Pipe for transporting poisonous gas

A technology for toxic gases and pipes, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems that the inner wall is easily corroded and affects the service life of the pipeline, so as to avoid rain erosion, improve service life, and improve corrosion resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

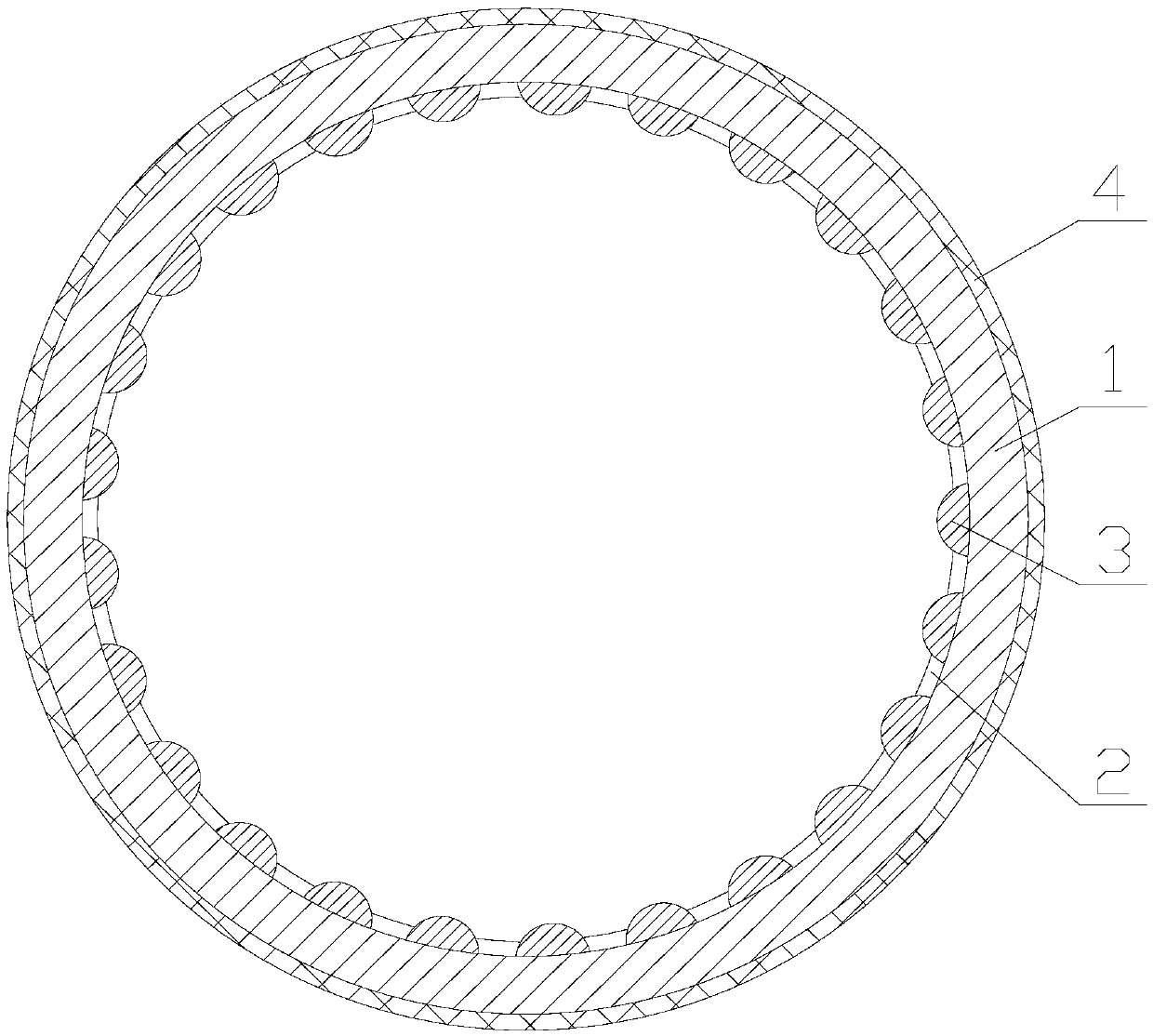

[0020] Such as figure 1 As shown, the present invention is a pipe used for the transportation of toxic gases, comprising a pipe body 1, the inner wall of the pipe body 1 is coated with a layer of corrosion-resistant layer 2, and the inner wall of the pipe body 1 is provided with several wear-resistant protrusions 3, and the wear-resistant The top surface of the protrusion 3 passes through the corrosion-resistant layer 2 and is placed in the inner cavity 11 of the pipe body 1. A protective layer 4 is provided on the outer wall of the pipe body 1. The pipe body 1 is specifically a cement pipe, and the protective layer 4 is specifically polymer cement. Base layer of waterproof coating.

[0021] The wear-resistant protrusions 3 are hemispherical ceramic protrusions with a diameter of 3-6 mm, and the distance between two adjacent wear-resistant protrusions 3 is half of the diameter of the wear-resistant protrusions 3 .

[0022] The thickness of the side wall of the pipe body 1 is ...

Embodiment 2

[0026] Such as figure 1 As shown, the present invention is a pipe used for the transportation of toxic gases, comprising a pipe body 1, the inner wall of the pipe body 1 is coated with a layer of corrosion-resistant layer 2, and the inner wall of the pipe body 1 is provided with several wear-resistant protrusions 3, and the wear-resistant The top surface of the protrusion 3 passes through the corrosion-resistant layer 2 and is placed in the inner cavity 11 of the pipe body 1. A protective layer 4 is provided on the outer wall of the pipe body 1. The pipe body 1 is specifically a cement pipe, and the protective layer 4 is specifically polymer cement. Base layer of waterproof coating.

[0027] The wear-resistant protrusions 3 are hemispherical ceramic protrusions, the diameter of the ceramic protrusions is 4 mm, and the distance between two adjacent wear-resistant protrusions 3 is half of the diameter of the wear-resistant protrusions 3 .

[0028] The thickness of the side wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com