Rust resistance semi-metallic brake pad

A semi-metal and brake pad technology, applied in the field of rust-resistant semi-metal brake pads, can solve the problems of brake drum or brake disc damage, easy corrosion of semi-metal brake pads, high thermal conductivity, long service life and high temperature resistance. The effect of good thermal decay performance and high coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1: by weight 5 parts of tire powder (parts by weight, every part of 100 grams, the same below), 5 parts of expanded graphite, 7 parts of superfine iron oxide powder (300-325 order), 13 parts of phenolic resin, 18 parts Parts of stainless short fiber, 2 parts of cashew nut shell oil friction powder, 3 parts of foamed iron powder, 3 parts of graphite particles, 15 parts of barite (600 mesh), 3 parts of chromite powder (300-350 mesh), 2 parts of magnetic Iron ore powder, 3 parts of light calcium carbonate, 2 parts of heavy magnesium oxide, 9 parts of acicular wollastonite fiber, 1 part of antimony sulfide, and 0.5 part of copper sulfide powder are put into the high-speed disperser, stirred into powder and taken out , put it into the forming mold for pressing and forming, and then compound it with the steel back and put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa for 15 minutes, then take out the brake pads and remove ...

Embodiment 2

[0015] Embodiment 2: by weight 5 parts of tire powder (parts by weight, every part of 100 grams, the same below), 3 parts of expanded graphite, 9 parts of superfine iron oxide powder (300-325 order), 9 parts of phenolic resin, 20 parts Parts of stainless short fiber, 3 parts of cashew nut shell oil friction powder, 5 parts of foamed iron powder, 5 parts of graphite particles, 10 parts of barite (600 mesh), 5 parts of chromite powder (300-350 mesh), 4 parts of magnetic Iron ore powder, 5 parts of light calcium carbonate, 3 parts of heavy magnesium oxide, 11 parts of acicular wollastonite fiber, 2 parts of antimony sulfide, and 1 part of copper sulfide powder are put into the high-speed disperser, stirred into powder and taken out , put it into the forming mold for pressing and forming, and then compound it with the steel back and put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa for 15 minutes, then take out the brake pads and remove t...

Embodiment 3

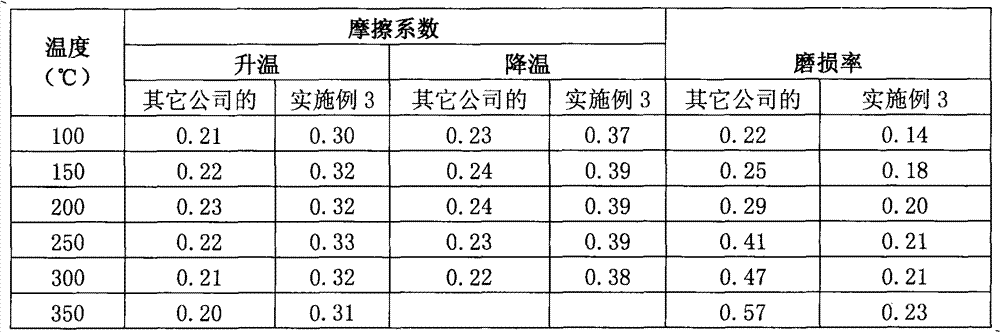

[0016] Embodiment 3: by weight 4 parts of tire powder (parts by weight, every part of 100 grams, the same below), 4 parts of expanded graphite, 10 parts of superfine iron oxide powder (300-325 order), 12 parts of phenolic resin, 15 parts Parts of stainless short fiber, 1.5 parts of cashew nut shell oil friction powder, 4 parts of foamed iron powder, 4 parts of graphite particles, 12 parts of barite (600 mesh), 4 parts of chromite powder (300-350 mesh), 3 parts of magnetic Iron ore powder, 4 parts of light calcium carbonate, 2.5 parts of heavy magnesium oxide, 12 parts of acicular wollastonite fiber, 2 parts of antimony sulfide, and 0.8 part of copper sulfide powder are put into the high-speed disperser, stirred into powder and taken out , put it into the forming mold for pressing and forming, and then compound it with the steel back and put it into a flat vulcanizing machine at a high temperature of 270°C and a pressure of 18MPa for 15 minutes, then take out the brake pads and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com