Preparation method of barium titanate powder body

A powder, metatitanic acid technology, used in chemical instruments and methods, calcium carbonate/strontium/barium, titanium compounds, etc., can solve the problems of uneven product particle size, narrow particle distribution, single morphology, etc. Material properties and chemical activity, narrow particle distribution, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

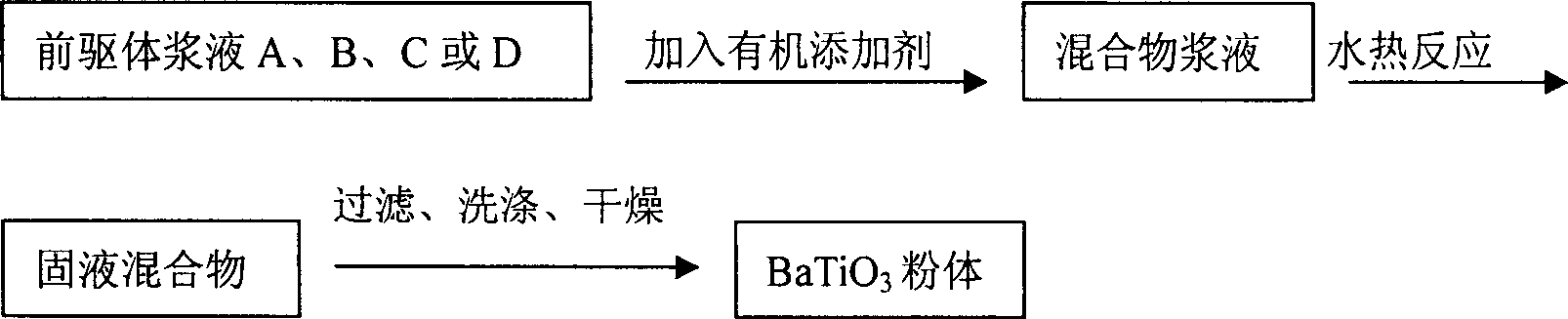

Method used

Image

Examples

Embodiment 1

[0019] Proportional to 38gTiCl 4 Slowly add 200g of water under stirring to obtain a concentration of 7% (as TiO 2 count) TiOCl 2 Aqueous solution, during which TiCl is absorbed by water 4 Hydrogen chloride gas released by hydrolysis; subsequently to TiOCl 2 Add 18.6g BaCl to the solution 2 solid, and stirred to completely dissolve; then, under stirring conditions, add solid sodium hydroxide to the solution until the pH value of the system reaches 7, continue to add solid sodium hydroxide, so that the alkali concentration of the system is 2.0mol / L, stir fully to make the system Uniformly; Finally, add 18mL ethanol to the above slurry, stir to disperse evenly; put the mixture into a reaction kettle, react at 180°C for 12 hours, and cool the reaction kettle to room temperature naturally, filter the product, wash with deionized water, Dry at 120 °C for 2 hours to obtain nano-BaTiO 3 Powder. The powder has a cubic phase structure, and the particles are uniform spherical with...

Embodiment 2

[0021] Proportional to 38gTiCl 4 Slowly add 200g of water under stirring to obtain a concentration of 7% (as TiO 2 count) TiOCl 2 Aqueous solution, during which TiCl is absorbed by water 4 Hydrogen chloride gas released by hydrolysis; subsequently to TiOCl 2 Add 18.6g BaCl to the solution 2 solid, and stirred to completely dissolve; then, under stirring conditions, add solid sodium hydroxide to the solution until the pH value of the system reaches 7, continue to add solid sodium hydroxide, so that the alkali concentration of the system is 2.0mol / L, stir fully to make the system uniform; finally add 18mL triethylenetetramine to the above slurry, stir to disperse evenly; put the mixture into the reaction kettle, react at 180°C for 12 hours, the reaction kettle is naturally cooled to room temperature, filter the product, and use Washed with ion water and dried at 120°C for 2 hours to obtain nano BaTiO 3 Powder. The powder has a cubic phase structure, the particles are unifo...

Embodiment 3

[0023] Proportional to 61 grams of TiCl 4 Slowly add 200 grams of deionized water under stirring to obtain a concentration of 10% (as TiO 2 count) TiOCl 2 Aqueous solution, during which TiCl is absorbed by water 4 Hydrogen chloride gas released by hydrolysis; then heat the solution to 110°C under stirring, keep it warm for 2 hours, cool to room temperature, filter and wash to obtain metatitanic acid. Add metatitanic acid and 202g of barium hydroxide octahydrate to 350g of deionized water, stir and beat to make the mixture uniform, put the slurry into the reaction kettle, and conduct a hydrothermal reaction at 200°C for 2 hours, the reaction kettle is naturally cooled to room temperature, and the product is Filter, wash with deionized water, and dry at 120°C for 2 hours to obtain BaTiO 3 Powder. The powder has a cubic phase structure, the particles are uniform spherical, the particle size is 100-120nm, and the transmission electron microscope observation has good dispersion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com