Organic-inorganic hybrid fluorine titanium potassium red-light fluorescent powder and preparation method thereof

A technology of red fluorescent powder and hybridization, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of poor moisture resistance, decreased luminous intensity, no luminescence, etc., and achieve high luminescence with low requirements for reaction conditions Thermal stability, the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

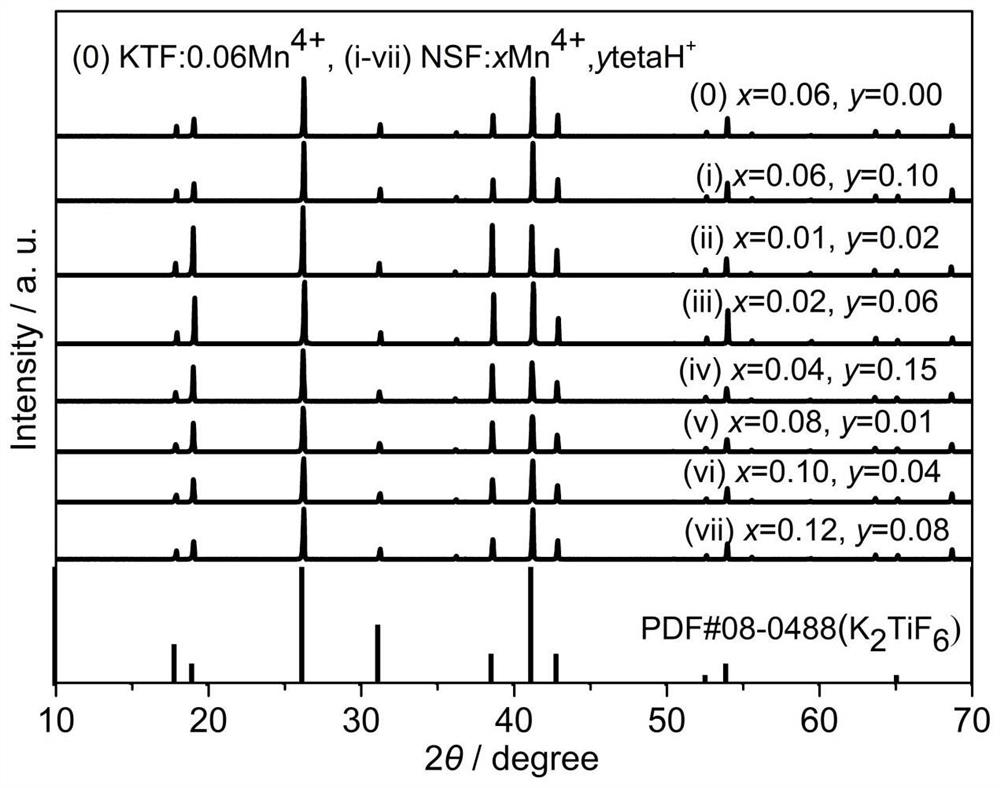

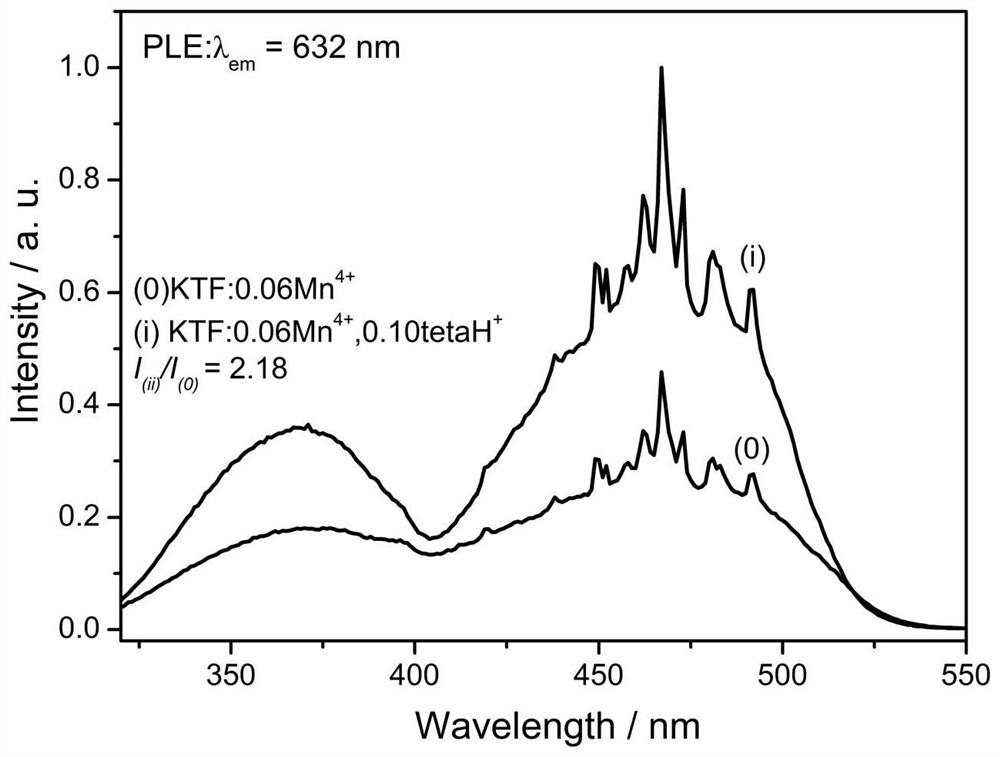

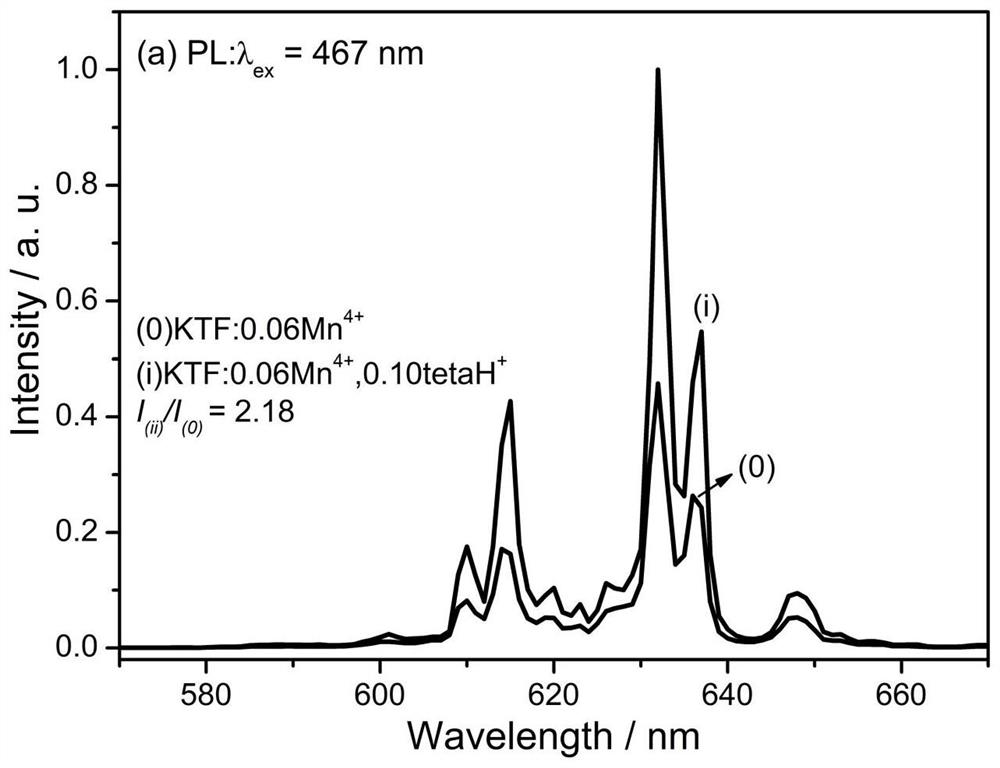

[0035] Embodiment 1: Preparation [KTF:0.06Mn 4+ ,0.10tetaH + ]

[0036] (1) First, under stirring, add 1.4623g (10mmol) of tetra dropwise to 48.01g (100mmol) of 50% H 2 TiF 6 H in solution 2 TiF 6 -tetaH + Mix the solution, then add 11.06g (80.0mmol) K 2 CO 3 Added to 30mL of deionized water, stirred until completely dissolved to obtain K 2 CO 3 solution; then, under stirring, the K 2 CO 3 The solution was added dropwise to the above H 2 TiF 6 -tetaH + After dripping the mixed solution until the pH is 7.0, continue to stir for 30 minutes, then seal the mouth of the beaker with plastic wrap and place it in an oven at 90°C for 3 hours; finally remove the plastic wrap and place it in an oven at 120°C Under drying for 4h, to obtain the intermediate K 2 TiF 6 :0.10tetaH + ;

[0037] (2) get 12.39mLHF solution (mass concentration 40%) (V HF / W 基质 =3.0mL / g), 0.413g KF·2H 2 O(W KF / W 基质 =0.1), 0.2966g (1.2mmol) K 2 MnF 6 The powder is placed in a 50mL plastic ...

Embodiment 2

[0046] Embodiment 2: preparation [KTF:0.01Mn 4+ ,0.02tetaH + ]

[0047] (1) First, under stirring, add 0.2925g (2mmol) of tetra dropwise to 48.01g (100mmol) of 50% H 2 TiF 6 H in solution 2 TiF 6 -tetaH + Mix the solution, then add 13.27g (96.0mmol) K 2 CO 3 Add 30mL of deionized water and stir until completely dissolved to obtain K 2 CO 3 solution; then, under stirring, the K 2 CO 3 The solution was added dropwise to the above H 2 TiF 6 -tetaH + After dropping the mixed solution until the pH is 7.0, continue to stir for 20 minutes, then seal the mouth of the beaker with a plastic wrap and place it in an oven for 3.5 hours at 85°C; finally remove the plastic wrap and place it in an oven at 130°C Dry at ℃ for 3h, to obtain intermediate K 2 TiF 6 :0.02tetaH + ;

[0048] (2) get 4.4mLHF solution (mass concentration 40%) (VHF / W 基质 =1.0mL / g), 0.872g KF·2H 2 O(W KF / W 基质 =0.2), 0.0494g (0.2mmol) K 2 MnF 6 The powder is placed in a 50mL plastic beaker, stirre...

Embodiment 3

[0051] Embodiment 3: preparation [KTF:0.02Mn 4+ ,0.06tetaH + ]

[0052] (1) First, under stirring, add 0.8774g (6mmol) of tetra dropwise to 48.01g (100mmol) of 50% H 2 TiF 6 H in solution 2 TiF 6 -tetaH + Mix the solution, then put 12.16g (88.0mmol) K 2 CO 3 Add 30mL of deionized water and stir until completely dissolved to obtain K 2 CO 3 solution; then, under stirring, the K 2 CO 3 The solution was added dropwise to the above H 2 TiF 6 -tetaH + After dropping the mixed solution until the pH is 7.0, continue stirring for 25 minutes, then seal the mouth of the beaker with plastic wrap and place it in an oven at 95°C for 4 hours; finally remove the plastic wrap and place it in an oven at 130°C Under drying for 3.5h, intermediate K was obtained 2 TiF 6 :0.06tetaH + ;

[0053] (2) Take 19.63mL HF solution (mass concentration 40%) (V HF / W 基质 =4.0mL / g), 1.4723g KF 2H 2 O(W KF / W 基质 =0.3), 0.0989g (0.4mmol) K 2 MnF 6 The powder is placed in a 50mL plastic b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com