Antibacterial functionalizing-corrosion-resistant modification method for aluminum alloy surface

A technology for surface and functionalization of aluminum alloys, applied in the field of aluminum alloys, can solve the problems of changes in the structure and composition of aluminum alloys, limited antibacterial components, and easy peeling of coatings, and achieves the effect of improving corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

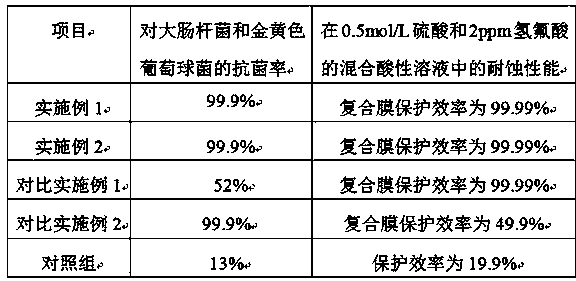

Examples

Embodiment 1

[0026] A method for antibacterial functionalization-corrosion-resistant modification of the surface of an aluminum alloy, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0027] (1) Pretreatment method of aluminum alloy surface:

[0028] The aluminum alloy was polished with sandpaper, cleaned ultrasonically in acetone, rinsed with absolute ethanol and deionized water in sequence, chemically etched for 30 minutes after polishing, heated in a sodium hydroxide solution at 60°C for 30 seconds, and then heated in an oxalic acid electrolyte. Carry out anodic oxidation for 25 minutes in the medium, then ultrasonically clean with absolute ethanol and deionized water for 10 minutes respectively, take it out and dry it in the air, put the aluminum alloy with clean surface into 40°C deionized water, seal it with a plastic wrap and keep it warm for 5 minutes, take it out and dry it in the air Dry hot water treated...

Embodiment 2

[0041] A method for antibacterial functionalization-corrosion-resistant modification of the surface of an aluminum alloy, characterized in that it comprises the following steps, and the following raw materials are calculated by weight:

[0042] (1) Pretreatment method of aluminum alloy surface:

[0043]The aluminum alloy was polished with sandpaper, cleaned ultrasonically in acetone, rinsed with absolute ethanol and deionized water in sequence, chemically etched for 40 minutes after polishing, heated in a sodium hydroxide solution at 65°C for 20 seconds, and then heated in an oxalic acid electrolyte. Anodize in a medium for 35 minutes, then ultrasonically clean with absolute ethanol and deionized water for 20 minutes respectively, take it out and dry it in the air, put the aluminum alloy with clean surface into 80°C deionized water, seal it with a plastic wrap and keep it warm for 3 minutes, then take it out and dry it in the air Dry hot water treated surface activated aluminu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com