Preparation method of layered stacked TiO2/MoS2 core-shell structural composite material as lithium ion battery cathode

A lithium-ion battery, core-shell structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of low energy density of negative electrode materials, rate performance, and cycle performance that cannot meet the needs of electric vehicle development, etc. The effect of uniform sample size, high crystallinity and large discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

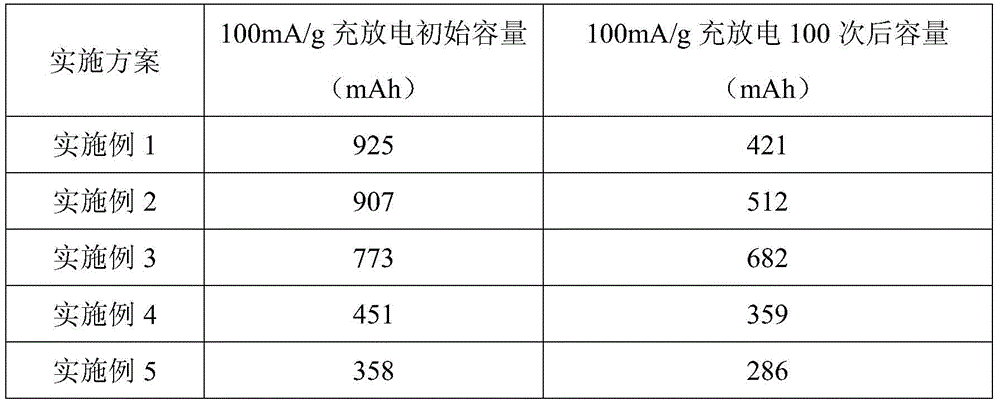

Examples

Embodiment 1

[0023] The method of the present invention comprises the following steps:

[0024] S1: Dissolve 0.1g titanium tetrafluoride in 40ml benzyl alcohol;

[0025] S2: Pour the above solution into a hydrothermal kettle with a volume of 50ml, raise the temperature to 180 degrees, and keep it for 12 hours;

[0026] S3: Centrifuge the obtained product, after cleaning, dry it at 60°C and anneal at 500°C for 2 hours to obtain TiO 2 ;

[0027] S4: Weigh 30mg of TiO 2 , 30mg of oxalic acid, 60mg of sodium molybdate, 120mg of thioacetamide were added to 80ml of deionized water, fully stirred and then poured into a hydrothermal kettle with a volume of 100ml, heated to 200 degrees, and reacted for 20 hours;

[0028] S5: Centrifuge the obtained product, after cleaning, dry it at 60 degrees to obtain TiO 2 / MoS 2 Core-shell composites.

Embodiment 2

[0030] The method of the present invention comprises the following steps:

[0031] S1: Dissolve 0.1g titanium tetrafluoride in 40ml benzyl alcohol;

[0032] S2: Pour the above solution into a hydrothermal kettle with a volume of 50ml, raise the temperature to 180 degrees, and keep it for 12 hours;

[0033] S3: Centrifuge the obtained product, after cleaning, dry it at 60°C and anneal at 500°C for 2 hours to obtain TiO 2 ;

[0034] S4: Weigh 30mg of TiO 2 After adding 80ml of deionized water to 30mg of oxalic acid, 45mg of sodium molybdate, and 90mg of thioacetamide, pour it into a hydrothermal kettle with a volume of 100ml after fully stirring, heat up to 200 degrees, and react for 20 hours;

[0035] S5: Centrifuge the obtained product, after cleaning, dry it at 60 degrees to obtain TiO 2 / MoS 2 Core-shell composites.

Embodiment 3

[0037] The method of the present invention comprises the following steps:

[0038] S1: Dissolve 0.1g titanium tetrafluoride in 40ml benzyl alcohol;

[0039] S2: Pour the above solution into a hydrothermal kettle with a volume of 50ml, raise the temperature to 180 degrees, and keep it for 12 hours;

[0040] S3: Centrifuge the obtained product, after cleaning, dry it at 60°C and anneal at 500°C for 2 hours to obtain TiO 2 ;

[0041] S4: Weigh 30mg of TiO 2 , 30mg of oxalic acid, 30mg of sodium molybdate, 60mg of thioacetamide were added to 80ml of deionized water, fully stirred and then poured into a hydrothermal kettle with a volume of 100ml, heated to 200 degrees, and reacted for 20 hours;

[0042] S5: Centrifuge the obtained product, wash it, and dry it at 60 degrees to obtain a TiO2 / MoS2 core-shell structure composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com