A deep-sea long-term pressure-resistant composite structure and its manufacturing method

A composite structure and working technology, applied in the direction of climate change adaptation, warships, etc., can solve the problems of large total mass, inability to carry enough payload, and troublesome operation, and achieve the effects of low cost, reduced acoustic target characteristics, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

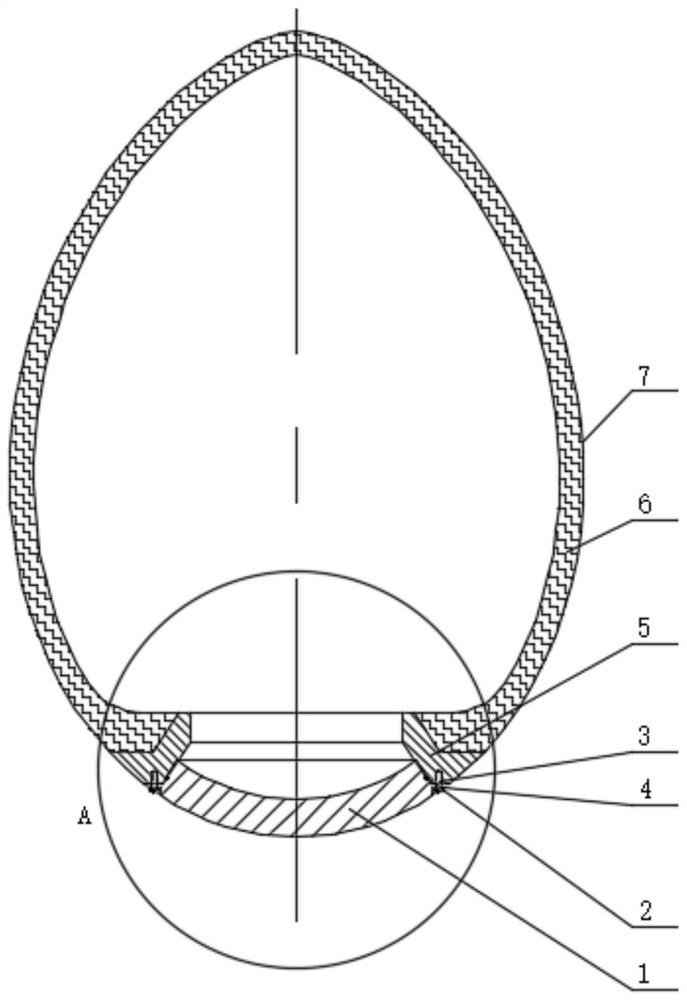

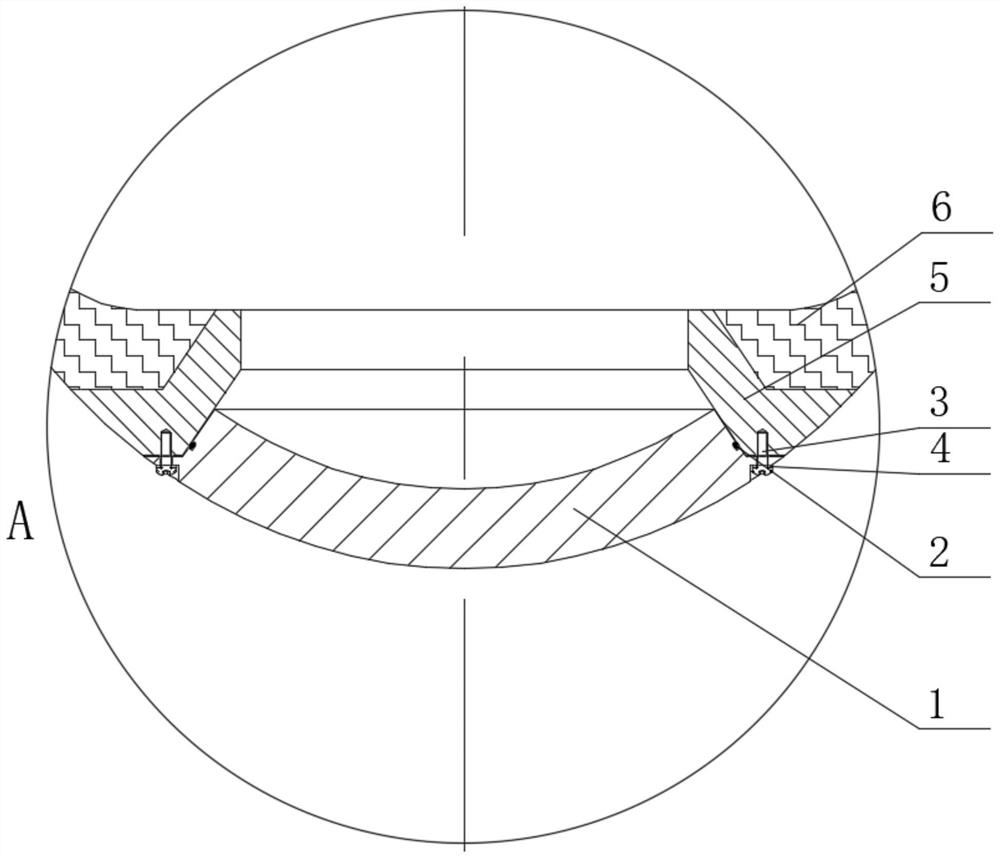

[0049] The following in conjunction with the accompanying drawings, illustrates a specific embodiment of the present invention.

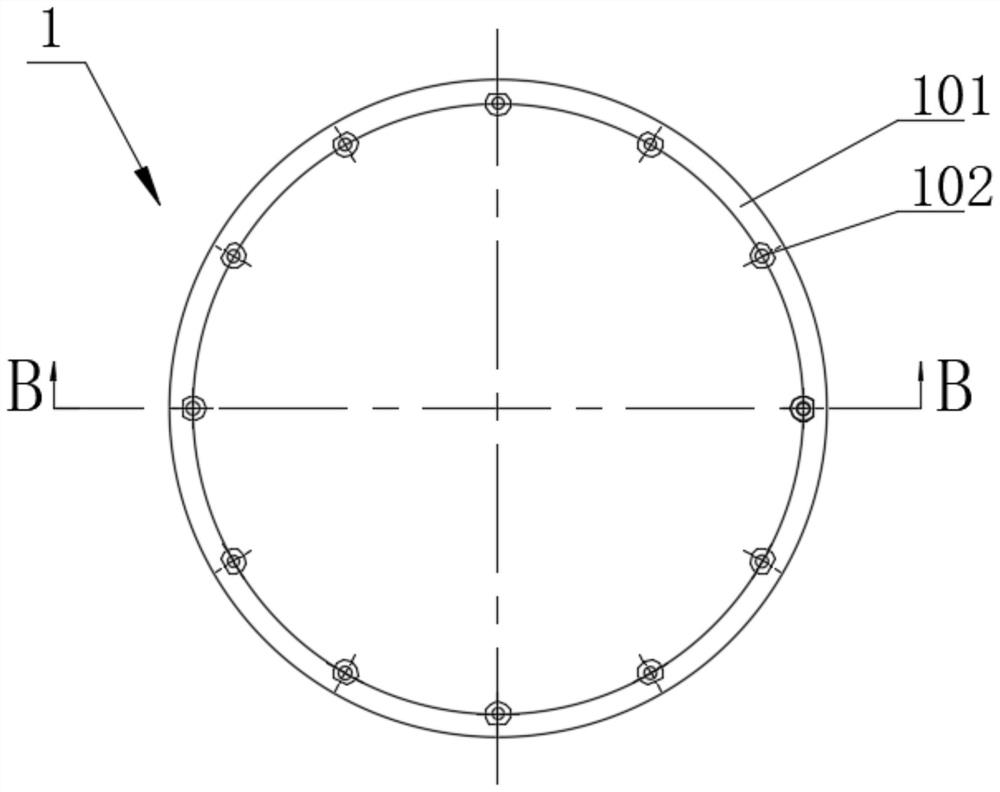

[0050] as Figure 1-Figure 10 As shown, the deep-sea long-term working pressure-resistant composite structure of the present embodiment, comprising a metal head 1, the shape of the metal head 1 is part of the hyperbolic slewing body, the upper part of the metal head 1 is mounted by metal preset 5 with a carbon fiber pressure-resistant housing 6, the metal head 1, the metal preset 5 and the carbon fiber pressure resistant housing 6 are installed in combination to form an oval double curvature swivel structure, the metal head 1 and the metal preset 5 are sealed between the cone, and the use of bolt 3 and the anti-loosening gasket 4 lock, The outer of the carbon fiber pressure-resistant housing 6 is coated with a polyurea waterproof coating 7.

[0051] The structure of the metal head 1 is: comprising the top is an open head body 101, the circumferential dir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com