Titanium dioxide mesoporous microsphere photocatalytic material co-doped with nitrogen and fluorine and preparation method of material

A photocatalytic material, titanium dioxide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of long reaction time, difficult to popularize and apply, and achieve high reuse rate and high practicality The effect of value and process is simple and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

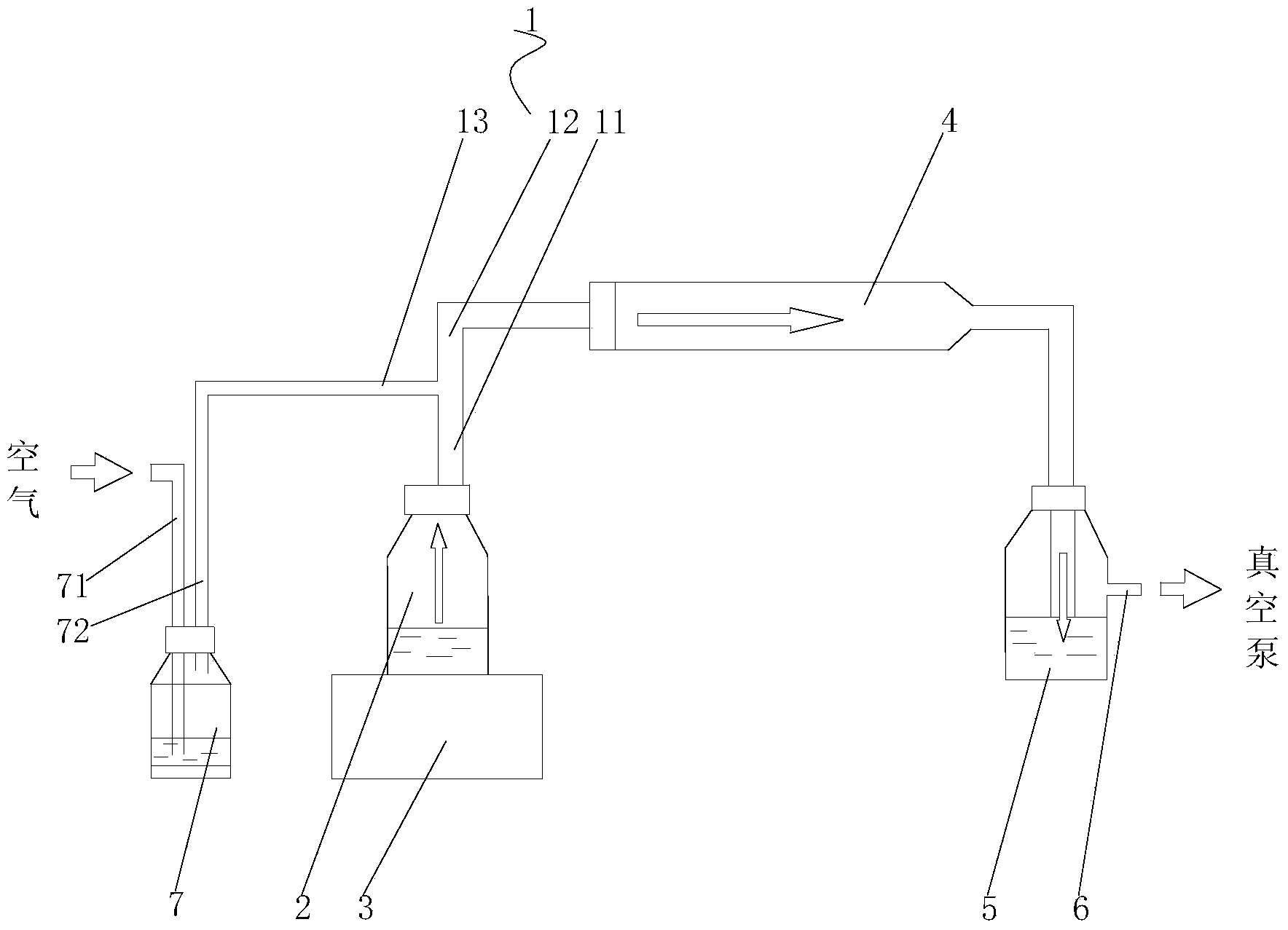

[0042] The preparation method is an ultrasonic atomization method, which includes the following steps:

[0043] 1) Dissolving titanium tetrafluoride in a hydrochloric acid solution with a concentration of 1.0 mol / L and stirring for 1-3 hours to obtain a transparent precursor;

[0044] 2) The precursor liquid is atomized in the reaction bottle under the action of an ultrasonic atomizer, and forms an aerosol rich in tiny droplets together with ammonia gas, the frequency of the ultrasonic atomizer is 1.7 MHz;

[0045] 3) The aerosol is driven by the vacuum pump into the high-temperature tube furnace. Each aerosol forms a microreactor in the tube furnace. The reaction temperature is 500-600 ℃, and the ammonia flow rate is 10-30 L / min. The reaction process The middle titanium tetrafluoride is hydrolyzed to form titanium dioxide. Nitrogen and fluorine are doped into the titanium dioxide crystal and form spherical granular solid powder;

[0046] 4) Driven by the vacuum pump, the solid powder...

Embodiment 1

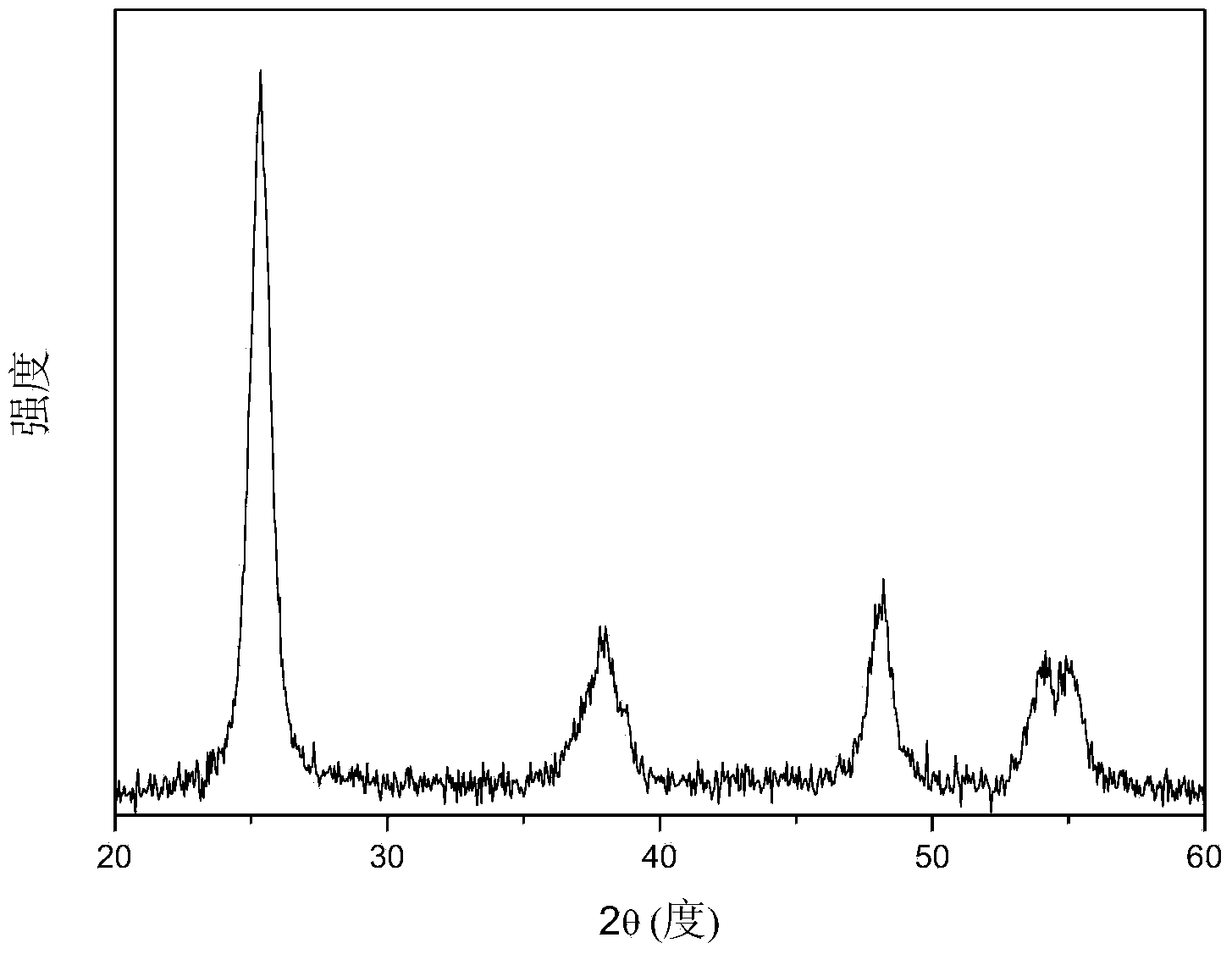

[0051] 1.5 g of titanium tetrafluoride was dissolved in a hydrochloric acid solution with a concentration of 1.0 mol / L. After 2 hours of stirring, a transparent solution was obtained; the solution was atomized in an ultrasonic atomizer with a frequency of 1.7 MHz, and the carrier gas The aerosol belt enters the high temperature tube furnace (500 ℃) to react; the flow rate of the carrier gas is 10 L / min, the carrier gas does not pass through the ammonia solution, and the solid powder generated is collected with distilled water after the tube furnace, washed, centrifuged Drying at 85°C; the obtained solid powder is continuously calcined in a muffle furnace at 550°C for 2.5 hours at a heating rate of 5°C / min to obtain a fluorine-doped titanium dioxide mesoporous microsphere photocatalytic material, which is used as a fluorine and nitrogen co- Comparative example of doped titanium dioxide mesoporous microspheres.

Embodiment 2

[0053] 1.5 g of titanium tetrachloride was dissolved in a hydrochloric acid solution with a concentration of 1.0 mol / L, and after 2 hours of stirring, a transparent solution was obtained; the solution was atomized in an ultrasonic atomizer with a frequency of 1.7 MHz, The aerosol is carried by the carrier gas into the high temperature tube furnace (500 ℃) for reaction; the flow rate of the carrier gas is 10 L / min, and the carrier gas first passes through the ammonia aqueous solution with the concentration of 5 mol / L to make the carrier gas rich in ammonia ; After the tube furnace, collect the resulting solid powder with distilled water, wash it, centrifuge and dry it at 85°C; the obtained powder solid will continue to be calcined in the muffle furnace at 550°C for 2.5 hours at a heating rate of 5°C / min To obtain a yellow nitrogen-doped titanium dioxide mesoporous microsphere photocatalytic material, which is used as a comparative example of fluorine and nitrogen co-doped titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com