A kind of halogen-free flame-retardant polyethylene material and its preparation method and application

A technology of flame retardant polyethylene and flame retardant, which is applied in the field of flame retardant materials to achieve the effect of not easy to break, easy to process and shape, and low hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

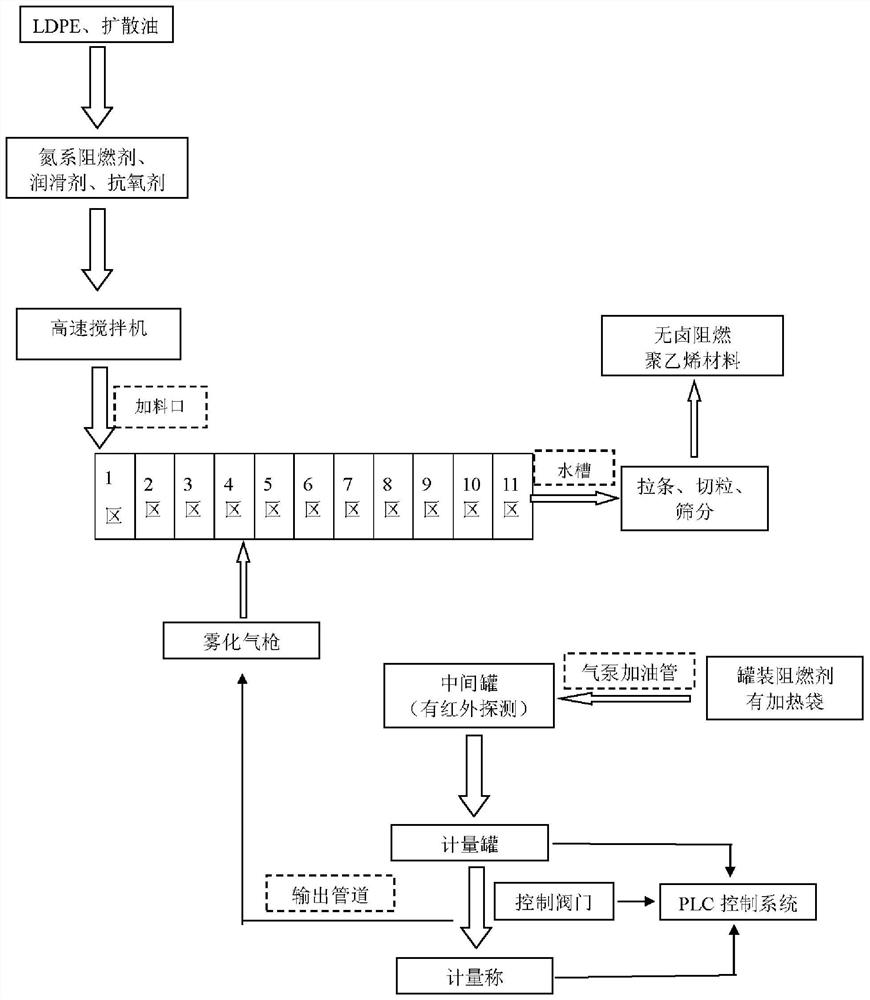

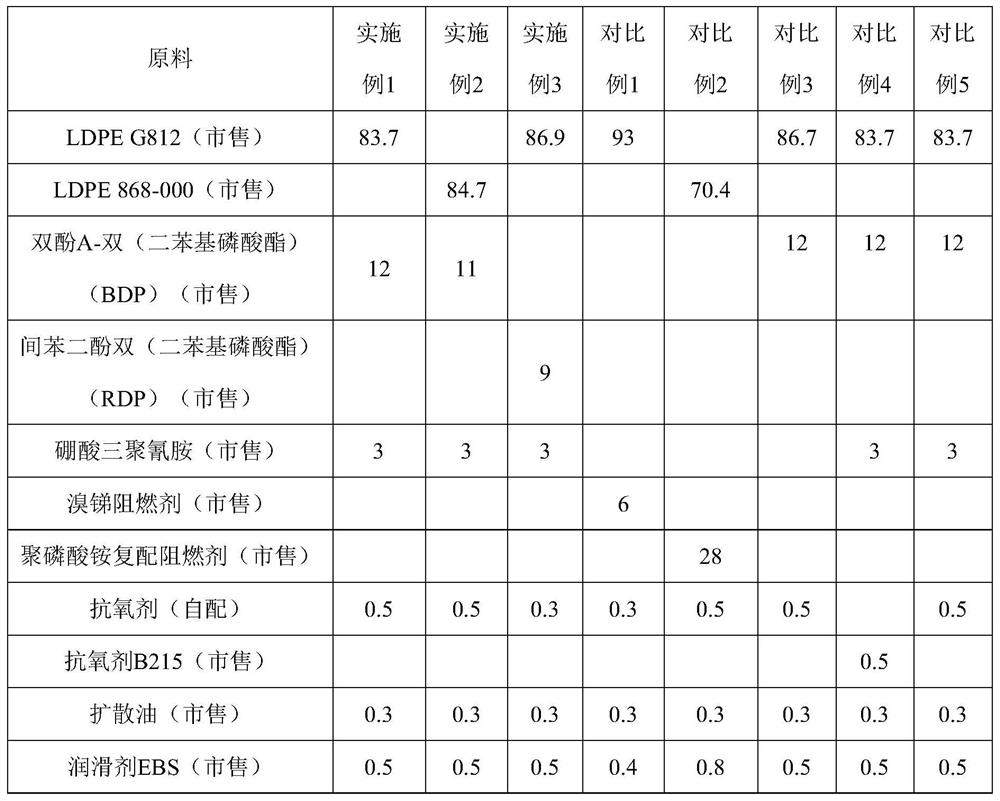

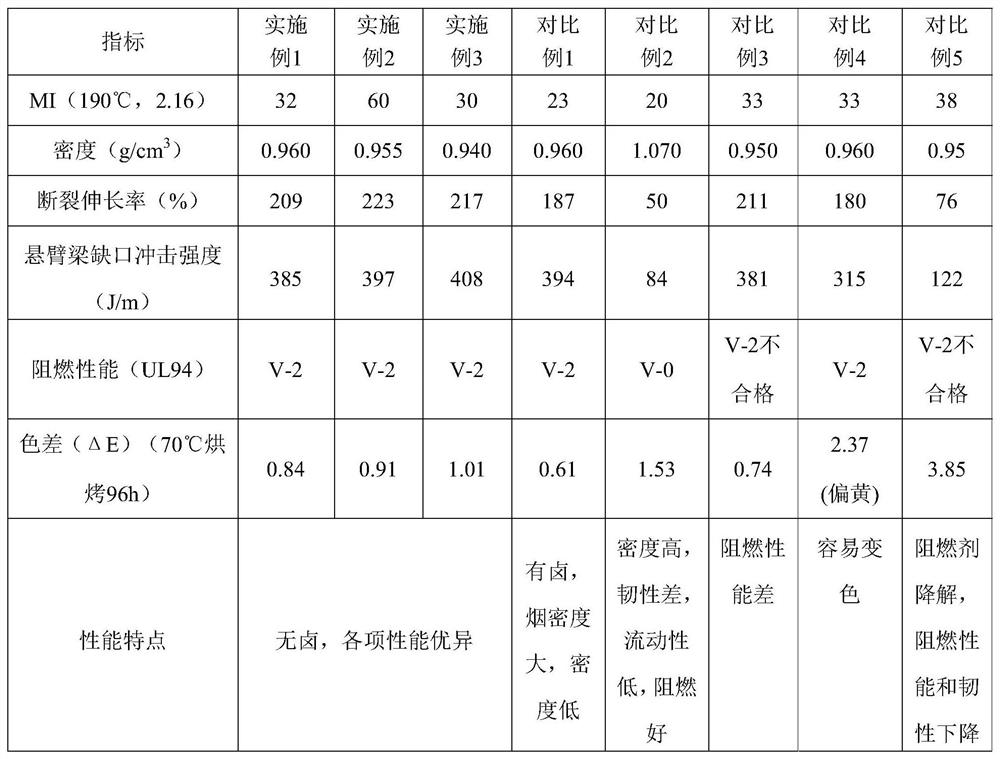

[0047] attached figure 1 It is a schematic diagram of the preparation method of the halogen-free flame-retardant polyethylene material of the present invention. refer to figure 1 , the preparation method of the flame-retardant polyethylene material of embodiment 1~3 and comparative example 3~4 is illustrated and comprises the following steps:

[0048] 1) Put LDPE into the high-speed mixer (500r / min) according to the mass ratio in Table 1, cover the lid, start stirring, add the proportion of diffusion oil from the oil filler on the lid, stir for 1min, and set the temperature at 50°C ;

[0049] 2) Add the nitrogen-based flame retardant, antioxidant, and lubricant into the mixture obtained in step 1) according to the proportion, stir for 2 minutes, and add the uniformly mixed material into the twin-screw extruder from the main feed;

[0050] 3) Add the halogen-free phosphate ester flame retardant into the twin-screw extruder through the liquid flame retardant adding device fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com