Red fluorescent powder with high luminous intensity, thermal stability and water resistance and preparation method thereof

A technology of red phosphor and thermal stability, which is applied in the direction of luminescent materials, chemical instruments and methods, electrical components, etc., and can solve the problems of inactivation, low thermal stability, and non-luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

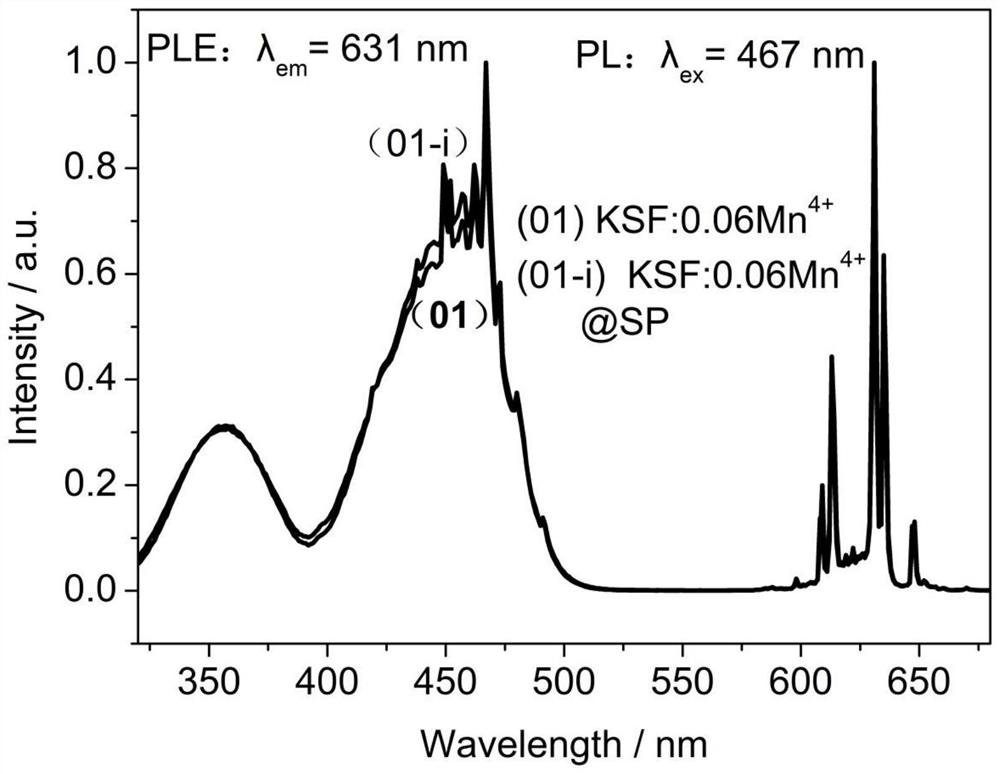

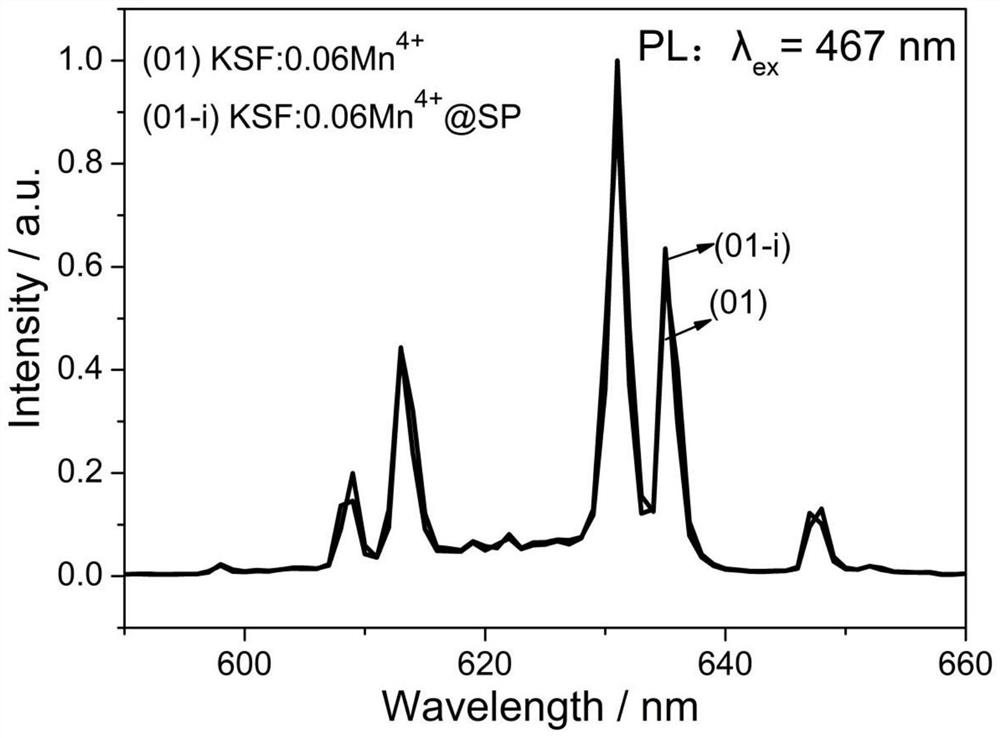

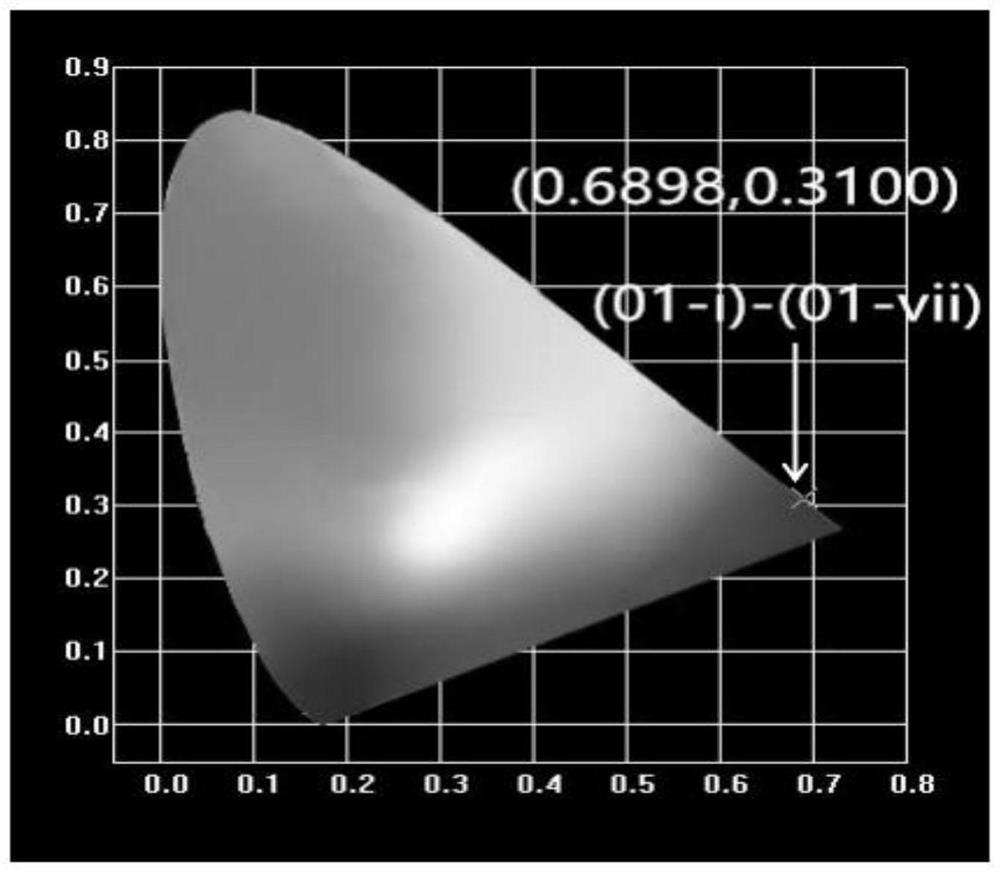

[0043] Embodiment 1. Preparation [K 2 SiF 6 :0.06Mn 4+ -SP], referred to as (KSF:0.06Mn 4+ -SP)

[0044] (1) Get 18.63mLHF solution (mass concentration 40%) (V HF / W K2SiF6 =0.9mL / g), 8.28gKF·2H 2 O(W KF / W K2SiF6 =0.4), 0.9482g (6mmol) KMnO 4 The powder is placed in a 200mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid material is completely dissolved to obtain a purple solution; then 20.71g (94.0mmol) K 2 SiF 6 Powder is added in the above-mentioned solution (x=(KMnO 4 / (K 2 SiF 6 +KMnO 4 ), x=0.06), seal the mouth of the beaker with plastic wrap, stir and react at normal temperature and pressure for 40h to obtain the reactant mixture (i), and the reaction mixture (i) is filtered with absolute ethanol After washing, dry at 80°C for 3.5 hours to obtain KSF without surface modification: 0.06Mn 4+ (Sample No. (01));

[0045] (2) Add 80 mL of 20% hydrofluoric acid (mass percentage concentration) to the reaction...

Embodiment 2

[0054] Embodiment 2. preparation [K 2 SiF 6 :0.01Mn 4+ -SP], referred to as (KSF:0.01Mn 4+ -SP)

[0055] Get 20.72mLHF solution (mass concentration 40%) (V HF / W K2SiF6 =0.95mL / g), 10.90gKF·2H 2 O(W KF / W K2SiF6 =0.50), 0.1580g (1.0mmol) KMnO 4 The powder is placed in a 200mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid material is completely dissolved to obtain a purple-red solution; then 21.72g (99.0mmol) K 2 SiF 6 Powder is added in the above-mentioned solution (x=(KMnO 4 / (K 2 SiF 6 +KMnO 4 ), x=0.01), seal the mouth of the beaker with plastic wrap, stir and react at normal temperature and pressure for 45h to obtain the reaction mixture (i);

[0056] Then add 80 mL of 20% hydrofluoric acid (mass percentage concentration) to the above-mentioned reaction mixture (i) under stirring and stir evenly, then slowly add 21.72 g of oxalic acid powder, continue stirring for 15 min after adding, and filter under reduc...

Embodiment 3

[0059] Embodiment 3. preparation [K 2 SiF 6 :0.02Mn 4+ -SP], referred to as (KSF:0.02Mn 4+ -SP)

[0060] Get 21.59mLHF solution (mass concentration 40%) (V HF / W K2SiF6 =1.00mL / g), 11.58gKF·2H 2 O(W KF / W K2SiF6 =0.60), 0.31611g (2.0mmol) KMnO 4 The powder is placed in a 200mL plastic beaker, stirred with a magnetic stirrer at normal temperature and pressure until the solid raw material is completely dissolved to obtain a purple-red solution; then 21.59g (98.0mmol) K 2 SiF 6 Powder is added in the above-mentioned solution (x=(KMnO 4 / (K 2 SiF 6 +KMnO 4 ), x=0.02), seal the mouth of the beaker with plastic wrap, stir and react at normal temperature and pressure for 50h to obtain the reaction mixture (i);

[0061] Then add 80mL of 20% hydrofluoric acid (mass percentage concentration) to the above-mentioned reaction mixture (i) under stirring and stir evenly, then slowly add 21.59g of oxalic acid powder, continue stirring for 20min after adding, and depressurize Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| internal quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com