An energy-saving polymer corrosion-resistant cable tray

A cable tray and polymer technology, applied in electrical components and other directions, can solve the problems of increasing the labor intensity and labor time of the staff, failing to protect the cable, and easily breaking the cable skin, etc., achieving a reasonable and practical structure, preventing the Cable tray, the effect of preventing the inflow of rainwater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

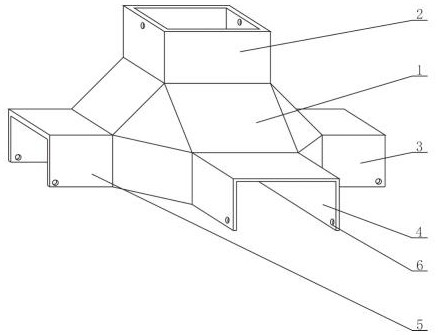

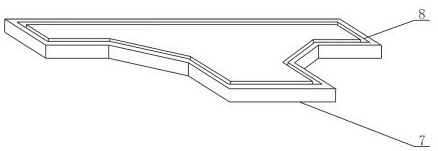

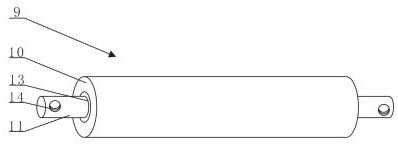

[0033] Embodiment 1, combining Figure 1~5 The present invention arranges the first connection block 2, the second connection block 3, the third connection block 4, the fourth connection block 5 and the base 7 on the housing, the first connection block 2, the second connection block 3, the third connection block The block 4 and the fourth connecting block 5 are all equipped with a rainproof device 21, and the joints between the housing 12 and the first connecting block 2, the second connecting block 3, the third connecting block 4 and the fourth connecting block 5 are provided with Connecting rod 22, connecting rod 22 is provided with fixed column 11, is provided with bearing 13 on fixed column 11, is provided with pulley 10 on bearing 13, reaches the purpose of being convenient to backguy and isolating rain with this.

[0034]In addition, the first connecting block 2, the second connecting block 3, the third connecting block 4 and the fourth connecting block 5 are all provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com