Positioning, assembling and welding method for ship stern thrust equipment

A technology of equipment and stern thrust, applied in the direction of ships, etc., can solve the problems of difficult and inaccurate positioning of stern thrust equipment, and achieve the effects of convenient pulling, accurate positioning and easy installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

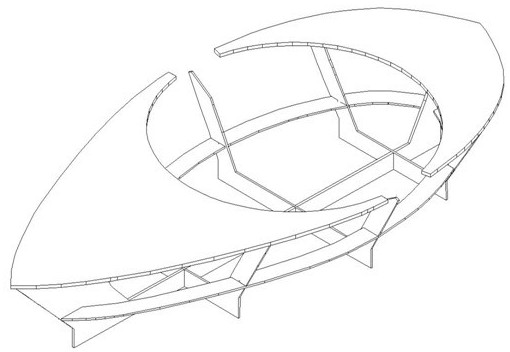

[0029] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

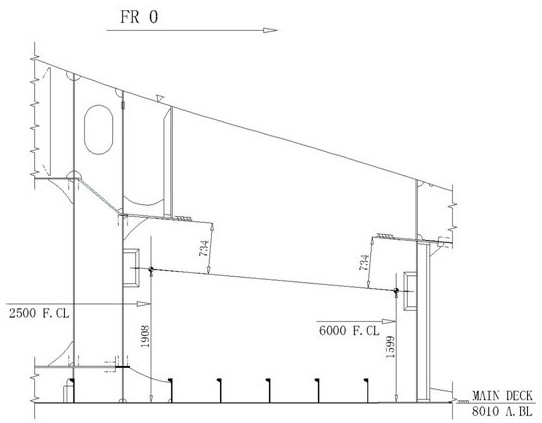

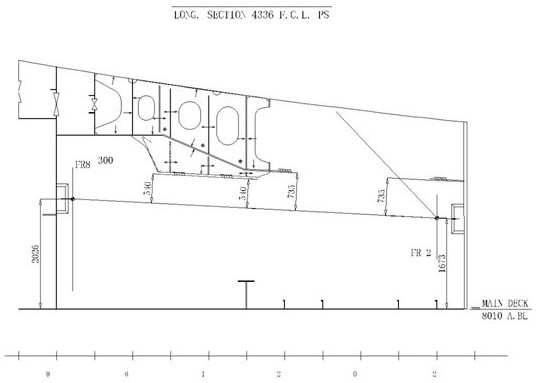

[0030] Taking the stern thruster of S1049 liquefied gas ship as an example, the splicing work of the platform plate needs to be completed before the installation of the stern thruster equipment, the platform plate needs to be leveled, and the allowable tolerance is ±2mm. The platform plate is hoisted to this section for positioning. In order to ensure that the hull platform plate meets the installation requirements of 5° fore and stern deviation and 3° left and right deviation for equipment installation, it is necessary to position the hull platform plate along the width and length of the ship by pulling steel wires. ,Such as Figure 1-2 As shown, the specific positioning data is as follows:

[0031] Along the width of the ship: midship anchor point: X=FR0, Y=±2500,

[0032] Z= 6092 (from baseline), 1908 (from main deck, excluding plate thickness);

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com