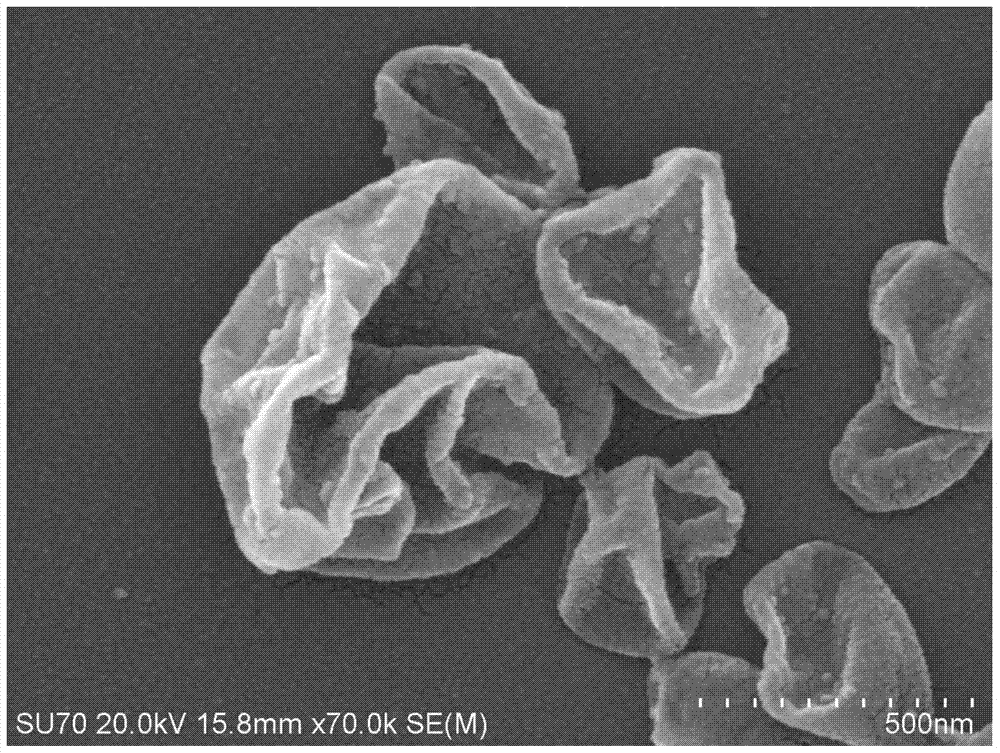

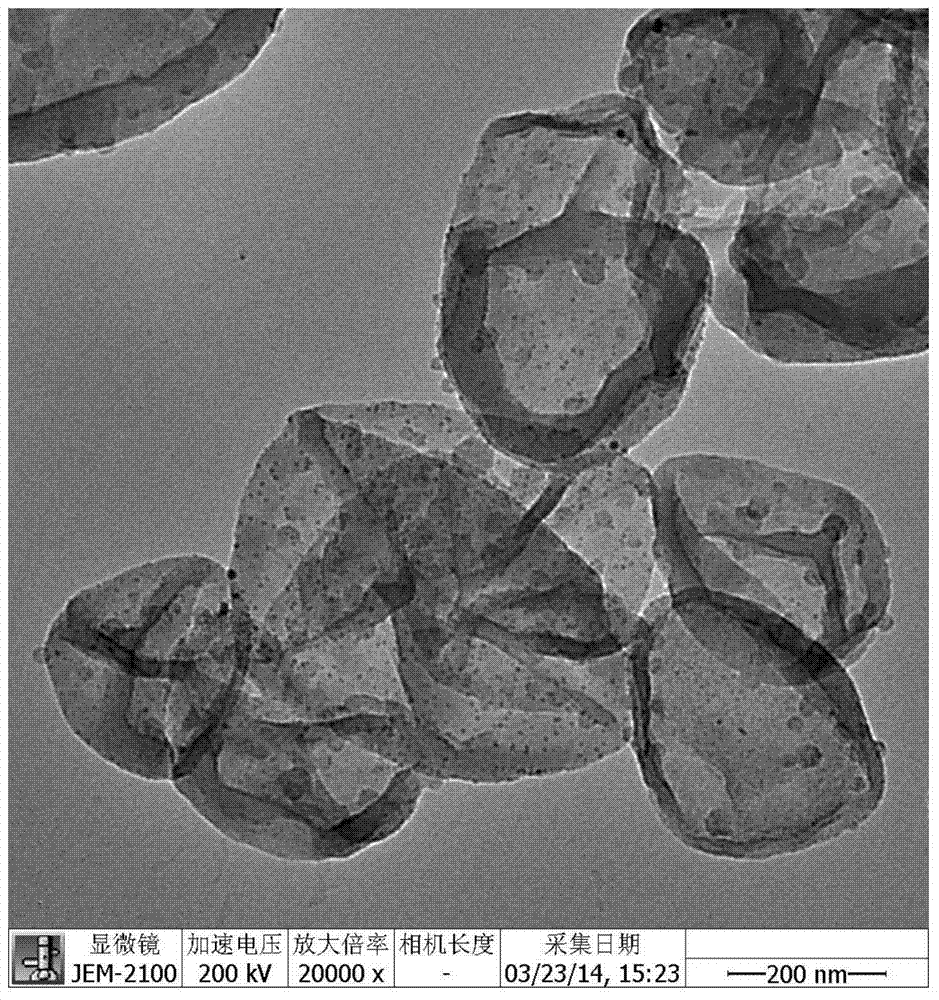

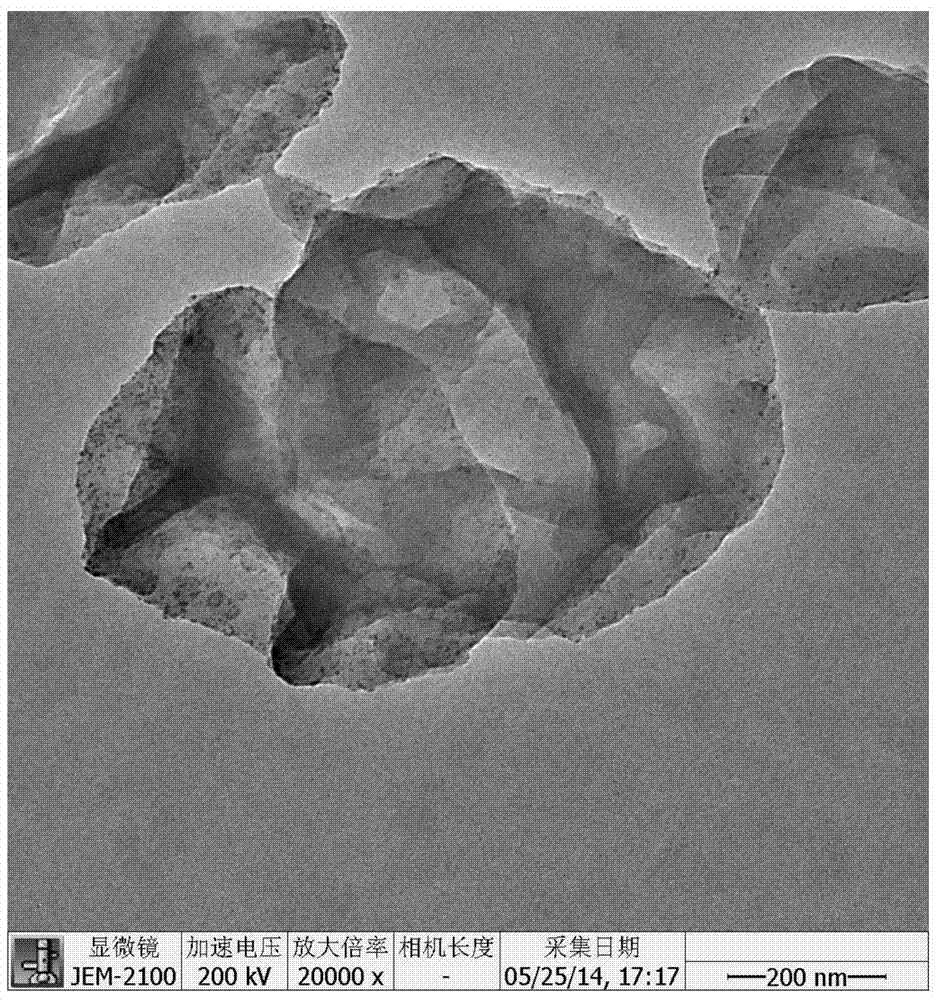

A kind of nanometer noble metal loaded polymer vesicle and preparation method thereof

A precious metal and polymer technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, chemical/physical processes, etc., can solve the problems of low yield and complex synthesis process of polymer vesicles, etc. To achieve the effect of dense distribution, simple and easy preparation method and strong universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of phenolic resin prepolymer (Resol)

[0031] Weigh 25g of phenol, weigh 42g of formaldehyde solution according to the molar ratio of phenol:formaldehyde=1:2, and divide it into two parts of 33g and 9g for use. Weigh 1.25g of sodium hydroxide solid according to 5% of the mass of phenol, add 5g of deionized water to prepare a 20% NaOH aqueous solution, and divide it into two portions of 5g and 1.25g for use.

[0032] Add 25g of phenol and 5g of NaOH aqueous solution into a three-neck flask equipped with a mechanical stirrer, stir and mix evenly, and place in a constant temperature water bath at 45°C for 20 minutes; add 33g of formaldehyde solution and raise the temperature to 60°C for constant temperature reaction for 60 minutes; add the remaining 1.25g of NaOH aqueous solution , continue to react at a constant temperature of 60°C for 30 minutes; add the remaining 9g of formaldehyde solution and then raise the temperature to 70°C and react at a constant te...

Embodiment 2

[0042] Step 1) With reference to Embodiment 1, details are not repeated.

[0043] 2) Preparation of polymersomes

[0044] Measure 0.5mL of styrene (St) and 0.05mL of tetravinylpyridine (4VP) in a sample bottle containing 5mL of ethylene glycol, absorb the phenolic resin prepolymer with a disposable syringe, and weigh 0.1g drop by differential method Into the sample bottle, ultrasonic treatment for 30min to mix well.

[0045] Weigh 0.03g nonionic surfactant (at least one of polyethylene oxide, polyethylene glycol, polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer, polyvinylpyrrolidone) and dissolve in Add 2mL deionized water into the St-Resol ethanol solution that is mixed well, and ultrasonically treat for 30min to mix well

[0046] Add the prepared mixed solution of St-4VP-Resol and surfactant ethylene glycol / water into a stainless steel reaction kettle with a polytetrafluoroethylene lining, and tighten the seal, and place the reaction kettle in a blast ov...

Embodiment 3

[0051] Step 1) With reference to Embodiment 1, details are not repeated.

[0052] 2) Preparation of polymersomes

[0053] Measure 0.5mL of styrene (St) and 0.05mL of tetravinylpyridine (4VP) in a sample bottle containing 5mL of isopropanol, use a disposable syringe to absorb the phenolic resin prepolymer, and weigh 0.1g drop by differential method Into the sample bottle, ultrasonic treatment for 30min to mix well.

[0054] Weigh 0.03g nonionic surfactant (at least one of polyethylene oxide, polyethylene glycol, polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer, polyvinylpyrrolidone) and dissolve in Add 7mL deionized water into the St-Resol ethanol solution that is mixed well, and ultrasonically treat for 30min to mix well

[0055] Add the prepared mixed solution of St-4VP-Resol and surfactant ethylene glycol / water into a stainless steel reaction kettle with a polytetrafluoroethylene lining, and tighten the seal, and place the reaction kettle in a blast oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com