Novel rotor press plate structure

A pressure plate and rotor technology, which is applied in the field of new rotor pressure plate structure, can solve the problems of high operation requirements, high labor operation requirements and high processing costs, and achieves the effect of low personnel operation ability requirements, simplified installation procedures and high safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The novel rotor press plate structure of the present invention adopts the sheet metal manufacturing process, and the materials can be non-magnetic isolation materials such as spcc and Q345.

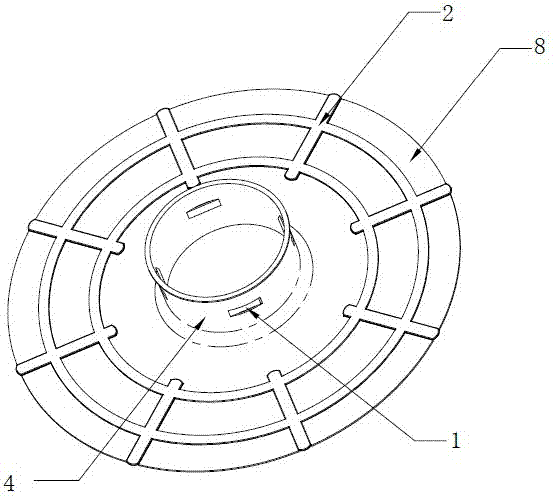

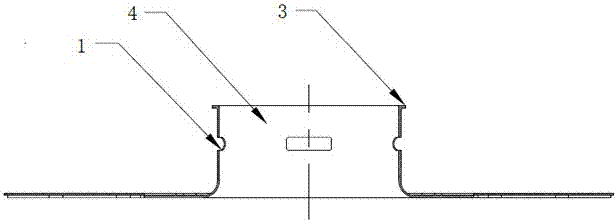

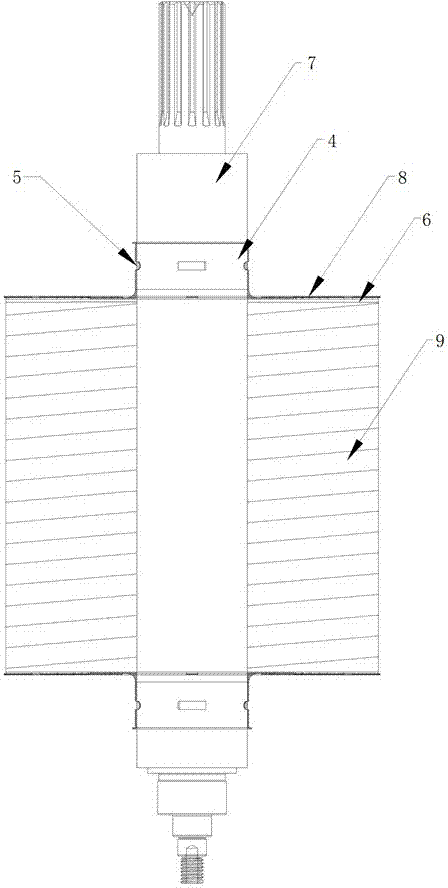

[0028] Such as Figure 1-3 As shown, the novel rotor pressure plate structure of the present invention includes a pressure plate body 8, a shaft hole is provided at the center of the pressure plate body, and a cylindrical surface 4 integrally formed with the pressure plate body and vertically upward is provided on the circumference of the shaft hole. 7 passes through it to increase the contact area.

[0029] The upper end of the cylindrical surface 4 is provided with an outer flanging structure 3 to increase the strength, and the upper surface of the pressure plate body 8 is provided with raised ribs 2 .

[0030] The middle part of the cylindrical surface 4 is provided with a riveting protrusion 1 that cooperates with the rotor shaft 7 through a riveting process, and a riveting sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com