Fibroin oxidized bacterial cellulose nano-composite membrane and preparation method thereof

A technology of bacterial cellulose and oxidative bacteria, applied in the field of textile materials, can solve problems affecting the biocompatibility of bacterial cellulose and silk protein composite materials, hidden dangers of biological material safety performance, and affecting the environmental protection and safety performance of materials, and achieve mechanical Effects of improved performance, increased breaking strength, and good load transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

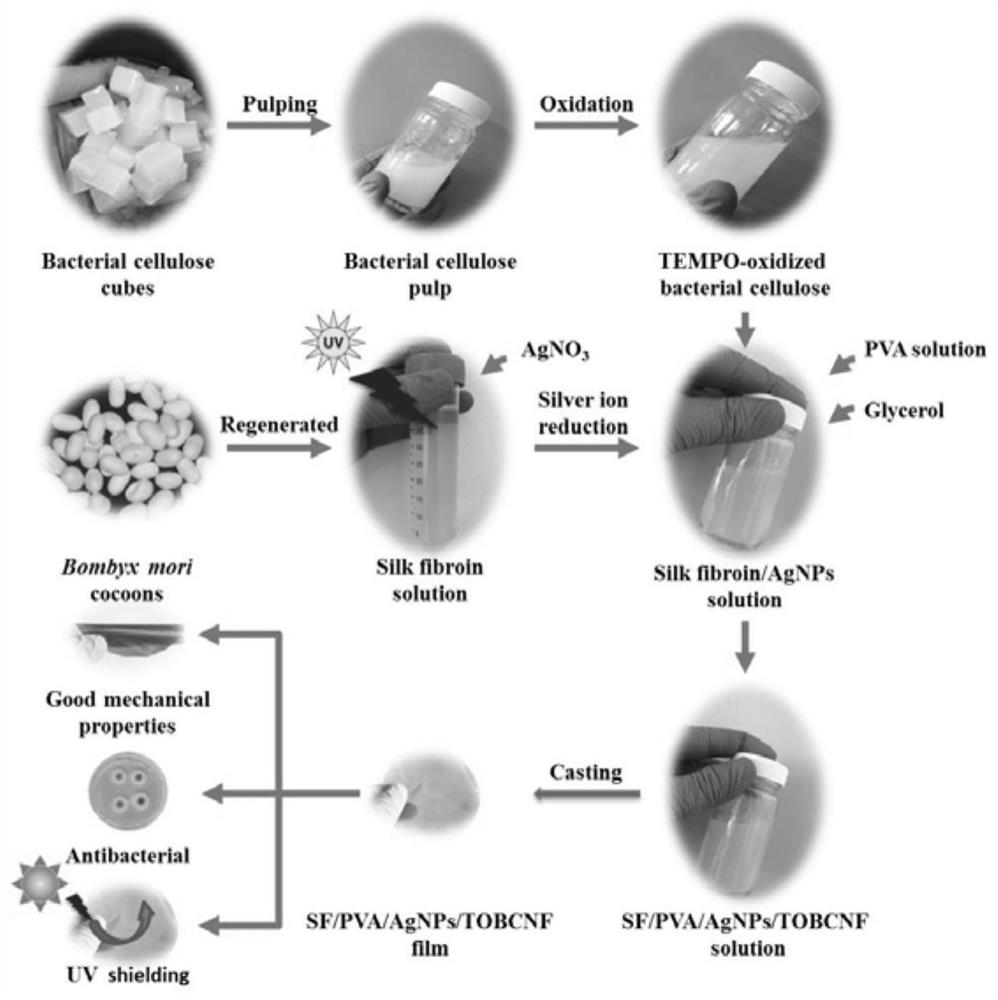

[0033] A preparation method of silk protein oxidized bacterial cellulose nanocomposite film, comprising the following steps:

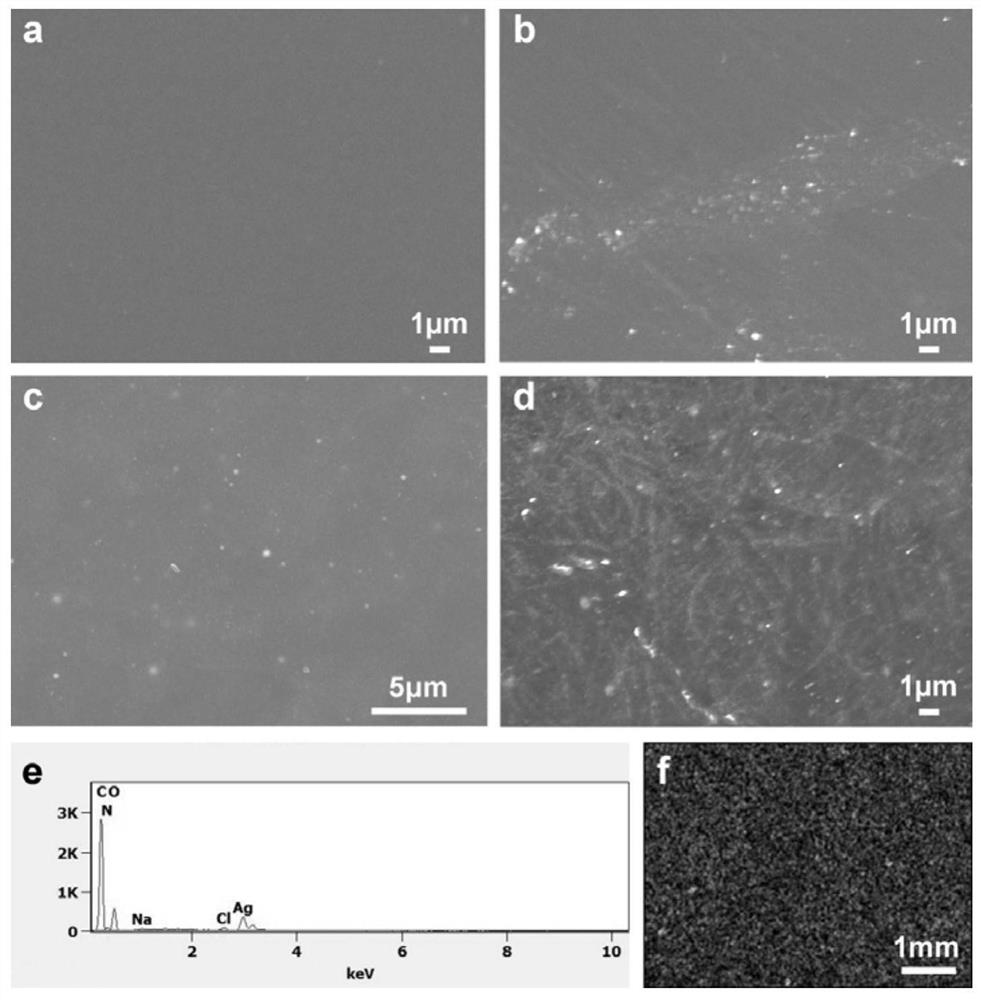

[0034] S1. Preparation of silk fibroin / nano-silver colloidal solution: Add silver nitrate to the regenerated silk fibroin aqueous solution with a concentration of 2wt%, the solid-liquid ratio of silver nitrate and regenerated silk fibroin aqueous solution is 4mg: 1mL, mix and stir evenly to obtain Silk fibroin / silver nitrate mixed solution, and then irradiate the mixed solution to 200w. hr / m 2 , UV irradiation with a wavelength of 300nm and stirring to form a silk fibroin / nano-silver colloidal solution;

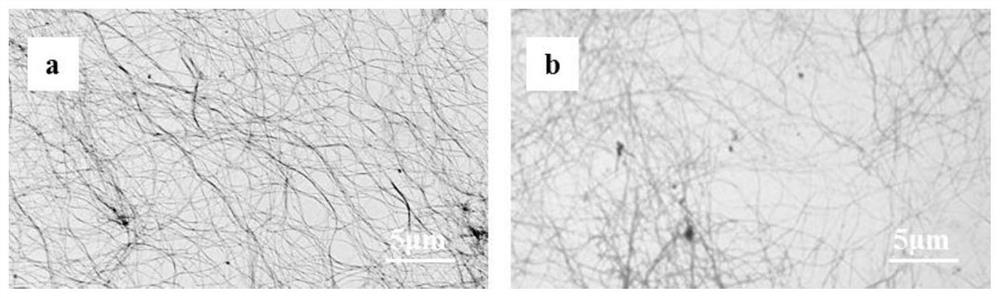

[0035] S2. Preparation of oxidized bacterial cellulose: Pretreat the bacterial cellulose to obtain a bacterial cellulose homogenate with a concentration of 0.1 wt%, and then add a mixed oxidation system of TEMPO / NaBr / NaClO to the bacterial cellulose homogenate, the bacteria Cellulose, TEMPO, the mass ratio of sodium bromide and sodium hypochlorite a...

Embodiment 2

[0038] A preparation method of silk protein oxidized bacterial cellulose nanocomposite film, comprising the following steps:

[0039] S1. Preparation of silk fibroin / nano-silver colloidal solution: Add silver nitrate to the regenerated silk fibroin aqueous solution with a concentration of 2wt%, the solid-liquid ratio of silver nitrate and regenerated silk fibroin aqueous solution is 4mg: 1mL, mix and stir evenly to obtain Silk fibroin / silver nitrate mixed solution, and then irradiate the mixed solution to 200w. hr / m 2 , UV irradiation with a wavelength of 300nm and stirring to form a silk fibroin / nano-silver colloidal solution;

[0040] S2. Preparation of oxidized bacterial cellulose: pretreat the bacterial cellulose to obtain a bacterial cellulose homogenate with a concentration of 0.15 wt%, and then add a mixed oxidation system of TEMPO / NaBr / NaClO to the bacterial cellulose homogenate, the bacteria Cellulose, TEMPO, the mass ratio of sodium bromide and sodium hypochlorite ...

Embodiment 3

[0043] A preparation method of silk protein oxidized bacterial cellulose nanocomposite film, comprising the following steps:

[0044] S1. Preparation of silk fibroin / nano-silver colloidal solution: Add silver nitrate to the regenerated silk fibroin aqueous solution with a concentration of 2wt%, the solid-liquid ratio of silver nitrate and regenerated silk fibroin aqueous solution is 4mg: 1mL, mix and stir evenly to obtain Silk fibroin / silver nitrate mixed solution, and then irradiate the mixed solution to 300w. hr / m 2 , UV irradiation with a wavelength of 250nm and stirring to form a silk fibroin / nano-silver colloidal solution;

[0045] S2. Preparation of oxidized bacterial cellulose: Pretreat the bacterial cellulose to obtain a bacterial cellulose homogenate with a concentration of 0.1 wt%, and then add a mixed oxidation system of TEMPO / NaBr / NaClO to the bacterial cellulose homogenate, the bacteria Cellulose, TEMPO, the mass ratio of sodium bromide and sodium hypochlorite a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com