A kind of enameled wire suspension mold paint forming method and paint film forming mold

A forming method and technology of enameled wire, applied in the direction of conductor/cable insulation, electrical components, circuits, etc., can solve the problems of easy damage of enameled wire, high production cost, and difficulty in pulling wires, so as to achieve low production cost, prevent paint film damage, and avoid Effect of bending or indentation phenomena

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

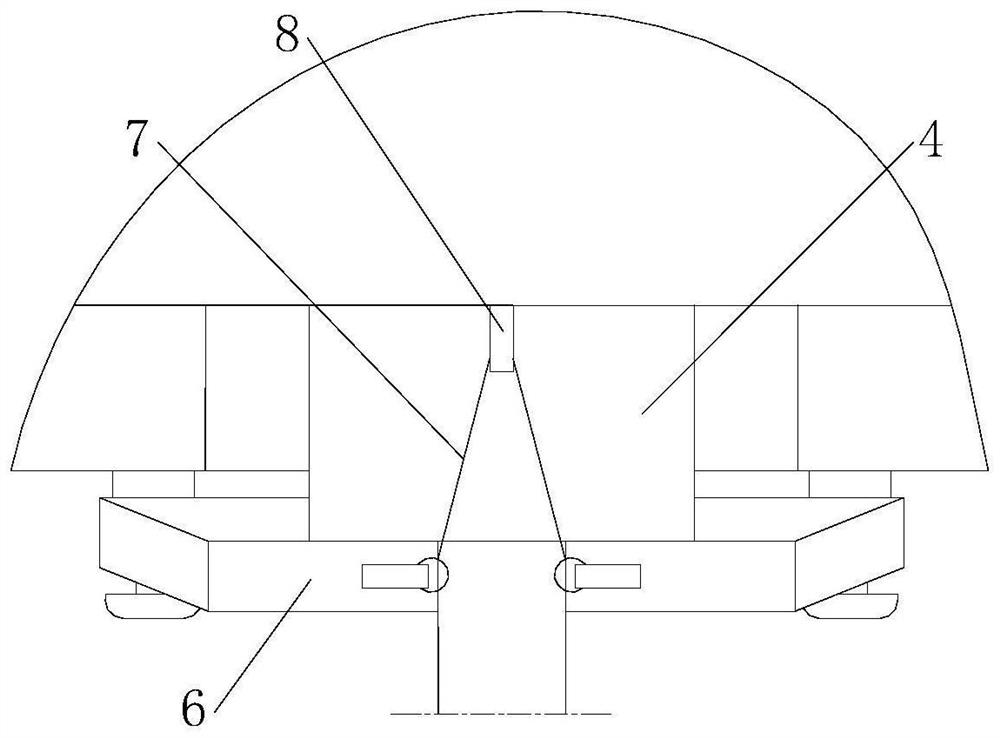

[0028] Example. A suspension mold coating forming method for enameled wire: the coated enameled wire passes through the shaping mold core and enters the enamelling furnace, and the shaping mold core removes excess insulating varnish on the surface of the enameled wire through the forming cavity, and at the same time, the paint liquid forms a squeeze in the forming cavity. The pressure keeps the shaped core in suspension; when the enameled wire is routed, the height of the shaped core is automatically positioned with the enameled wire, and the angle of the shaped core rotates vertically with the threading angle of the enameled wire.

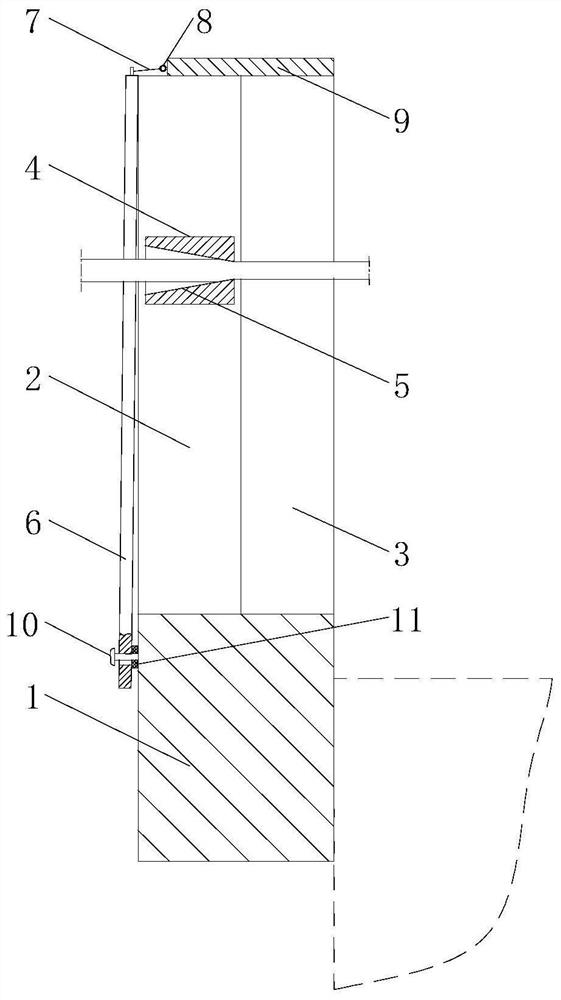

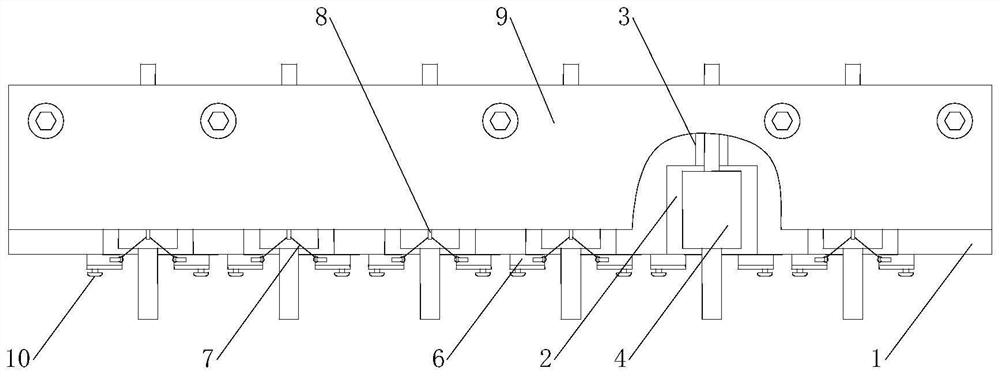

[0029] A kind of paint film forming mold used in the suspension type mold painting forming method of enameled wire, constitutes as follows figure 1 As shown, it includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com