Patents

Literature

35results about How to "Suitable for quantitative production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

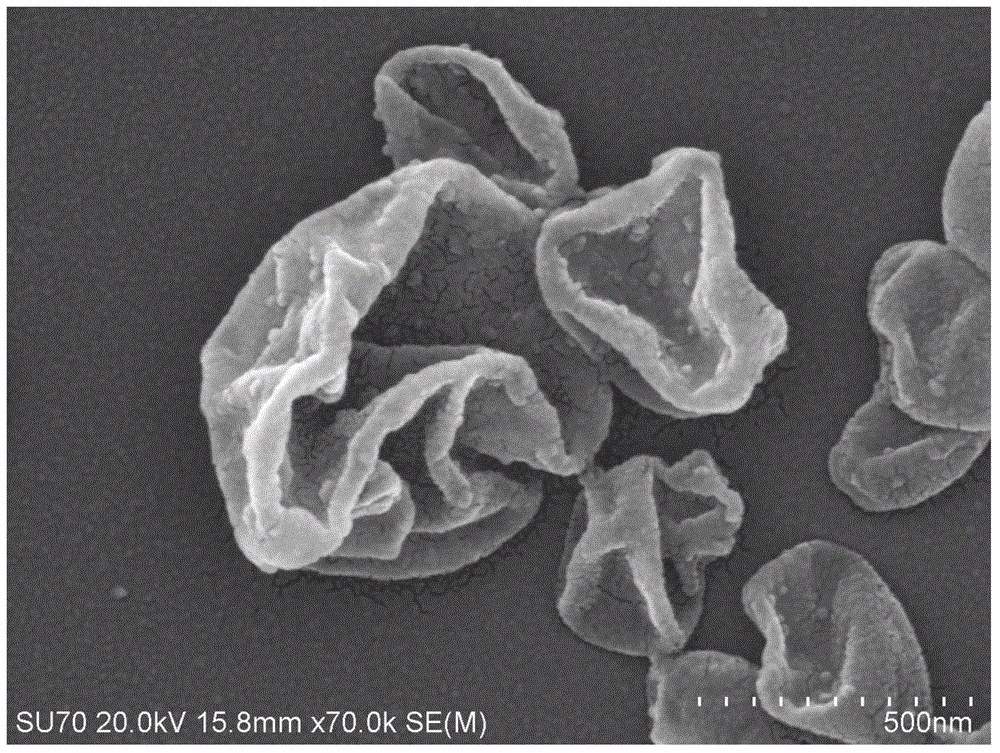

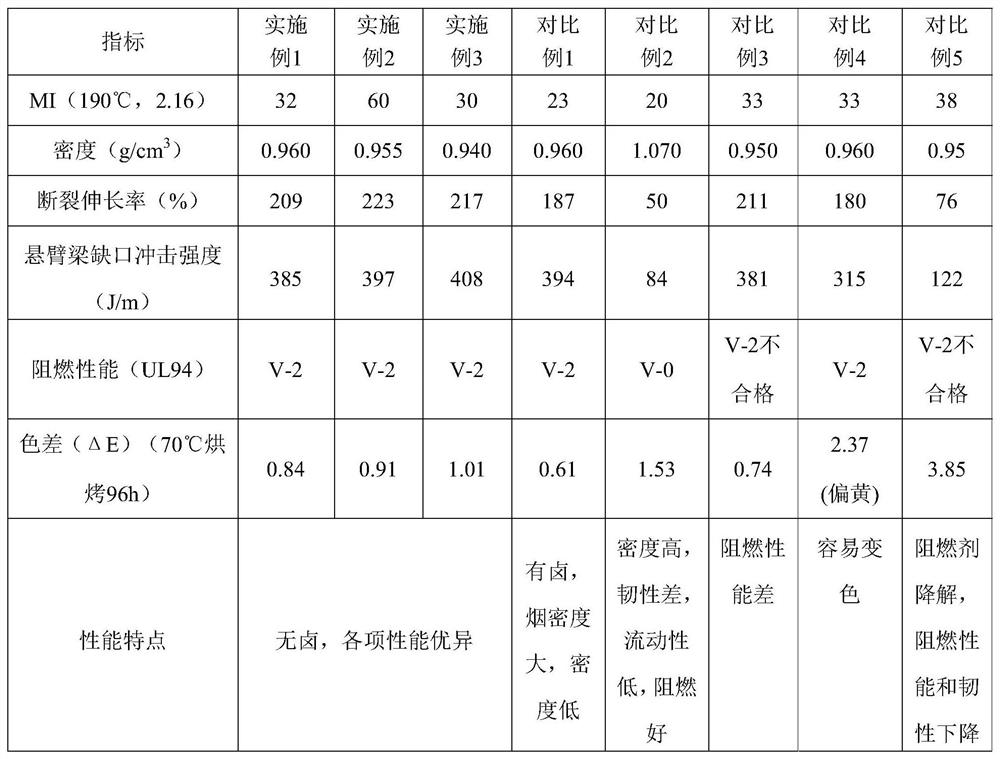

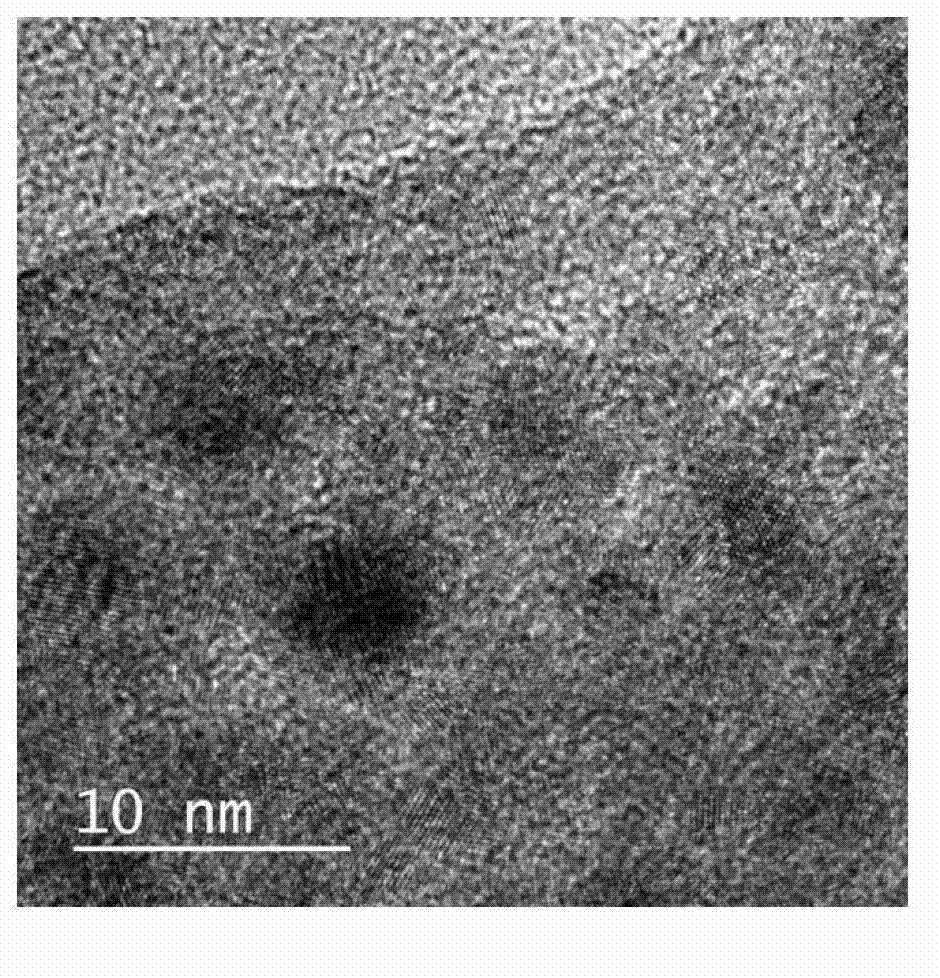

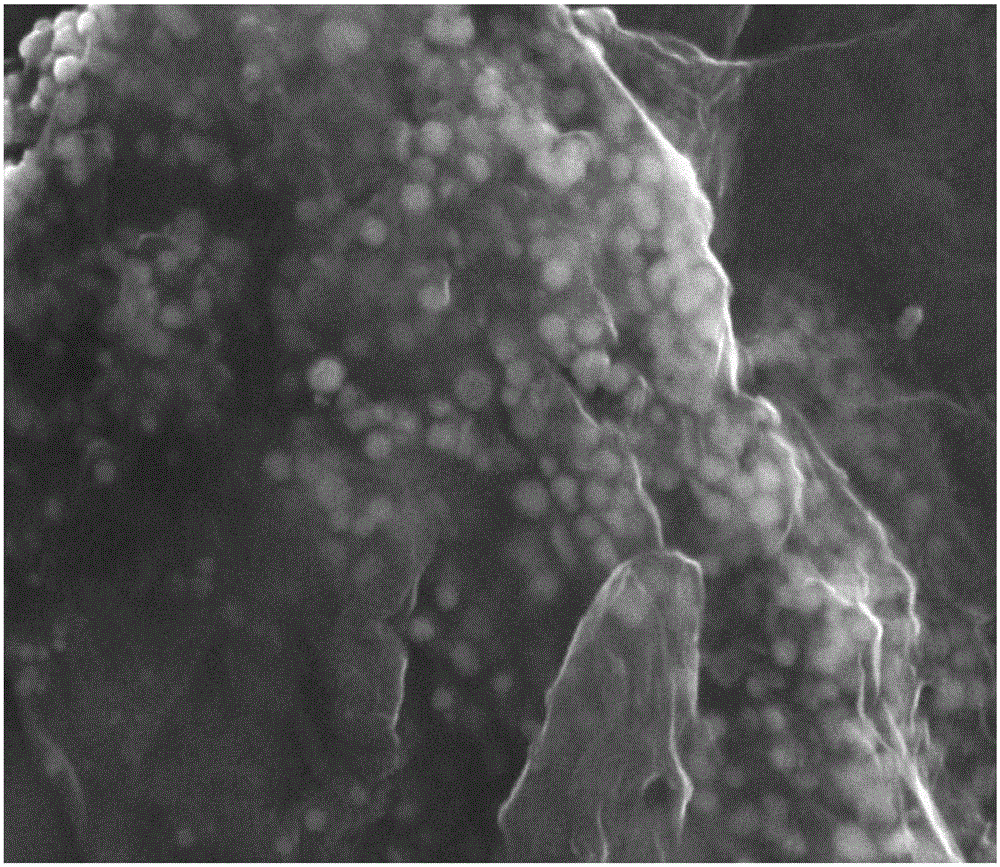

Method for preparing graphene/nickel nanocomposite material by utilizing gamma ray

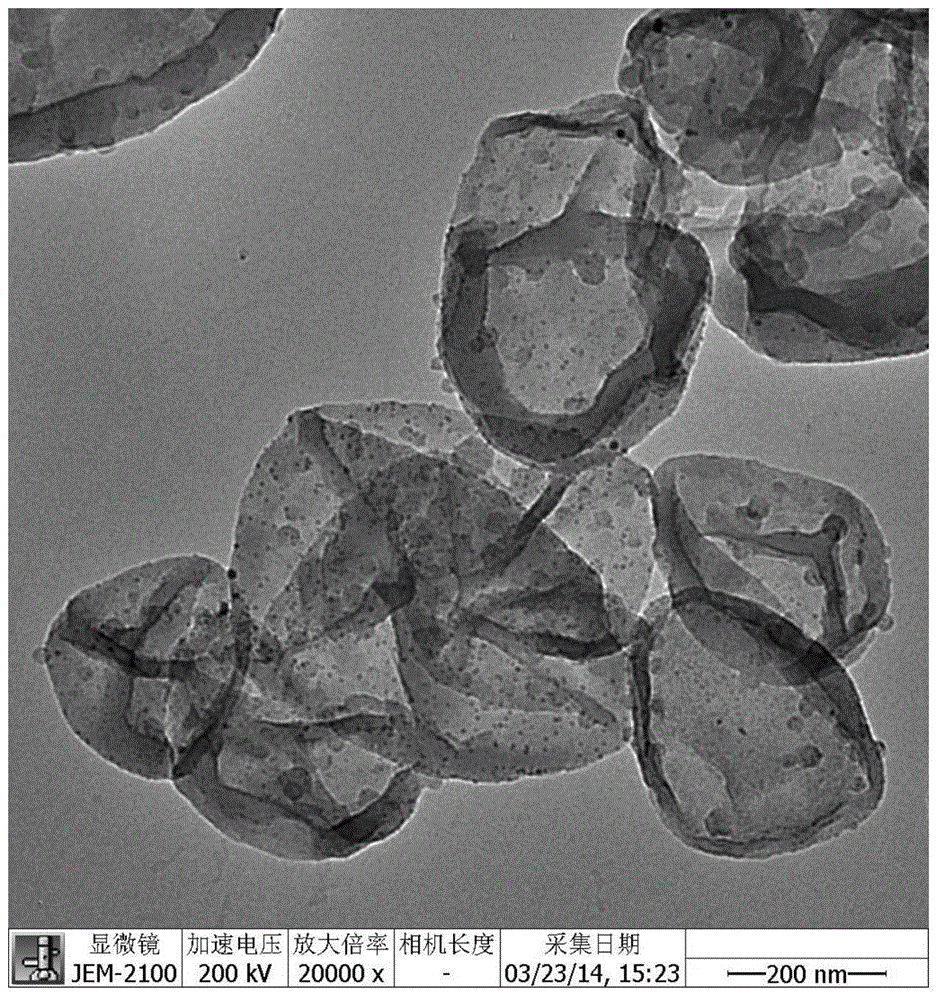

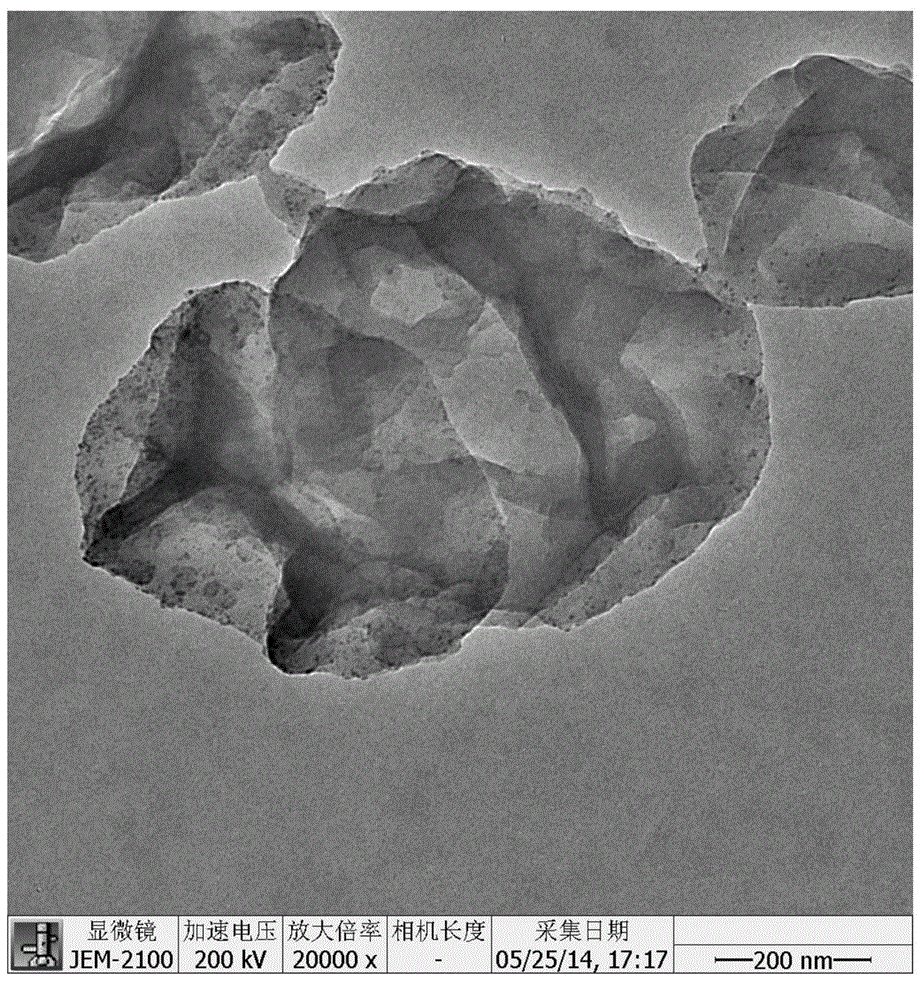

ActiveCN103011151ASuitable for quantitative productionMild reaction conditionsMaterial nanotechnologyGrapheneRadiation chemistryGamma ray

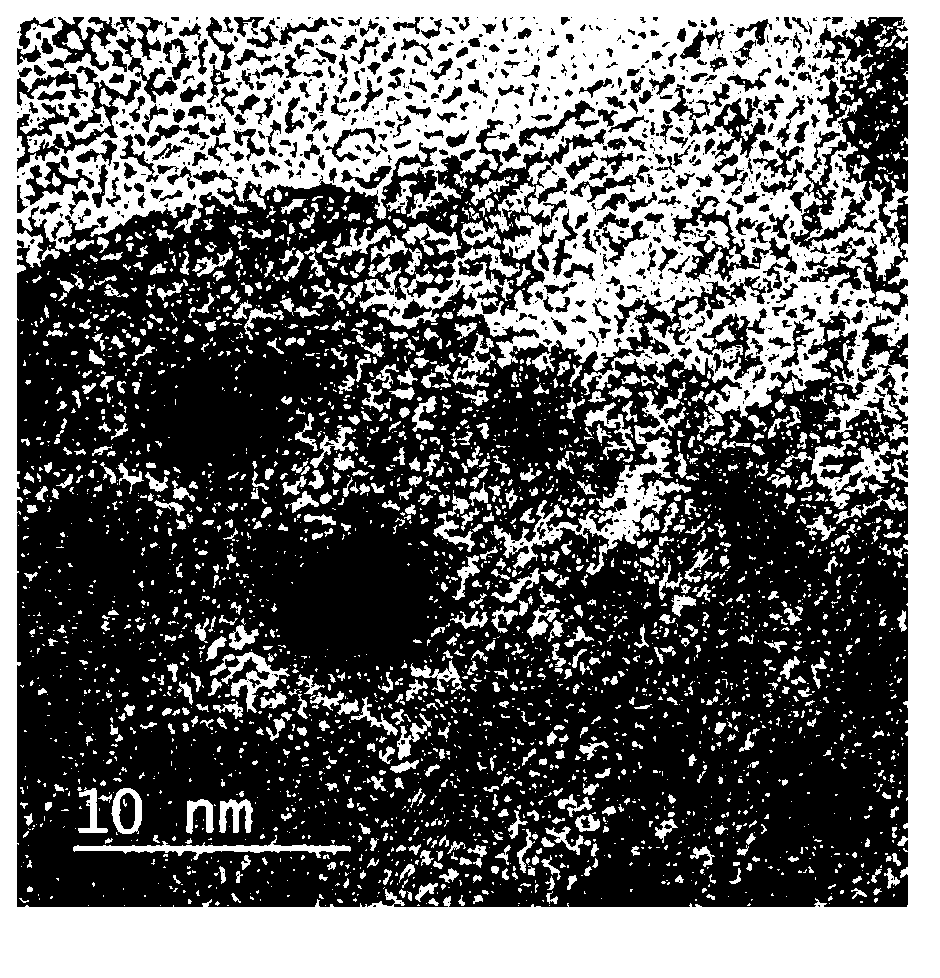

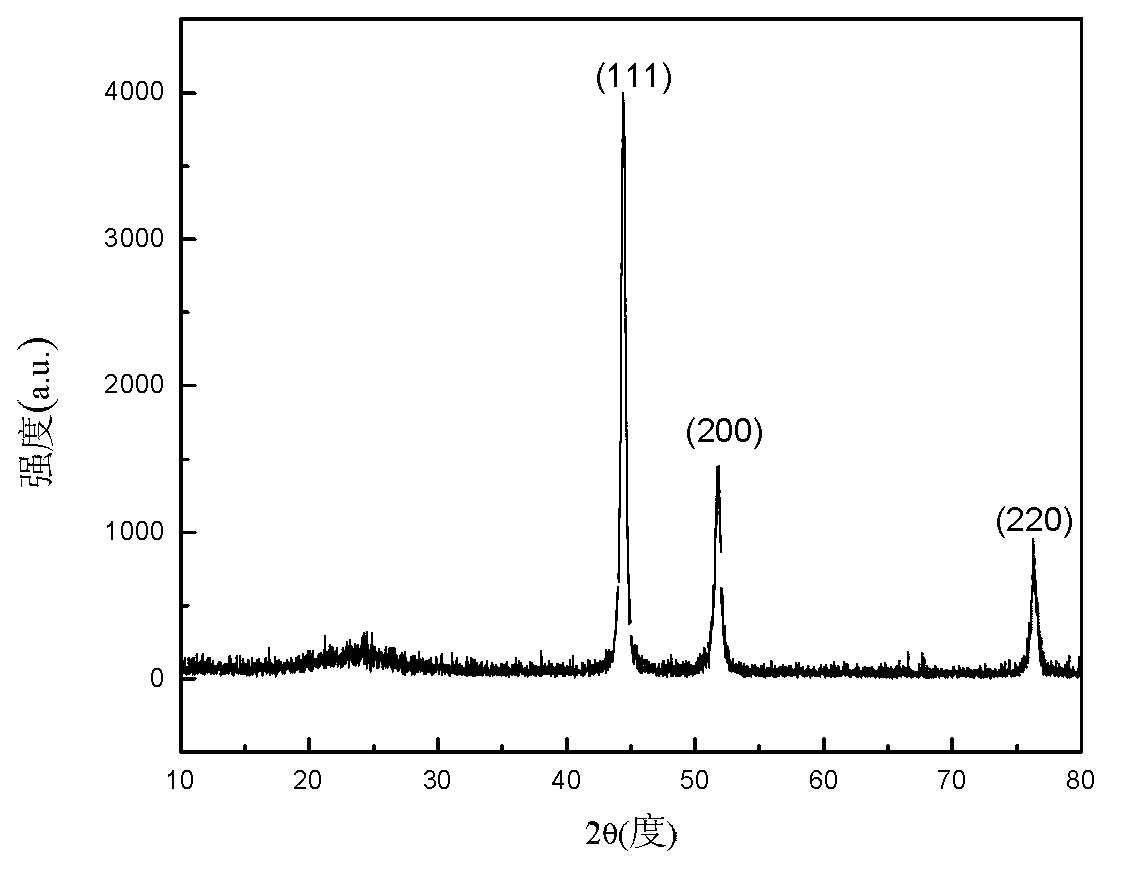

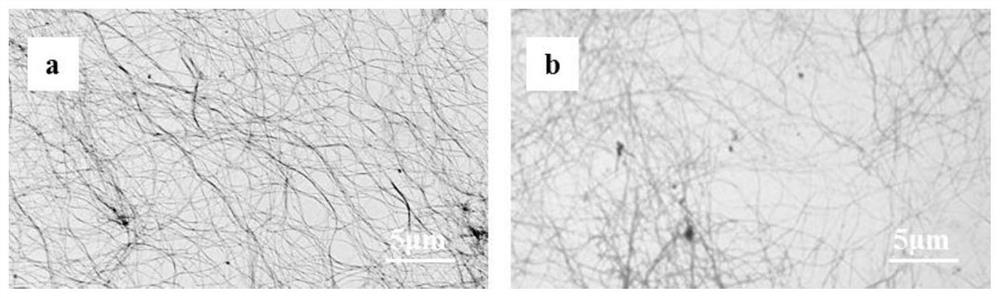

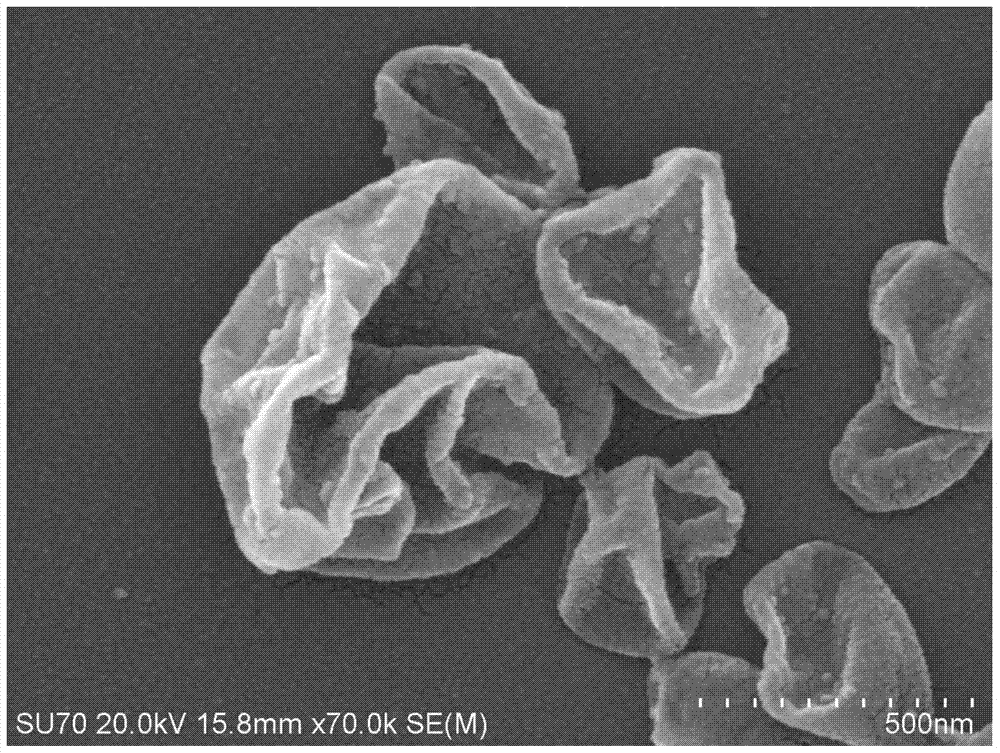

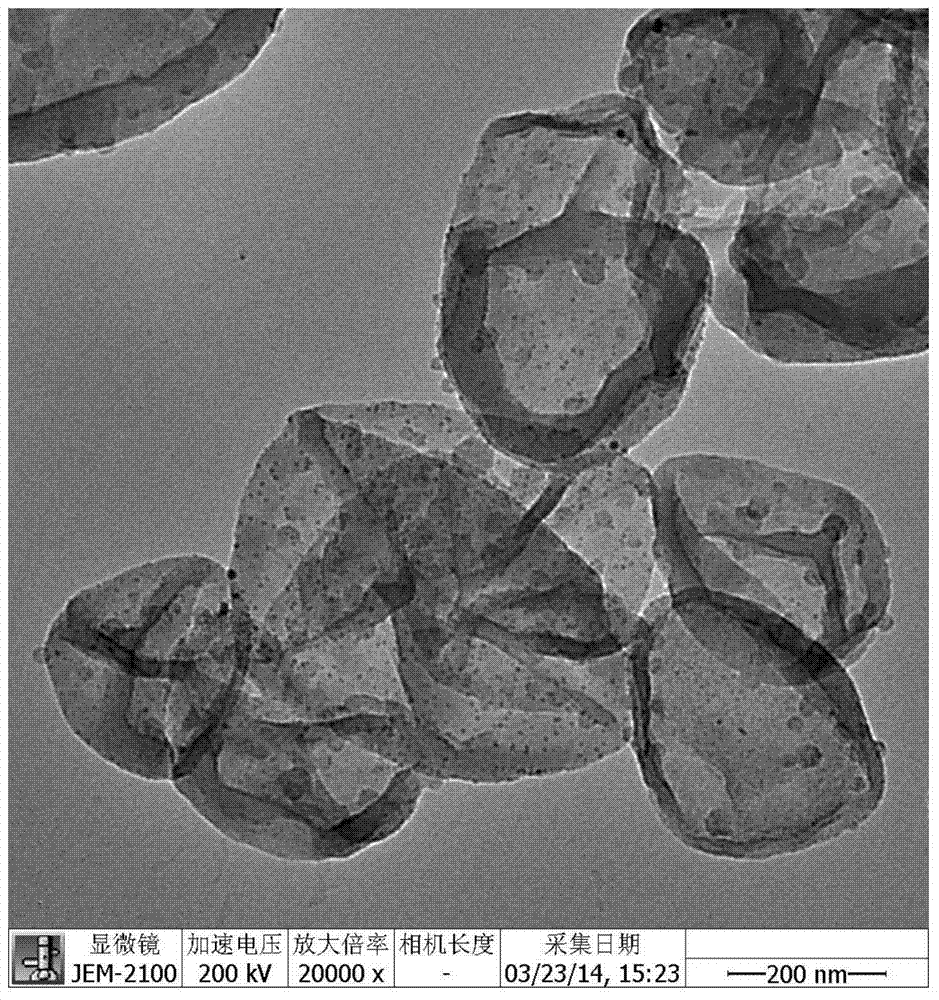

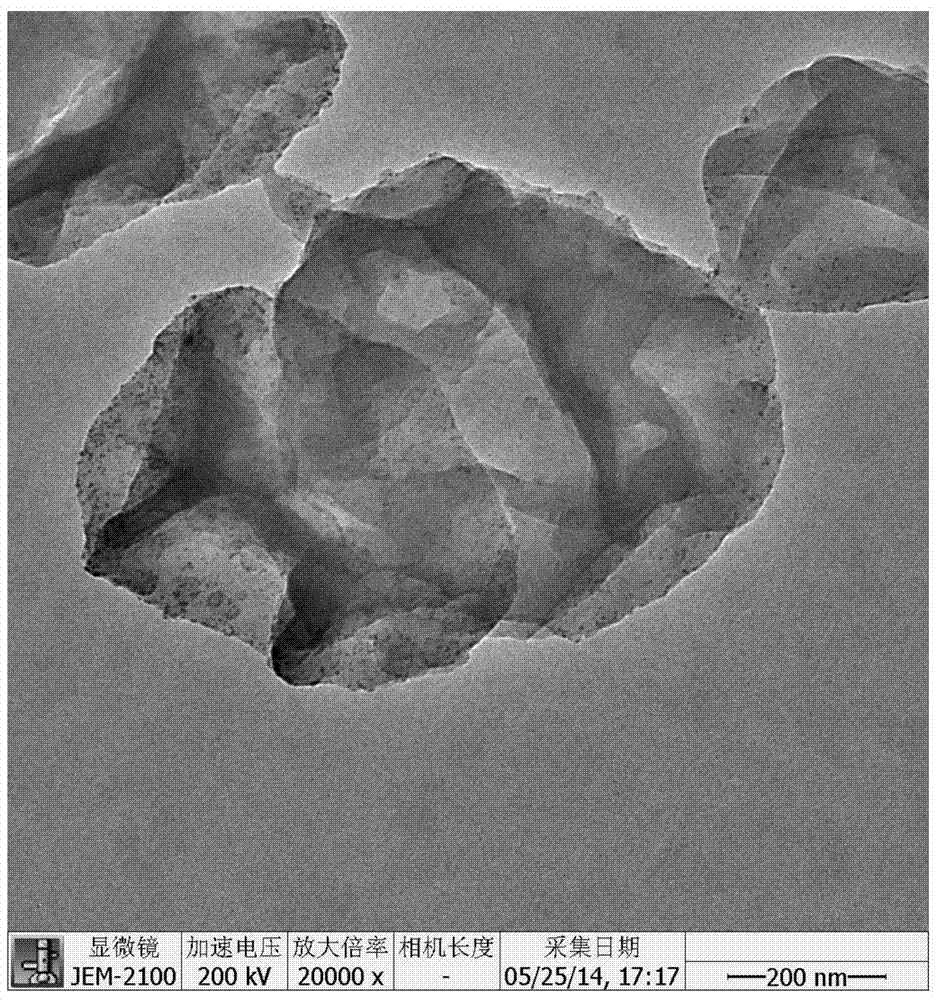

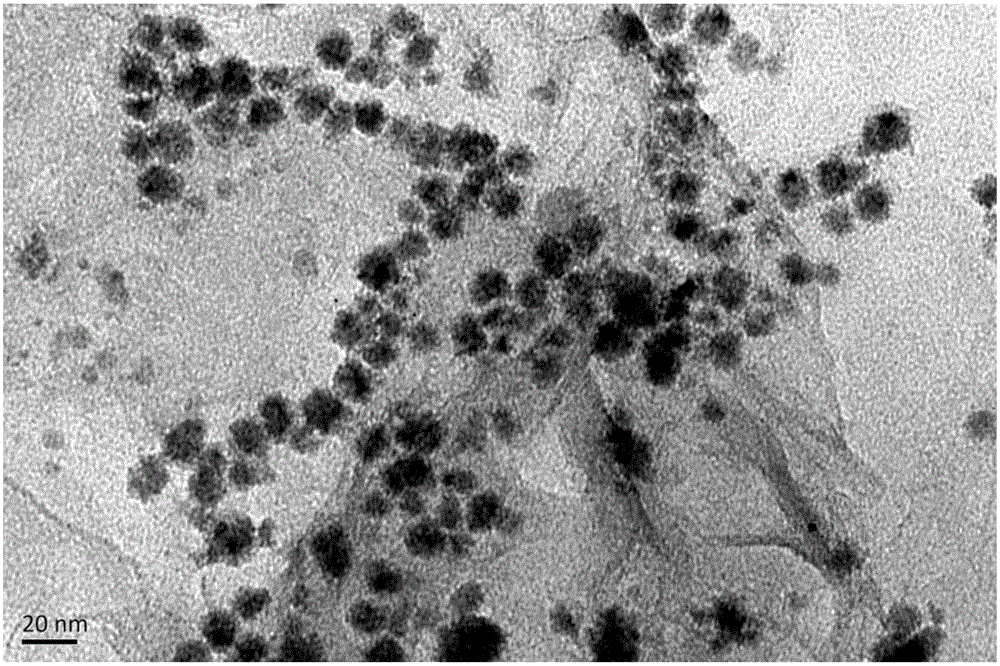

The invention discloses a method for preparing a graphene / nickel nanocomposite material by utilizing a gamma ray, belongs to the field of crossing of the nanocomposite material and radiation chemistry, and in particular relates to a method for preparing the graphene / nickel nanocomposite material by utilizing the gamma ray. The problem that the graphene-nickel nanocomposite material prepared by the conventional method is high in cost and severely damages the environment is solved. The method comprises the following steps of: 1, preparing oxidized graphite; 2, preparing mixed solution; 3, reacting under the irradiation of the gamma ray to obtain a product; and 4, centrifugally separating, cleaning and drying the product to obtain the graphene / nickel nanocomposite material. The method is applied to the field of preparation of the graphene / nickel nanocomposite material.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

Sulfonate type ultraviolet curing waterborne polyurethane and preparation method thereof

InactiveCN111253547AHigh solid contentGood dispersionPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHydrophilic monomerPolyester

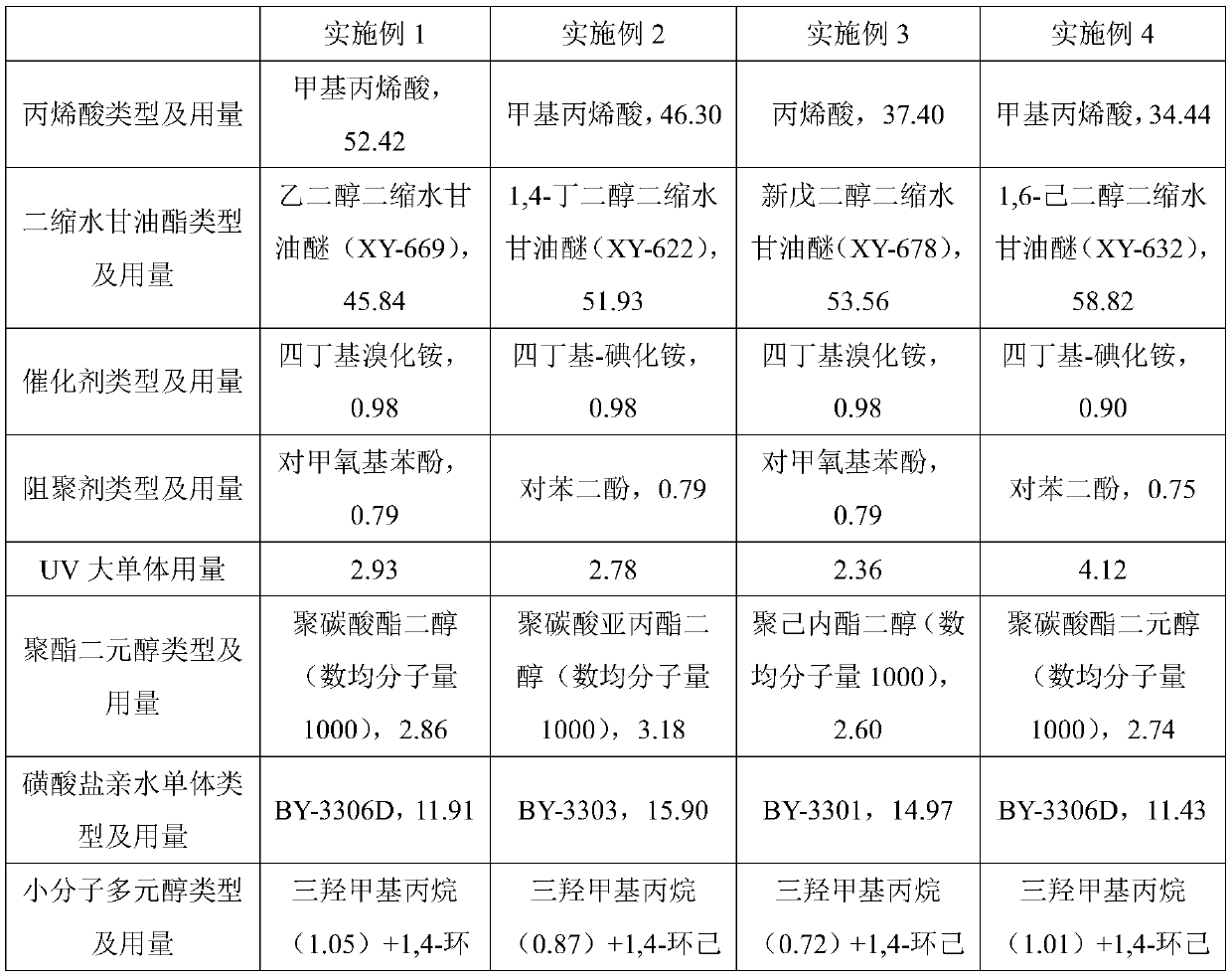

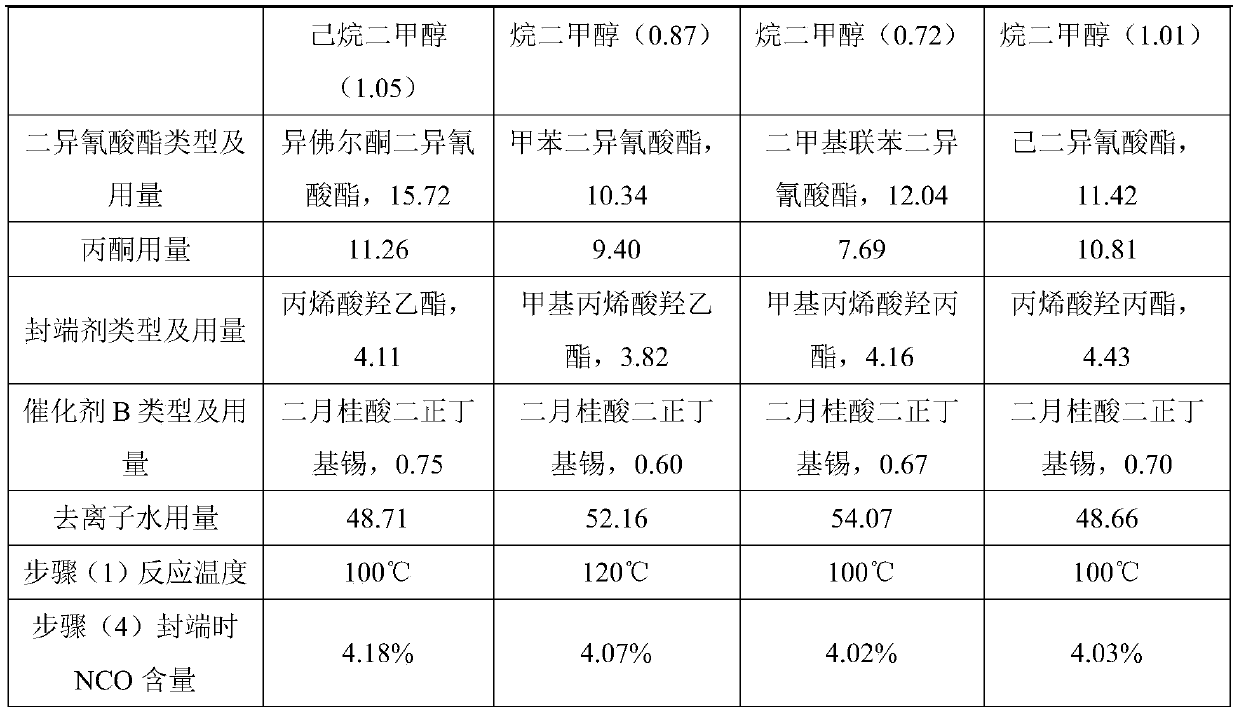

The invention relates to sulfonate type ultraviolet curing waterborne polyurethane and a preparation method thereof. The preparation method comprises the following steps: taking acrylic acid, diglycidyl ether and a polymerization inhibitor as raw materials, performing a catalytic reaction at 100-120 DEG C to synthesize a UV macromonomer containing unsaturated double bonds, and performing the catalytic reaction on the UV macromonomer, polyester diol, a sulfonate hydrophilic monomer, micromolecular polyol and diisocyanate to finally obtain a target product. Compared with the existing similar products, the sulfonate type ultraviolet curing waterborne polyurethane provided by the invention has the advantages of high solid content, zero VOC emission, no amine smell and the like, and a cured adhesive film is high in gloss and hardness and good in water resistance and solvent resistance.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

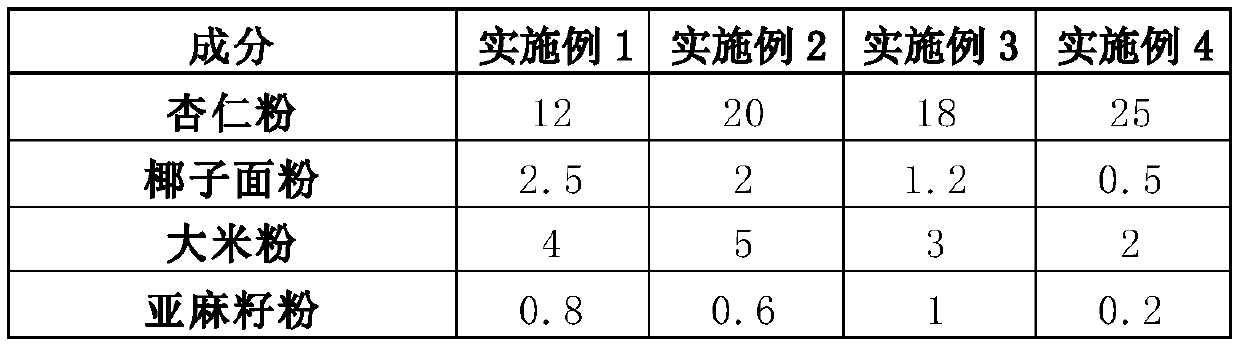

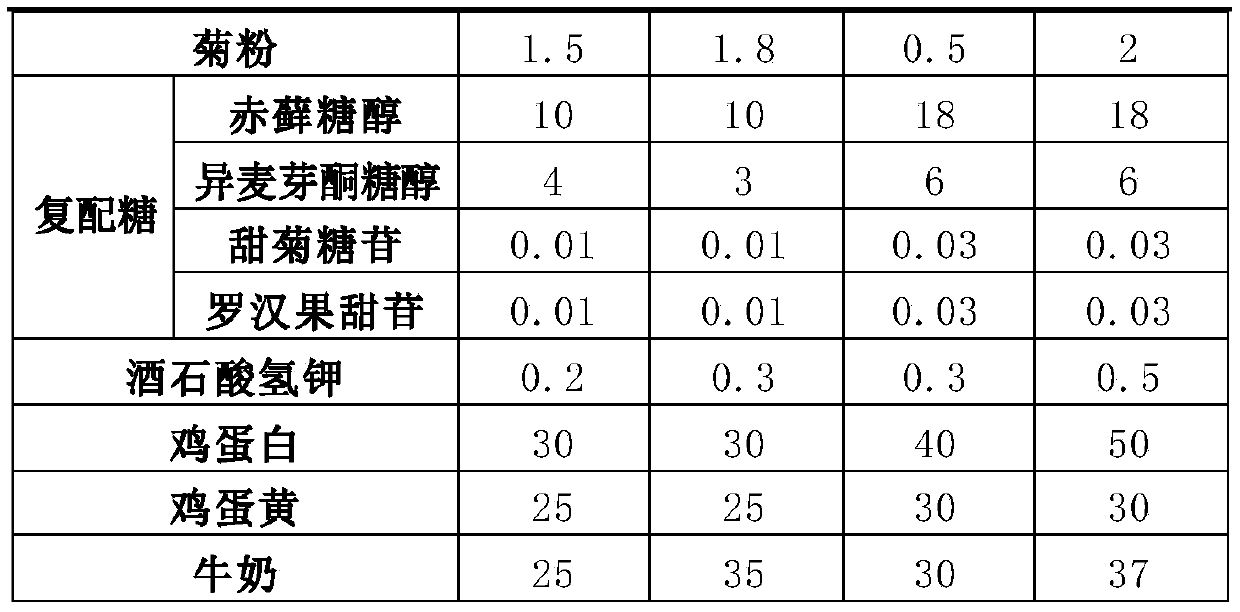

Sucrose-free oil-free gluten-free cake and production process thereof

The invention relates to a sucrose-free oil-free gluten-free cake and a production process thereof. The sucrose-free oil-free gluten-free cake is prepared from the following raw materials in parts byweight: 12-25 parts of almond powder, 0.5-3 parts of coconut flour, 2-5 parts of rice flour, 0.2-1 part of linseed powder, 0.5-2 parts of inulin, 13.02-26.6 parts of compound sugar, 0.2-0.5 part of potassium hydrogen tartrate, 30-50 parts of egg white, 20-30 parts of egg yolk and 20-37 parts of milk. The cake is not added with any animal and vegetable oil, sucrose and raw material containing gliadin and glutenin, and is a true oil-free, sucrose-free and gluten-free product. Moreover, the process uses non-traditional pastry ingredients such as the almond powder and the coconut flour as main materials, and the mouth feel of the product is close to that of traditional cakes, but the cake tastes slightly different from traditional cakes. Under the condition of stable quality assurance, the cake is more abundant in mouth feel, and the finished product is better in color and better in taste.

Owner:邹亚红

Method for preparing reduced oxidized graphite/nano nickel composite wave-absorbing material by using gamma ray

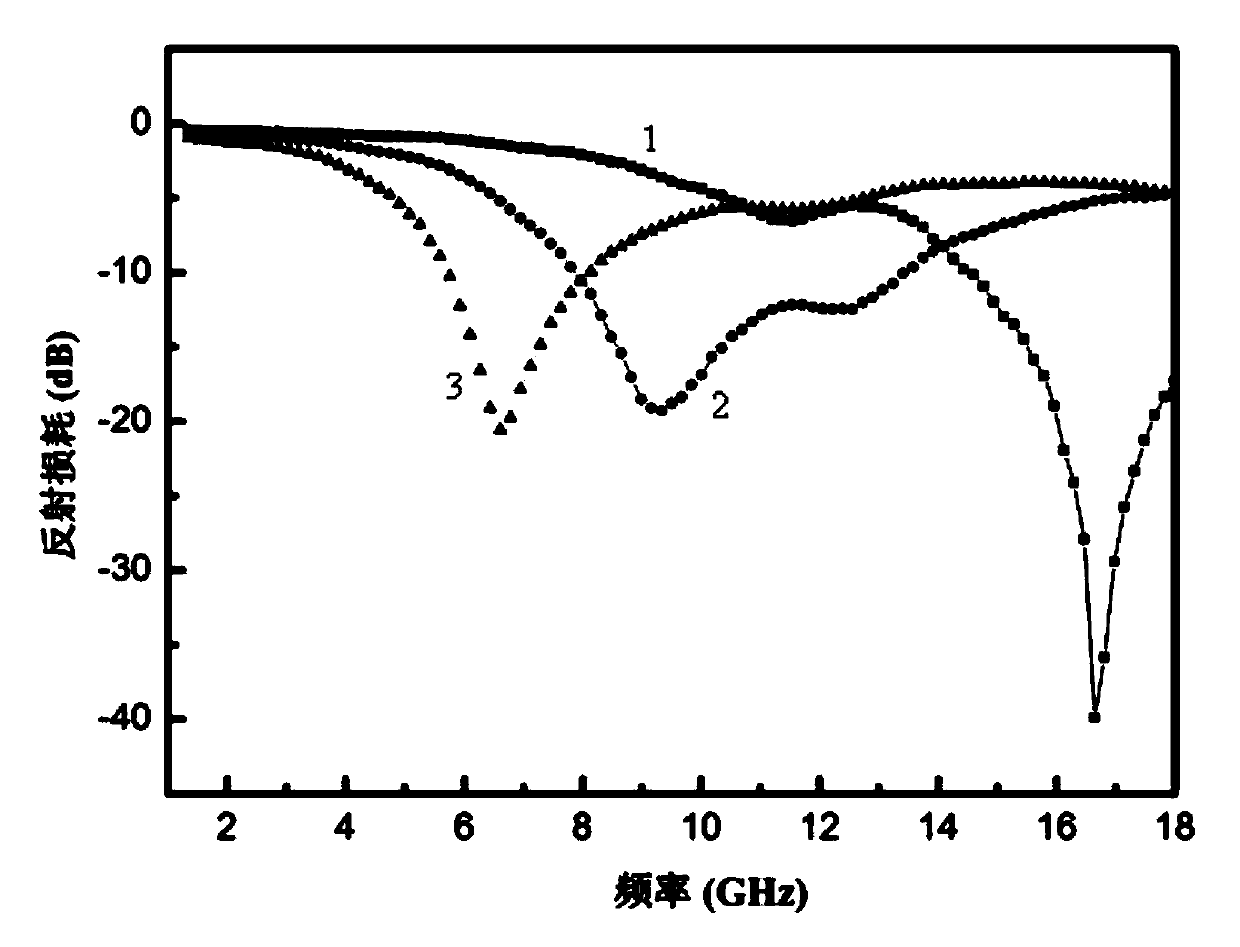

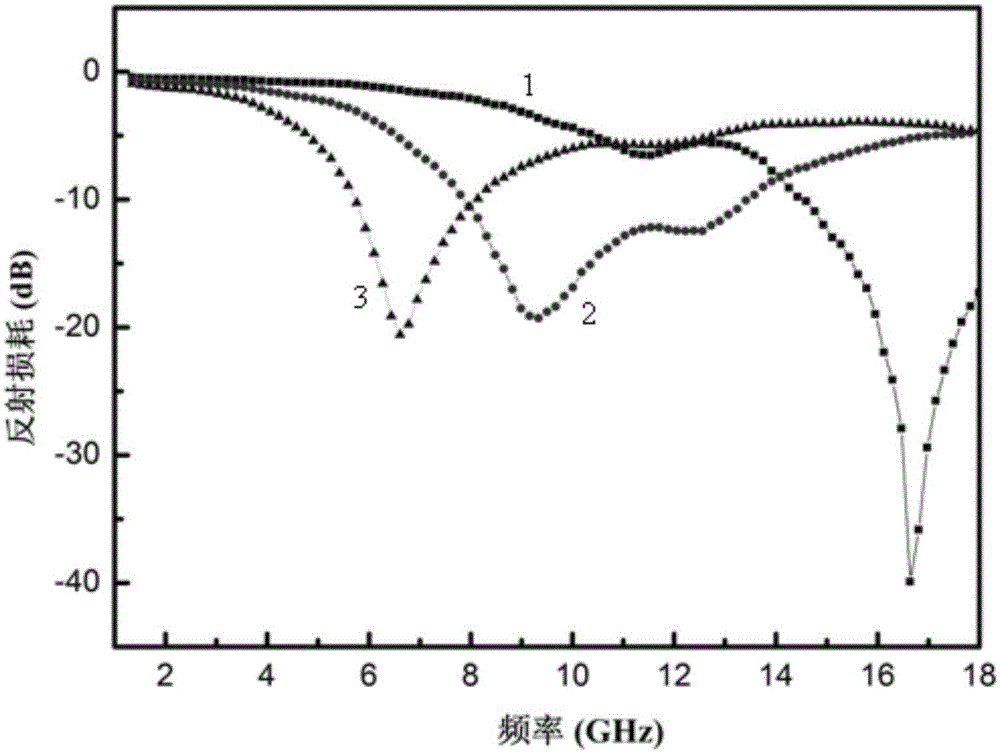

ActiveCN103788921AMild reaction conditionsLow cost of preparationOther chemical processesNickelGraphite oxide

The invention discloses a method for preparing a reduced oxidized graphite / nano nickel composite wave-absorbing material by using gamma ray and relates to a method for preparing the reduced oxidized graphite / nano nickel composite wave-absorbing material, for solving such technical problems of the conventional method for preparing the reduced oxidized graphite / nano nickel composite wave-absorbing material as high preparation cost, complicated preparation process and high reaction temperature. The preparation method comprises the following steps: 1, preparing graphite oxide, 2, preparing a mixture solution, 3, reacting under the radiation of gamma ray to obtain a product, and 4, filtering, separating, washing and drying the product so as to obtain the reduced oxidized graphite / nano nickel composite wave-absorbing material. The reaction in the method is performed at normal temperature and normal pressure, and the method is gentle in reaction condition, low in preparation cost, simple in application method and particularly applicable to large-scale production of the material. The method is applied to the field of preparation of the reduced oxidized graphite / nano nickel composite wave-absorbing material.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

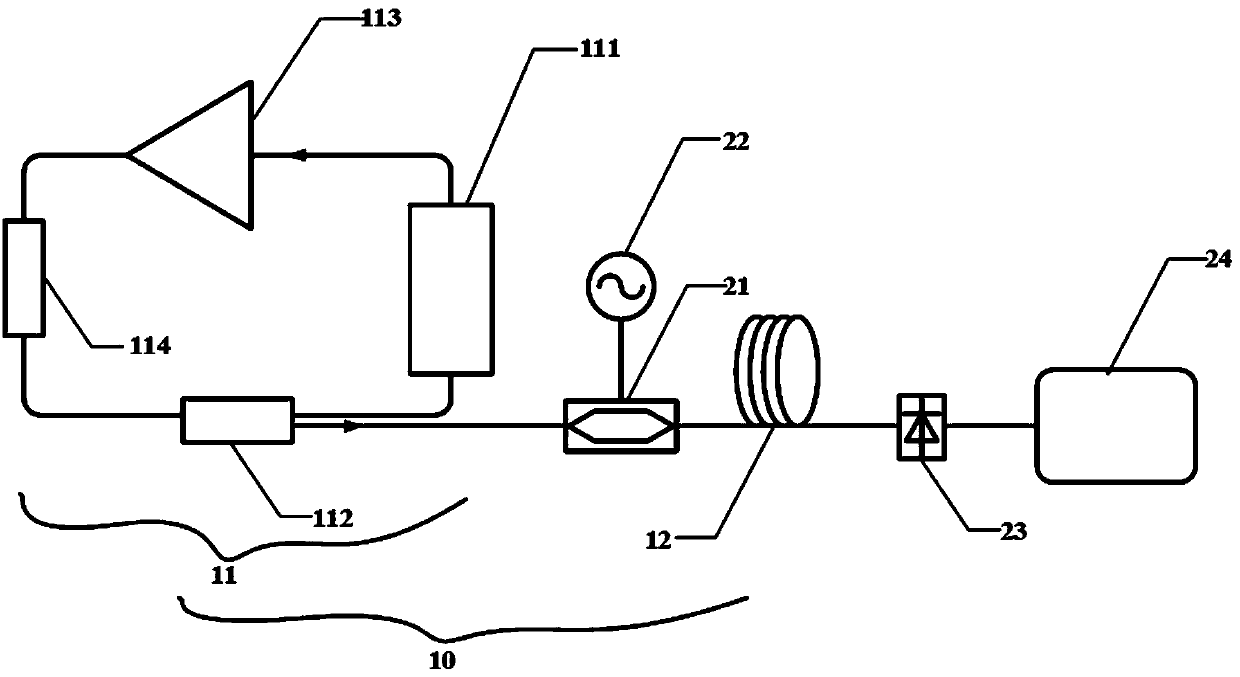

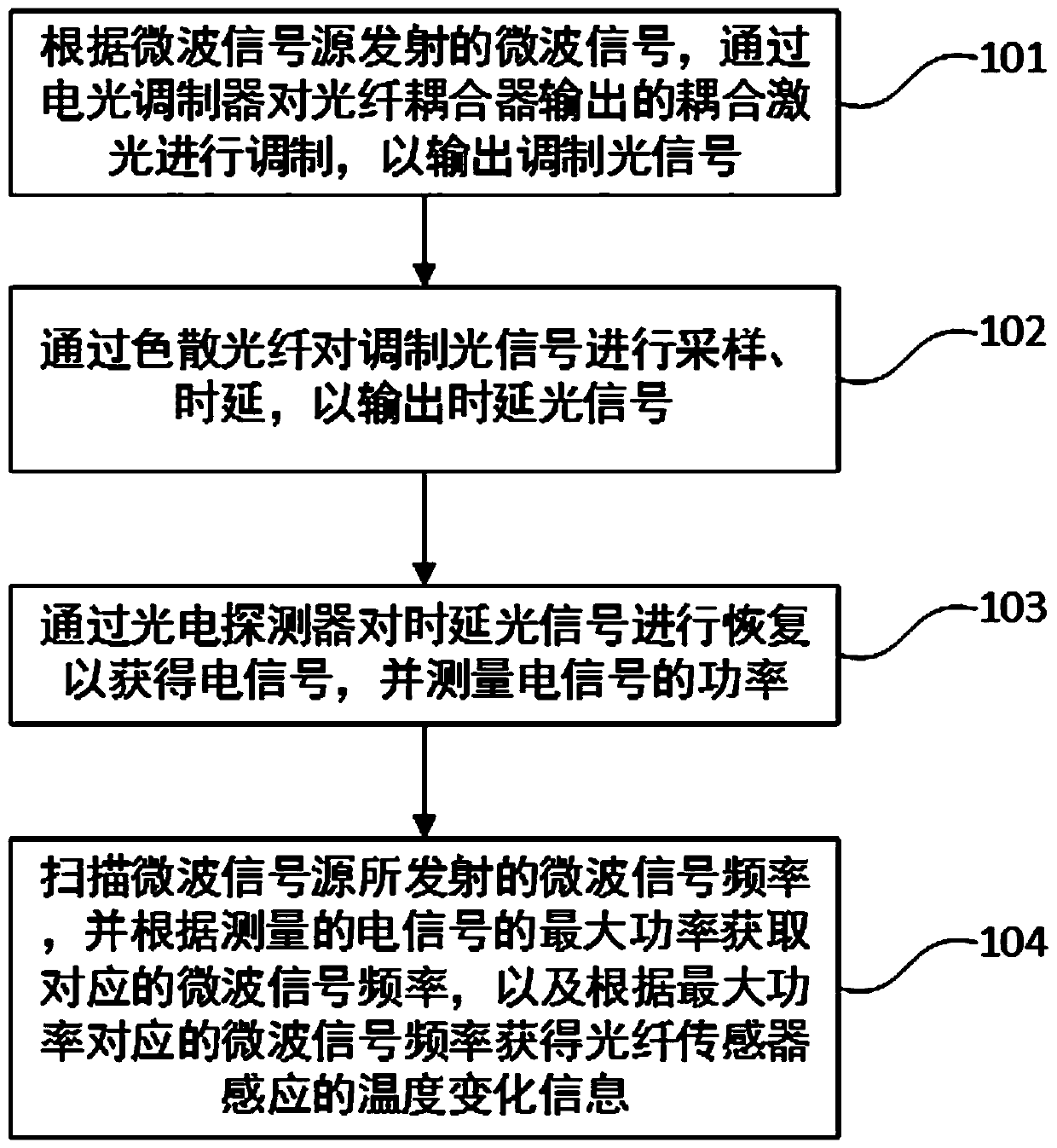

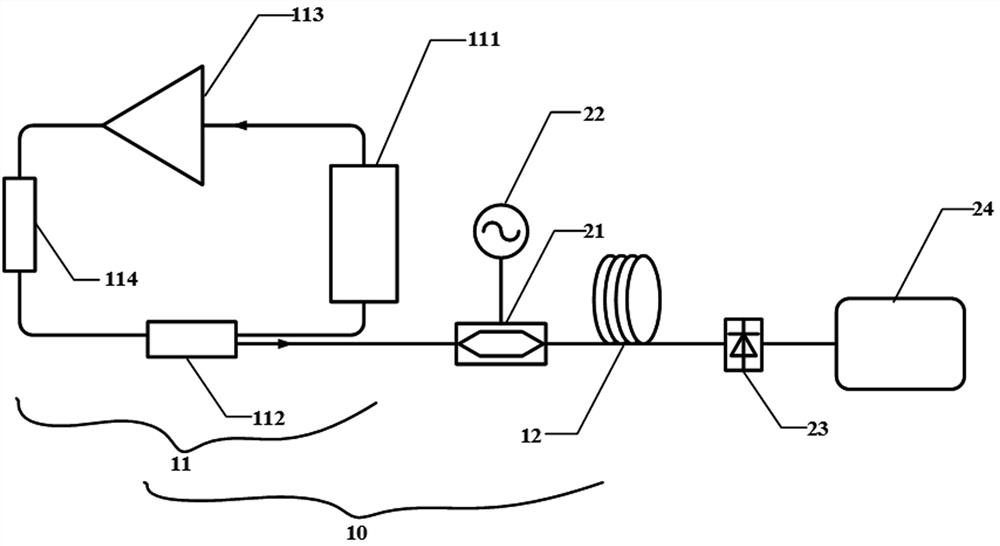

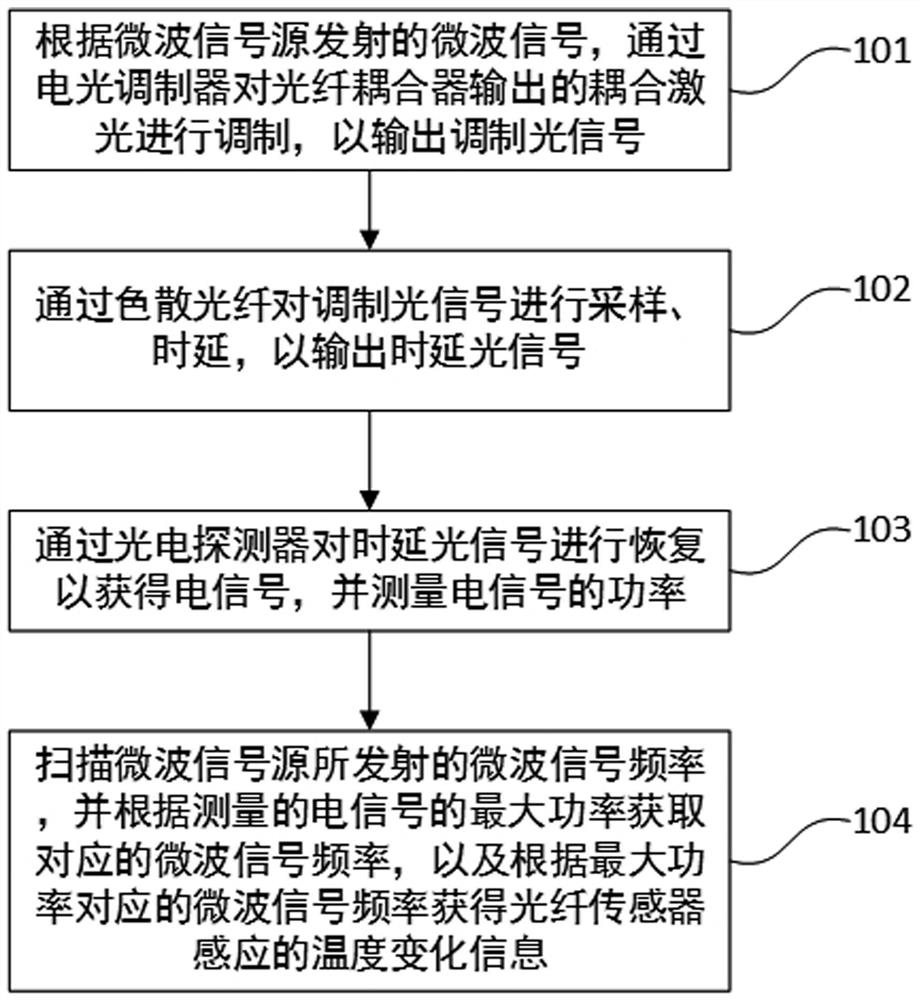

Temperature sensing demodulation device and method based on microwave photon filter

ActiveCN109580038AAchieve temperatureRealize demodulationThermometers using physical/chemical changesElectric powerMulti wavelength

The invention discloses a temperature sensing demodulation device and method based on a microwave photon filter. The microwave photon filter comprises a multi-wavelength fiber laser and a dispersion optical fiber for forming a laser, and coupled output of the laser is carried out; the temperature sensing demodulation device comprises an electro-optic modulator, a microwave signal source, a photoelectric detector, an electric power meter and a temperature demodulator; the electro-optic modulator is used for modulating the coupled laser to output a modulated optical signal; the dispersion optical fiber is used for sampling delay of the modulated optical signal to output a delayed optical signal; the photoelectric detector is used for recovering the delayed optical signal to obtain an electrical signal; the electric power meter is used for measuring the power of the electrical signal; the temperature demodulator is used for scanning the microwave signal frequency and acquiring the corresponding microwave signal frequency according to the maximum power of the electrical signal measured by the electric power meter and obtaining temperature change information induced by an optical fibersensor; and optical fiber temperature sensing and demodulating are achieved through a simple structure, and meanwhile, the required cost is reduced.

Owner:INFORMATION & COMMNUNICATION BRANCH STATE GRID JIANGXI ELECTRIC POWER CO +1

Nano precious metal load polymer vesica and preparing method thereof

ActiveCN104998683AImprove catalytic performanceCatalytic performance is beneficial toOrganic-compounds/hydrides/coordination-complexes catalystsFunctional monomerActive agent

The invention discloses a nano precious metal load polymer vesica and a preparing method thereof. The method includes the steps that firstly, phenolic resin prepolymer is prepared to serve as a reaction precursor, a P4VP-PF-PSt composite vesica is further prepared through a hydrothermal method in combination with functional monomer styrene and 4-vinylpyridine, then the surface of the vesica is evenly loaded with precious metal nano particles by adding a salt solution and a reduction agent of the precious metal, and a nano hybrid material is obtained. The preparing method is simple, environmentally friendly, suitable for industrialized production and capable of being used for preparing vesicae of different particle sizes and different thin film thicknesses by adjusting the reaction temperature, the reaction time, solvents and surfactant.

Owner:XIAMEN UNIV

Polyvinylidene fluoride high-anti-UV color fluorine film for photovoltaic industry and preparation method of color fluorine film

The invention discloses a polyvinylidene fluoride high-anti-UV color fluorine film for photovoltaic industry and a preparation method of the color fluorine film. The color fluorine film comprises thefollowing specific materials: 70-90% of polyvinylidene fluoride, 10-30% of polymethyl methacrylate, 1-20% of an inorganic or organic pigment, 1-5% of an impact-resistant modifier, 0.1-2% of a BASF UVcut-off agent, 0.1-2% of an antioxidant, and 0.1-5% of a paraffin dispersant. The product prepared by the method shields damage to the inner layer of a component by ultraviolet rays, blocks erosion ofthe inner layer material by water vapor, replaces outer-layer glass to reduce the overall weight of the component, and can be directly bound to a wall, increase the use area, and prevent light pollution caused by light reflection; the technical requirements of the photovoltaic film are high enough, so that the film can be used as a protective film of an outer wall, the color is beautiful, and thefilm is bonded with materials such as a PVC substrate, a marble substrate and bamboo fibers, has a simple whole processing technology, and is suitable for mass production.

Owner:苏州顺创新能源科技有限公司

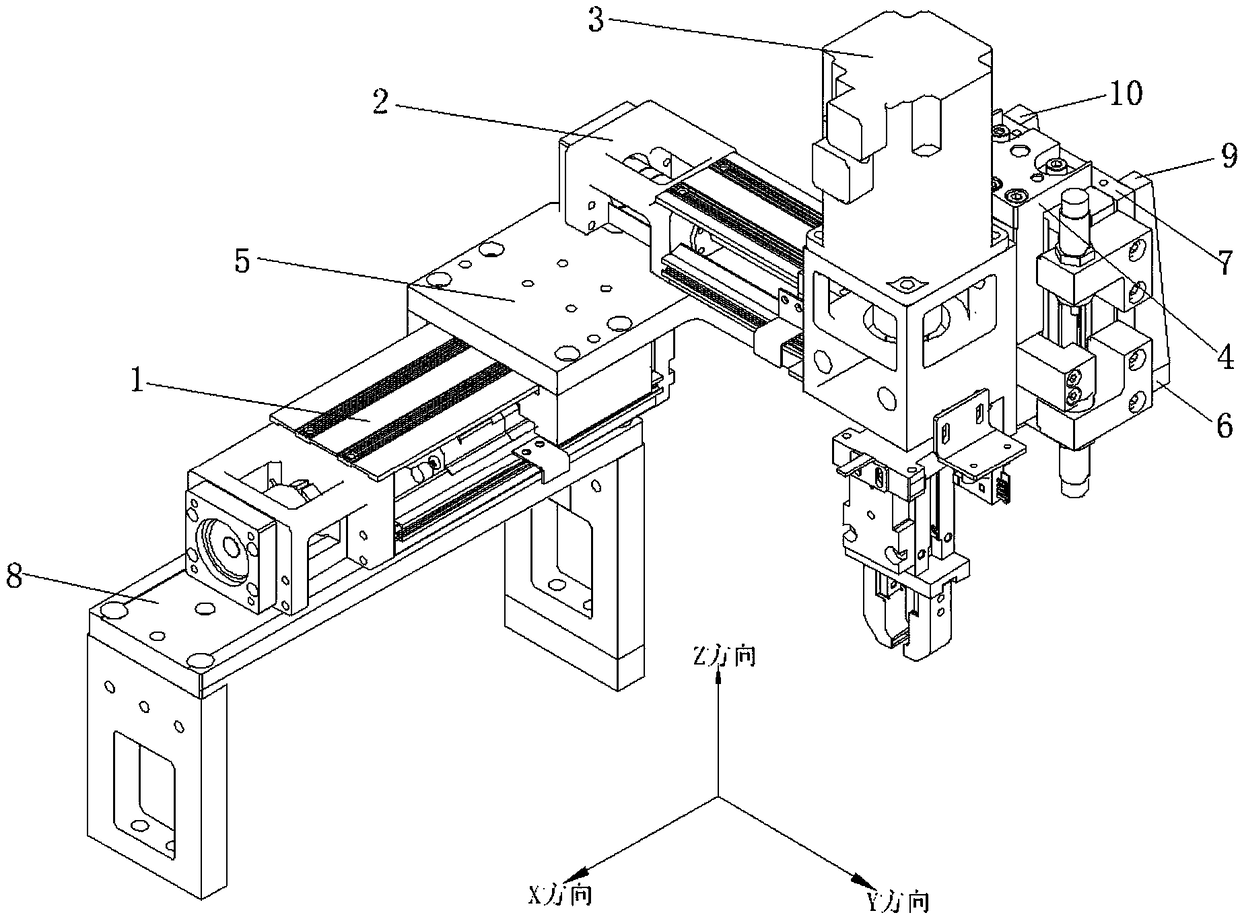

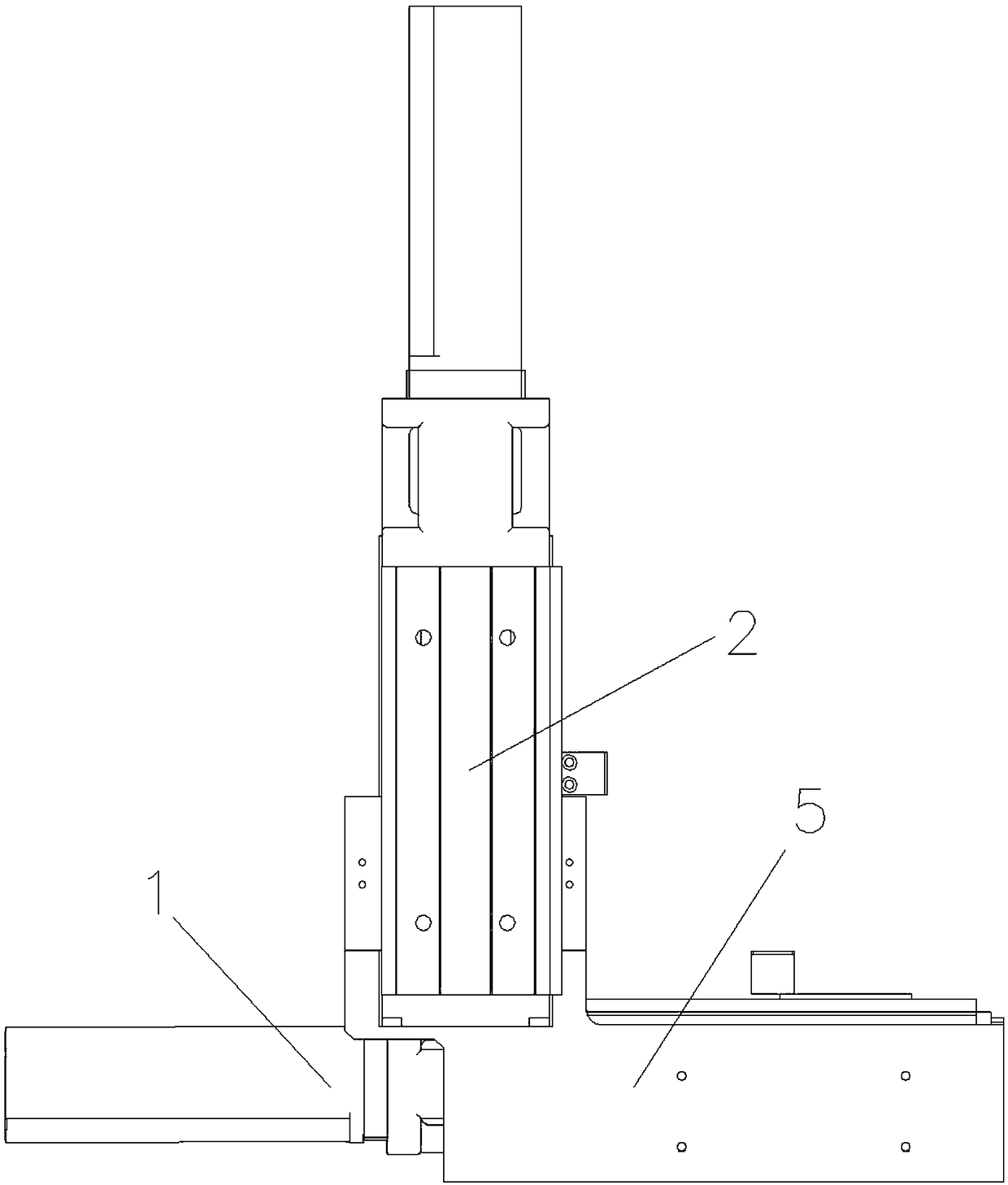

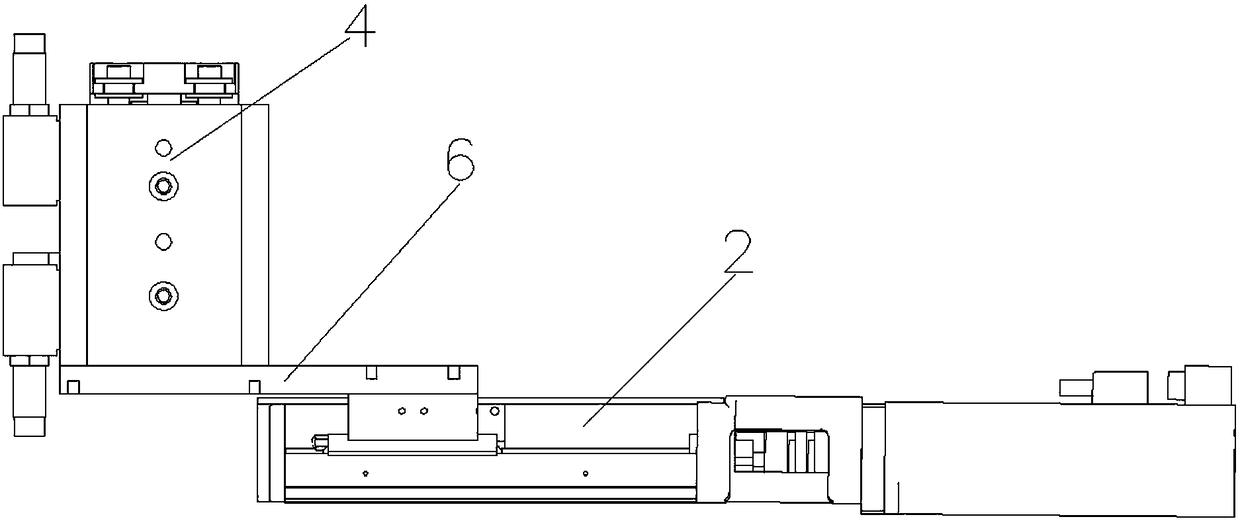

Four-axis adjusting device

InactiveCN108527337ASimple structureEasy to operateProgramme-controlled manipulatorAutomatic controlComputer science

The invention relates to the technical field of automatic control and discloses a four-axis adjusting device. The four-axis adjusting device comprises an X-directional adjusting module, a Y-directional adjusting module, a rotating angle adjusting module, an Z-directional adjusting module, a first connection plate, a second connection plate, a third connection plate and a base. The X-directional adjusting module and the Y-directional adjusting module are connected through the first connection plate, the second connection plate is fixedly connected with the third connection plate, the Z-directional adjusting module is fixedly connected with the third connection plate, the rotating angle adjusting module is connected with the Z-directional adjusting module, and the base is fixedly connected with the X-directional adjusting module. The four-axis adjusting device is integrally simple and compact in structure, X-directional, Y-directional and Z-directional position adjustment can be realizedfully automatically, angle adjustment is realized through the rotating angle adjusting module, adjusting speed and control precision are improved, production efficiency can be effectively improved, and the four-axis adjusting device is suitable for quantified production of products.

Owner:HANS LASER TECH IND GRP CO LTD

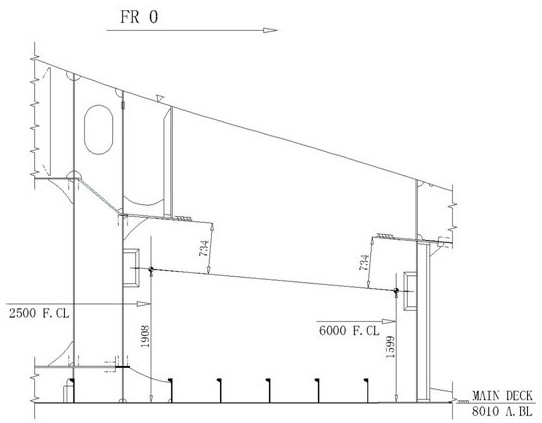

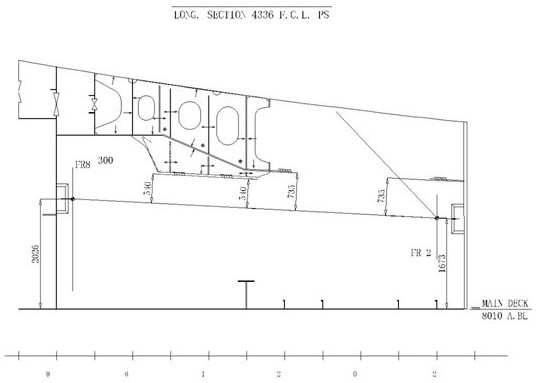

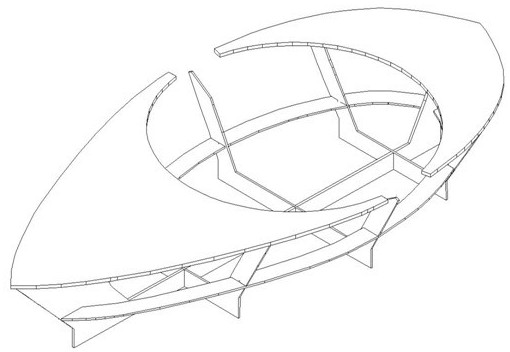

Positioning, assembling and welding method for ship stern thrust equipment

ActiveCN113428315AConvenient pull cordPrecise positioningWaterborne vesselsProsthesisStructural engineering

The invention discloses a ship stern thrust equipment positioning and assembling and welding method, and relates to the technical field of ship manufacturing, the ship stern thrust equipment positioning and assembling and welding method comprises the following steps: manufacturing and installing a prosthesis, positioning a stay wire of a prosthesis structure, adjusting and cutting a ship body rib plate according to the fitting condition of the prosthesis and the ship body rib plate, then installing stern thrust equipment, and adjusting the fitting condition of an equipment rib plate and the ship body rib plate. The wire pulling is convenient, and the positioning is convenient. The stern thrust equipment is easy to install, the prosthesis can be repeatedly used, and the stern thrust equipment is suitable for quantitative production.

Owner:ZHEJIANG INT MARITIME COLLEGE

High-valent silver oxide-loaded cyclodextrin polymeric microspheres and preparation method thereof

InactiveCN110339820AImprove adsorption capacityGood slow releaseBiocideOther chemical processesCross-linkEpoxy

The invention discloses high-valent silver-oxide-loaded cyclodextrin polymeric microspheres and a preparation method thereof. Cyclodextrin microspheres are used as base spheres and are filled with high-valent silver oxide composite nanoparticles; under the alkaline condition, an inorganic soluble silver salt serves as a silver source, cyclodextrin and polyvinyl alcohol serve as dispersing agents,and silver ions react for synthesizing high-valent silver oxide nano-particles through a strong oxidizing agent; then epoxy chloropropane is taken as a cross-linking agent and beta-cyclodextrin is taken as a monomer, the high-valent silver oxide nanoparticles are doped, and cyclodextrin polymeric microspheres coated with high-valent silver oxide are synthesized by taking kerosene as an oil phase.The cyclodextrin polymeric microspheres disclosed by the invention are large in specific surface area and good in adsorption effect. Meanwhile, the high-valent silver oxide nanoparticles are protectedby the cyclodextrin polymeric microspheres, so that an excellent slow release property is achieved, and the long-acting property is well reflected while the efficient sterilization effect is achieved. The preparation method of the high-valent silver-oxide-loaded cyclodextrin polymeric microspheres provided by the invention only needs two synchronous processes, the process is simple and is easy torepeat, and the method is suitable for mass production.

Owner:苏州火睿新材料科技有限公司

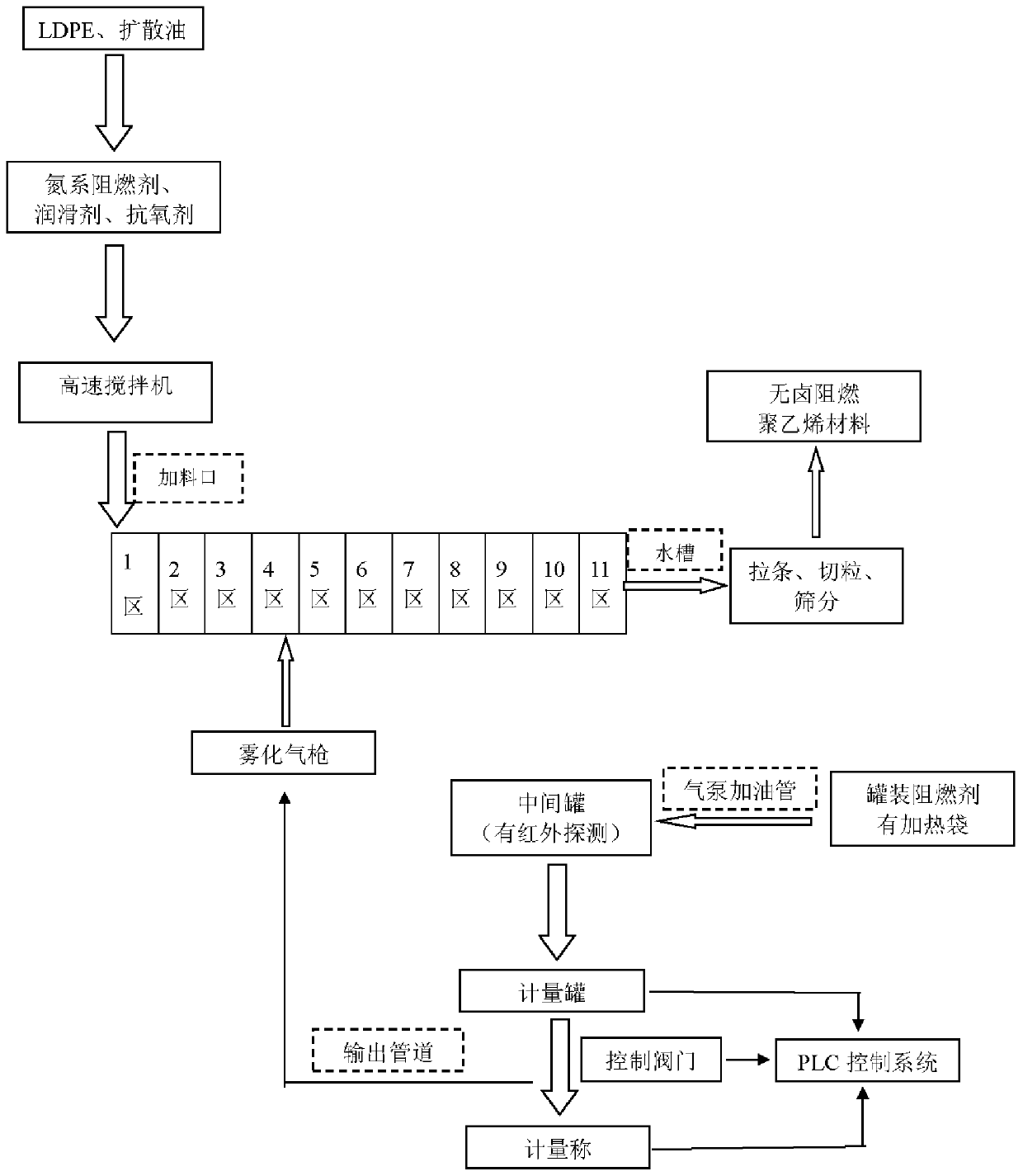

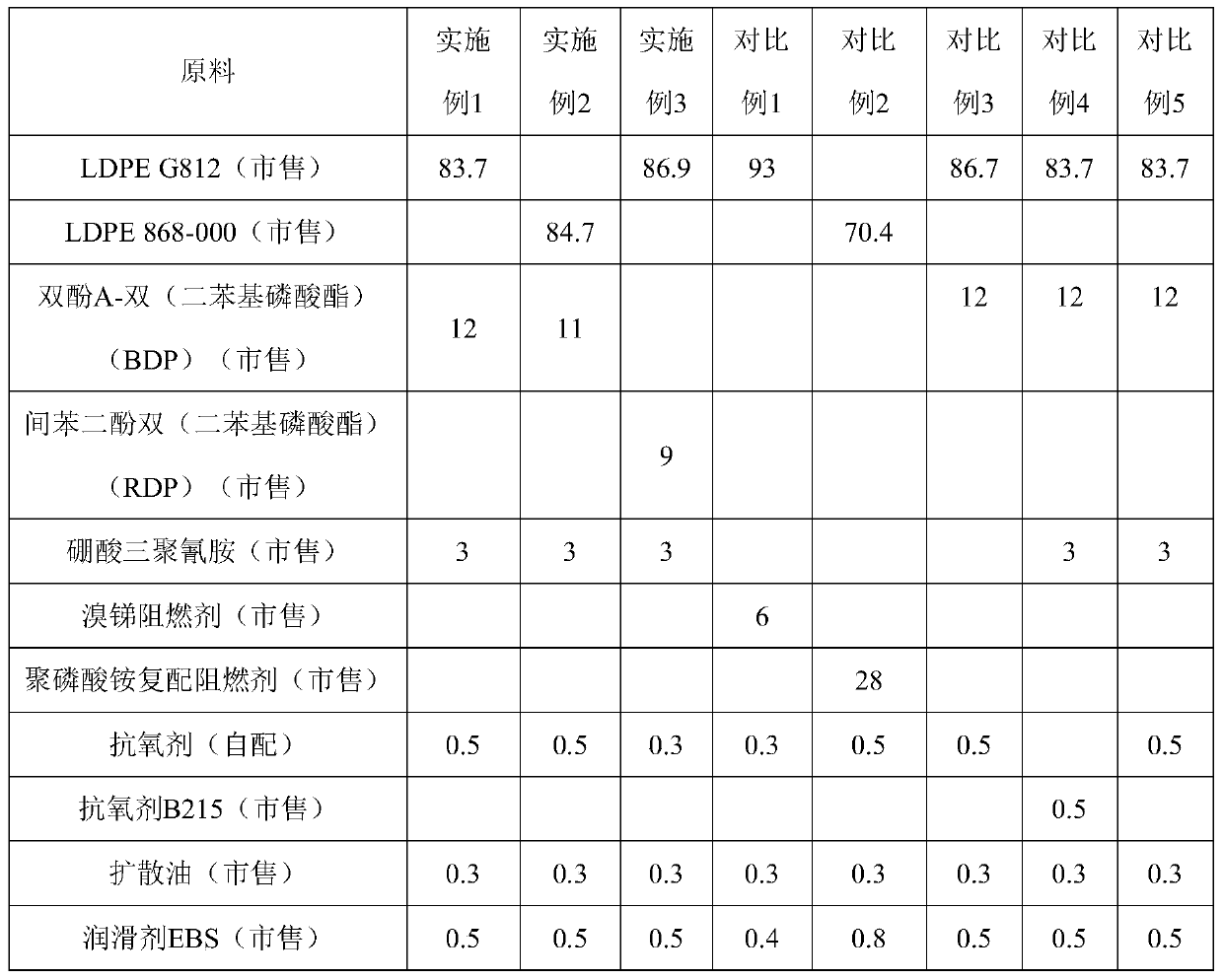

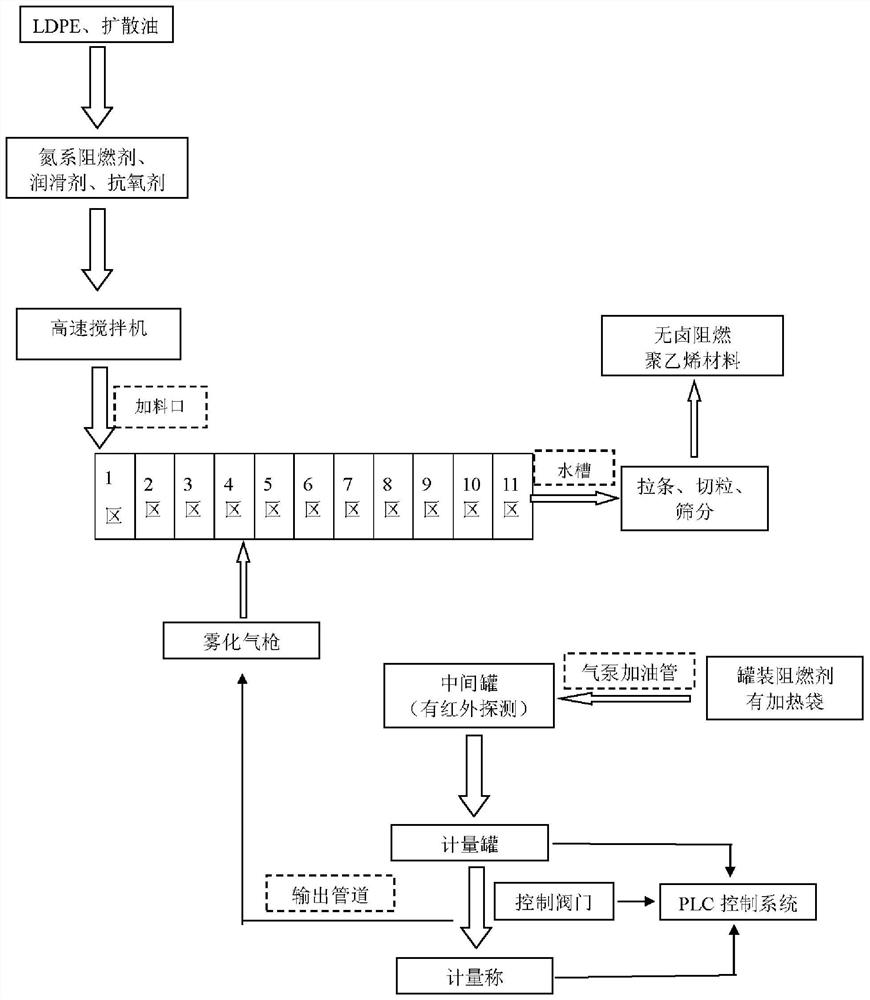

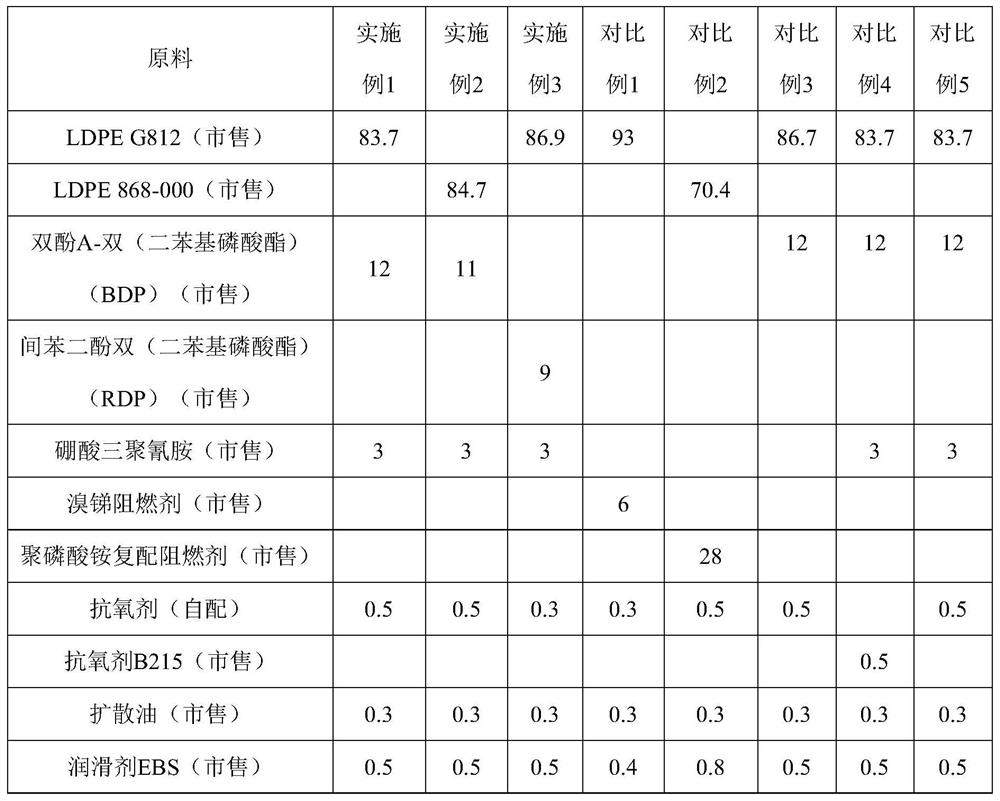

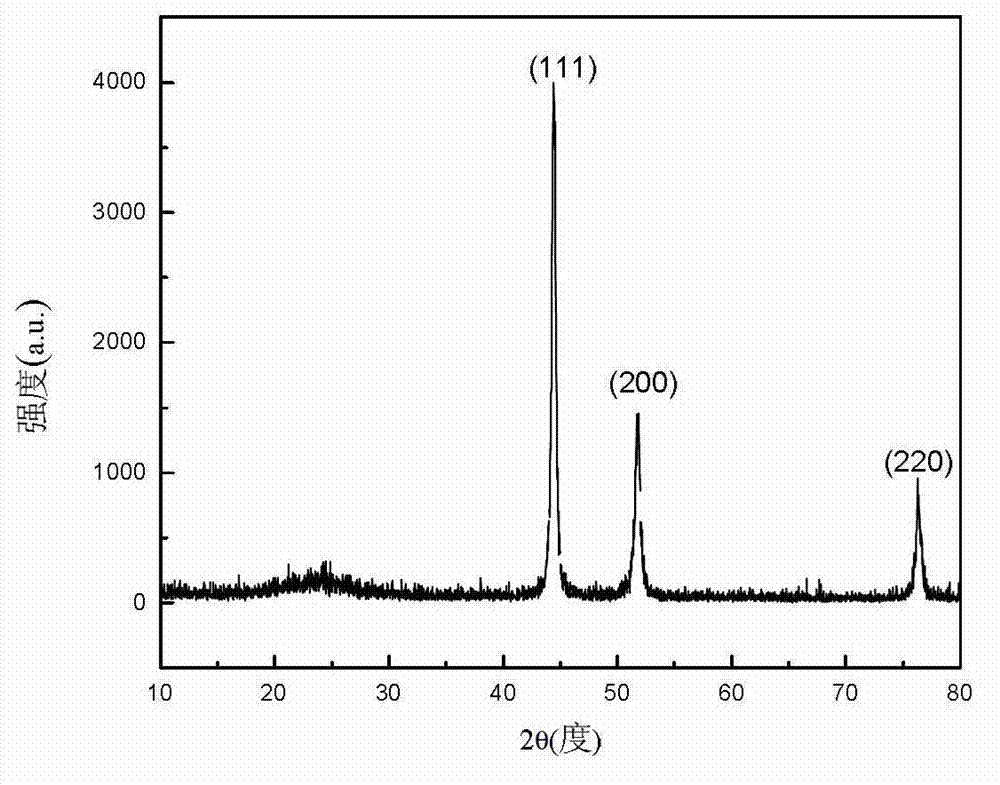

Halogen-free flame-retardant polyethylene material and preparation method and application thereof

ActiveCN110066443AExcellent flame retardant and mechanical propertiesGood flexibilityPhosphoric acidChemistry

The invention discloses a halogen-free flame-retardant polyethylene material and preparation method and application thereof. The halogen-free flame-retardant polyethylene material is prepared from, bymass, 80-95 parts of LDPE, 5-15 parts of a halogen-free phosphate ester flame retardant, 1-5 parts of a nitrogen flame retardant, 0.2-0.8 part of an antioxidant, 0.1-0.5 part of diffusion oil and 0.3-0.7 part of a lubricant. The invention also discloses the preparation method of the halogen-free flame-retardant polyethylene material, and also discloses the application of the halogen-free flame-retardant polyethylene material. The halogen-free flame-retardant polyethylene material has the advantages that the flame-retardant and mechanical properties are excellent, the flexibility of a workpiece is good, the material does not prick the hand when touched by hand, the rebound resilience is good, the material can be recycled, environmentally friendly and nontoxic, the flame resistance can reach UL94 V-2, the self-extinguishment is good, the preparation method is simple, the production cost is low, industrial large-scale production is easy, and the material is suitable for preparing simulation decorations and plug inner membranes.

Owner:GUANGDONG JUSHI CHEM CO LTD

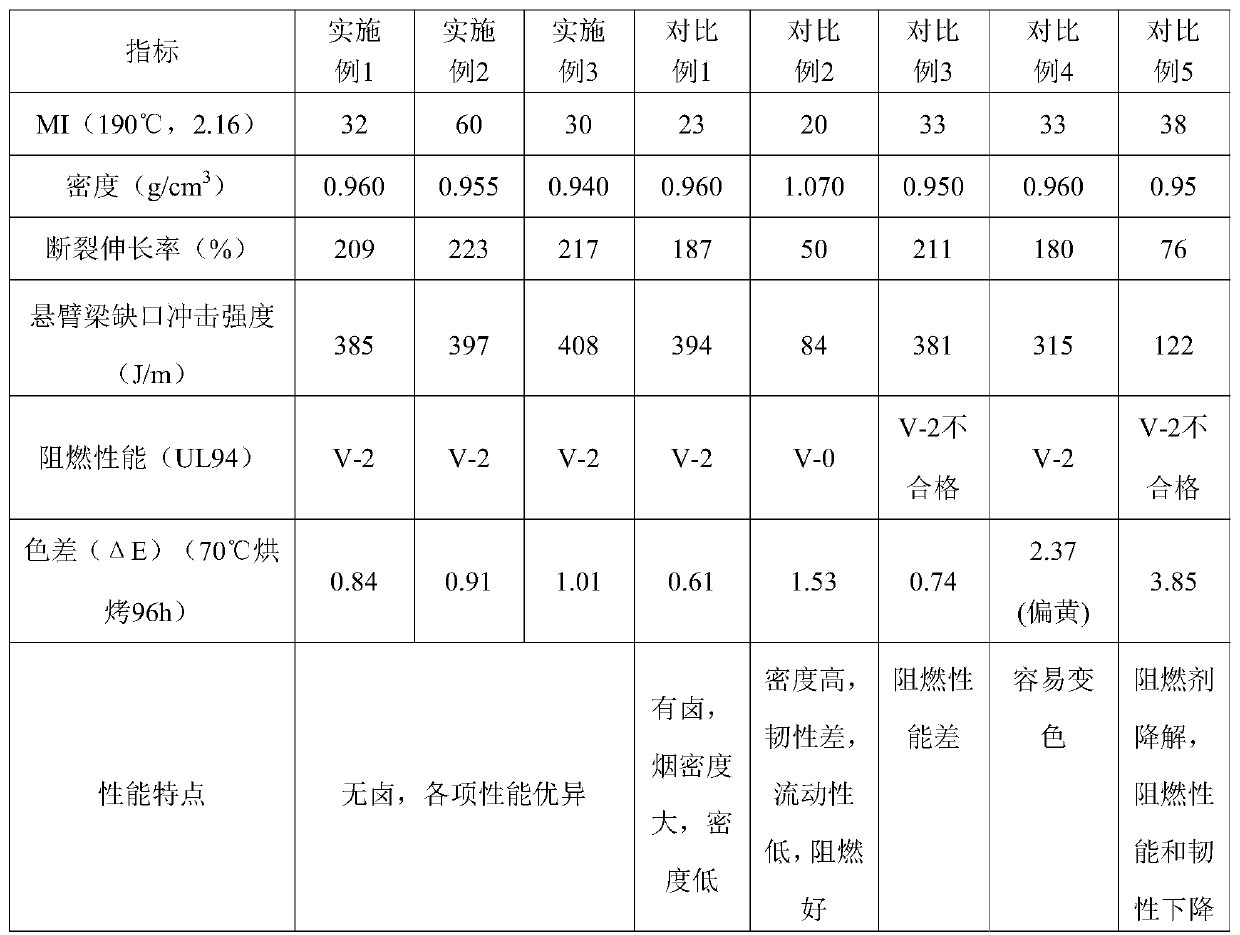

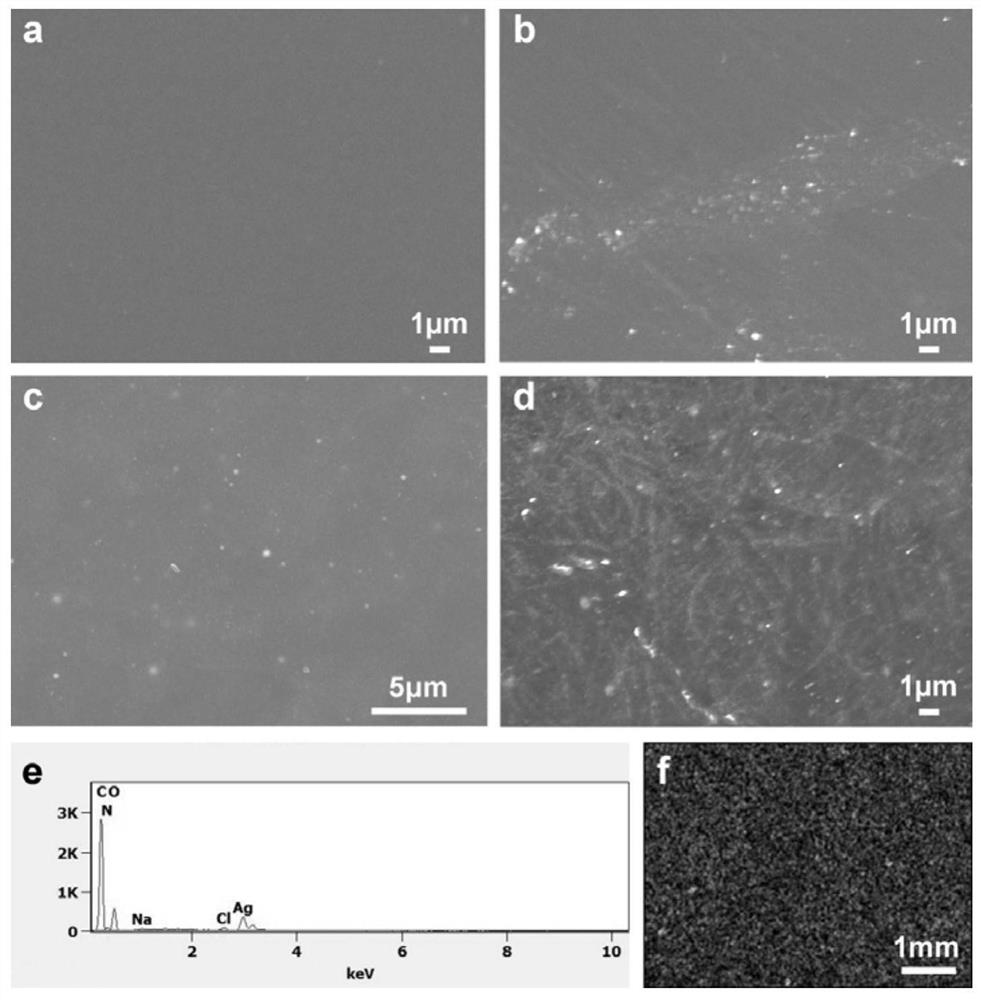

Fibroin oxidized bacterial cellulose nano-composite membrane and preparation method thereof

The invention provides a fibroin oxidized bacterial cellulose nano composite membrane and a preparation method thereof. The fibroin oxidized bacterial cellulose nano composite membrane comprises silk fibroin, nano silver, polyvinyl alcohol and oxidized bacterial cellulose, the fibroin oxidized bacterial cellulose contains a three-dimensional network structure, the three-dimensional network structure is a network structure formed by bacterial cellulose, the nano-silver is attached to the three-dimensional network structure formed by the oxidized bacterial cellulose, and the composite film is formed by casting. The prepared film can be applied to the fields of storage packaging materials and biomedical materials, and the preparation method is simple, mild in condition, convenient to operate, easy to control, free of cross-linking agents and suitable for quantitative production.

Owner:YANCHENG INST OF IND TECH +1

Medical non-woven fabric breathable film

InactiveCN108099318AImprove water absorptionSuper thin and lightSynthetic resin layered productsMedical devicesPolyesterFiber

The invention discloses a medical non-woven fabric breathable membrane. The medical non-woven fabric breathable membrane comprises a non-woven fabric layer and a composite film layer, wherein the composite film layer is adhered to the surface of the non-woven fabric layer through an adhering solvent; the specific processing technology of the non-woven fabric layer comprises the following steps: a,compounding a polyester film and polyester staple fiber hot-rolled cloth through a dry compound machine; b, then spraying a 3 to 5mg / m<2> silica gel layer onto the surfaces of the polyester film andthe polyester staple fiber hot-rolled cloth through a spray gun; c, finally performing rolling and slitting, so as to obtain a finished product, and ensuring that the thickness of the polyester film is 0.025 to 0.05mm, and the thickness is 0.08 to 0.12mm. The membrane has the advantages that cactus extract powder and peanut coat extract powder which are specially treated are added in a composite film, the membrane not only has the effect of antibacterial property, bactericidal activity and antiinflammation, but also has the characteristics of high breathability, water absorption and ultrathinproperty of the non-woven fabric layer, and is very suitable for medical bandaging, low in total cost, environmentally friendly to use, simple in processing method, and suitable for mass production.

Owner:浙江德清金乾新材料有限公司

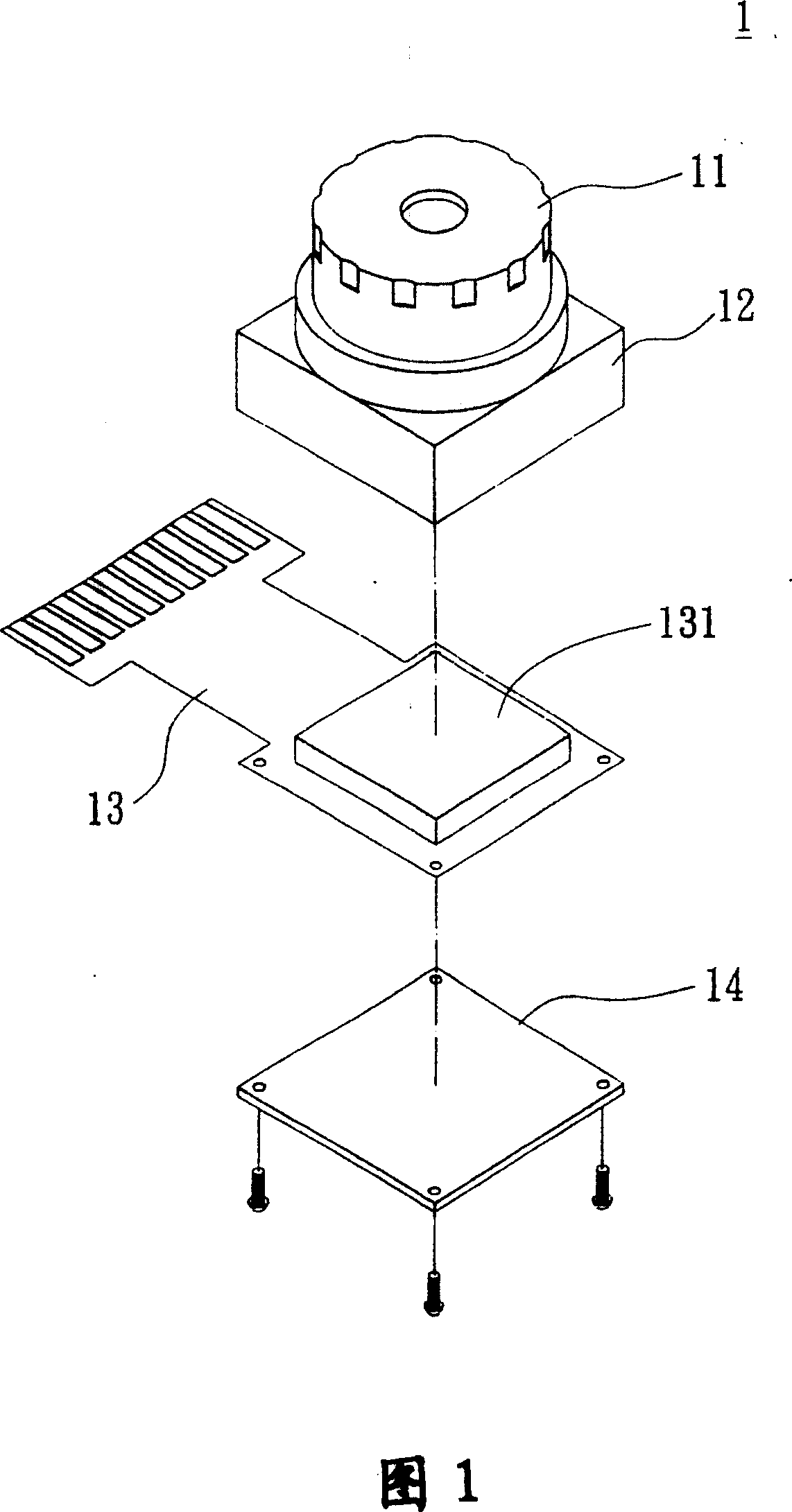

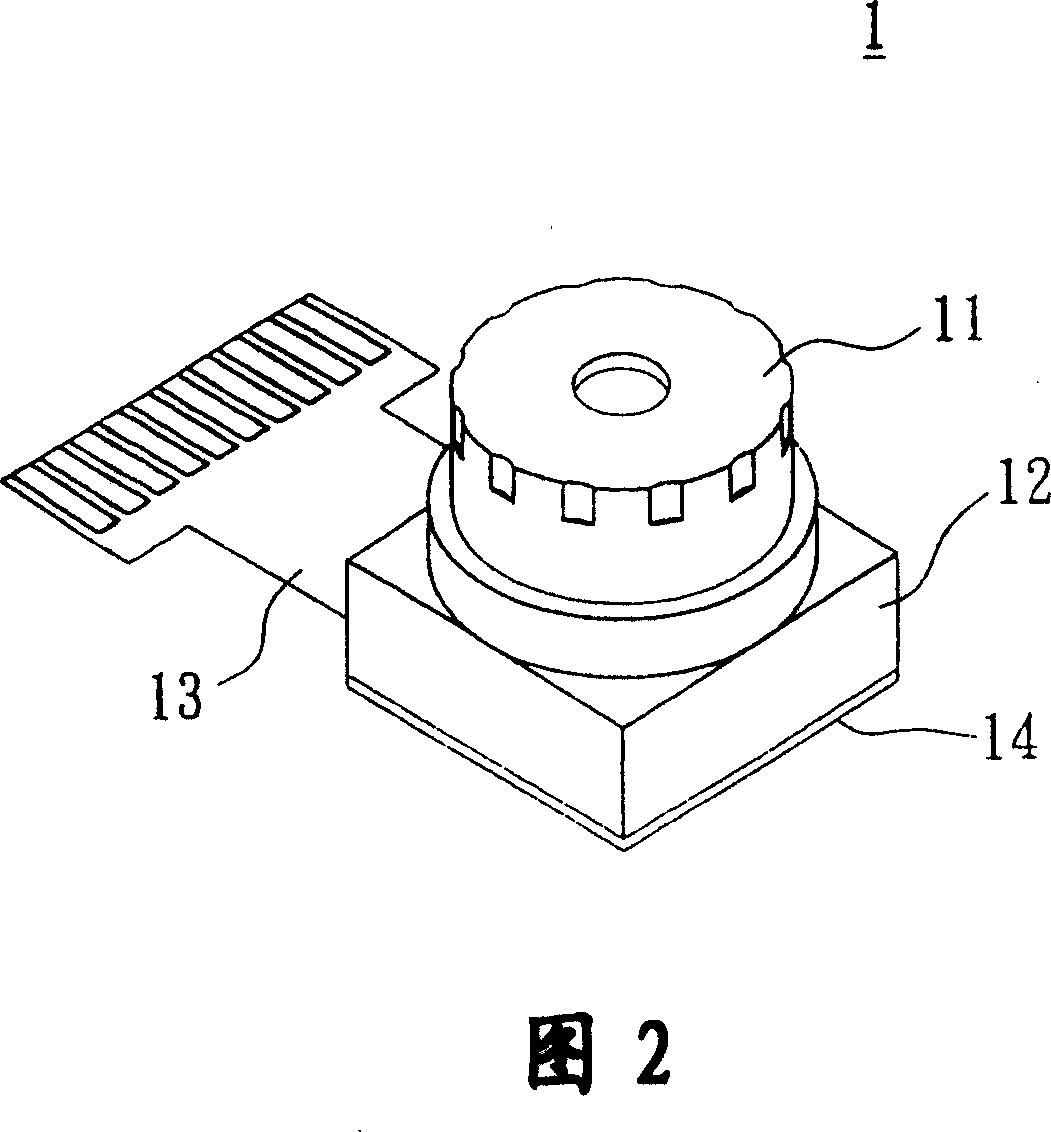

Method for setting lens module and structure

InactiveCN100347580CLow costSuitable for industrial applicationsTelevision system detailsColor television detailsCamera lensSurface mounting

A camera lens module consists of module body including camera lens unit, image induction processing unit and signal terminal as well as base including signal terminal set. Its installing method includes applying surface mounting technique to connect base on circuit board of an electronic appliance, connecting module body on base to let light enter image induction processing unit for forming image signal through camera unit and to send image signal to said circuit board through base terminal set.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

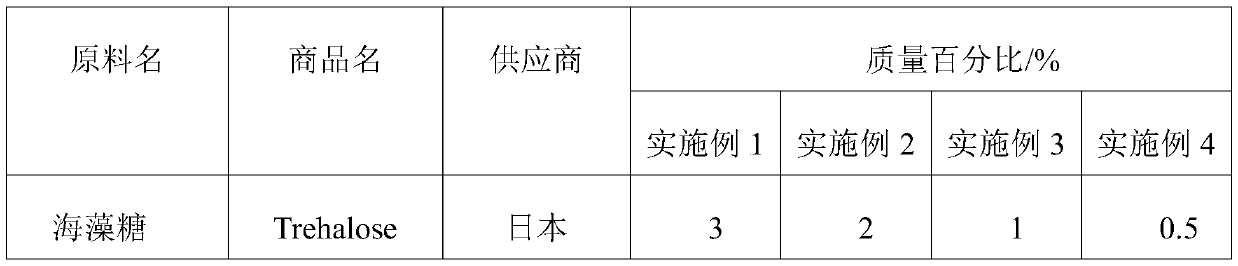

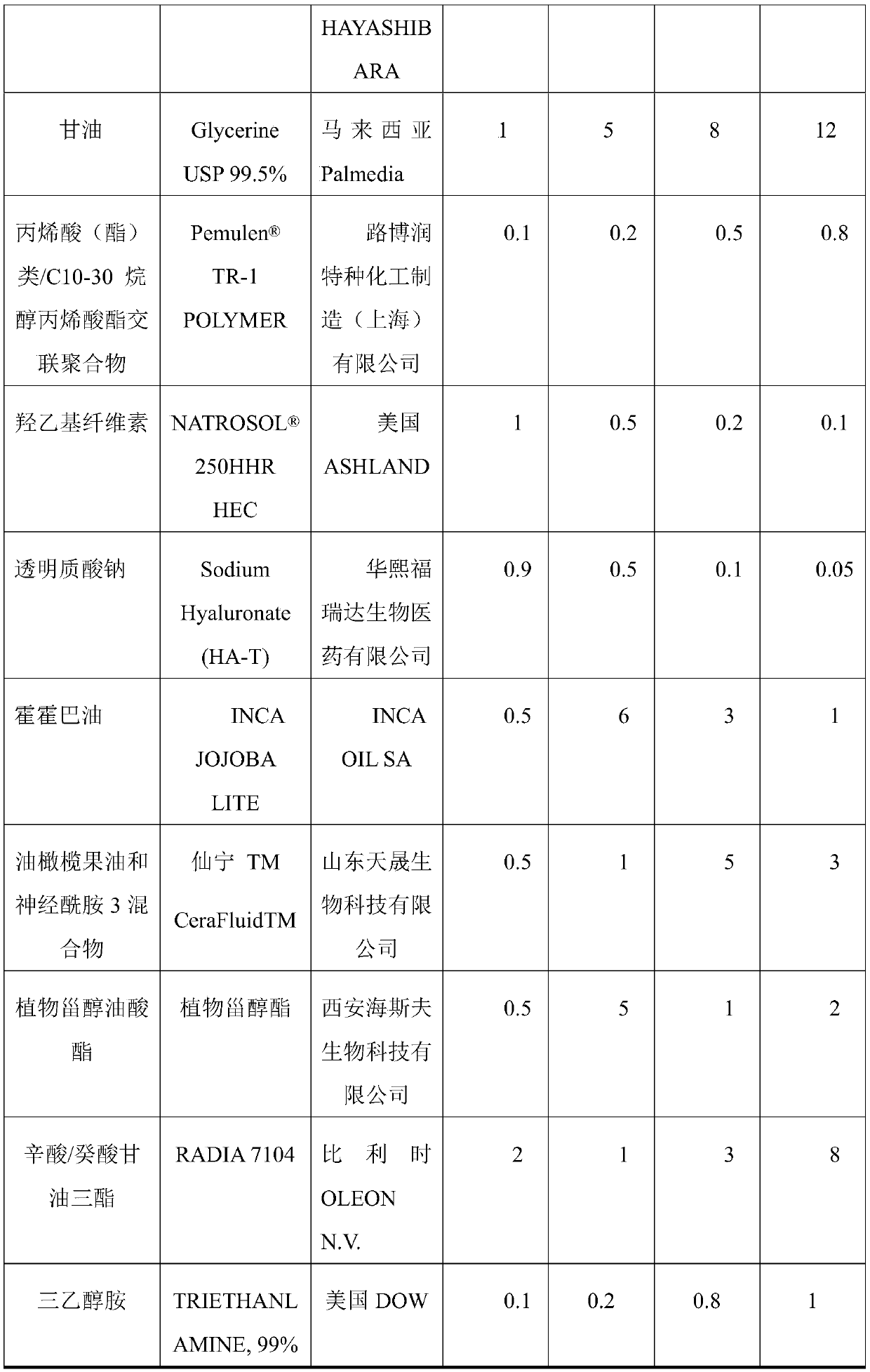

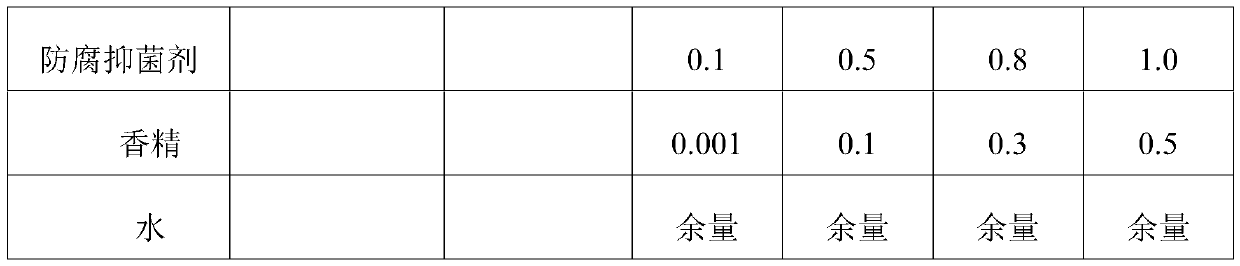

Emulsion type facial mask liquid and preparation method thereof

InactiveCN110840778AEnhanced barrier functionMaintain healthCosmetic preparationsToilet preparationsCelluloseJojoba oil

The invention relates to facial mask liquid and a preparation method, particularly discloses emulsion type facial mask liquid and a preparation method thereof and aims to solve the technical problemsof weak moisturizing endurance property and poor mildness of an existing facial mask. The emulsion type facial mask liquid comprises mycose, glycerol, jojoba oil, olive-pomace oil and ceramide 3 mixture, phytosterols oletate, caprylic / capric triglyceride and sodium hyaluronate. The preparation method includes the steps: mixing, stirring and heating water, the mycose, the glycerol, acrylic / C10-30 alkanol acrylate cross-linked polymers, hydroxyethyl cellulose and the sodium hyaluronate to obtain solution a; mixing, stirring and heating the jojoba oil, the olive-pomace oil and ceramide 3 mixture,the phytosterols oletate and the caprylic / capric triglyceride to obtain solution b; adding the b into the a, adding triethanol, and stirring and homogenizing the b, the a and the triethanol; adding antiseptic and bacteriostatic agents and essence and uniformly stirring the antiseptic and bacteriostatic agents and the essence to obtain the facial mask liquid. Fewer emulsifiers are added into the facial mask liquid, and the facial mask liquid is better in mildness.

Owner:广州诗妃生物科技有限公司

Water-soluble PVP (polyvinyl pyrrolidone)-based pressure sensitive adhesive and preparation method thereof

InactiveCN110628365AGood water solubilityIncrease viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesSolubilitySolvent

The invention provides a water-soluble PVP (polyvinyl pyrrolidone)-based pressure sensitive adhesive and a preparation method thereof. The water-soluble PVP-based pressure sensitive adhesive is prepared from water as a solvent, polyvinylpyrrolidone as a main structure substance, polyvinyl alcohol and hydroxypropyl methyl cellulose as cohesion improvers, high-activity silver ions as an antibacterial agent and benzotriazole as a stabilizer together with polyhydric alcohols and polysaccharide humectants through mechanical stirring at a constant temperature. The water-soluble PVP-based pressure sensitive adhesive provided by the invention is prepared from substances which are easy to dissolve (soluble) in water as raw materials, is quite remarkable in water solubility, can be removed with slight force after clean water flashing after being smeared to articles, is free of residue substance and can do no harm to the articles. The adhesive has good viscosity, moisture retention performance and water solubility, the adhesive can be applied to metallic surface, and in addition, is barely corrosive to metals, and the preparation method of the adhesive is simple in process, easy to repeat andapplicable to on-scale production.

Owner:苏州火睿新材料科技有限公司

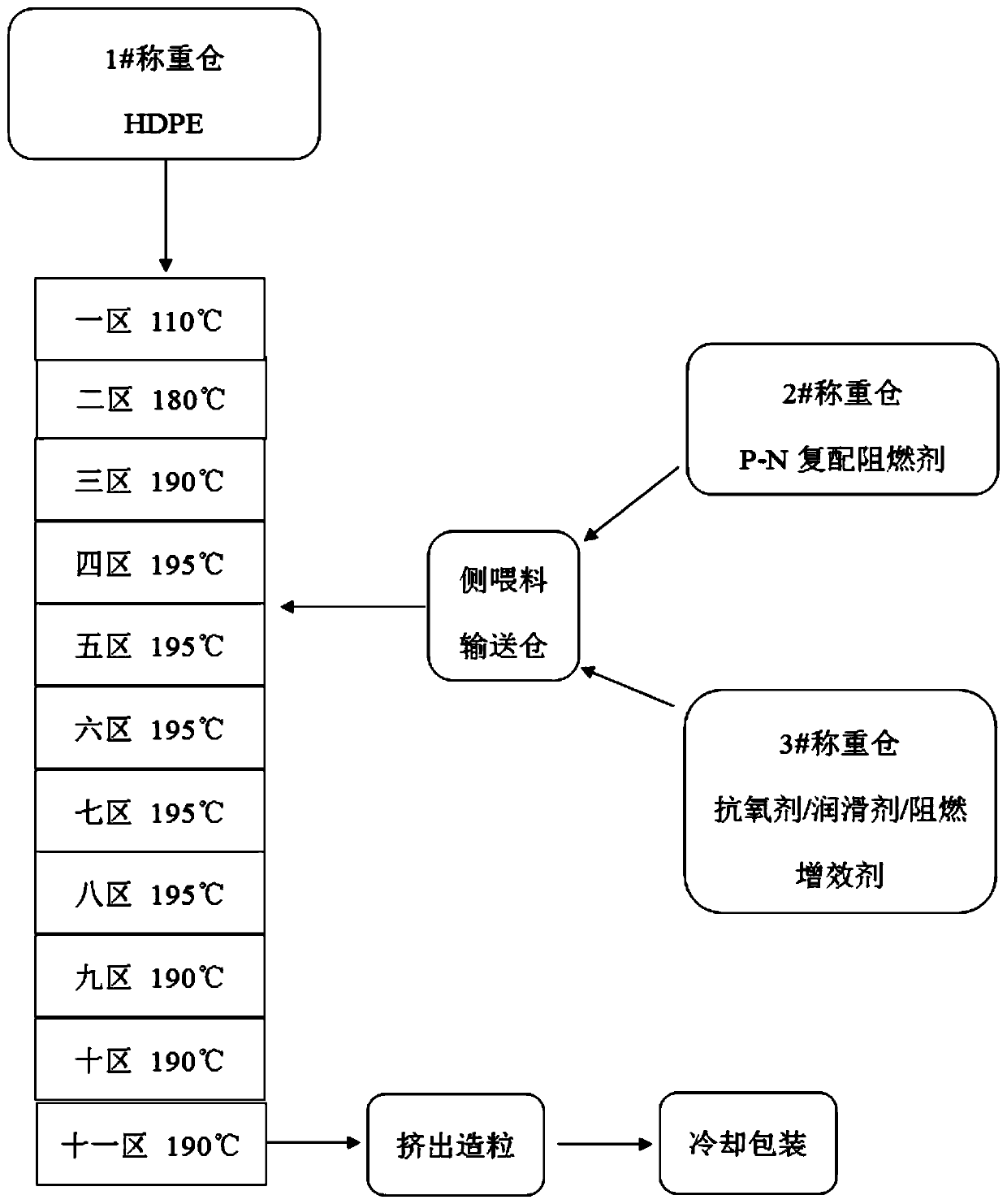

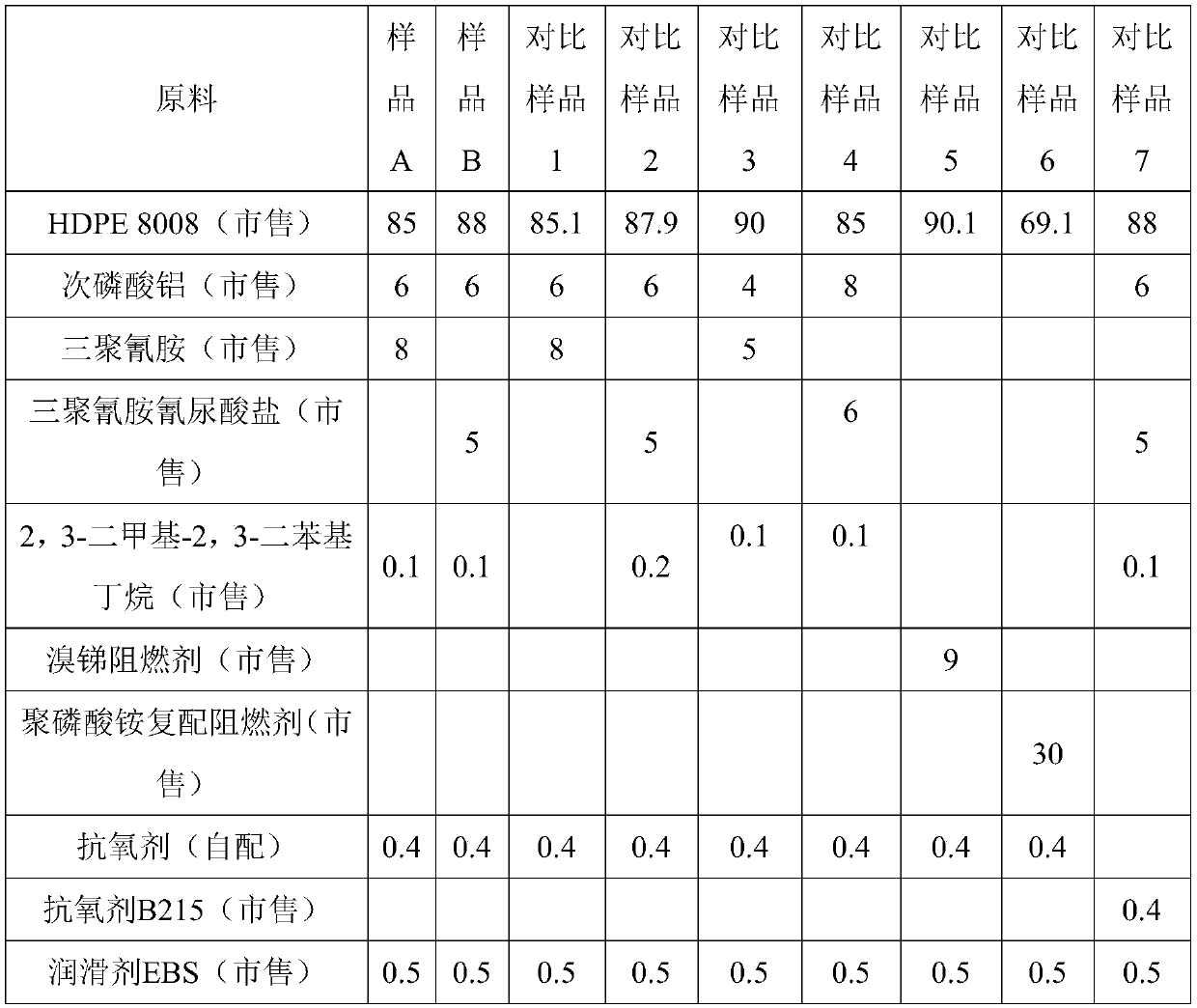

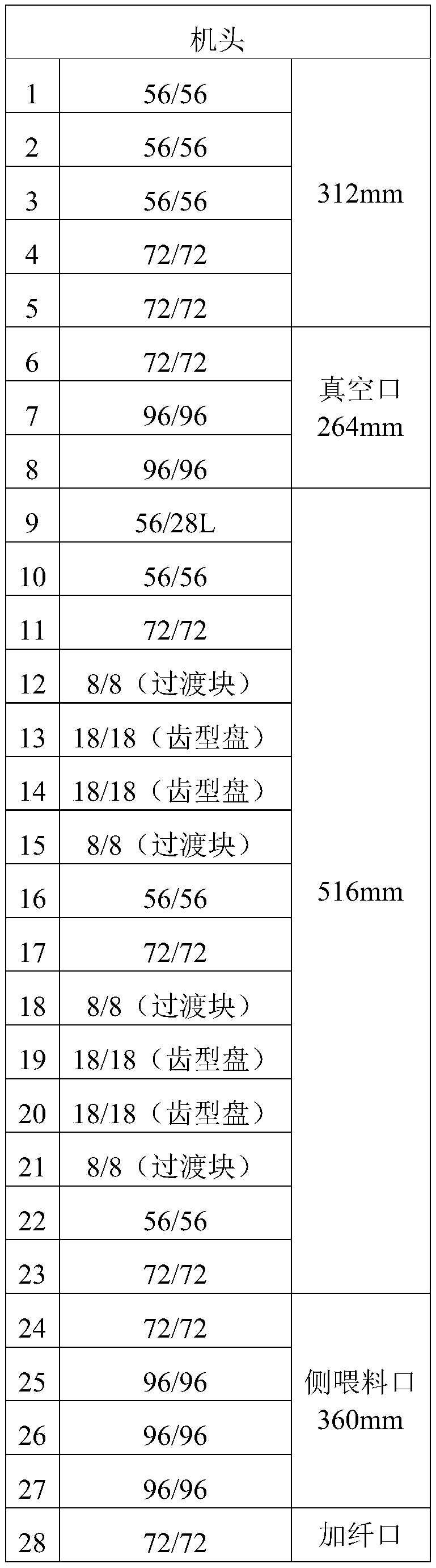

Halogen-free flame-retardant high-density polyethylene material and preparation method and application thereof

The embodiment of the invention provides a halogen-free flame-retardant high-density polyethylene material and a preparation method and application thereof. According to the halogen-free flame-retardant high-density polyethylene material, the flame-retardant property UL94 reaches a V-2 level, the mechanical property is excellent, and the elongation at break of a workpiece reaches 842%; the material can be recycled, is environment-friendly and halogen-free, does not generate corrosive gases during combustion and has excellent self-extinguishment; and the problem that in the prior art, a halogen-free flame-retardant technology of HDPE has an environment-friendly problem in mechanical property and bromine-antimony flame retarding is solved.

Owner:GUANGDONG JUSHI CHEM CO LTD

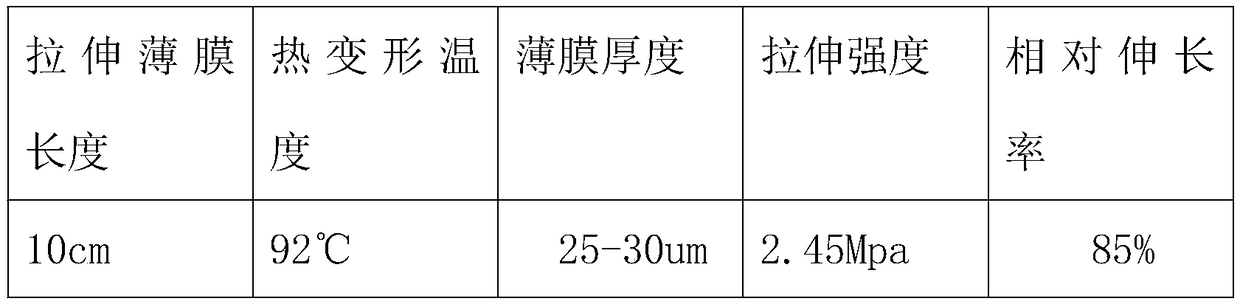

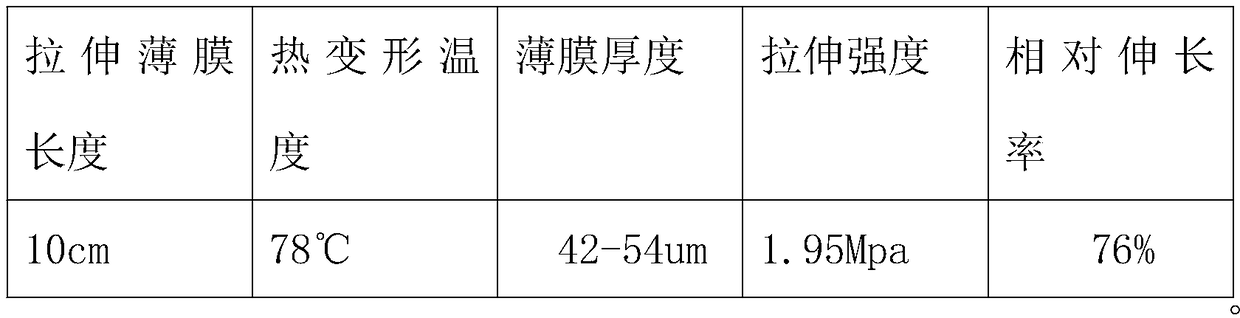

Ultra-thin stretching film for hands and preparation method thereof

The invention discloses an ultra-thin stretching film for hands and a preparation method thereof, wherein the ultra-thin stretching film for hands includes the following specific materials in parts: 5-8 parts of polystyrene, 3-5 parts of polystyrene, 1.5-4 parts of a butadiene-styrene copolymer, 3.5-9 parts of diphenylmethane diisocyanate, 6-12 parts of polyethylene glycol terephthalate, 4-8 partsof polyvinylidene fluoride, 3.5-9 parts of polyvinyl chloride, 2-4.5 parts of polyperfluoroethylene propylene, 7-14 parts of polypropylene, 2-5 parts of polyamide, 4-8 parts of polyethylene glycol terephthalate, 3-6 parts of cellulose acetate, 2-5 parts of carboxymethyl cellulose, 0.4-0.8 part of polyethylene glycol, 1-2 parts of glutaraldehyde, 1.4-3 parts of polycarbonate, 0.5-2.5 parts of a plasticizer, and 0.3-1.2 parts of an auxiliary film-forming agent. The prepared stretching film is light, thin, uniform in thickness, good in tensile strength and not easy to tear; the whole thin film has the advantages of high sealing property, simple processing technology and low raw material cost, and is suitable for quantitative production.

Owner:深圳市双源包装材料有限公司

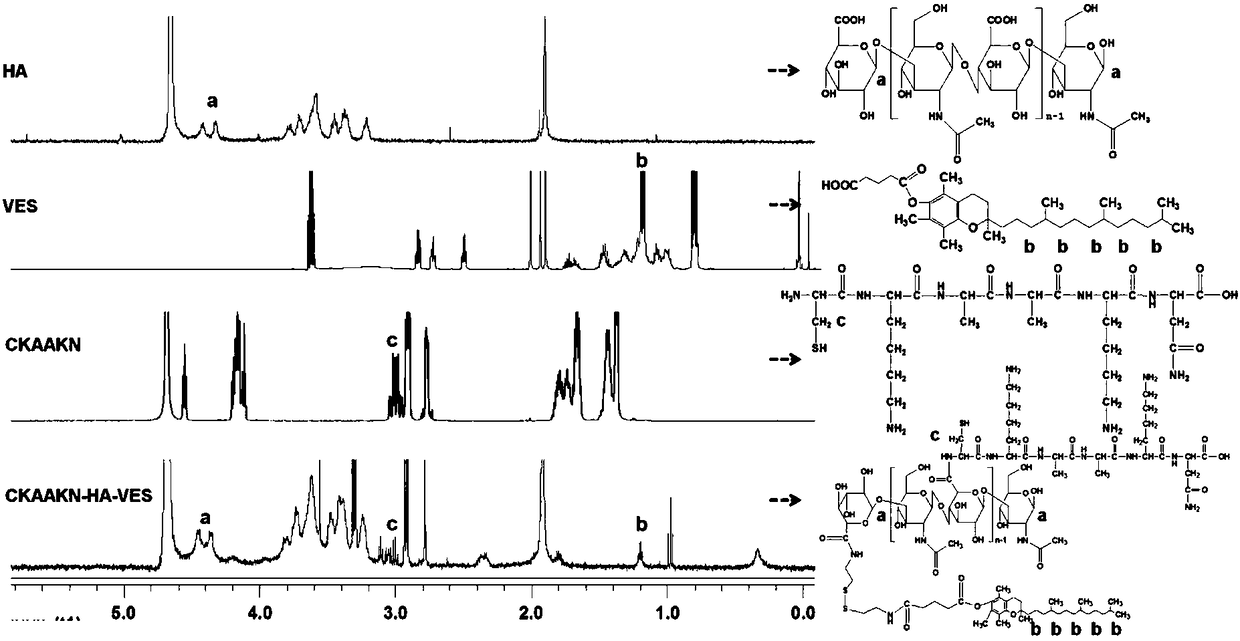

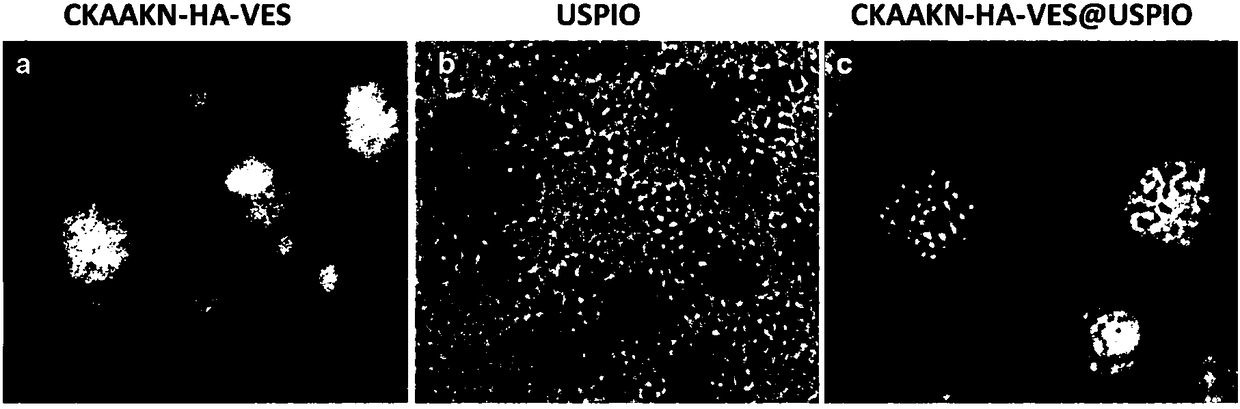

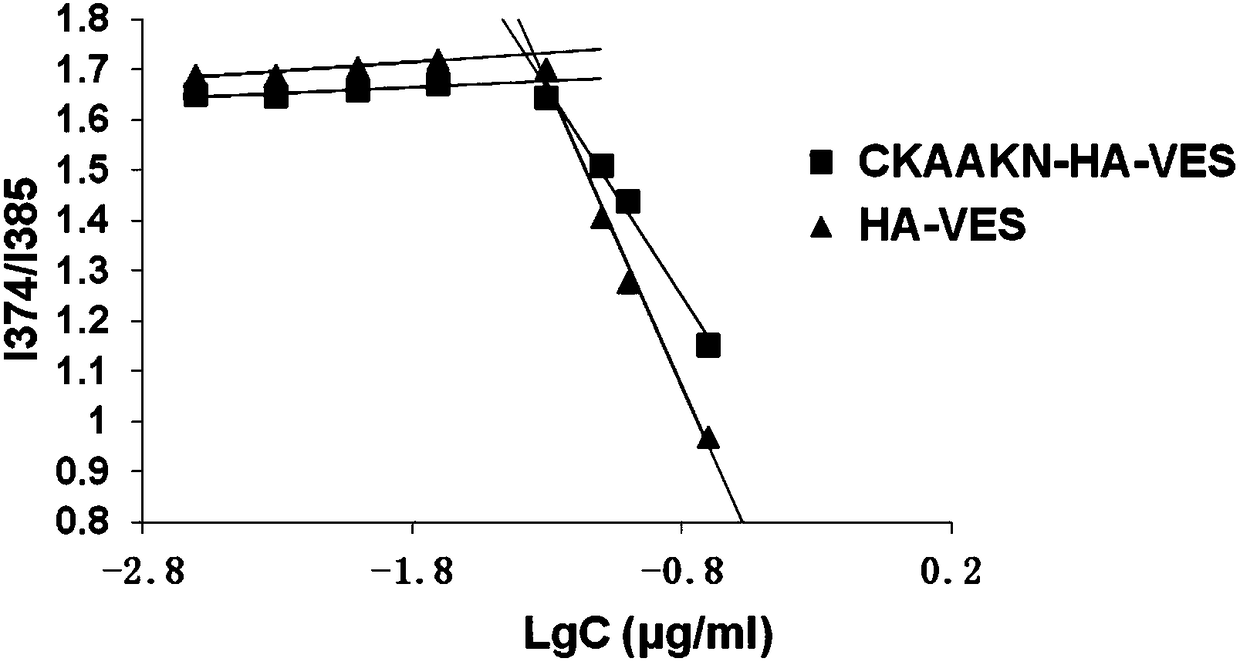

Pancreatic cancer double-targeted polymer magnetic nanoparticles and preparation method and application thereof

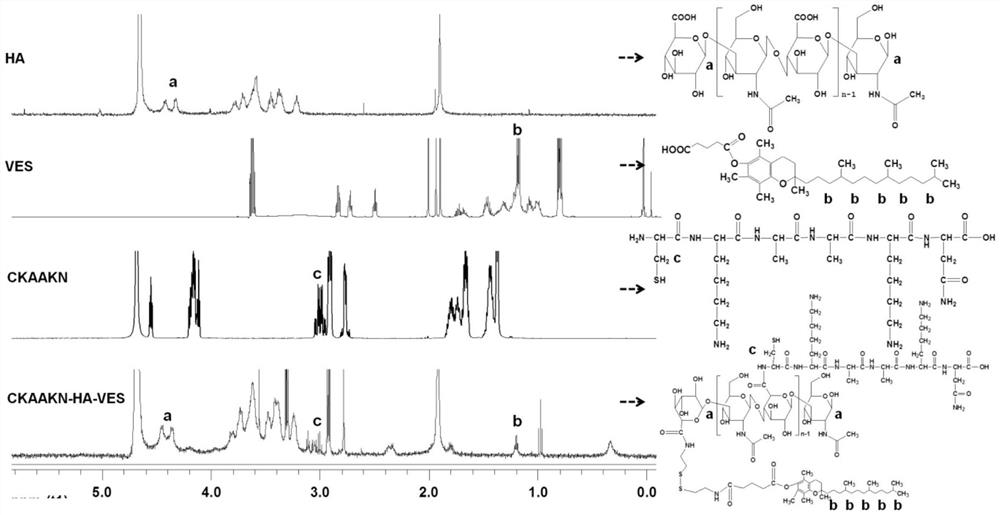

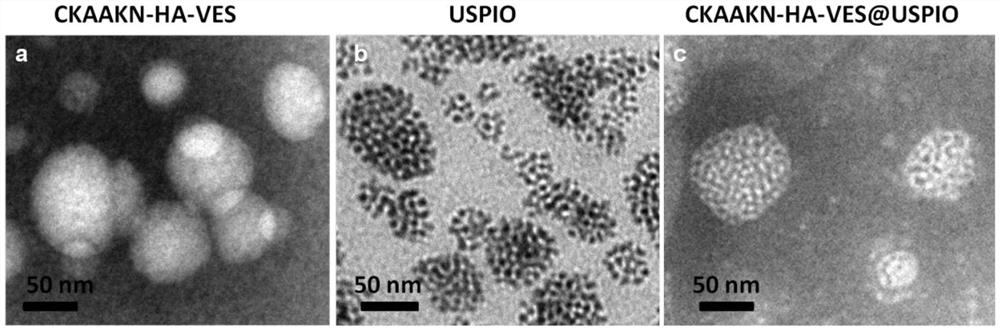

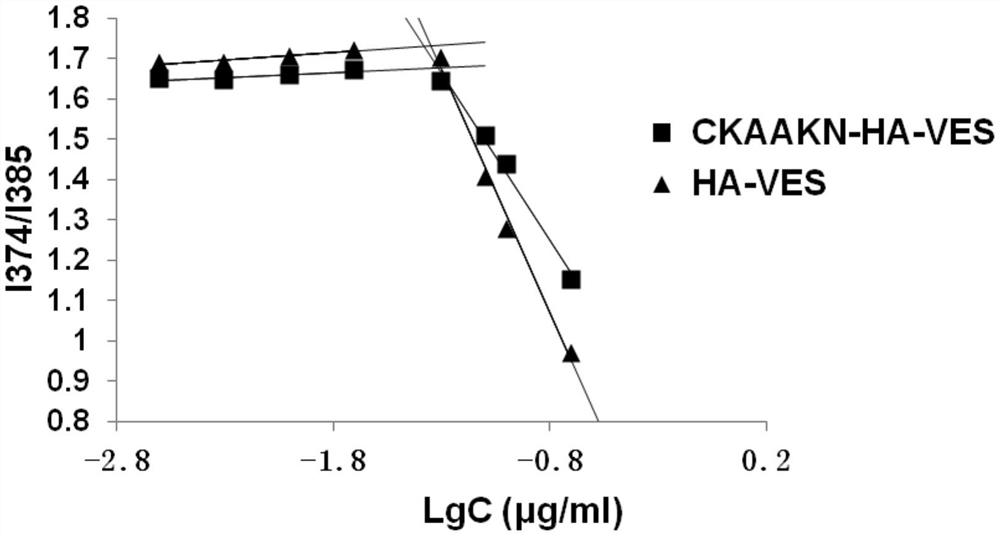

ActiveCN109395102AImprove tumor targetingReduce the injection doseEmulsion deliveryMacromolecular non-active ingredientsMotilityMagnetite Nanoparticles

The invention discloses pancreatic cancer double-targeted polymer magnetic nanoparticles. The pancreatic cancer double-targeted polymer magnetic nanoparticles are prepared from the following components: CKAAKN-hyaluronan-vitamin E succinate polymer micelle, a ferroferric oxide magnetic nanoparticle solution and deionized water through a following method that a hyaluronan-vitamin E succinate copolymer modified by CKAAKN polypeptides is wrapped with ultra-small paramagnetic Fe3O4 magnetic nanoparticles. According to the pancreatic cancer double-targeted polymer magnetic nanoparticles, the polymer magnetic nanoparticles subjected to targeted modifying by the CKAAKN polypeptides can simulate a Wnt protein to be specifically bound with a pancreatic cancer cell membrane receptor through a Wnt signaling pathway, meanwhile, a hyaluronan receptor CD44 and a receptor for hyaluronan-mediated motility (RHAMM) can also be highly expressed on the surfaces of tumor cells, therefore, pancreatic cancercells can be subjected to specific targeting in early diagnosis of pancreatic cancer, and accordingly, a double-targeted magnetic resonance contrast agent with higher specificity and imaging abilityis provided for early diagnosis of the pancreatic cancer.

Owner:贵州中医药大学

Formula and preparation method of environment-friendly high strength plastic particle

InactiveCN110498971AHigh hardnessImprove thermal conductivityPolyethylene terephthalate glycolPolyvinyl alcohol

The invention discloses a formula and a preparation method of an environment-friendly high strength plastic particle. The formula comprises the following components: 2.5-4 parts of polymethylmethacrylate, 1-3 parts of polylactic acid, 3-5 parts of polycarbonate, 3-7 parts of polystyrene, 3.5-8 parts of polyvinyl alcohol, 1-2 parts of polyacrylic acid, 1.5-4 parts of polyisobutylene, 2-5 parts of polyamide, 1.5-3 parts of polycarbonate, 0.5-1 part of polylactic acid, 2.5-4 parts of polytetrafluoroethylene, 1.5-4 parts of polyethylene terephthalate, 0.5-1.5 parts of phenol-formaldehyde resin, 2.5-4 parts of polyurethane, 5-8 parts of polybutadiene, 5-10 parts of polyperfluorinated ethylene propylene, 7-14 parts of polypropylene, 2-5 parts of epoxy resin, 4-8 parts of polyphenylene sulfide, 2-6 parts of ethylene oxide, 2.5-6 parts of melamine, and 3.2-7 parts of dicyanodiamide. The plastic particle designed by the invention adopts a variety of organic raw materials for mixed processing, has high hardness, can be recycled, at the same time has stable heat conduction and long service life, the whole processing technology is simple, and is suitable for mass production.

Owner:临沂泛泰新材料科技有限公司

A kind of nanometer noble metal loaded polymer vesicle and preparation method thereof

ActiveCN104998683BImprove catalytic performanceCatalytic performance is beneficial toOrganic-compounds/hydrides/coordination-complexes catalystsFunctional monomerActive agent

The present invention discloses a nano noble metal supported polymer vesicles and a preparation method, the phenolic resin prepolymer as a reaction precursor is first prepared, binding and tetra-functional monomer, styrene-vinyl pyridine was prepared by hydrothermal method step of P4VP-PF-PSt composite vesicles, then by adding a noble metal salt solution and a reducing agent, the membrane surface was uniformly supported noble metal nanoparticles, nano hybrid material obtained.Preparation method is simple, environmentally friendly, suitable for industrial production, and may, reaction time, solvent, and a surfactant vesicles prepared of different particle sizes and different film thickness by adjusting the reaction temperature.

Owner:XIAMEN UNIV

A kind of halogen-free flame-retardant polyethylene material and its preparation method and application

ActiveCN110066443BImprove flame retardant performanceImprove mechanical propertiesPolymer scienceAntioxidant

The invention discloses a halogen-free flame-retardant polyethylene material, a preparation method and application thereof. This halogen-free flame-retardant polyethylene material includes the following raw materials in parts by mass: 80-95 parts of LDPE; 5-15 parts of halogen-free phosphate flame retardant; 1-5 parts of nitrogen-based flame retardant; 0.2-0.8 parts of antioxidant parts; 0.1-0.5 parts of diffusing oil; 0.3-0.7 parts of lubricant. At the same time, the preparation method of the halogen-free flame-retardant polyethylene material is also disclosed, and the application of the halogen-free flame-retardant polyethylene material is also disclosed. The halogen-free flame-retardant polyethylene material of the present invention has excellent flame-retardant and mechanical properties, good flexibility of the product, no sticky touch, good resilience, repeated recycling, environmental protection and non-toxicity, and flame-retardant performance reaching UL94 V‑2 , good self-extinguishing property, simple preparation method, low production cost, easy industrialized large-scale production, and suitable for preparing imitation decorations and inner membranes of plugs.

Owner:GUANGDONG JUSHI CHEM CO LTD

Method for preparing graphene/nickel nanocomposite material by utilizing gamma ray

ActiveCN103011151BSuitable for quantitative productionMild reaction conditionsMaterial nanotechnologyGrapheneRadiation chemistryGamma ray

The invention discloses a method for preparing a graphene / nickel nanocomposite material by utilizing a gamma ray, belongs to the field of crossing of the nanocomposite material and radiation chemistry, and in particular relates to a method for preparing the graphene / nickel nanocomposite material by utilizing the gamma ray. The problem that the graphene-nickel nanocomposite material prepared by the conventional method is high in cost and severely damages the environment is solved. The method comprises the following steps of: 1, preparing oxidized graphite; 2, preparing mixed solution; 3, reacting under the irradiation of the gamma ray to obtain a product; and 4, centrifugally separating, cleaning and drying the product to obtain the graphene / nickel nanocomposite material. The method is applied to the field of preparation of the graphene / nickel nanocomposite material.

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

A kind of pancreatic cancer dual-targeting polymer magnetic nanoparticles and its preparation method and application

ActiveCN109395102BImprove tumor targetingReduce the injection doseEmulsion deliveryMacromolecular non-active ingredientsPancreas CancersCD44

A dual-targeting polymer magnetic nanoparticle for pancreatic cancer, the magnetic nanoparticle is made of the following components and methods: CKAAKN-hyaluronic acid-vitamin E succinate polymer micelles, ferroferric oxide magnetic nanoparticle solution , deionized water, hyaluronic acid-tocopherol succinate copolymer modified by CKAAKN polypeptide is encapsulated with ultra-small paramagnetic Fe 3 o 4 Made of magnetic nanoparticles, the present invention designs polymer magnetic nanoparticles modified by CKAAKN polypeptides to mimic Wnt protein to specifically bind to pancreatic cancer cell membrane receptors through the Wnt signaling pathway, and at the same time, the surface of tumor cells can also highly express hyaluronic acid Acid receptors——CD44 and hyaluronic acid-mediated automaticity receptors (RHAMM), so they can specifically target pancreatic cancer cells in the early diagnosis of pancreatic cancer, thus providing a specific and imaging method for early diagnosis of pancreatic cancer Dual-targeting MRI contrast agents with enhanced capabilities.

Owner:贵州中医药大学

Resin protective film material and preparation method thereof

The invention discloses a resin protective film material and a preparation method thereof. The formula comprises the following specific materials in parts by weight; 1-3 parts of phenolic resin, 3-5 parts of polystyrene, 1.2-2.5 parts of polyester resin, 3.5-9 parts of polyamide resin, 6-12 parts of polytetrafluoroethylene, 6-12 parts of polyvinylidene fluoride, 5-8 parts of polystyrene, 5-10 parts of polycarbonate, 7-14 parts of polypropylene, 2-5 parts of epoxy resin, 4-8 parts of polyphenylene sulfide, 2-6 parts of polyether-ether-ketone, 1.5-5 parts of polyamide, 1.2-3.5 parts of polyethersulfone, 3-5 parts of isoamyl methacrylate, 0.5-1.4 parts of a dispersing agent, 0.7-1.5 parts of an antioxidant and 0.8-1.6 parts of a compatilizer. The protective film material designed by the invention is good in elasticity, good in tensile strength, good in impact resistance, excellent in bonding strength, good in dielectric property, small in deformation shrinkage rate, good in product sizestability, relatively good in flexibility, simple in whole processing technology, relatively environment-friendly and suitable for mass production.

Owner:昆山新博皓薄膜电子材料有限公司

Temperature sensing demodulation device and demodulation method based on microwave photon filter

ActiveCN109580038BAchieve temperatureRealize demodulationThermometers using physical/chemical changesPhotodetectorEngineering

The invention discloses a temperature sensing demodulation device and a demodulation method based on a microwave photonic filter. The microwave photonic filter comprises a multi-wavelength fiber laser and a dispersion fiber, which are used to form laser light and couple and output the laser light; The inductive demodulation device includes an electro-optical modulator, a microwave signal source, a photodetector, an electric power meter and a temperature demodulator; the electro-optical modulator is used to modulate the coupled laser to output a modulated optical signal; the dispersive fiber is used to sample the modulated optical signal when Delay to output the time-delayed optical signal; the photodetector is used to recover the time-delayed optical signal to obtain the electrical signal; the electric power meter is used to measure the power of the electrical signal; the temperature demodulator is used to scan the frequency of the microwave signal, and the The maximum power of the electrical signal obtains the corresponding microwave signal frequency, and obtains the temperature change information induced by the optical fiber sensor; thus, the optical fiber temperature sensing and demodulation can be realized through a simple structure, and at the same time, the required cost is reduced.

Owner:INFORMATION & COMMNUNICATION BRANCH STATE GRID JIANGXI ELECTRIC POWER CO +1

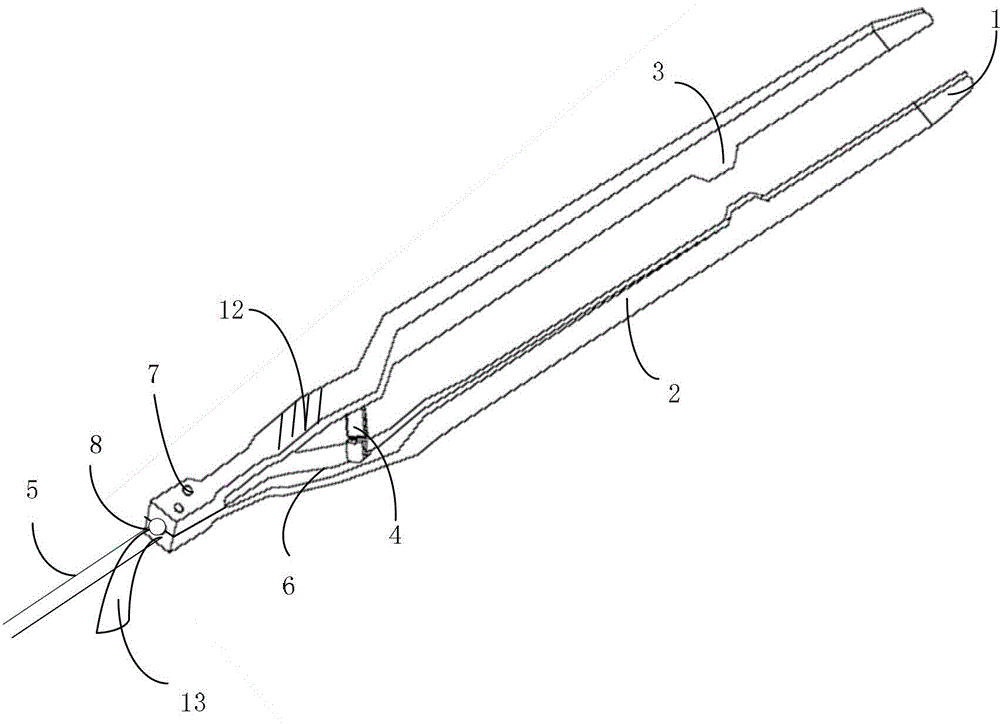

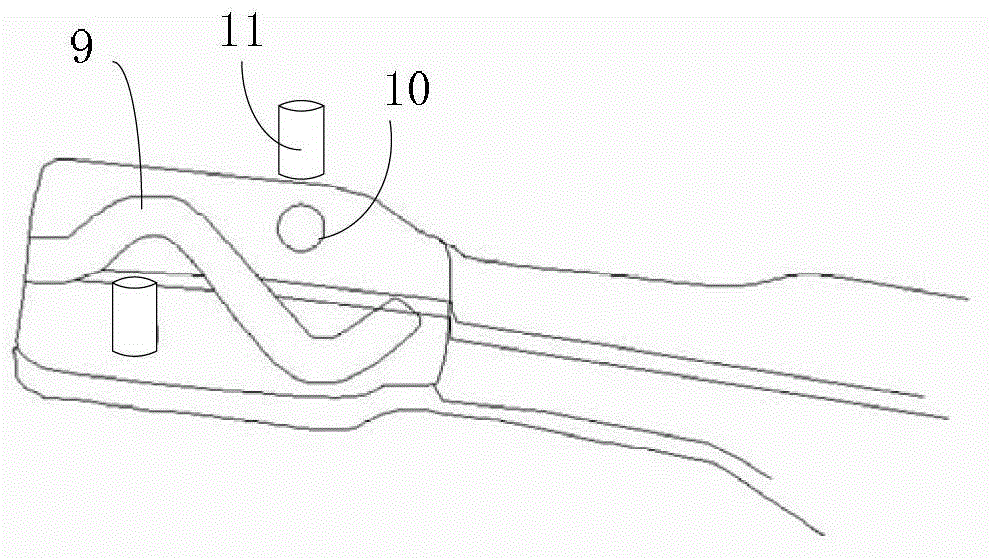

Non-sticky bipolar electrocoagulation forceps

InactiveCN103393466BNot easy to stickReduce weightSurgical instruments for heatingForcepsEngineering plastic

The invention discloses a pair of non-sticky bipolar electrocoagulation forceps which comprises a left forceps rod, a right forceps rod, and forceps tips fixed at the heads of the forceps rods; a lead groove is formed in the inner side of each forceps rod; a lead wire is arranged in each lead groove; the lead wires are hollow copper pipe; one end of each lead wire is fixedly connected one forceps tip, and the other end is connected with a lead used for being connected with the host of an electrocoagulator; the non-sticky bipolar electrocoagulation forceps are further provided with a dripping pipe connector connected with medical water delivery equipment. The lead wires of the forceps not only can be used for electric conduction but also can serve as a dripping pipe, the structure is simple, and the cost is lower; meanwhile, each forceps adopts a whole piece of silver alloy, the forceps rods are made of modified engineering plastic, so that the characteristics of high electric conductivity and high thermal conductivity can be achieved, rapid heat dissipation can be ensured during electrocoagulation, and terminal burn to the perienchyma can not be caused easily during electrocoagulation; the forceps rods cover all conductive parts completely, so that a better insulation effect can be achieved, and the whole coagulation forceps are attractive and light.

Owner:黄盛 +1

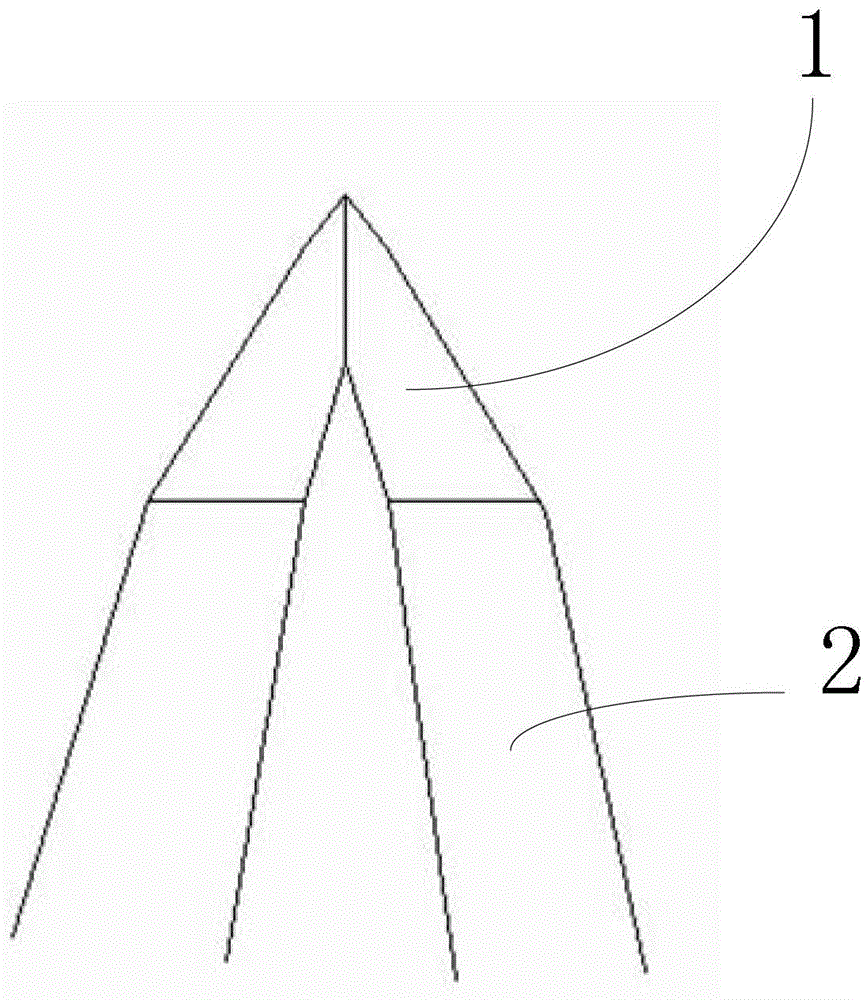

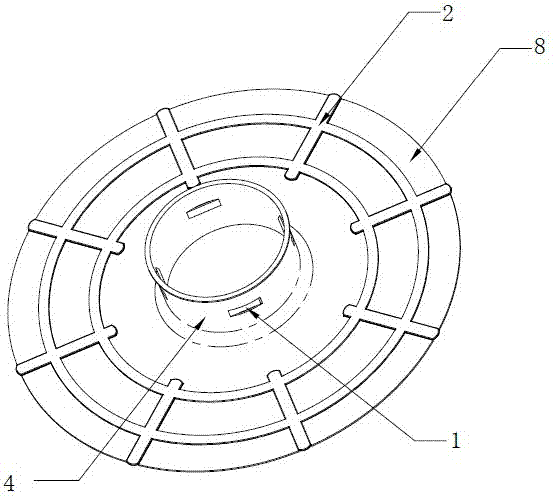

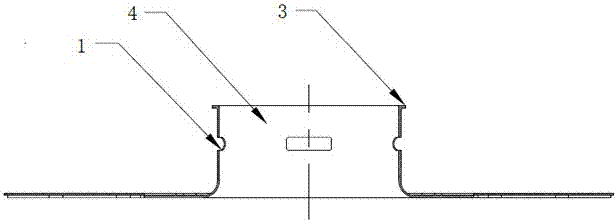

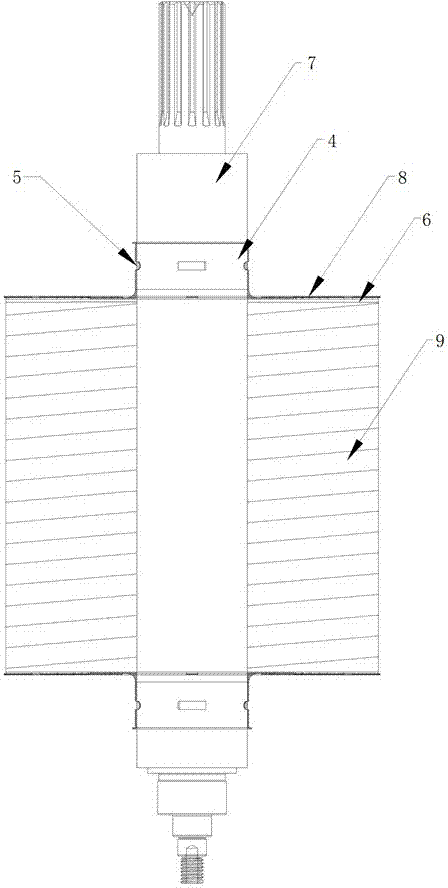

Novel rotor press plate structure

PendingCN107508394ASimplify the installation processImprove efficiencyMagnetic circuit rotating partsManufacturing stator/rotor bodiesPunchingMetal machining

The invention discloses a novel rotor press plate structure, which comprises a press plate body. The center of the press plate body is equipped with a shaft hole. A cylindrical surface, which is integrally formed with the press plate body, is arranged on the circumference of the shaft hole. The upper end of the cylindrical surface is provided with a flanging structure. The middle of the cylindrical surface is provided with punching and riveting protrusions that fit a rotor rotating shaft through punching and riveting. Punching and riveting clamping grooves are arranged in corresponding positions of the rotor rotating shaft. When the press plate body and a rotor are assembled, a magnetic separation thin plate is additionally arranged between the press plate body and a rotor iron core. The cylindrical surface and the rotor rotating shaft are cooperated and mounted through a punching and riveting structure, press mounting can be directly carried out in a cold condition, mounting procedures are simplified and the efficiency is high through cooperation and fixation between punching and riveting convex grooves and concave grooves, and quantitative production is suitable. Compared with a heating and welding solution, the solution of the invention has the advantages that safety coefficients are higher and requirements on operating skills of people are relatively low. In addition, a sheet metal machining process is adopted, parts can be molded easily, walls of materials are thin, the cost is low, and the weight and the dynamic balance of the rotor can be reduced.

Owner:HEFEI JUYI POWER SYST CO LTD

A method for preparing reduced graphite oxide/nano-nickel composite wave-absorbing material by using gamma rays

ActiveCN103788921BSuitable for quantitative productionMild reaction conditionsOther chemical processesReaction temperatureGamma ray

Owner:TECHN PHYSICS INST HEILONGJIANG ACADOF SCI

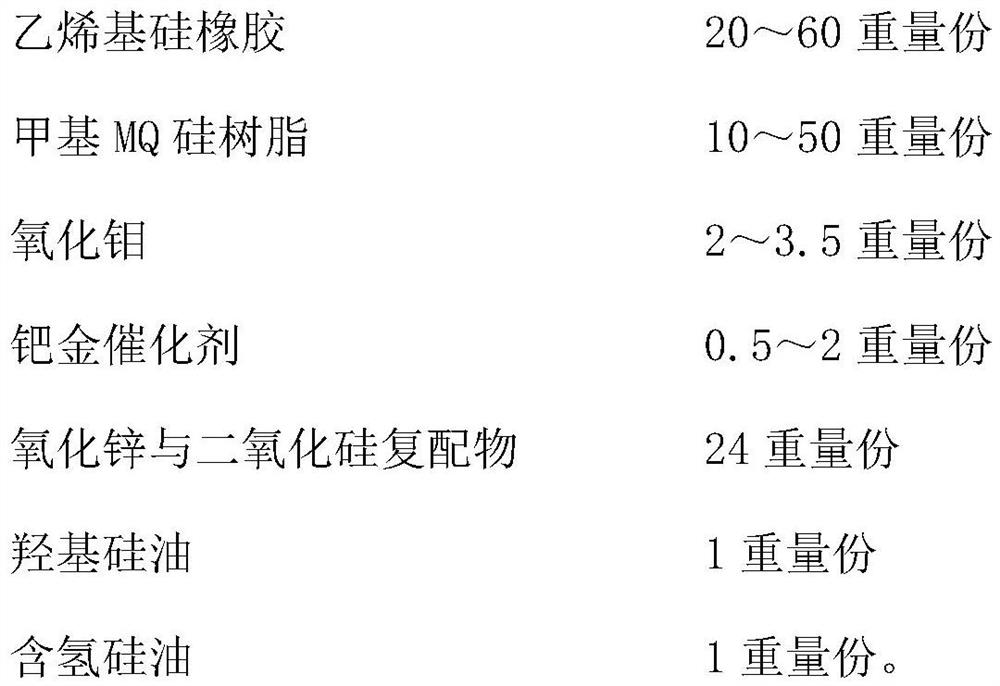

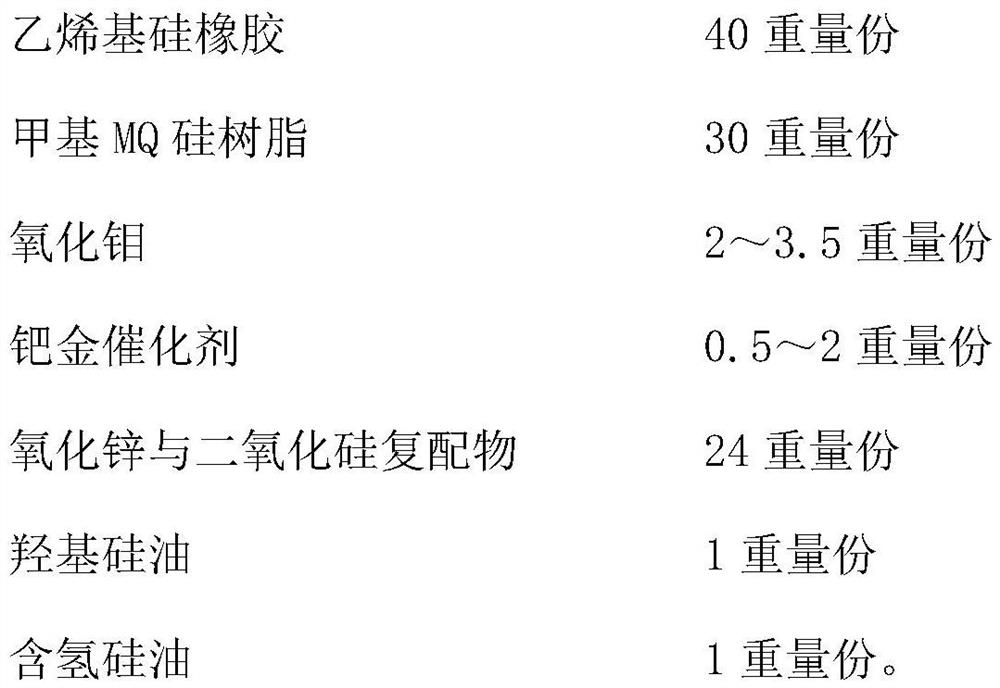

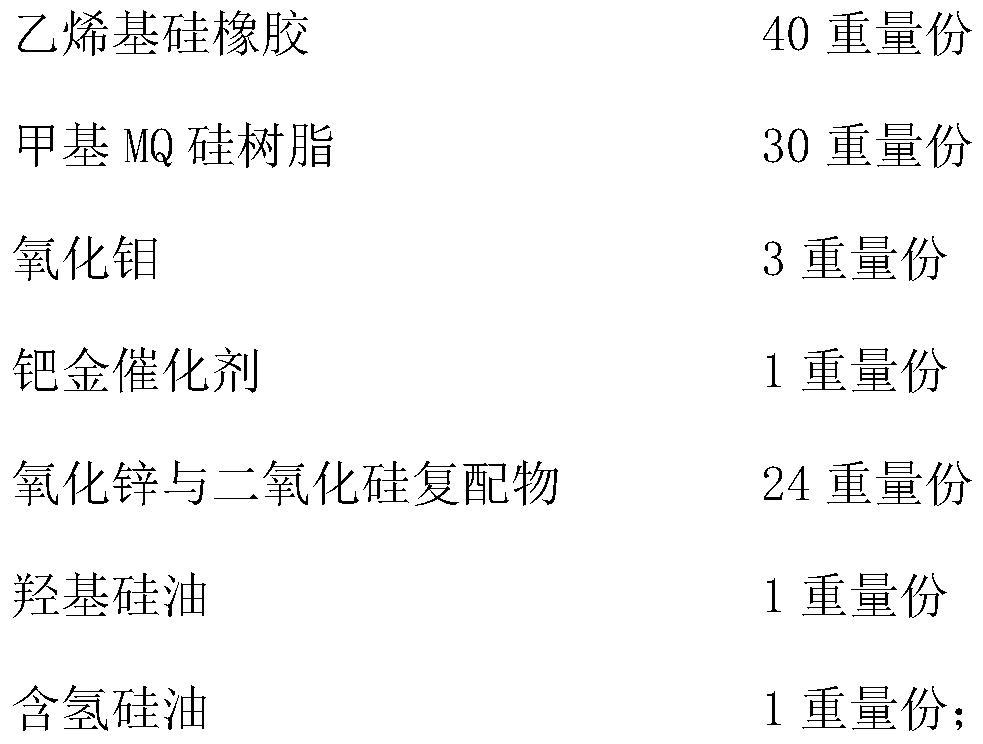

A kind of hydrogen-sensitive composite silica gel material and preparation method thereof

The invention relates to a hydrogen-sensitive composite silica gel material and a preparation method thereof. The hydrogen-sensitive composite silica gel material includes a composite silica gel matrix and hydrogen-sensitive active components, and changes color when encountering hydrogen gas. The hydrogen-sensitive composite silica gel material provided by the present invention can rapidly change color within 60 seconds when exposed to hydrogen at room temperature, providing a convenient, fast and sensitive hydrogen detection method for people to intuitively judge the presence of hydrogen with the naked eye.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com