A kind of hydrogen-sensitive composite silica gel material and preparation method thereof

A technology of silica gel and vinyl silicone rubber, which is applied in the field of hydrogen-sensitive composite silica gel materials and its preparation, can solve the problems of limited leakage point location capability, leakage, obvious changes in pressure/consumption, etc., and achieve rapid discoloration of mechanical properties and processes. Non-toxic and harmless, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

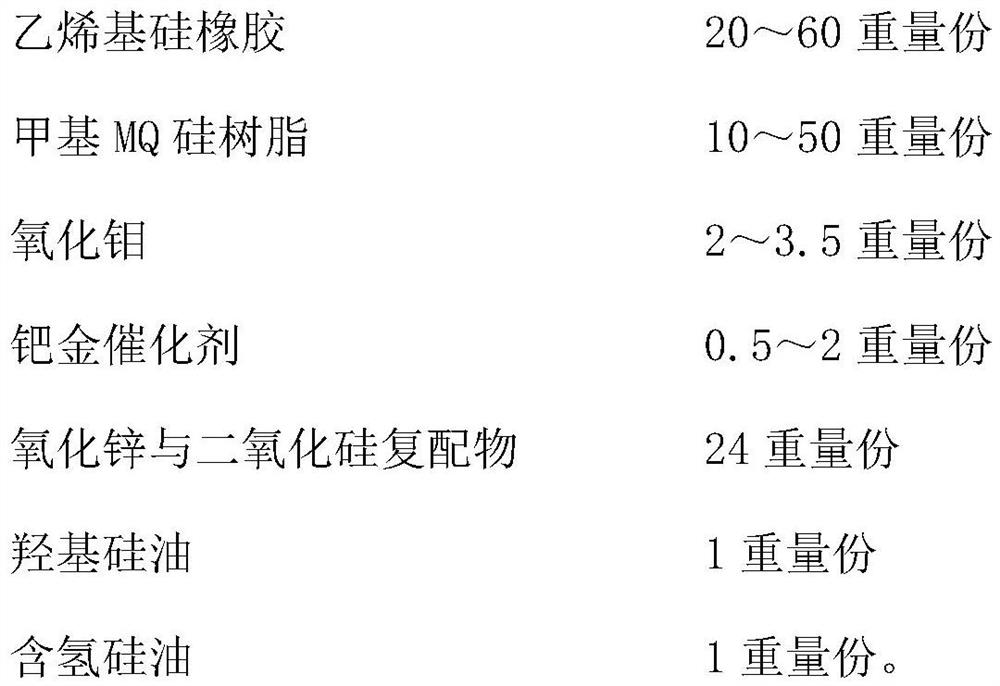

[0043] Raw material ratio:

[0044]

[0045] Among them, the reinforcing whitening filler is compounded by zinc oxide and silicon dioxide in a weight ratio of 1:1.

[0046] Preparation:

[0047] Put 60 parts by weight of vinyl silicone rubber, 10 parts by weight of methyl MQ silicone resin, and 24 parts by weight of a compound of zinc oxide and silicon dioxide into a vacuum drying oven for drying; the drying temperature of the vacuum drying oven is 50 ° C, and the drying time is for 3 hours;

[0048] Put it into the mixer, the speed of the mixer is 180r / min, and the stirring time is 8 minutes; the mixture after stirring is put into the double-roller mill, the speed of the double-roller mill is 100r / min, the roller temperature is 150°C, and the refining time is For 10 minutes, add 2 parts by weight of molybdenum oxide, 2 parts by weight of palladium-gold catalyst, 1 part by weight of hydroxyl silicone oil, and 1 part by weight of hydrogen-containing silicone oil, and carry...

Embodiment 2

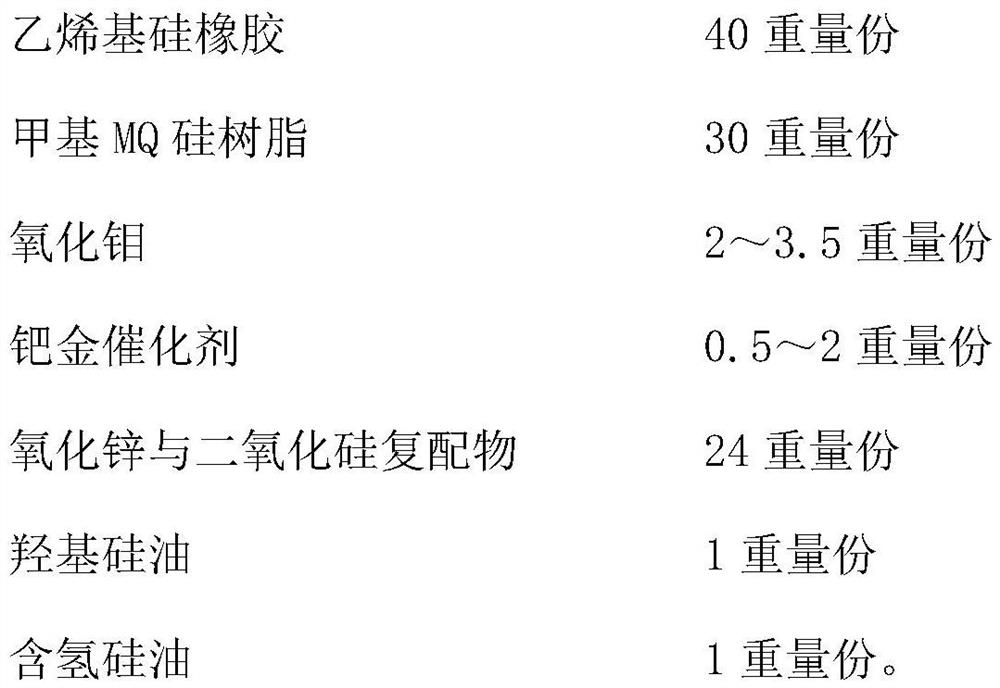

[0050] Raw material ratio:

[0051]

[0052] Among them, the reinforcing whitening filler is compounded by zinc oxide and silicon dioxide in a weight ratio of 1:1.

[0053] Preparation:

[0054] Put 50 parts by weight of vinyl silicone rubber, 20 parts by weight of methyl MQ silicone resin, and 24 parts by weight of zinc oxide and silicon dioxide compound into a vacuum drying oven for drying; the drying temperature of the vacuum drying oven is 70 ° C, and the drying time is 8 hours;

[0055] Put it into the mixer, the speed of the mixer is 320r / min, and the stirring time is 20 minutes; the mixture after stirring is added into the double-roller mill, the speed of the double-roller mill is 200r / min, the roller temperature is 210°C, and the refining time is For 20 minutes, add 2 parts by weight of molybdenum oxide, 2 parts by weight of palladium-gold catalyst, 1 part by weight of hydroxyl silicone oil, and 1 part by weight of hydrogen-containing silicone oil, and carry out c...

Embodiment 3

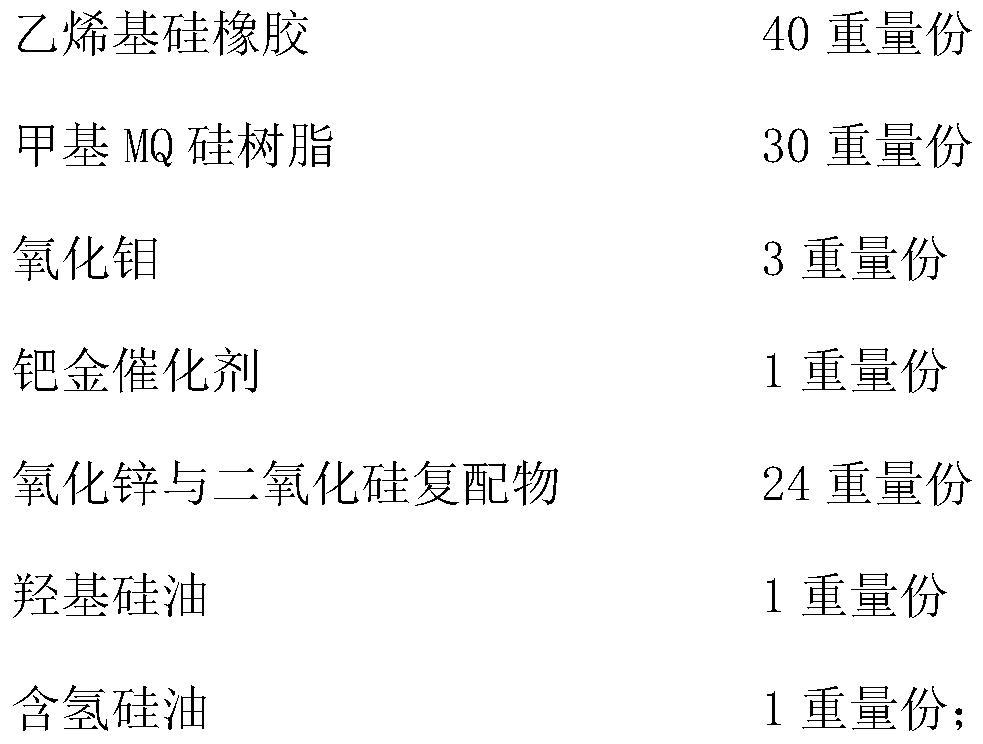

[0057] Raw material ratio:

[0058]

[0059]

[0060] Among them, the reinforcing whitening filler is compounded by zinc oxide and silicon dioxide in a weight ratio of 1:1.

[0061] Preparation:

[0062]Put 40 parts by weight of vinyl silicone rubber, 30 parts by weight of methyl MQ silicone resin, and 24 parts by weight of zinc oxide and silicon dioxide compound into a vacuum drying oven for drying; the drying temperature of the vacuum drying oven is 60 ° C, and the drying time is 4 hours;

[0063] Put into the mixer, the rotating speed of the mixer is 240r / min, and the stirring time is 10 minutes. After stirring, the mixture is added into the double-roller mill. The rotating speed of the double-roller mill is 150r / min, and the roller temperature is 180°C. After 15 minutes, add 2 parts by weight of molybdenum oxide, 2 parts by weight of palladium-gold catalyst, 1 part by weight of hydroxyl silicone oil, and 1 part by weight of hydrogen-containing silicone oil, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com