reasonableness of the process laboratory, the auxiliary supporting facilities and office facilities, meet orderly running of operation procedures of all chemical analysis items of the nuclear power station, ensure timeliness and accuracy of chemical and radiation chemistry parameter analysis results of the whole nuclear power station, and meet requirements on safety production and stable running of various systems of the nuclear power station.

Owner:CHINA NUCLEAR POWER ENG CO LTD

Method for manufacturing nano-copper

The present invention is nano copper preparing process and belongs to the field of nano material preparing technology in radiochemistry. The technological process includes adopting copper sulfate as copper source, isopropanol as oxidant clearer in water solution, hydrophilic suitable for PVA for controlling the crystal kernel growth speed and grain size and electronic accelerator to produce electron beam for irradiation treatment; washing irradiated solution, centrifugal separation and stoving to obtain claret nano copper powder. The present invention has simple technological process, short production period, no pollution and high safety.

Owner:SHANGHAI UNIV

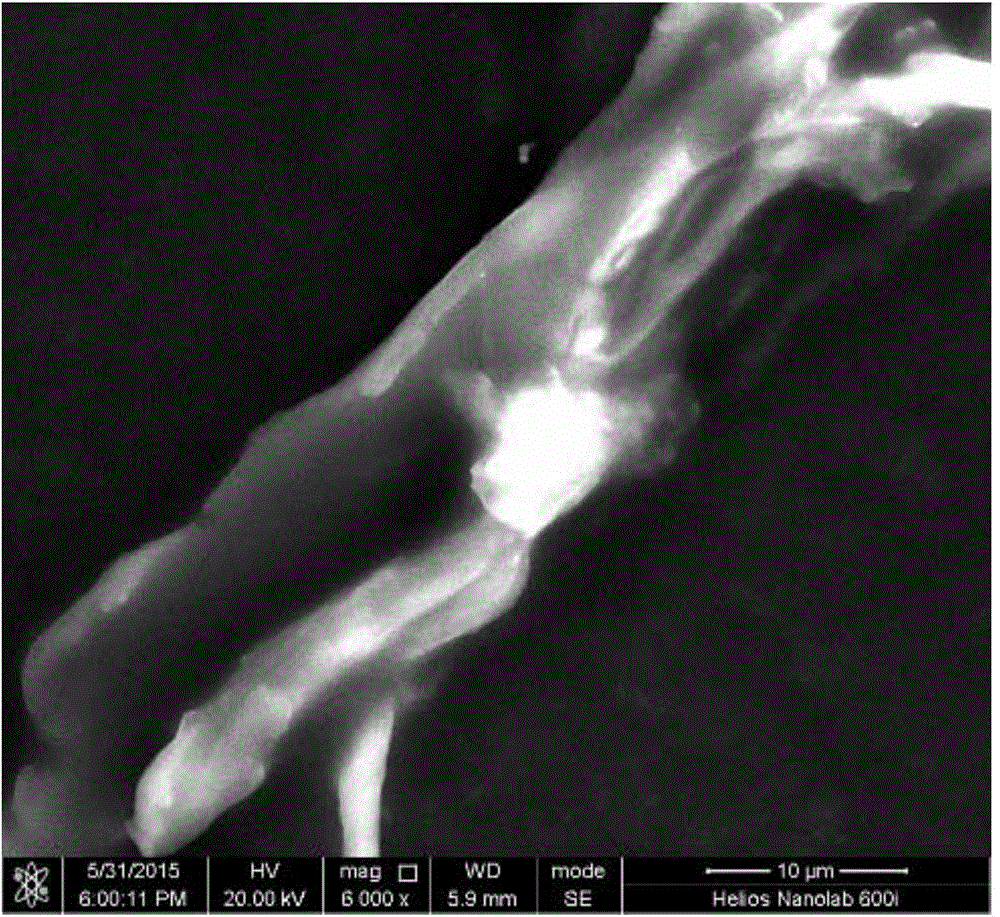

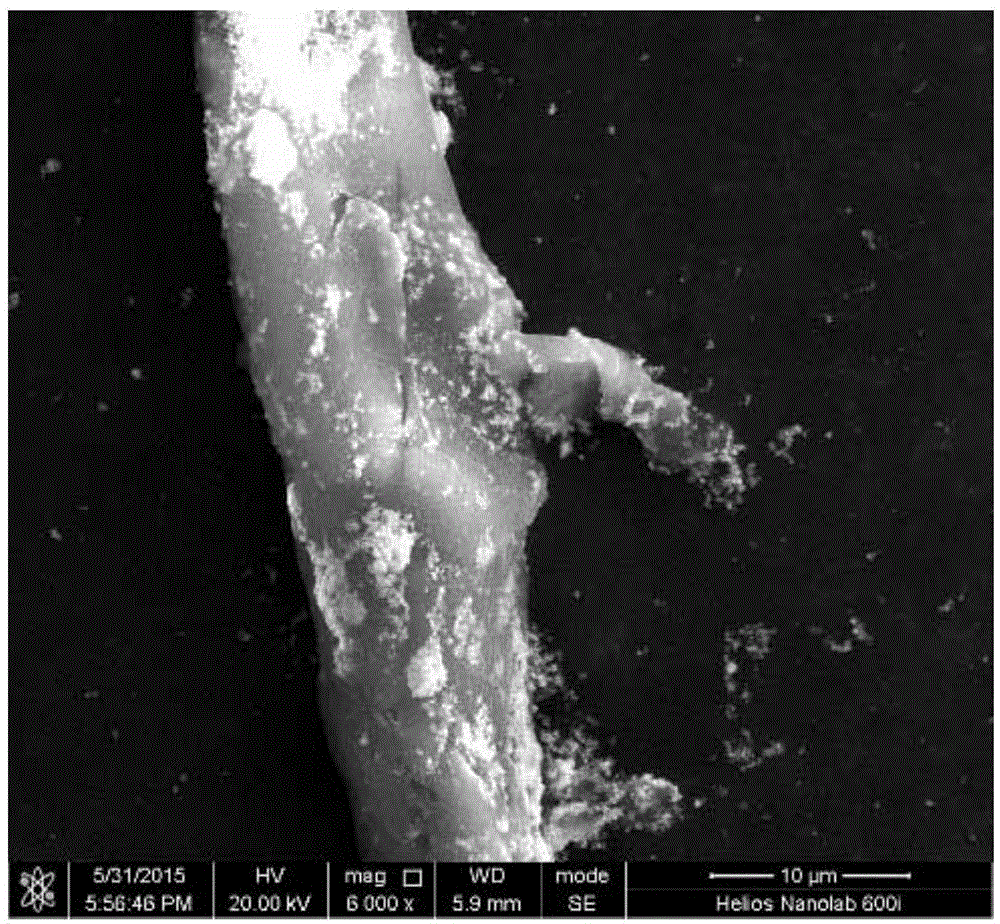

Radiation synthesizing method for cadminium sulfide coated carbon nano tube composite nano material

The invention relates to a kind of irradiation synthetic method of carbon nanophase pipe compound nanophase covered by nanophase cadmium sulfide, the invention belongs to nanophase synthetic material and radiation chemical technological field. The preparation method of this invention is as follows: acidify carbon nanophase pipe with mixed acid of oil of vitriol and dense nitric acid firstly, then disperse its ultrasonic into de-ionized water and it forms solution, regulate pH value to 8-1 with KOH, put cadmium chloride and hypo into carbon nanophase pipe solution in turn; then accede to surface active agent--polyvinyl alcohol and surge it with ultrasonic to make it disperse evenly, rejoin isopropanol which is a kind of oxidizability free radical scavenger; then set the solution prepared above in the produced by microtron of 2.5MeV and 40mA to irradiate; the irradiation agent is 150-300KGy; Then absterge the product with ethanol, and separate them with centrifugal machine, after being dried, we finally get carbon nanophase compounding nanophase material covered by nanophase cadmium sulfide.

Owner:SHANGHAI UNIV

Mask

InactiveUS7632621B2Easy to disassembleReadily dispersibleInksOriginals for photomechanical treatmentWater solublePolymer

A mask is described for forming an image on a substrate. The mask may be selectively applied to a radiant energy sensitive material on the substrate. Actinic radiation applied to the composite chemically changes portions of the radiant energy sensitive material not covered by the mask. The mask and portions of the radiant energy sensitive material are removed using a suitable aqueous base developer. The mask is composed of aqueous base soluble or dispersible polymers and light-blocking agents.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Antibacterial wood plastic composite preparation method through gamma rays

The invention relates and belongs to the crossed fields of nanocomposites and radiation chemistry, in particular to an antibacterial wood plastic composite preparation method through gamma rays and aims to solve the problem of poor antibacterial performance of the existing wood plastic composite. The method includes, 1, dissolving AgNO3 into deionized water, adding ammonia after dissolving until the produced precipitate disappears completely, adding wood flour and isopropanol for ultrasonic dispersion, and obtaining wood flour mixed liquid; 2, inputting nitrogen gas for 1 hour, irradiating through 60 Co-gamma rays, and obtaining the wood flour loading nano sliver grains; 3, performing centrifugating separation, washing, and obtaining modified wood flour after drying; 4, mixing the modified wood powder, maleic anhydride-grafted polypropylene and antioxidant, and obtaining the antibacterial wood plastic composite. The disadvantages of impure product due to adoption of antibacterial agent and reducing agent and low stability are avoided.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

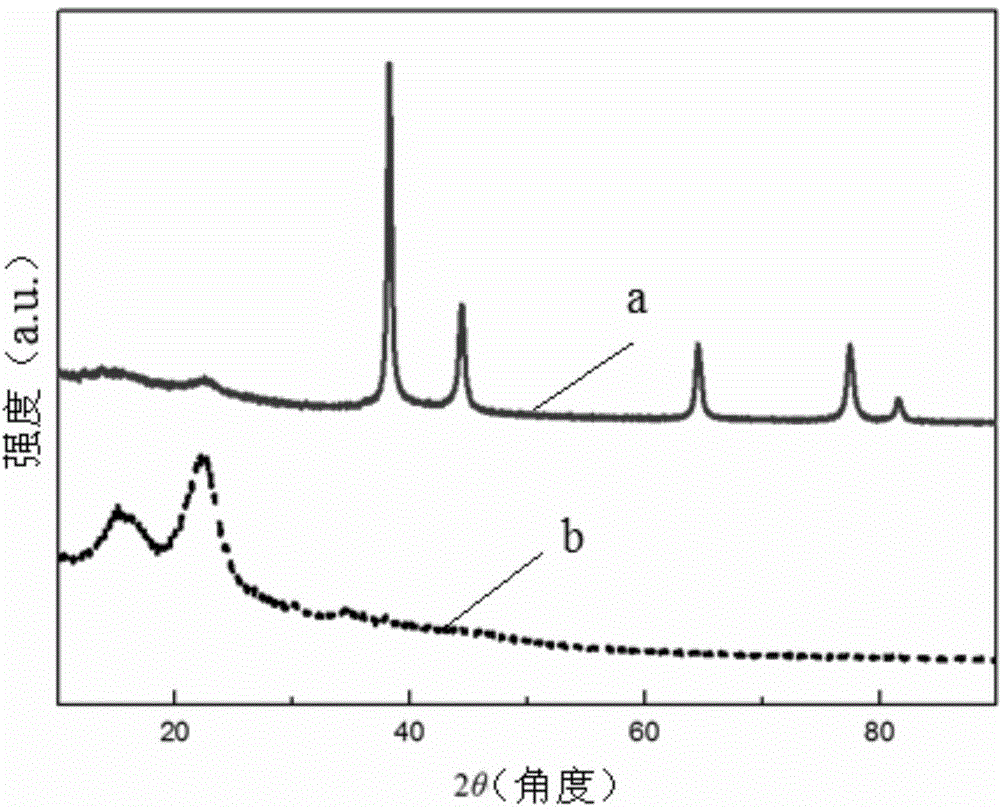

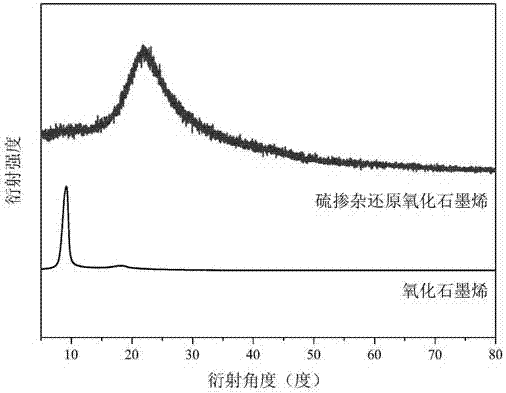

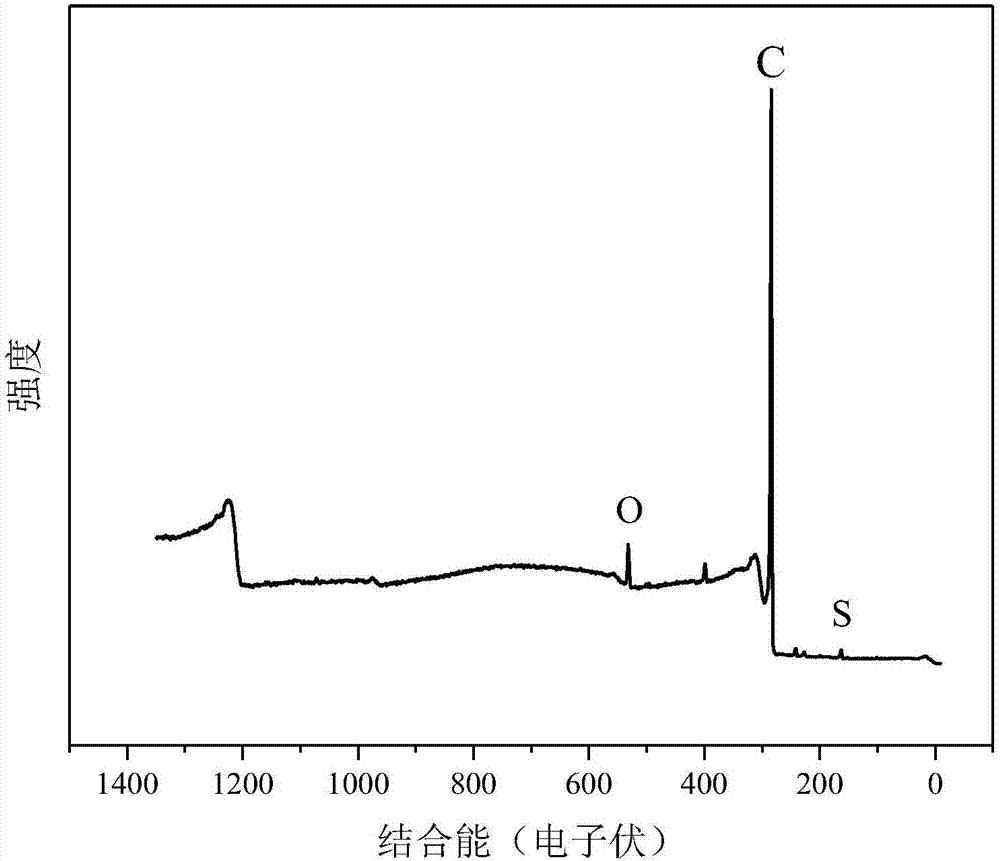

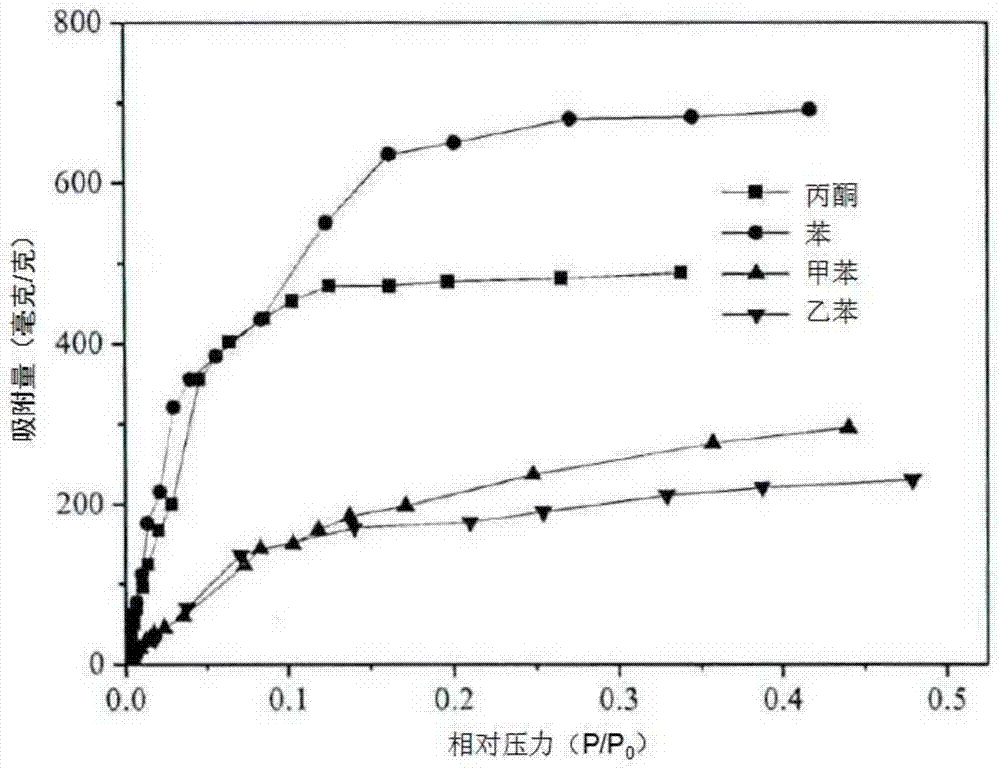

Synthesis method of sulfur-doped reduced graphene used for adsorbing organic pollutants

InactiveCN106975446AImprove adsorption capacityImprove efficiencyGas treatmentOther chemical processesSynthesis methodsPolyethylene glycol

The invention belongs to the technical fields of radiation chemistry and graphene nano-materials, and provides a synthesis method of sulfur-doped reduced graphene used for adsorbing organic pollutants. The method comprises the following steps: preparing an ethanol solution of graphene oxide, with the concentration of 0.5-2 mg / mL, adding polyethylene glycol 1500 to make the concentration be 0.075-0.15 mg / L, carrying out ultrasonic dispersion for 30-60 min to dissolve water-soluble sulfides in the obtained graphene oxide suspension in order to make a mass concentration ratio of sulfur to graphene oxide be 1:1 to 1:5, adding 20-100 mL of isopropanol, stirring the obtained solution for 30-60 min, adding 4-15 mL of an ammonia water solution, and irradiating the obtained solution with electron beams at an irradiating dose of 70-350 kGy; and sequentially cleaning the obtained material with ethanol and distilled water after the irradiation is finished, centrifuging the cleaned material, repeating the cleaning and centrifuging steps, and drying the obtained solid to obtain a dried solid which is the sulfur-doped reduced graphene. The technical problems of complex preparation technology, use of toxic and harmful reagents, high reaction temperature and poor adsorption performance in the prior art are solved.

Owner:肖硕 +2

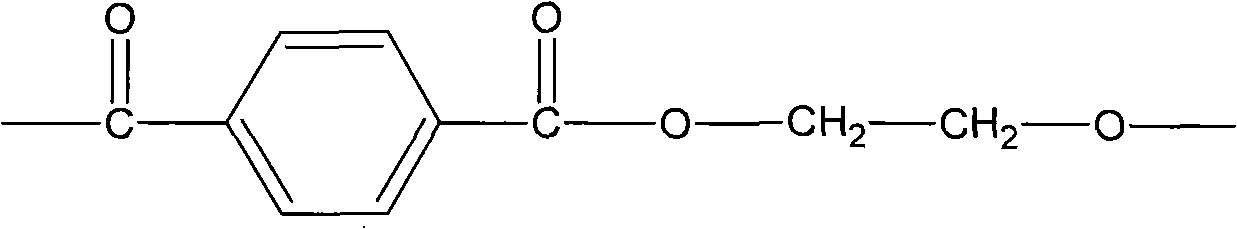

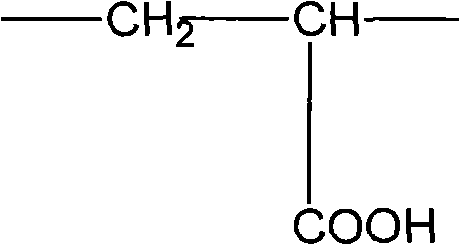

PET alloy material, special compatibilizer thereof and preparation method thereof

The invention discloses a radiation grafting compatibilizer modified PET alloy material, a special compatibilizer thereof and a preparation method thereof. The graft copolymer consists of a main chainformed by the structural units shown by formula I and a branched chain formed by the structural units shown by formula II; -CH2- in the formula II is connected with -CH2- in the formula I by chemicalbond; and the grafting rate is 0.09-0.18%. The preparation method of the graft copolymer comprises the steps: in inert atmosphere, evenly mixing PET, acrylic acid and polymerization inhibitor and then irradiating to have graft copolymerization reaction, and finally obtaining the graft copolymer; and the irradiation dose rate is 0.8-1.5kGy / h, and the absorbed dose is 20-30kGy. The PET alloy material comprises the components based on parts by weight: 68-85 parts of the PET, 15-20 parts of toughening agent, 0.1-0.2 part of antioxidant and 3-12 parts of the graft copolymer. The PET alloy materialis prepared by evenly mixing the components and melt extrusion. The invention not only expands the application of radiation chemistry in the field of preparing PET engineering material, but also provides the PET alloy material with excellent performance, thus having wide application value.

Owner:UNIV OF SCI & TECH OF CHINA

Addictive for decreasing irradiation smell

InactiveCN1883318AExtended shelf lifeEasy to masterFood preservationFood preparationIrritationCooked meat

The invention relates to atomic energy technology field, radiation machining field and more specificly a additive for reducing radiation odor. The invention is to aim at the problem of producing irritable irradiation odor when absorbed dosage is higher than 5kGy, to produce additive for decreasing radiation odor according to radiation chemistry principle. The inventive additive is 0.1%Vc+0.1%Ve aqueous solution. The additive is sprayed to food surface for making it become moist , spray volume being not over the food water content. It can decrease irradiation odor production under absorbed dose of 5-8kGy, irradiation dosage unevenness less than 1.5. The concentration of Vc and Ve use is in 0.05%-0.2%, which has same effect. The invention is suitable for instant food such as cooked meat, fresh sea product.

Owner:宁波超能科技股份有限公司

Method for manufacturing nano-sized Fe3O4

The invention relates to a method for manufacturing nanometer ferric oxide, that is, a method for preparing ultrafine particles of ferric oxide, which belongs to the technical field of radiation chemistry manufacturing nanometer materials. A method for manufacturing nano ferric oxide, which is mainly prepared by radiation chemistry. In the process, ferric chloride is mainly used as the source of iron particles, ammonia water is used as a precipitant, and isopropanol (IPA) is used as an aqueous solution. Medium-oxidizing free radical scavenger; and control the growth rate of the crystal nucleus to control the particle size through the hydrophilic surfactant polyvinyl alcohol (PVA), and use the electron beam generated by the electron accelerator to irradiate, and the radiation The irradiated solution is washed, centrifuged and dried to obtain black nanometer ferric oxide powder. The invention has simple technological process, short production cycle, no pollution, no pollution and good safety. The prepared nano ferroferric oxide has extremely small magnetic saturation strength and coercive force, and is a very good supermagnetic material and soft magnetic material.

Owner:SHANGHAI UNIV

Gamma-ray radiochromic solution and radiation dosemeter prepared by using the same

ActiveCN102433112AExtended linear range of color changeShow eye-catchingChemical dosimetersTenebresent compositionsRadiation chemistryNuclear technology

The invention, belonging to the field of radiation chemistry and nuclear technology, discloses a gamma-ray radiochromic solution, comprising the following ingredients: 0.02-1 weight portions of dye, 0-0.5 weight portions of photoinitiator, 0-0.5 weight portions of anti-oxidant, 0-10 weight portions of organic solvent, and the rest sovlent consisting of 100 weight portions of distilled water. The invention further discloses a radiation dosemeter prepared by using the gamma-ray radiochromic solution, comprises a radiochromic device and a colorimetric device. The gamma-ray radiochromic solution and the radiation dosemeter are suitable for large scale industrial irradiation. According to the invention, a test result of the radiation dosemeter is timely and intuitionistic, the radiation dosemeter can guide production on site to guarantee the irradiation quality, the radiation dosemeter can be placed in any position and even in the package of an object being irradiated to prevent pollution; the radiation dosemeter is fit for any object being irradiated, and even can be placed in a liquid or cream object being irradiated; the gamma-ray radiochromic solution is stable under the conditions of room temperature and room light illumination, and has equivalence that is close to the equivalence of the object being irradiated; and the gamma-ray radiochromic solution has the advantages of simple formula and preparation, easy obtainment of raw materials, and low cost, and the precision of the gamma-ray radiochromic solution is suitable for large scale irradiation processing.

Owner:SAAS BIOTECH & NUCLEAR TECH RES INST

Radiation synthesizing method for cadminium sulfide coated carbon nano tube composite nano material

The invention relates to a kind of irradiation synthetic method of carbon nanophase pipe compound nanophase covered by nanophase cadmium sulfide, the invention belongs to nanophase synthetic materialand radiation chemical technological field. The preparation method of this invention is as follows: acidify carbon nanophase pipe with mixed acid of oil of vitriol and dense nitric acid firstly, thendisperse its ultrasonic into de-ionized water and it forms solution, regulate pH value to 8-1 with KOH, put cadmium chloride and hypo into carbon nanophase pipe solution in turn; then accede to surface active agent--polyvinyl alcohol and surge it with ultrasonic to make it disperse evenly, rejoin isopropanol which is a kind of oxidizability free radical scavenger; then set the solution prepared above in the produced by microtron of 2.5MeV and 40mA to irradiate; the irradiation agent is 150-300KGy; Then absterge the product with ethanol, and separate them with centrifugal machine, after being dried, we finally get carbon nanophase compounding nanophase material covered by nanophase cadmium sulfide.

Owner:SHANGHAI UNIV

Method for manufacturing nano-zinc oxide

InactiveCN1235807CEasy to controlAvoid reunionZinc oxides/hydroxidesPolyvinyl alcoholZno nanoparticles

The present invention is preparing process of nano zinc oxide or superfine zinc oxide particle, and belongs to the field of nano material preparing technology in radiochemistry. The radiochemical process adopts zinc sulfate as zinc particle source, ammonia water as precipitant, IPA as oxidizing free clearing agent in aqua, hydrophilic surfactant PVA for controlling crystal kernel growing speed and particle size, and electron accelerator to produce electron beam for irradiation treatment, and the solution after being irradiated is washed, centrifugally separated and stoved to obtain white fibrous nano zinc oxide powder with high purity. The present invention has simple technological process, short production period, no pollution, and high safety.

Owner:SHANGHAI UNIV

Method for preparing graphene-based titanium dioxide composite photocatalyst by radiation of electron beams

ActiveCN101658786BPromote crystallizationImprove photocatalytic performanceWater/sewage treatment by irradiationWater contaminantsTitanium tetrafluorideRadiation chemistry

The invention relates to a method for preparing a graphene-based titanium dioxide composite photocatalyst by radiation of electron beams, belonging to the technical fields of radiation chemistry and photocatalyst preparation. The method comprises the following steps: firstly, preparing graphene by the prior art, then adding the graphene powder into a titanium tetrafluoride solution, and dispersing the graphene powder with ultrasonic waves to obtain a suspension; then putting the suspension in an electron beam generating device to be radiated by a certain dose of electron beams, the irradiation dose of which is 70-280KGy; after sealing, putting the suspension in an oven of 60 DEG C for reaction for 20 hours; and finally, obtaining the graphene-based titanium dioxide composite photocatalystby washing and drying. The inspection proves that the graphene-based titanium dioxide composite photocatalyst prepared by the method of the invention has higher photocatalytic activity. In addition, by inspecting with a transmission electron microscope (TEM), titanium dioxide crystals which are densely and evenly loaded on the graphene matrix can be seen.

Owner:安徽省通源环境节能股份有限公司

Method for preparing micro-hole array polyolefine film by electron beam radiation

The invention relates to a method of preparing micropore array polyolefin thin film by electron beam irradiation, which belongs to radiation chemistry and macromolecule thin film material processing technique field. The method includes steps: using polyolefin thin film as raw material (including polyolefin macromolecule thin film such as pp, pvc, ptfe), covering template with micropore array pattern on the raw material, using high energy electron beam of 100-400KGy generated by electron accelcrator to irradiate; immerging the raw material into mixed etch solution constituted of H2SO4 and K2Cr2O7, wherein the concentration of H2SO4 is 6-10mol / L, the concentration of K2Cr2O7 is 0.1-0.3mol / L; carrying etch under temperature of 60-90 DEG C for 2-6 h; cleaning, drying and obtaining the micropore array macromolecule polyolefin thin film with regular pattern and accordant size, in which average aperture is 10 mu m.

Owner:SHANGHAI UNIV

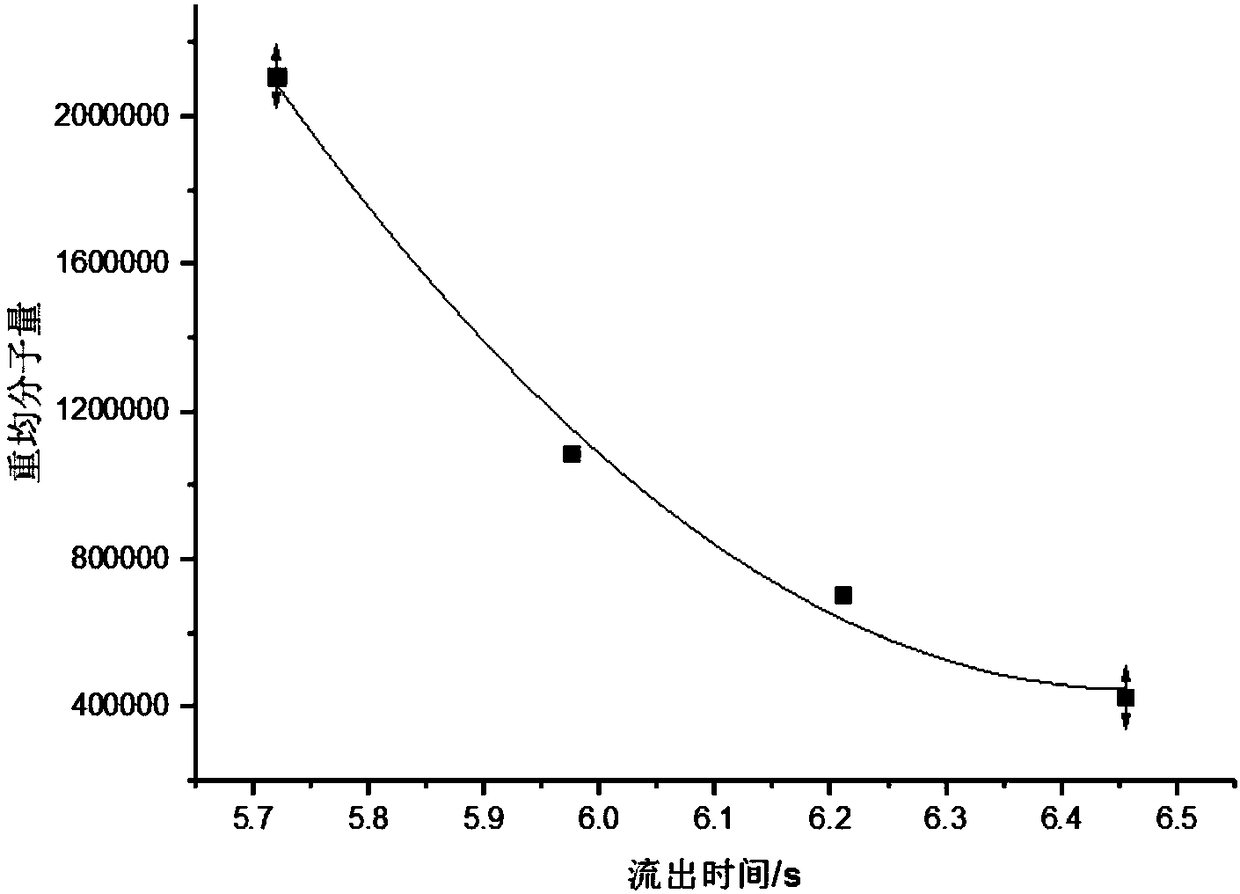

Intra-molecular cross-linking polymer, preparation method thereof and application thereof

The invention discloses an intra-molecular cross-linking polymer, a preparation method and application thereof. The invention provides the preparation method for the intra-molecular cross-linking polymer, and comprises the following steps: performing intra-molecular cross-linking reaction on polymer under gamma-ray irradiation in a polar organic solution, thereby obtaining the intra-molecular cross-linking polymer; a ratio of degradation radiation chemical yield of the polymer to cross-linking radiation chemical yield of the polymer is smaller than 1.00; and the polymer and the polar organic solution form an uniform-phase solution. The invention further provides the intra-molecular cross-linking polymer prepared by the preparation method, and the intra-molecular cross-linking polymer has low viscosity and great surface area characteristic, the intra-molecular cross-linking polymer can be used as an additive of paint and a binder, filler and pigments of a reinforcing material, carriersof medical and biological materials and the like, and has wide use range.

Owner:SHANGHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com