Graphene/titanium dioxide composite adopting hollow microspherical structure and preparation method of composite

A graphene composite and titanium dioxide technology, applied in the direction of microsphere preparation, chemical instruments and methods, microcapsule preparation, etc., can solve the problems of limited application range, cumbersome synthesis process, small specific surface area, etc., and achieve low cost and simple operation method , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

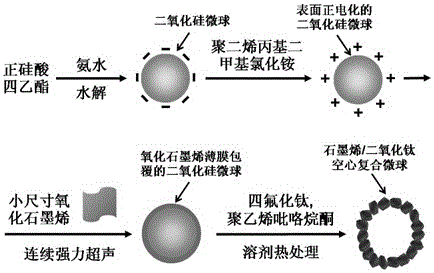

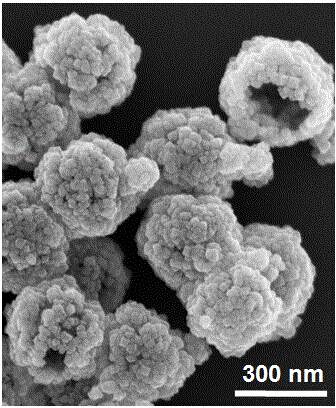

[0025] Embodiment 1: The method provided by the invention is used to prepare graphene / titanium dioxide hollow composite microspheres

[0026] (1) Silica colloidal microspheres with an average particle size of 220 nm were prepared according to a slightly improved St?ber method [(a) Wang, W.; Gu, B.; Liang, L.; Hamilton, W.A. J.Phys.Chem.B 2003, 107 , 3400-3404. (b) Wang, W.; Gu, B.; Liang, L.; Hamilton, W.A. J.Phys.Chem.B 2003, 107 ,12113-12117.].

[0027] (2) The silica microspheres prepared in step (1) were coated with a layer of graphene oxide by ultrasonic-assisted self-assembly method to obtain a silica / graphene oxide composite microsphere with an average particle size of 220nm (Xiao , W.; Zhang, Y.; Liu, B. ACS Appl. Mater. Interfaces 2015, 7 , 6041-6046.).

[0028] (3) Ultrasonically disperse 10 mg of the silica / graphene oxide composite microspheres in step (2) in 2 mL of water, then add dropwise to 20 mL of absolute ethanol under ultrasonic conditions, and then...

Embodiment 2

[0031] Embodiment 2: Graphene / titanium dioxide hollow composite microspheres prepared in the present invention are used for the photodegradation of methylene blue:

[0032] (1) Prepare a methylene blue aqueous solution with a concentration of 10 mg / L, get 48 mL of it and add it to the reaction tube, and then ultrasonically disperse the 5 mg graphene / titanium dioxide hollow composite microsphere sample prepared in Example 1 in 2 mL of methylene blue with a concentration of 10 mg / L aqueous solution, and then added dropwise to the above-mentioned reaction tube under stirring condition.

[0033] (2) Place the reaction tube in step (1) in a photochemical reaction instrument (its brand model is Qiaoyue JOYN-GHX-A type), use a high-pressure mercury lamp as an ultraviolet light source, set the power to 300W, and vigorously stir The photocatalytic reaction was carried out under the following conditions, and then 4 mL of dispersion liquid was pipetted from the reaction system every 5 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com