A method for preparing reduced graphite oxide/nano-nickel composite wave-absorbing material by using gamma rays

A composite wave absorbing material, γ-ray technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of high preparation cost, complex preparation process, harsh conditions, etc., to achieve stable product quality, simple implementation method, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

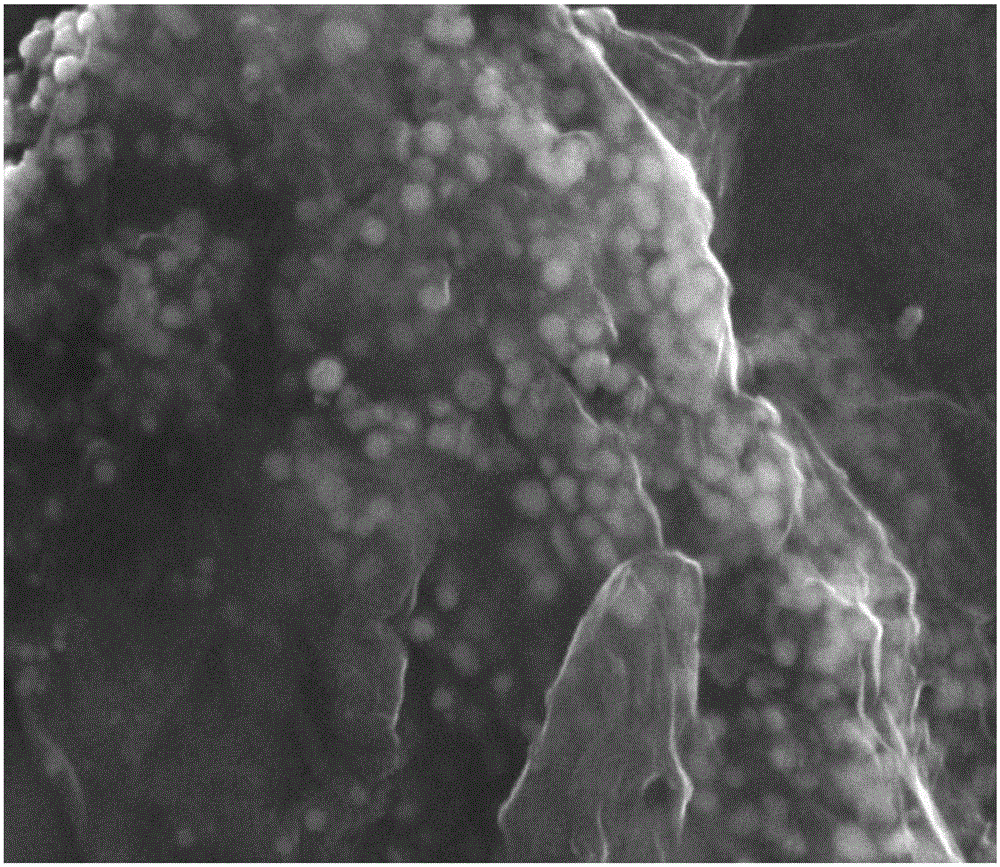

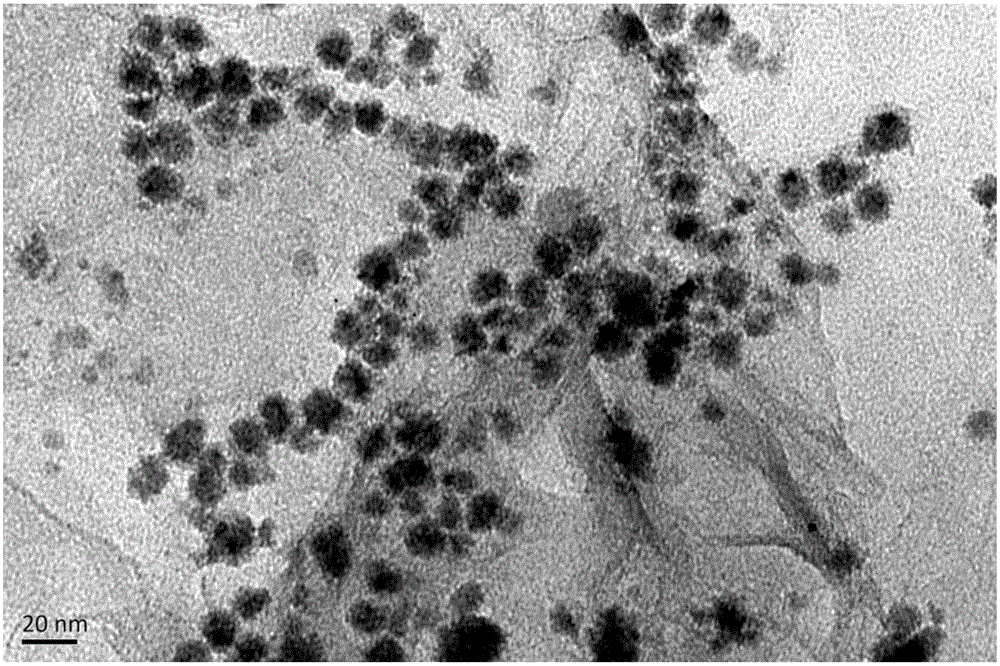

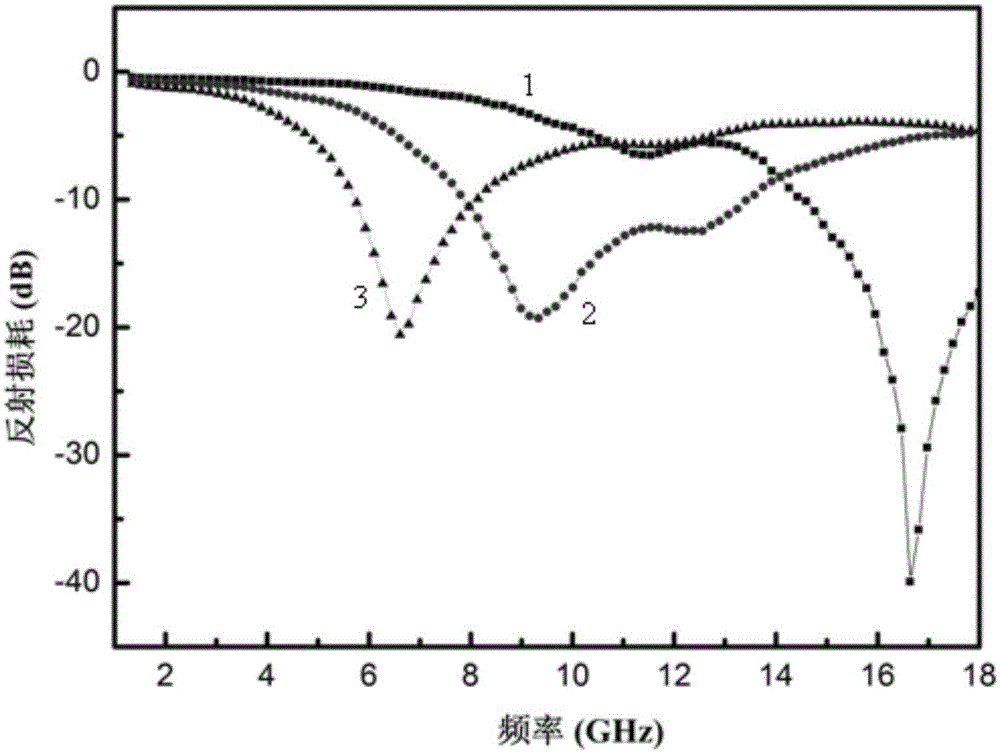

[0020] Specific implementation mode one: A method for preparing reduced graphite oxide / nano-nickel composite wave-absorbing material using gamma rays in this embodiment is carried out according to the following steps:

[0021] 1. Preparation of graphite oxide: adopt the closed oxidation method to prepare graphite oxide by oxidation reaction with natural flake graphite as raw material;

[0022] 2. Mix the graphite oxide prepared in step 1 with nickel salt, and then ultrasonically disperse it in deionized water to obtain a mixed solution; wherein, the mass ratio of graphite oxide and nickel salt in the mixed solution is 1: (1.2-10), and the mixed solution The concentration of graphite oxide is 1-5g / L;

[0023] 3. Add isopropanol dropwise to the mixed solution obtained in step 2, and then react under γ-ray irradiation to obtain the product; wherein, the volume ratio of the mixed solution to isopropanol is 1: (0.1~0.4), and the The dose of gamma rays mentioned above is 10-20KGy / h...

specific Embodiment approach 2

[0029] Specific embodiment two: the difference between this embodiment and specific embodiment one is: in the step one, adopt the airtight oxidation method to carry out oxidation reaction and prepare the method for graphite oxide with natural flake graphite as raw material:

[0030] 1. Add 1g of natural flake graphite, 3g of potassium permanganate, and 30mL of concentrated sulfuric acid with a mass concentration of 98% to the stainless steel reaction kettle, seal it and place it at a temperature of 1-2°C for 2h, and react at a temperature of 80°C for 1.5 h, to obtain the reaction solution;

[0031] 2. Transfer the reaction solution in step 1 into 500mL of distilled water, add 100mL of 30% hydrogen peroxide, continue to stir, settle, wash until the solution is neutral, and dry at 60°C to complete the preparation of graphite oxide. Other parameters and steps are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the nickel salt in step 2 is nickel acetate hexahydrate or nickel chloride. Other parameters and steps are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com