Halogen-free flame-retardant high-density polyethylene material and preparation method and application thereof

A high-density polyethylene and low-density polyethylene technology is applied in the field of halogen-free flame-retardant high-density polyethylene materials and preparation, and can solve the problems that the flame-retardant technology cannot meet the market demand, high toughness requirements, and low flame-retardant requirements. Achieve excellent self-extinguishing properties, excellent mechanical properties, and good flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

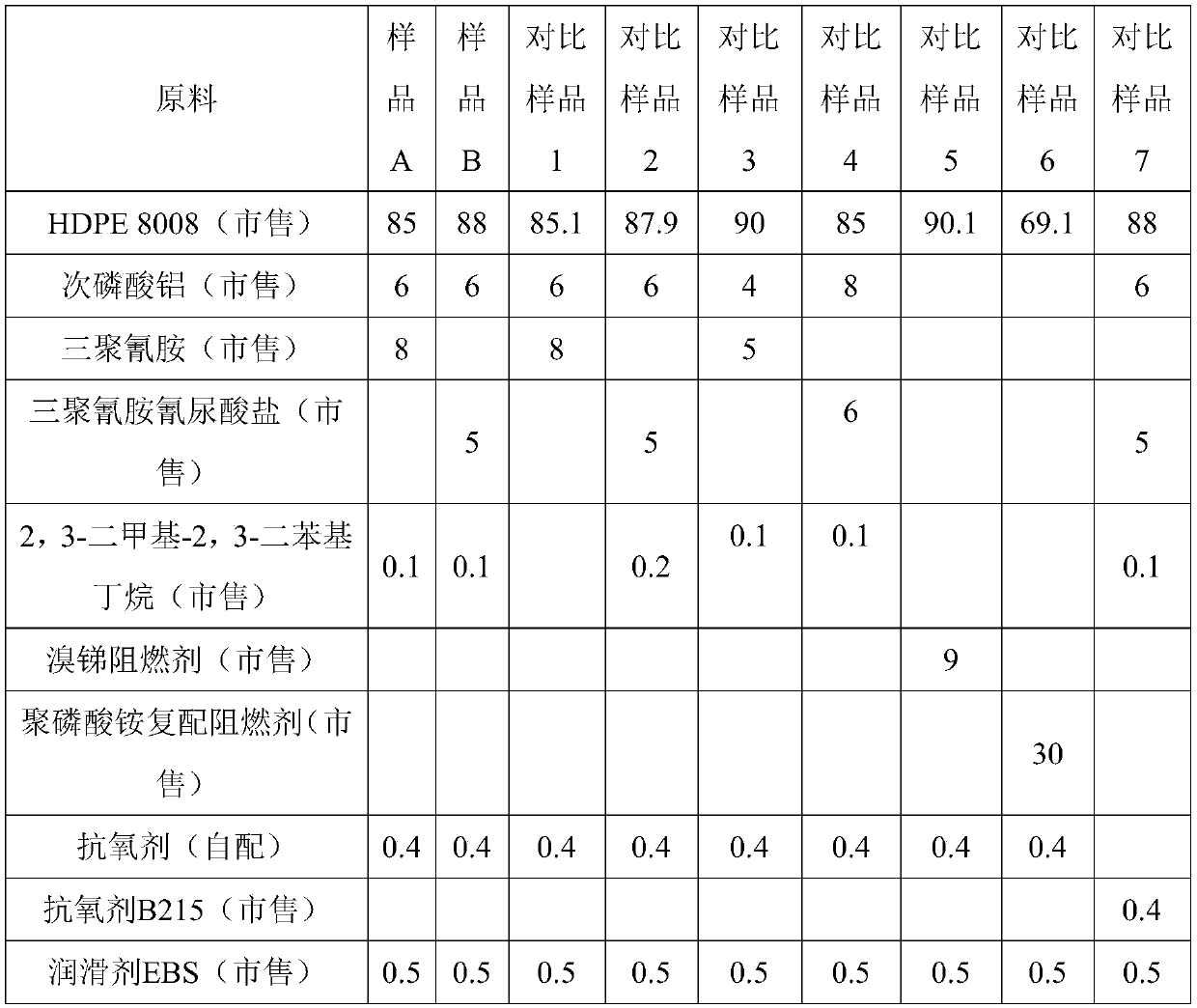

[0060] This example provides a halogen-free flame-retardant high-density polyethylene material, including the following raw materials in parts by weight:

[0061] HDPE: 80-95 parts,

[0062] Halogen-free compound flame retardant: 5-15 parts,

[0063] Flame retardant synergist: 0.1 parts,

[0064] Antioxidant: 0.2~0.8 parts,

[0065] Lubricant: 0.3 to 0.7 parts.

[0066] Among them, the flexural modulus of HDPE is 750-900 MPa. The elongation at break of HDPE is >800%. The melt index of HDPE under the test conditions of 190°C and 2.16kg is 4g / 10min~50g / 10min.

[0067] The halogen-free compound flame retardant is a P-N compound flame retardant, and the mass ratio of the P-based flame retardant to the N-based flame retardant in the P-N compound flame retardant is 1: (0.5-10). The P-based flame retardant includes at least one of hypophosphorous acid, aluminum hypophosphite, calcium hypophosphite, aluminum diethylphosphinate, and aluminum phenylphosphinate. The N series flame...

Embodiment 2

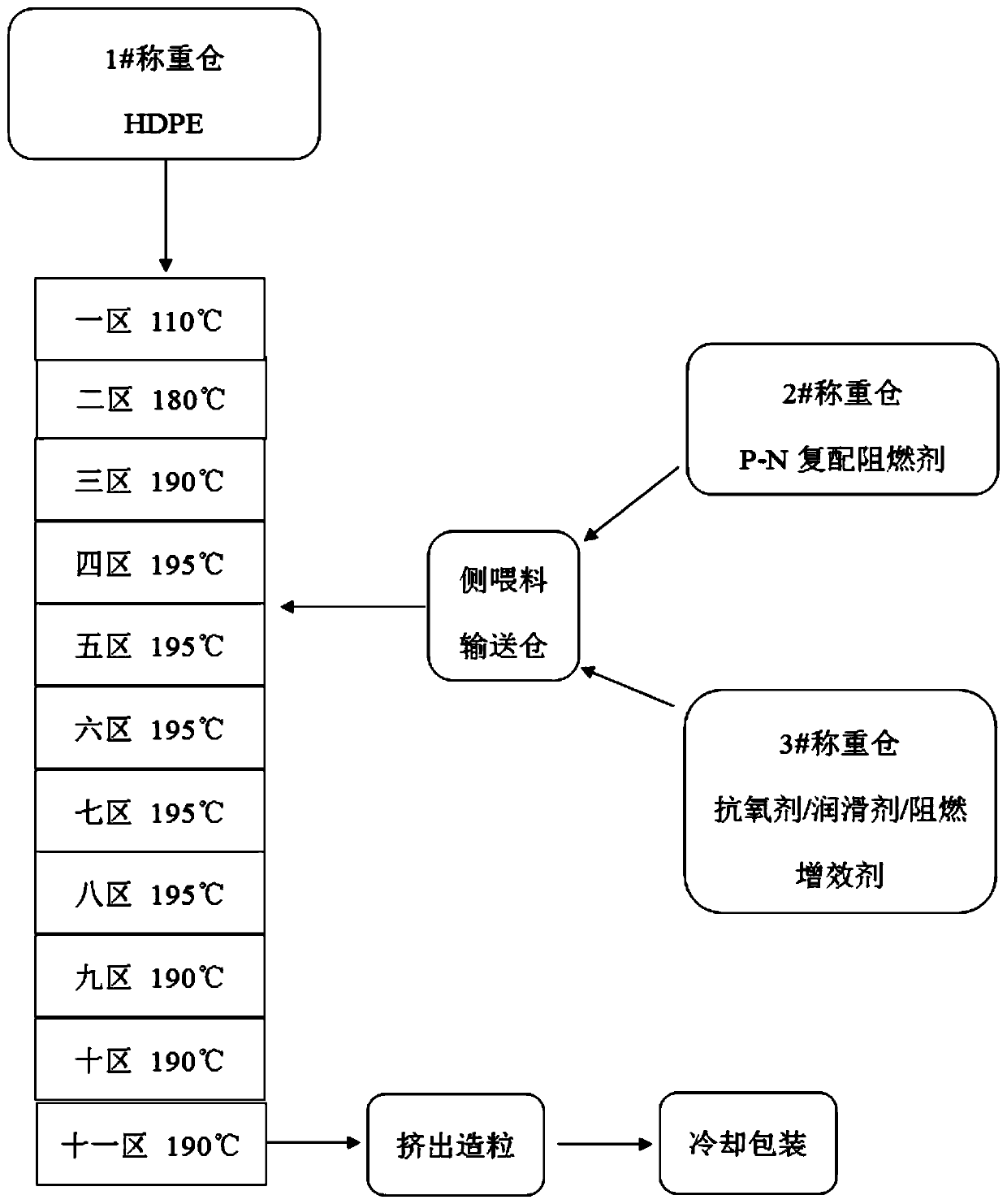

[0072] This example provides the preparation method of halogen-free flame-retardant high-density polyethylene material, the process is as follows figure 1 As shown, the steps include:

[0073] S1: Weigh the LDPE, halogen-free compound flame retardant, antioxidant and lubricant according to the proportion and mix them;

[0074] S2: After kneading by a twin-screw extruder, extrude and granulate to obtain the halogen-free flame-retardant low-density polyethylene material.

[0075] Specifically, the preparation method of the above-mentioned halogen-free flame-retardant high-density polyethylene material, the steps include:

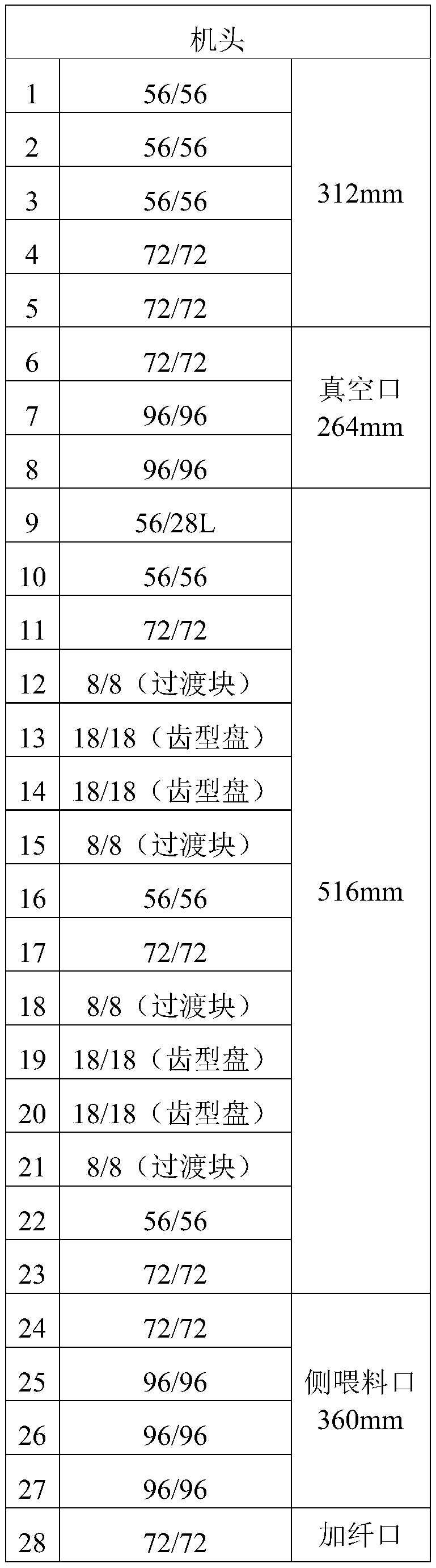

[0076] 1) Feed HDPE into the twin-screw extruder through the 1# loss-in-weight weighing bin from the main feeding port;

[0077] 2) Compound the P-N compound flame retardant according to the proportion and add it to the 2# loss-in-weight weighing chamber, and then add the flame-retardant synergist, antioxidant and lubricant to the 3# weight-loss weighing cha...

Embodiment 3

[0084] This example provides the application of halogen-free flame-retardant high-density polyethylene material in non-load-bearing plastic bins and trash cans.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com