Preparation method of composite transverse stabilizer bar and transverse stabilizer bar prepared by preparation method

A technology of stabilizer bars and composite materials, which is applied in the field of preparation of composite material stabilizer bars, can solve problems such as rollover and vehicle body instability, achieve high specific modulus, improve vehicle ride comfort, and have good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

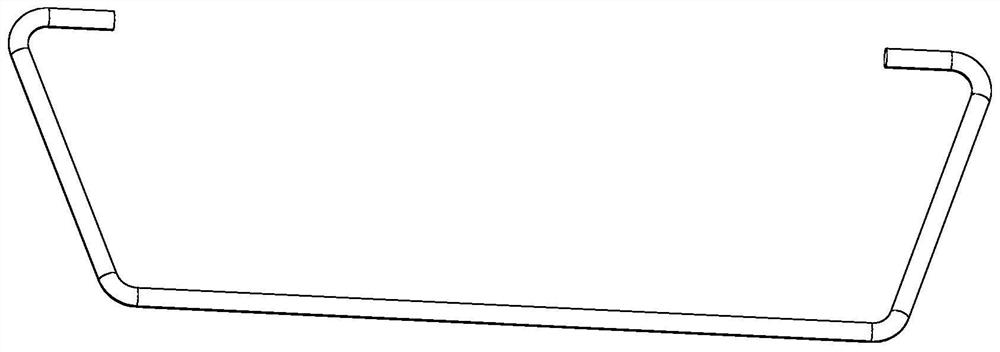

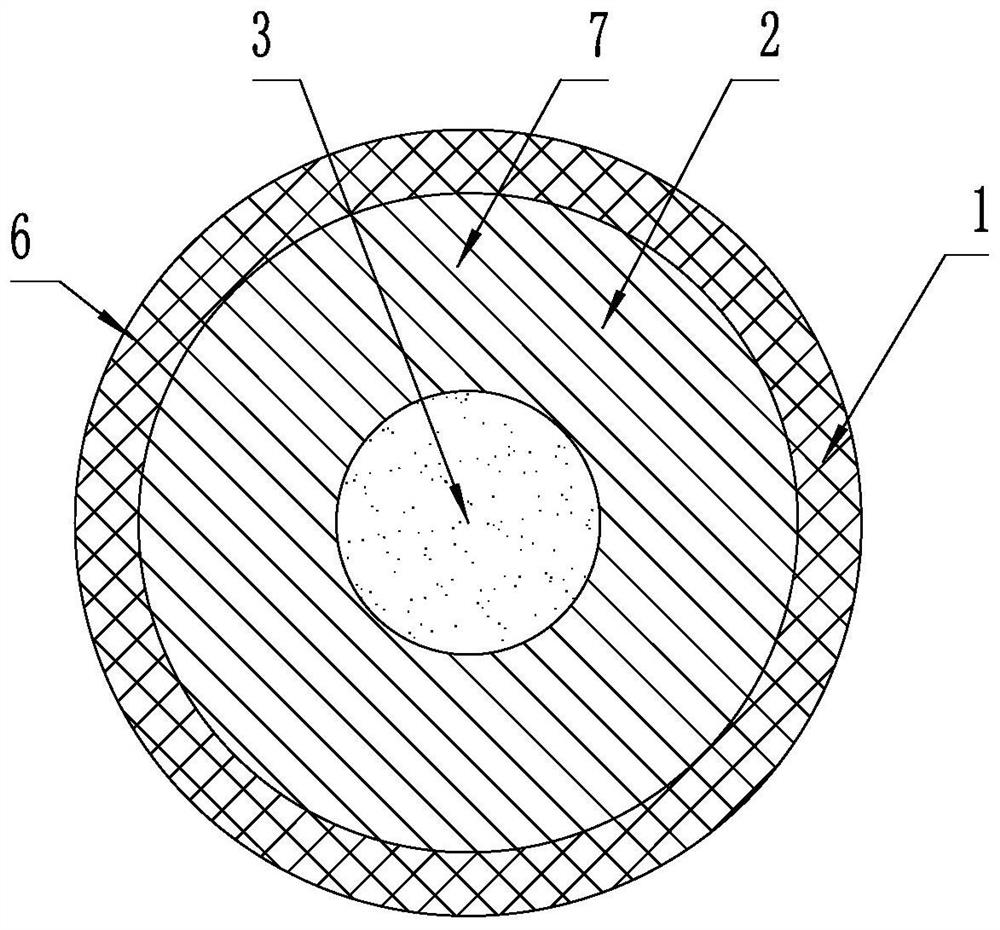

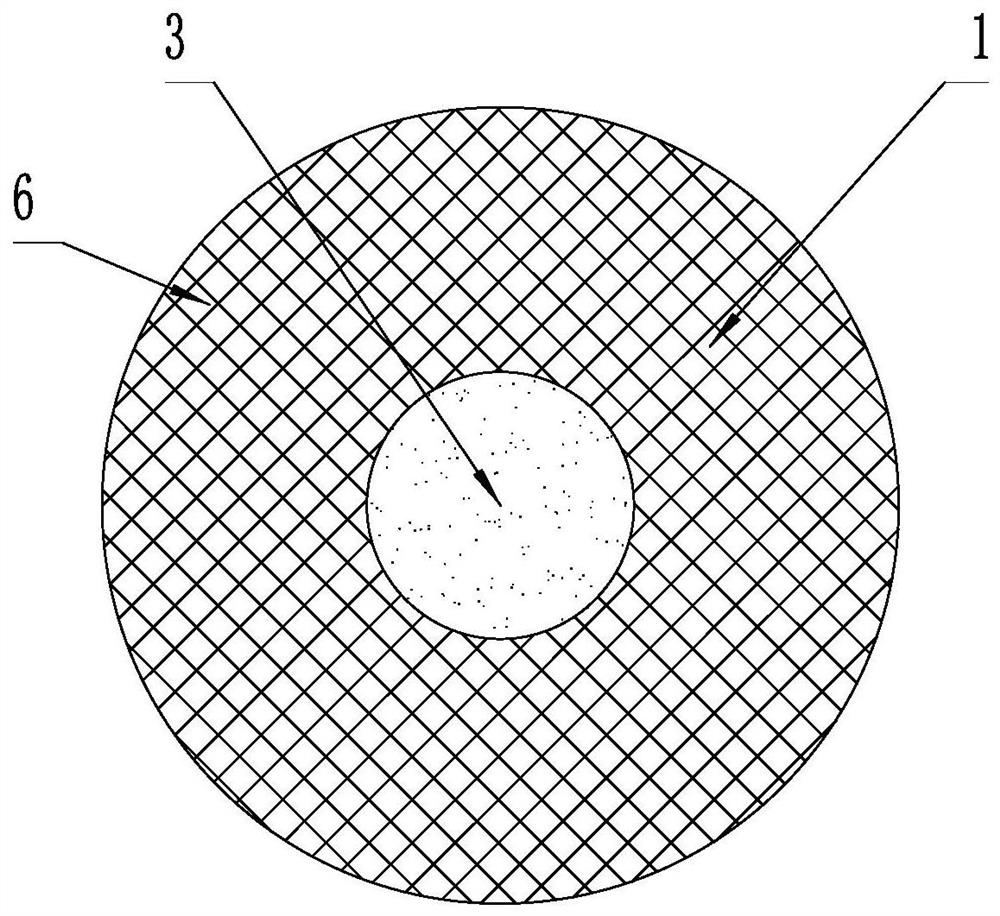

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a composite material stabilizer bar is U-shaped, and the cross section of its shaft 4 is circular; the shaft 4 of the stabilizer bar includes a central layer 3 and one or more layers wrapped outside the central layer 3 A wrapping layer; the wrapping layer is composed of a composite material woven with reinforcing fibers.

[0031] Since the stress condition on the outermost surface of the stabilizer bar is the worst, the weaving method of the reinforcing fiber in the composite material in the outermost wrapping layer 1 adopts the plain weave method, that is, the reinforcing fibers in the warp and weft directions are cross-woven to form a plain weave 6 The plain weave cloth 6 can not only ensure the strength of the shaft 4, but also enable the shaft 4 to be cove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com