Titanium fluoride modified load type chrome alum double-active center catalyst and preparation method thereof

A supported catalyst technology, applied in the field of supported chromium vanadium double-active center catalysts and its preparation, can solve the problems of poor comonomer insertion effect, insignificant improvement of polymerization activity, and inability to improve copolymerization performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0126] The preparation methods mentioned in the examples are conventional methods unless otherwise specified. The materials are commercially available unless otherwise specified. The silica gel used in the examples is commercially available Davison955.

[0127] Various polymer properties in the examples were measured according to the following methods:

[0128] High Temperature Gel Chromatography (HT-GPC)

[0129] The weight-average molecular weight and molecular weight distribution of polyethylene products are determined by high-temperature gel chromatography: In this experiment, PL-220 high-temperature gel permeation chromatography (Polymer Laboratories Company) is used to determine the molecular weight of polyethylene and its molecular weight distribution. In the experiment, 1,2,4-trichlorobenzene was used as solvent and measured at 160°C. Data were processed using a universal calibration method using narrow distribution polystyrene as the standard.

[0130] Differentia...

Embodiment 1

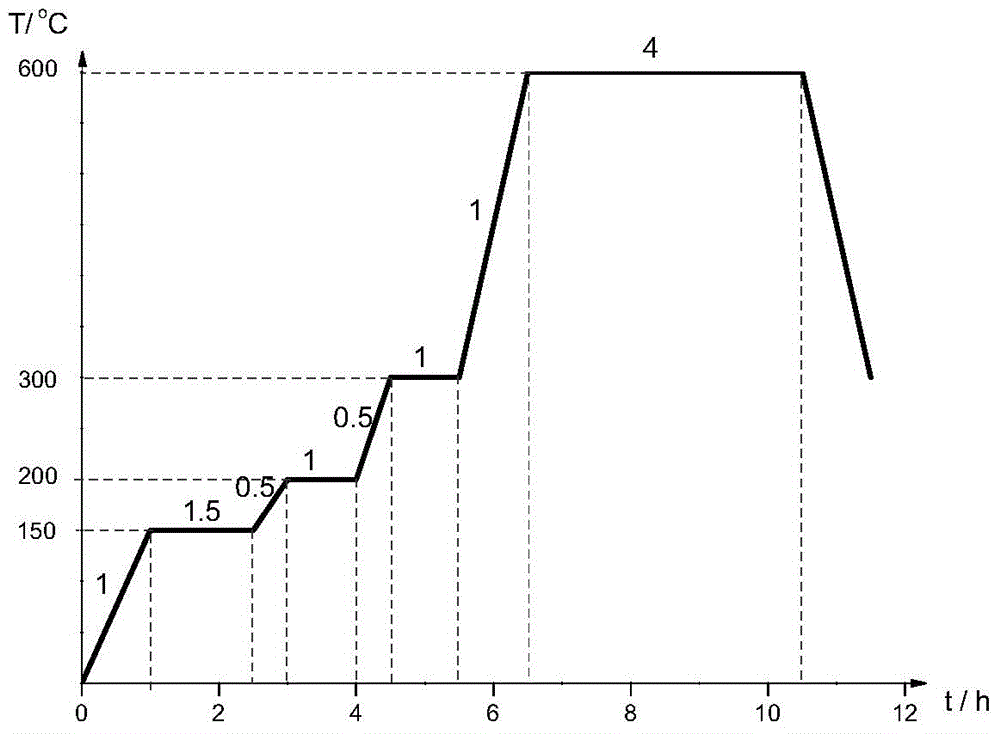

[0133] Put 10g of silica gel (pore volume is 1.5 ~ 1.7cm 3 / g, the surface area is 250~300m 2 / g) immersed in a n-hexane solution of tetra-n-butyl titanate (titanium loading: 3wt%), after continuous stirring for 4 hours, dry at 80°C in an oil bath for 4 hours, and then use vacuum drying for 2 hours to further remove the solvent in the silica gel carrier channel , transferred to a blast drying oven at 80°C for 8 hours; then the dried samples were roasted and activated in a fluidized bed, kept at 600°C for 4 hours under high-purity air, and the silica gel was finally cooled down naturally under nitrogen. The above-mentioned roasting procedure is as follows: figure 1 As shown, the titanium dioxide modified silica gel prepared by the impregnation method was obtained. The obtained titanium-modified silica gel was immersed in an aqueous solution of ammonium hexafluorosilicate (the fluorine load was 1.5 wt%). After continuous stirring for 4 hours, dry in an oil bath at 120°C for 6 ...

Embodiment 2

[0135] Put 10g of silica gel (pore volume is 1.5 ~ 1.7cm 3 / g, the surface area is 250~300m 2 / g) immersed in a n-hexane solution of tetra-n-butyl titanate (titanium loading: 3wt%), after continuous stirring for 4 hours, dry at 80°C in an oil bath for 4 hours, and then use vacuum drying for 2 hours to further remove the solvent in the silica gel carrier channel , transferred to a blast drying oven at 80°C for 8 hours; then the dried samples were roasted and activated in a fluidized bed, kept at 600°C for 4 hours under high-purity air, and the silica gel was finally cooled down naturally under nitrogen. The above-mentioned roasting procedure is as follows: figure 1 As shown, the titanium dioxide modified silica gel prepared by the impregnation method was obtained. The obtained titanium-modified silica gel was immersed in an aqueous solution of ammonium hexafluorosilicate (the fluorine load was 1.5 wt%). After continuous stirring for 4 hours, dry in an oil bath at 120°C for 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com