Preparation device and preparation method for 2,3,3,3-tetrafluoropropene

A tetrafluoropropene, liquid-phase reaction technology, applied in the field of fluorine chemical industry, can solve the problems of many reaction steps, redundant separation equipment, short catalyst life, etc., and achieves the effects of short process flow, simplified process flow and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

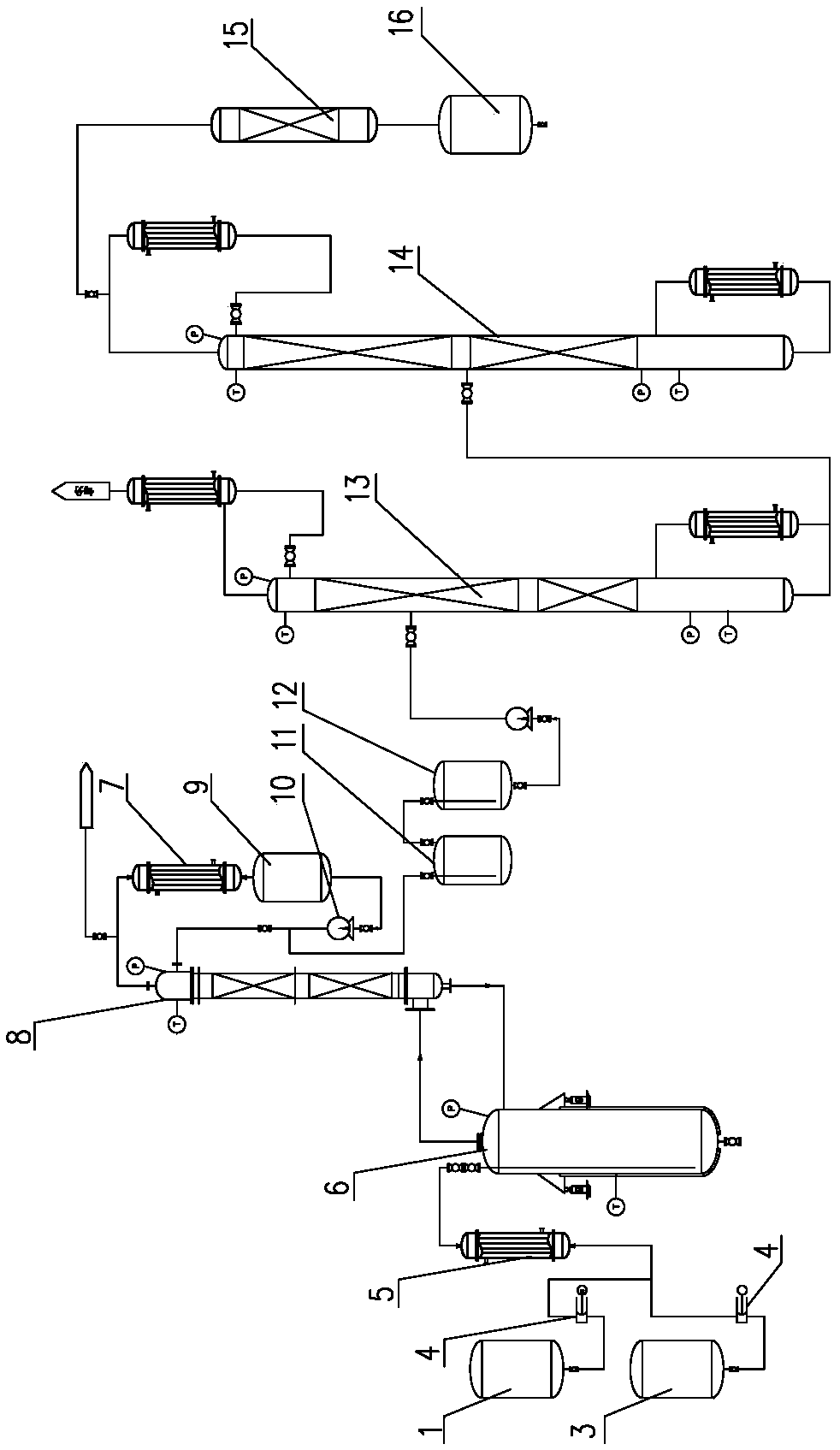

[0046] 1,1,2,3-Tetrachloropropene and hydrogen fluoride pass through the feed pump, and after being preheated by the preheater according to the ratio (3:1), they are injected into the liquid phase reaction kettle loaded with catalyst (catalyst accounts for 10% of the volume of the kettle) 0.3, the catalyst is tin chloride: tin fluoride: antimony chloride = 1:5:4); the temperature of the reactor is 80°C, the pressure is 0.9MPa; the reflux ratio at the top of the tower is controlled at 5:1, the reflux is 2h, and the reflux tank at the top of the tower is detected Inner material composition;

[0047] The composition of the material in the top reflux tank was analyzed by sampling, as shown in Table 1-1.

[0048] The HFO-1234yf crude product is washed with alkali, degassed (the pressure of the tower bottom is 0.5Mpa, the temperature of the tower bottom is 20°C), and rectified (the pressure of the top of the tower is 0.2Mpa, the temperature of the top of the tower is 10°C), and the ...

Embodiment 2

[0055] 1,1,2,3-Tetrachloropropene and hydrogen fluoride pass through the feed pump, and after being preheated by the preheater according to the ratio (3:1), they are injected into the liquid phase reaction kettle loaded with catalyst (catalyst accounts for 10% of the volume of the kettle) 0.5, tin chloride: tin fluoride: antimony chloride = 1:5:4); the temperature of the reactor is 90°C, the pressure is 0.9MPa; the reflux ratio is controlled at the top of the tower at 10:1, and the reflux is 1h, and the material in the reflux tank at the top of the tower is detected composition;

[0056] Analyze the composition of the material in the top reflux tank by sampling, as shown in Table 2-1.

[0057] The HFO-1234yf crude product is washed with alkali, degassed (the pressure of the tower bottom is 0.7Mpa, the temperature of the tower bottom is 25°C), and rectified (the pressure of the top of the tower is 0.3Mpa, the temperature of the top of the tower is 15°C), and the HFO-1234yf prod...

Embodiment 3

[0064] 1,1,2,3-Tetrachloropropene and hydrogen fluoride pass through the feed pump, and after being preheated by the preheater according to the ratio (3:1), they are injected into the liquid phase reaction kettle loaded with catalyst (catalyst accounts for 10% of the volume of the kettle) 0.6, tin chloride: tin fluoride: antimony chloride = 1:5:4)); the temperature of the reactor is 90°C, the pressure is 0.9MPa; material composition;

[0065] Analyze the composition of the material in the top reflux tank by sampling, as shown in Table 3-1.

[0066] The HFO-1234yf crude product is washed with alkali, degassed (tower pressure 0.9Mpa, tower temperature 30°C), and rectified (tower pressure 0.5Mpa, tower top temperature 20°C) to obtain HFO-1234yf product, which is analyzed and tested.

[0067] The composition of the overhead material in the rectification tower was analyzed by sampling, as shown in Table 3-2.

[0068] Table 3-1: Composition of materials in the top reflux tank of E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com