Method for preparing graphene-based titanium dioxide composite photocatalyst by radiation of electron beams

A technology of electron beam irradiation, titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

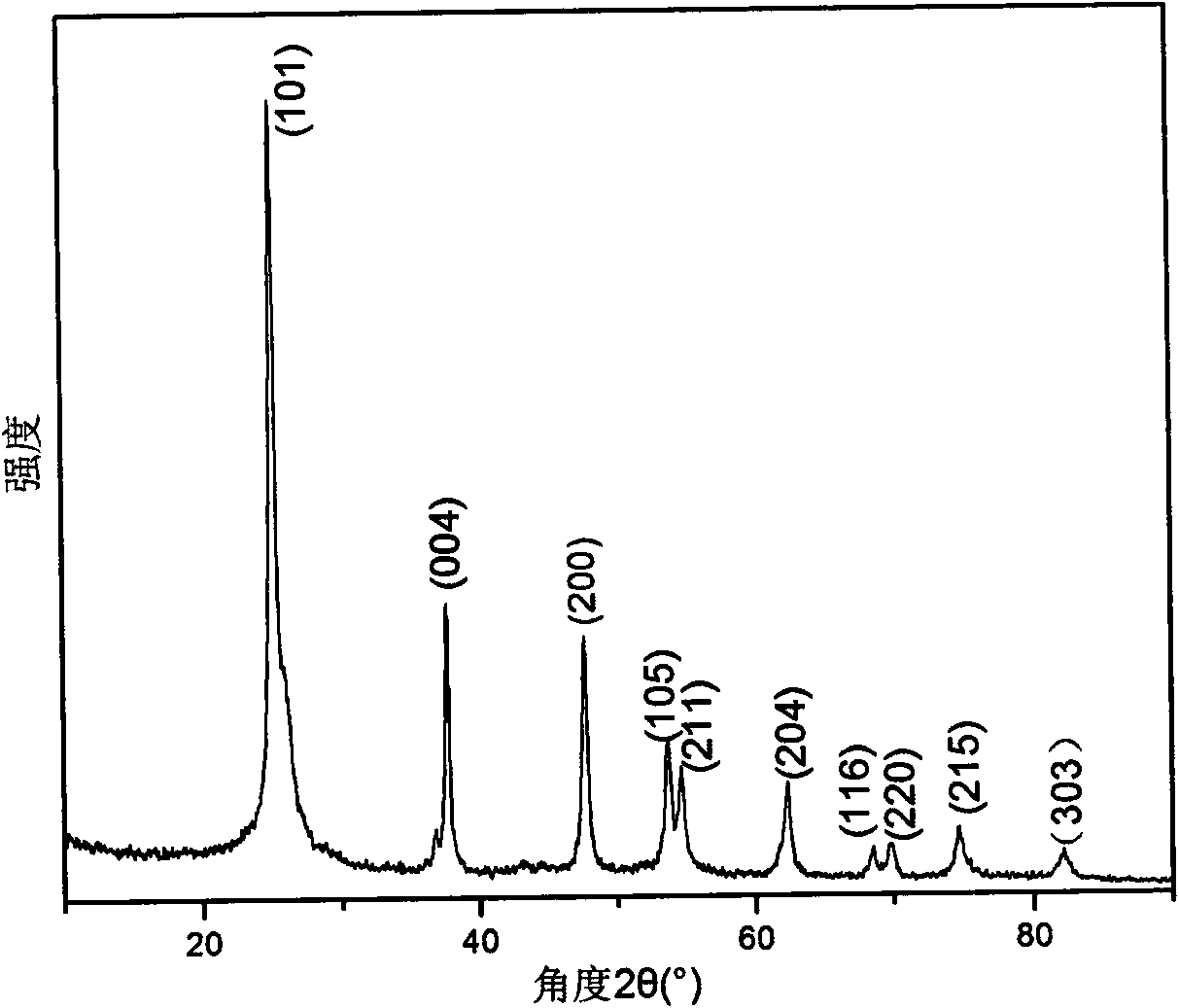

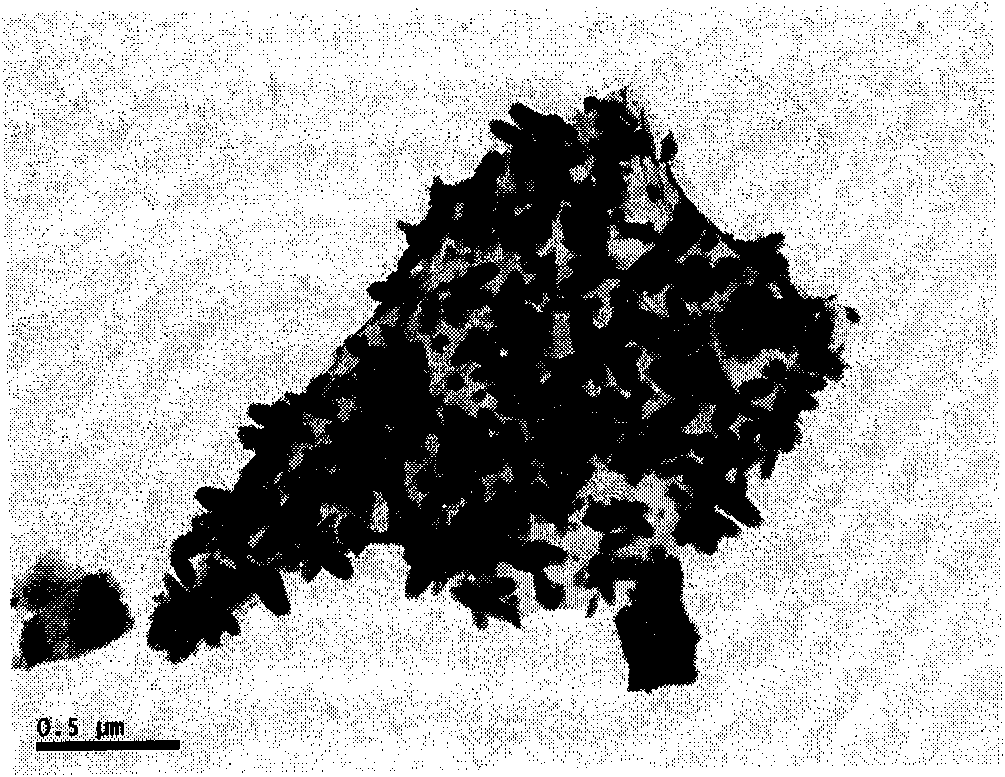

Image

Examples

Embodiment

[0028] Firstly, graphene is prepared according to the prior known technology (this technical method can refer to the document J.Am.Chem.Soc., 2008, 130(18), 5856-5857).

[0029] 1. Preparation of graphene

[0030] (1), preparation of graphene oxide

[0031] A certain amount of potassium persulfate (K 2 S 2 o 8 ) and phosphorus pentoxide (P 2 o 5 ) was dissolved in concentrated sulfuric acid, heated to 80°C, added a certain amount of natural graphite, kept at 80°C for 4.5 hours, and then cooled to room temperature; then diluted with deionized water, and left overnight; then filtered, washed, and the obtained filter residue was released Dry in a vacuum oven at 60°C; dissolve the dried filter residue in concentrated sulfuric acid, and slowly add potassium permanganate (KMnO 4 ), stirred at 35°C for 2 hours; then diluted with deionized water, and slowly added 30% hydrogen peroxide (H 2 o 2 ); then filter and wash, and vacuum-dry the washed product at 60° C. to obtain a gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com