High-performance micro-prestressing-force thermoplastic intelligent fiber rod and manufacturing method thereof

A micro-prestressed, intelligent optical fiber technology, applied in the fields of sensors, building composite materials, engineering inspection and solid mechanics, can solve problems such as inability to adapt to engineering components, inconvenient end bonding and fixing, affecting sensor sensitivity, etc., to avoid light blocking. , beautiful structure, suitable forming temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0058] 1. Smart Fiber Optic Rod

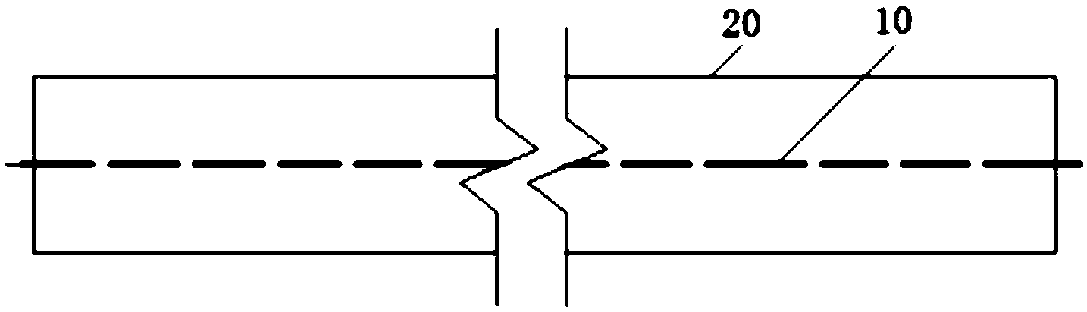

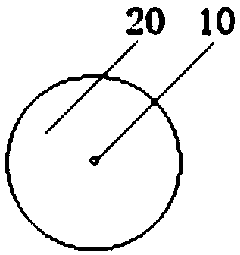

[0059] Such as figure 1 , 2 , the smart optical fiber rod includes a sensing optical fiber 10 and a thermoplastic rod body 20;

[0060] A thermoplastic rod 20 is included outside the sensing fiber 10 .

[0061] The sensing optical fiber 10 is a communication optical fiber applied with micro-prestress.

[0062] The thermoplastic rod body 20 is a polymer material wrapper.

[0063] 2. Production equipment of intelligent optical fiber rod

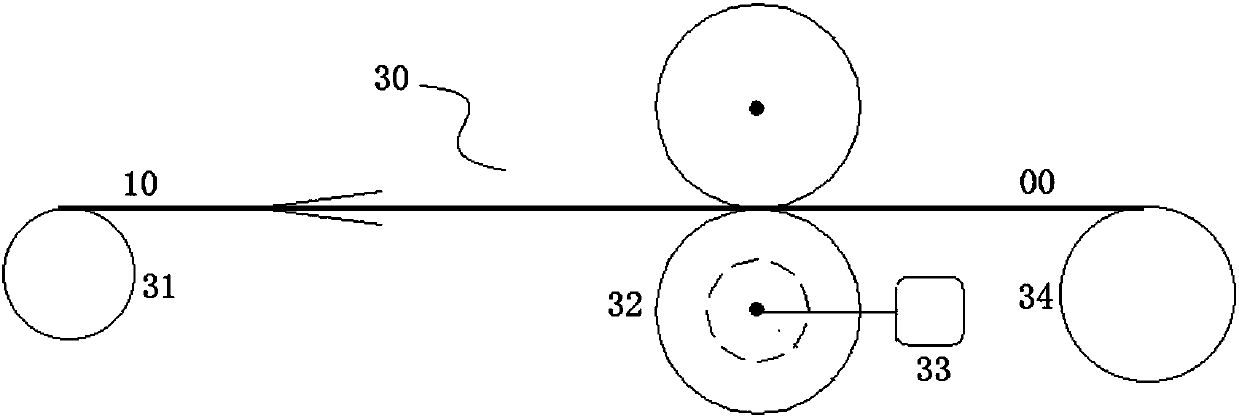

[0064] 1. Traction equipment 30

[0065]Such as figure 2 , The traction device 30 includes a traction wheel 31 , a pressing wheel 32 , a pressing adjustment mechanism 33 and a winding frame 34 .

[0066] 2. Thermoplastic molding line 40

[0067] Such as image 3 , The thermoplastic molding line 40 includes a working chamber 41, a main feeding port 42, an auxiliary feeding port 43 and a feeding port 44, and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com