Method for preparing titanium dioxide/mesoporous carbon composite photocatalyst by electron beam irradiation

An electron beam irradiation, titanium dioxide technology, applied in physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc. problem, to achieve the effect of enhancing photocatalytic performance, good photocatalytic effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

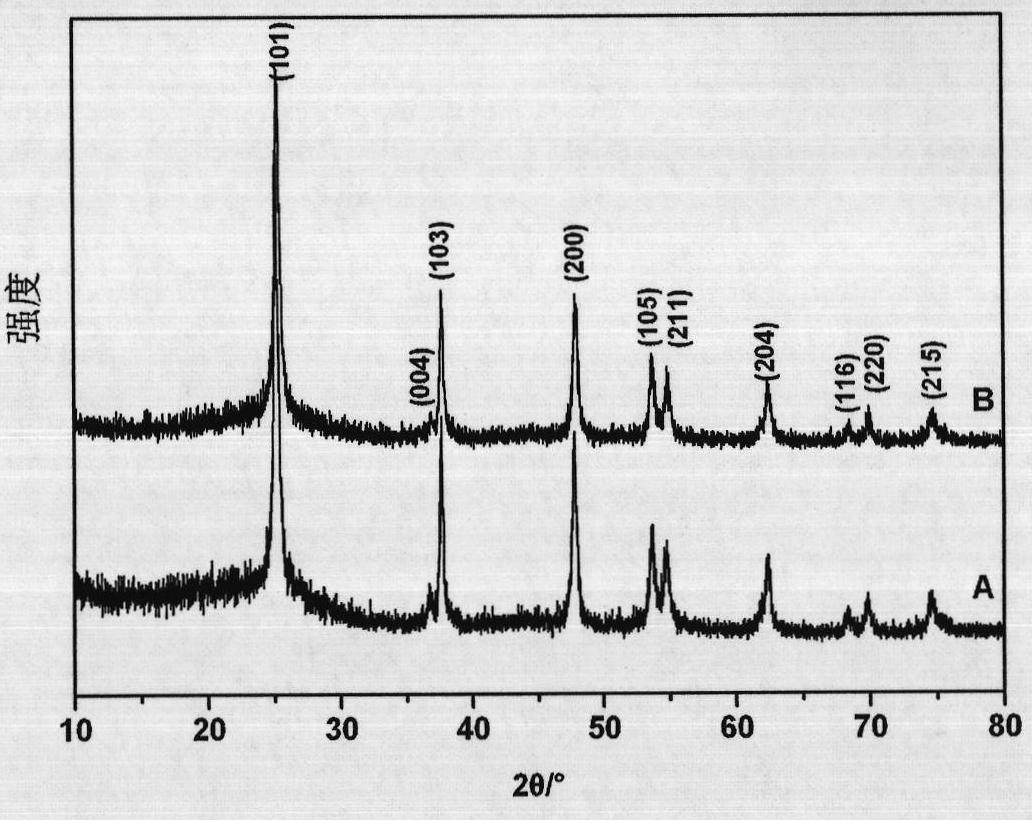

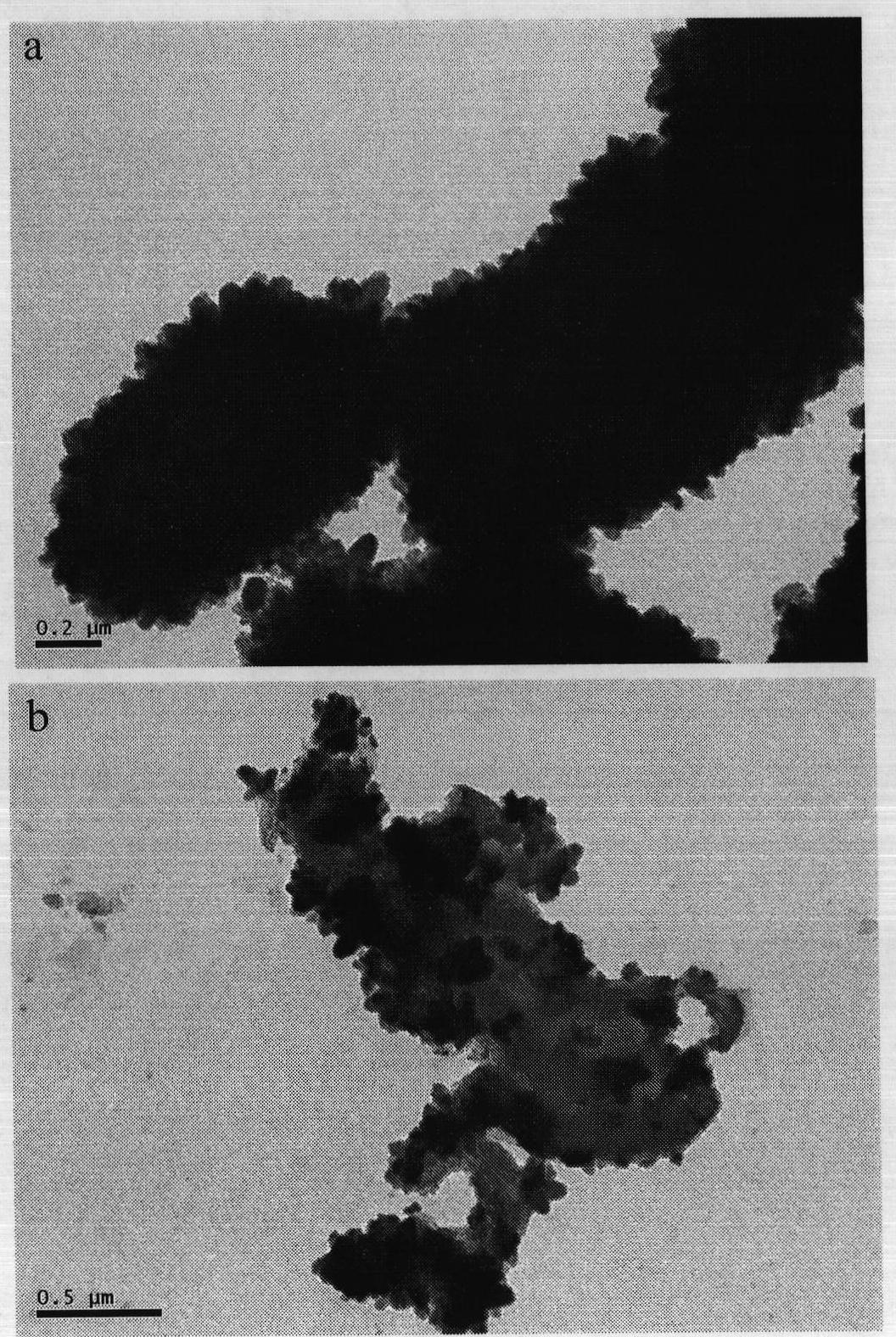

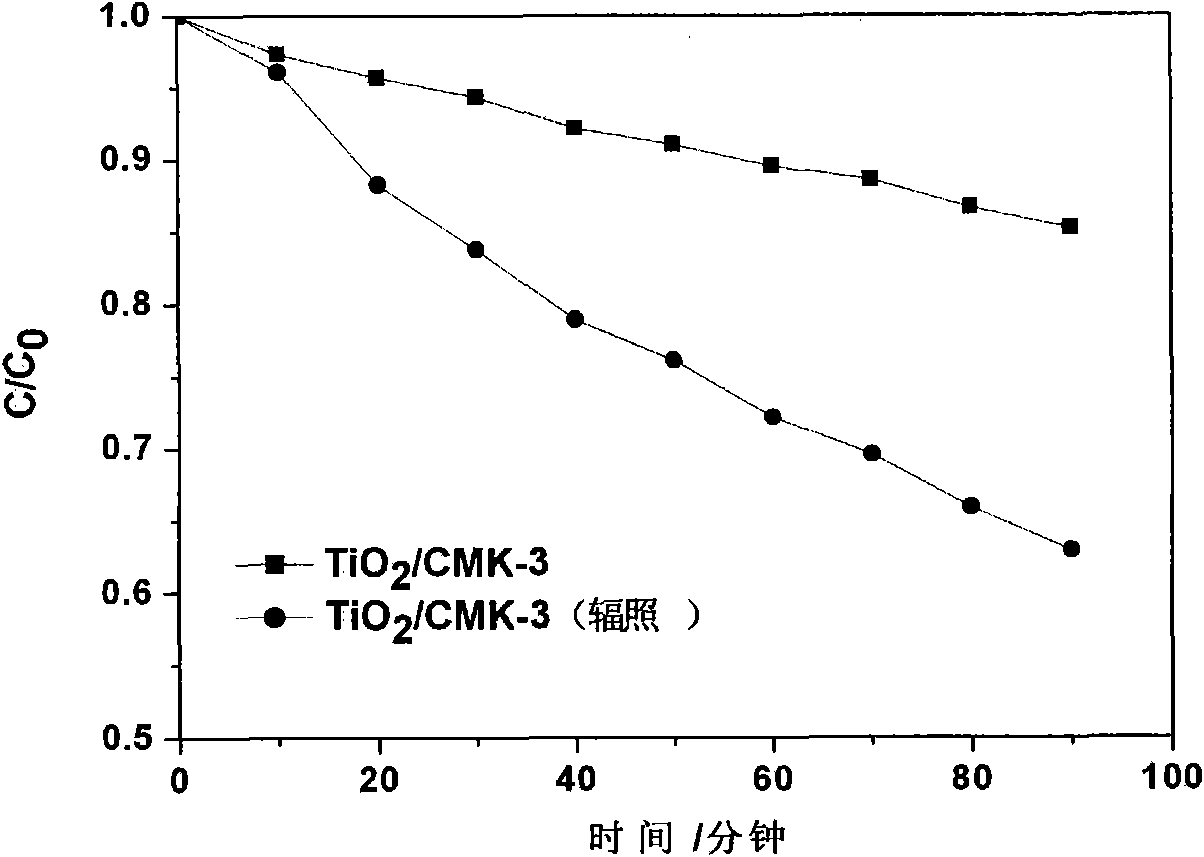

Embodiment 1

[0024] The preparation process and steps of this embodiment are as follows:

[0025] a. Weigh 0.025g mesoporous carbon (CMK-3) with an electronic balance and add it to 20mL 0.06mol / L TiF 4 in aqueous solution, and ultrasonic for 30 minutes to make it evenly mixed;

[0026] b. Transfer the above solution into a self-made sealing bag, place it in the irradiation area under the electron accelerator for irradiation, and the irradiation dose is 280kGy;

[0027] c. Transfer the above solution into a 100mL beaker, seal it with a parafilm and put it in an oven at 60°C for 20 hours;

[0028] d. wash the reaction product with water and ethanol successively;

[0029] e. Dry the washed product in a vacuum oven at 60°C for 6 hours to obtain TiO 2 / CMK-3 composite photocatalyst.

Embodiment 2

[0033] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is: the electron beam irradiation dose in this embodiment is 140kGy, and finally a composite photocatalyst is prepared.

Embodiment 3

[0035] The steps in this embodiment are exactly the same as those in Embodiment 1 above. The difference is that the electron beam irradiation dose in this embodiment is 420kGy, and finally a composite photocatalyst is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com