PET alloy material, special compatibilizer thereof and preparation method thereof

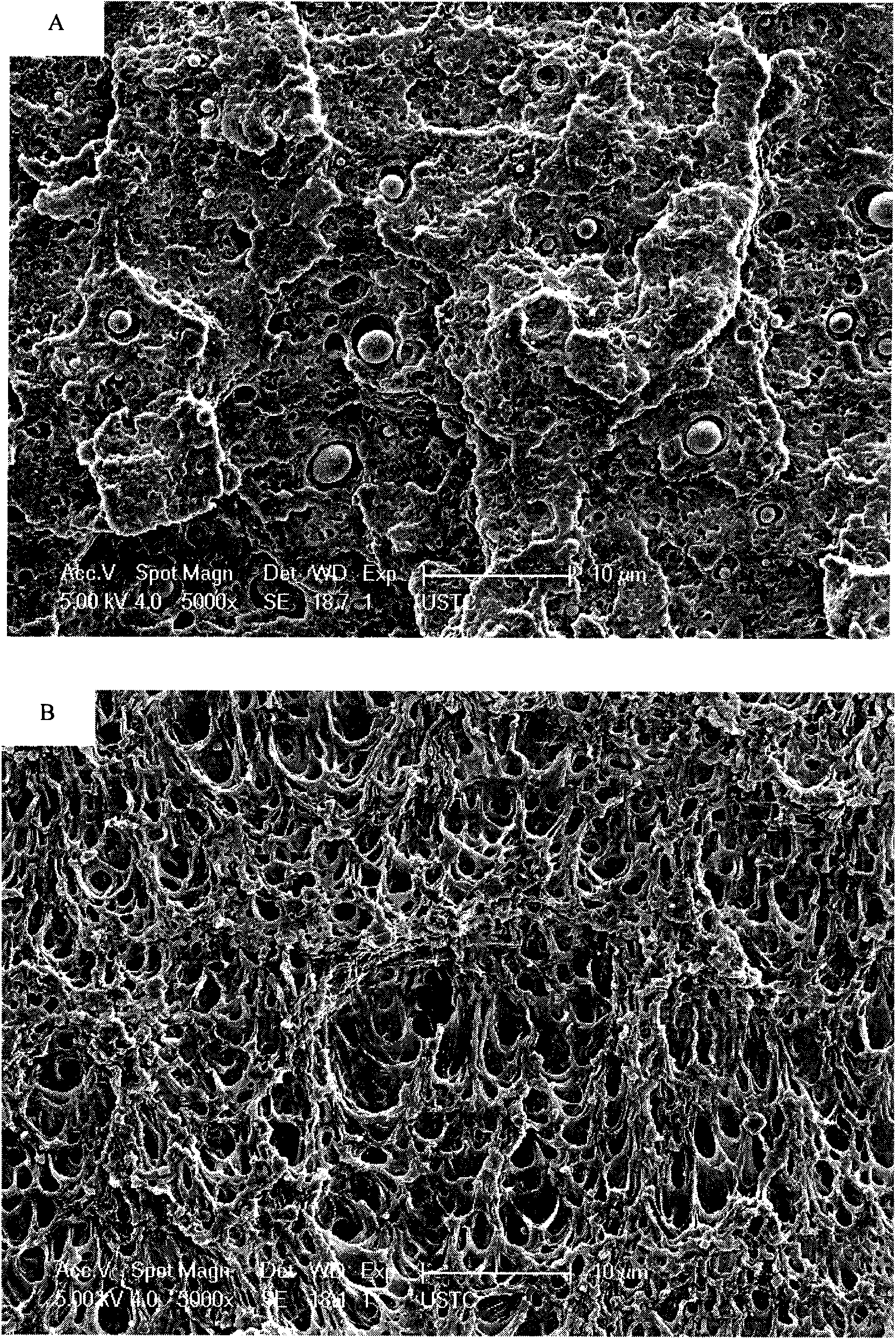

A technology of alloy material and toughening agent, which is applied in the field of engineering plastics, can solve the problems that the comprehensive performance of PET alloy cannot meet the actual needs, reduce the reaction efficiency, and the compatibility of the blended two phases is not high, so as to enhance the interface compatibility , increase the reaction efficiency, the effect of wide application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

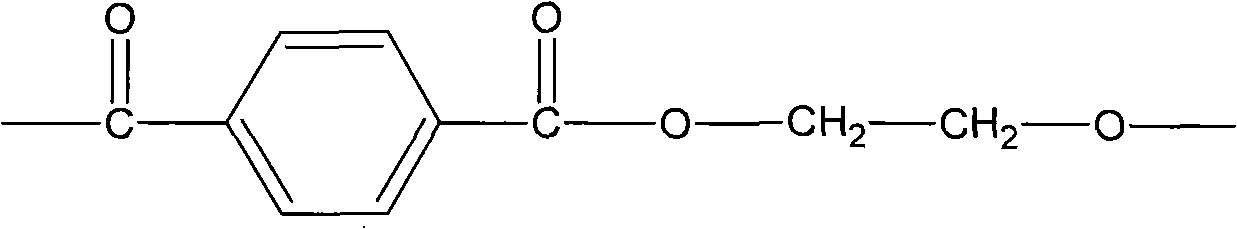

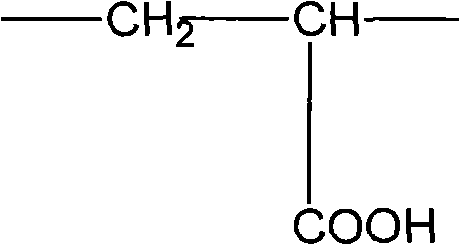

[0025] Embodiment 1, preparation graft copolymer (compatibilizer)

[0026] 60g PET, 14g AAc (acrylic acid), 0.4g FeSO 4 ·7H 2 O and 26g of distilled water were added into the reaction flask and mixed uniformly. After standing for 12 hours, nitrogen gas was introduced to remove oxygen and the reaction vessel was sealed. Then put it into Co-60 source for irradiation, the dose rate and absorbed dose are 0.8kGy / h and 30kGy respectively. After the reaction is completed, the homopolymer adsorbed on the surface of the resin is repeatedly washed with distilled water and dried to obtain the compatibilizer provided by the invention, i.e. PET grafted acrylic acid (PET-g-PAA) copolymer, and the grafting ratio is 0.18 %.

Embodiment 2

[0027] Embodiment 2, preparation graft copolymer (compatibilizer)

[0028]60g PET, 14g AAc (acrylic acid), 0.4g FeSO 4 ·7H 2 O and 26g of distilled water were added into the reaction flask and mixed uniformly. After standing for 12 hours, nitrogen gas was introduced to remove oxygen and the reaction vessel was sealed. Then put it into Co-60 source for irradiation, the dose rate and absorbed dose are 1.09kGy / h and 25kGy respectively. After the reaction is completed, the homopolymer adsorbed on the surface of the resin is repeatedly washed with distilled water and dried to obtain the compatibilizer provided by the invention, i.e. PET grafted acrylic acid (PET-g-PAA) copolymer, and the grafting ratio is 0.17 %.

Embodiment 3

[0029] Embodiment 3, preparation graft copolymer (compatibilizer)

[0030] 60g PET, 14g AAc (acrylic acid), 0.4g FeSO 4 ·7H 2 O and 26g of distilled water were added into the reaction flask and mixed uniformly. After standing for 12 hours, nitrogen gas was introduced to remove oxygen and the reaction vessel was sealed. Then put into Co-60 source irradiation, the dose rate and absorbed dose are 1.5kGy / h and 20kGy respectively. After the reaction is completed, the homopolymer adsorbed on the surface of the resin is repeatedly washed with distilled water and dried to obtain the compatibilizer provided by the present invention, i.e. PET grafted acrylic acid (PET-g-PAA) copolymer, and the grafting rate is 0.09 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com