Patents

Literature

48results about How to "Specific strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

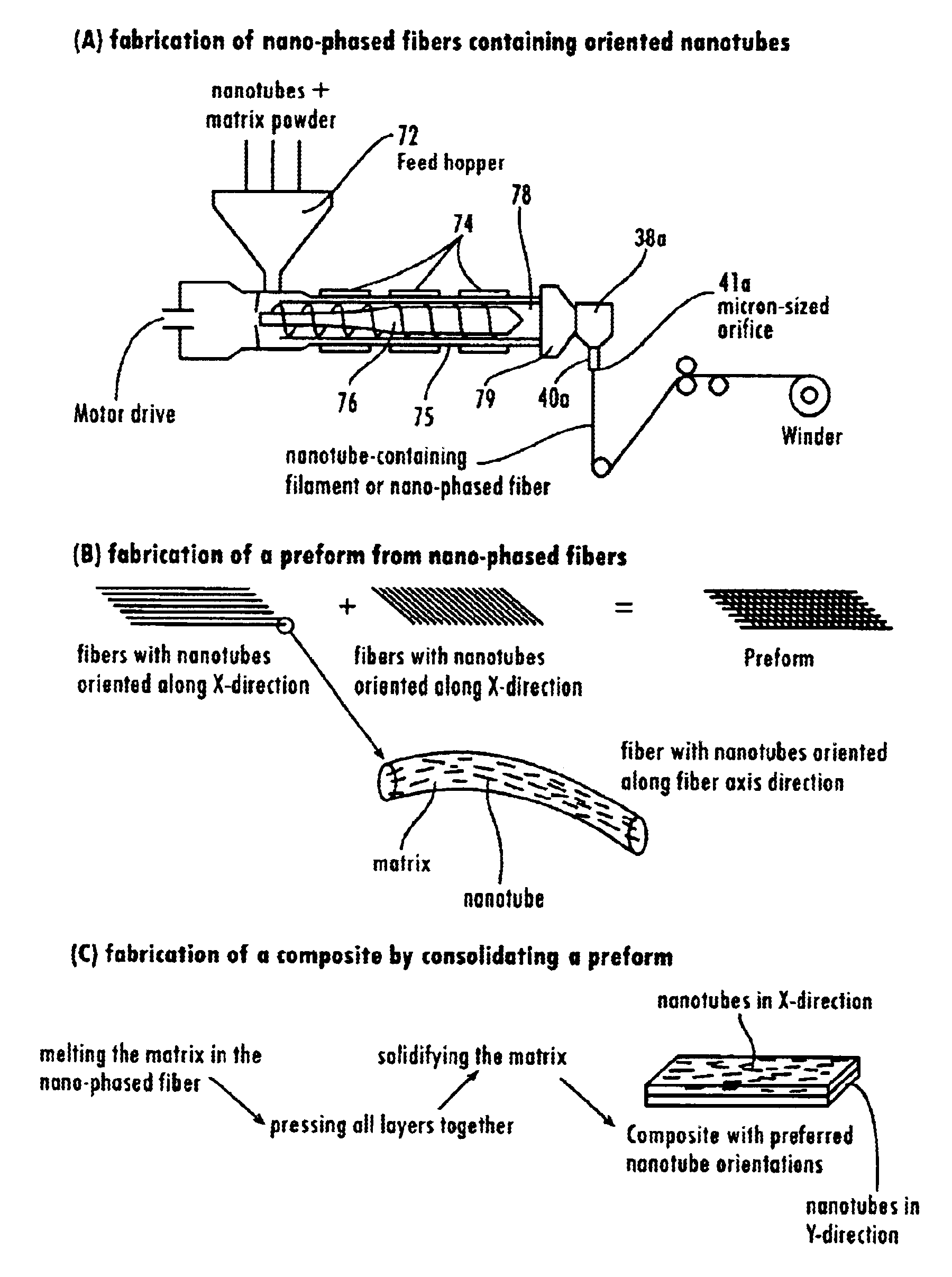

Nanotube fiber reinforced composite materials and method of producing fiber reinforced composites

InactiveUS6934600B2Requires minimizationGenerate efficientlyMaterial nanotechnologyAdditive manufacturing apparatusFiber-reinforced compositeMotion controller

Owner:AUBURN UNIV

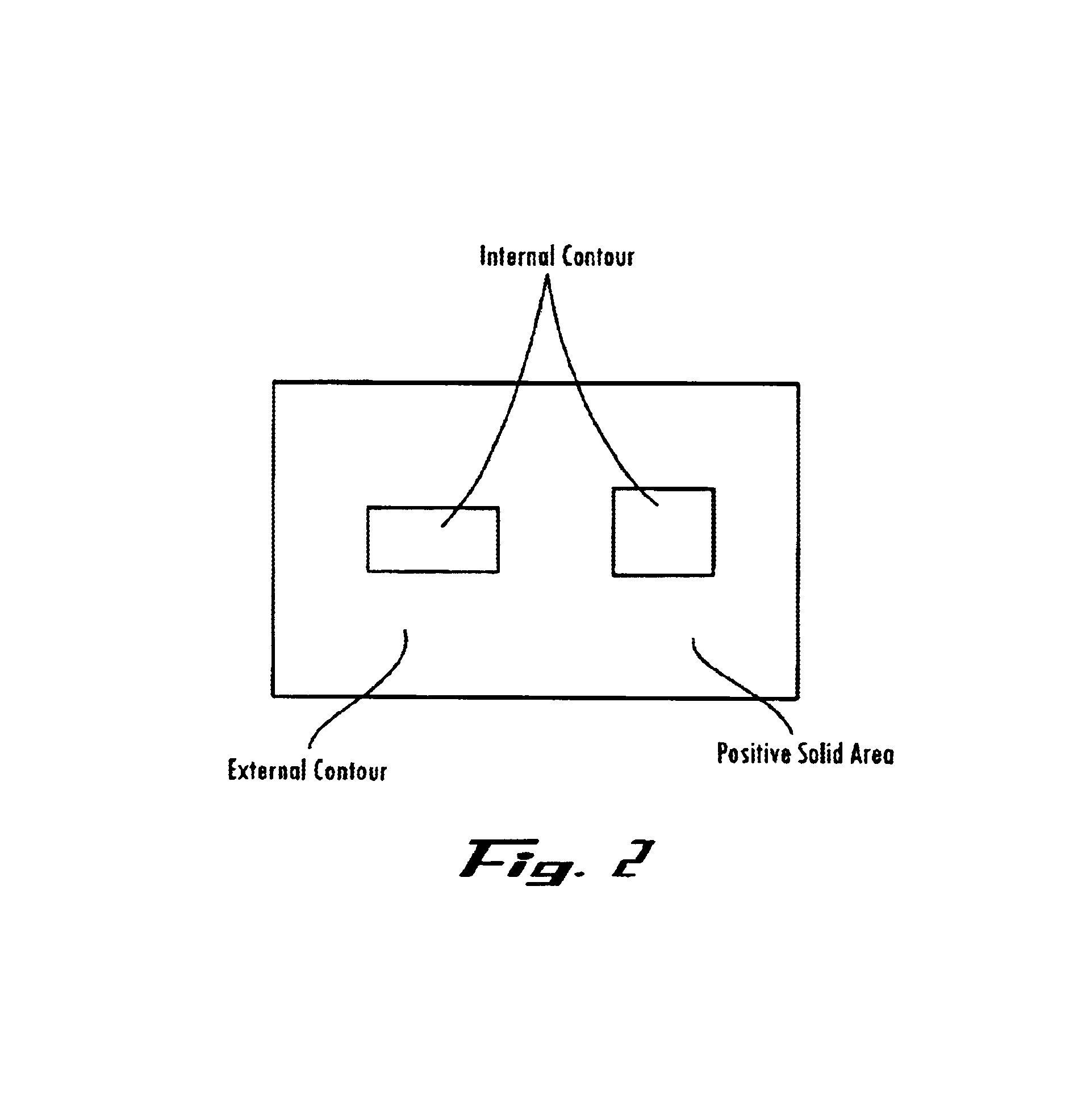

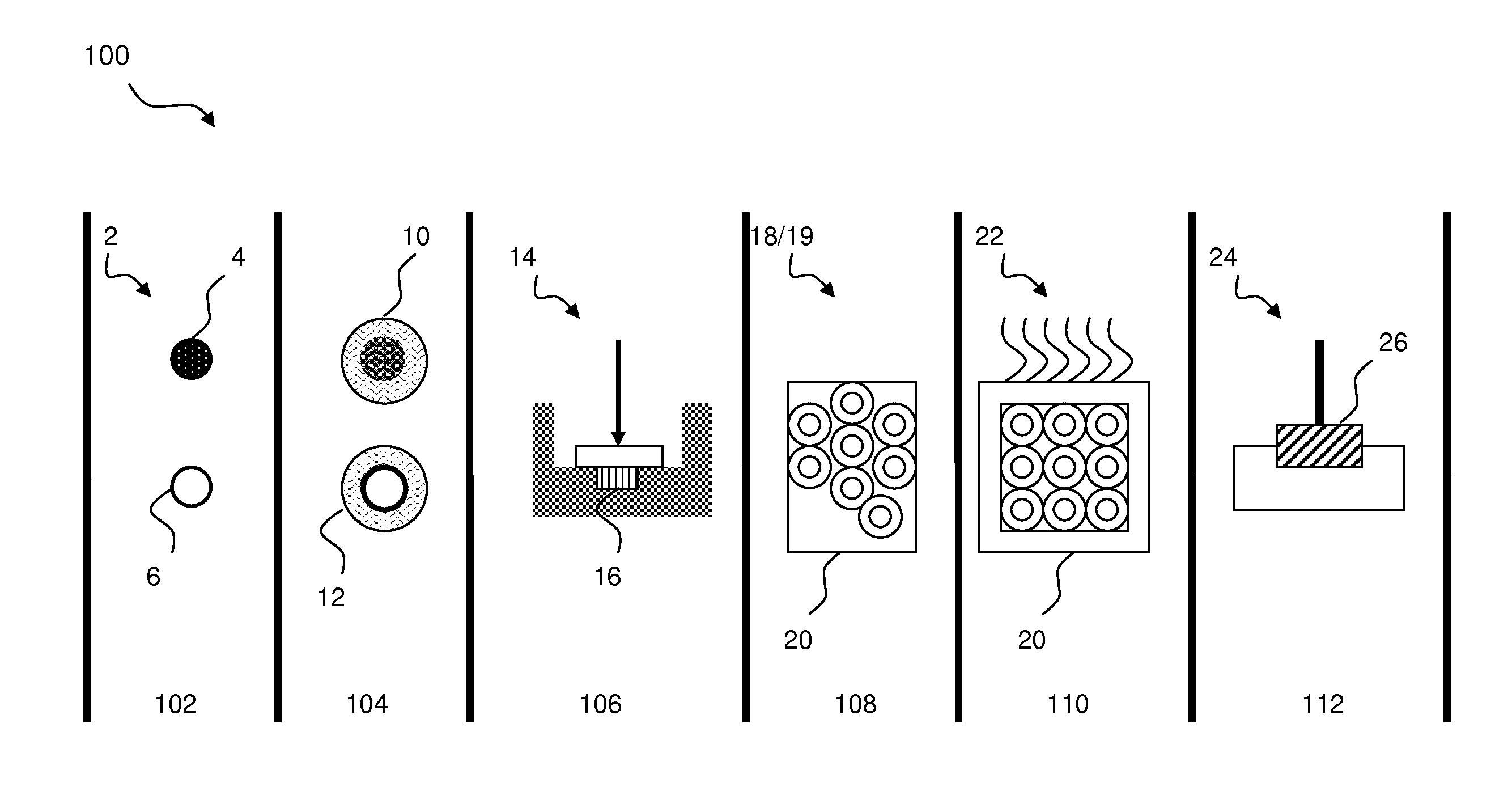

Multifunctional high strength metal composite materials

ActiveUS8535604B1Reduce densityVariable specific strengthMetal-working apparatusCoatingsMicrostructureMagnesium

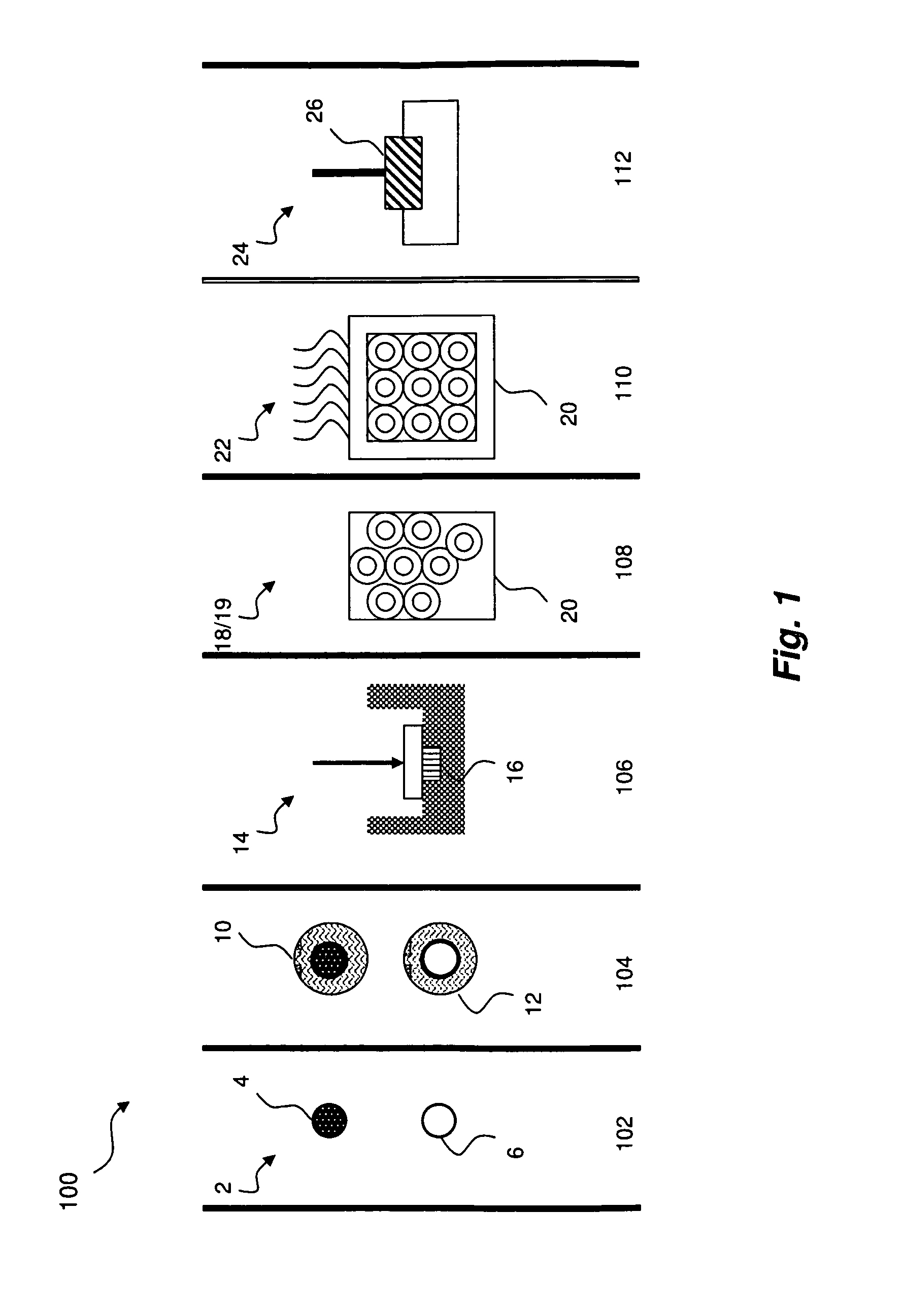

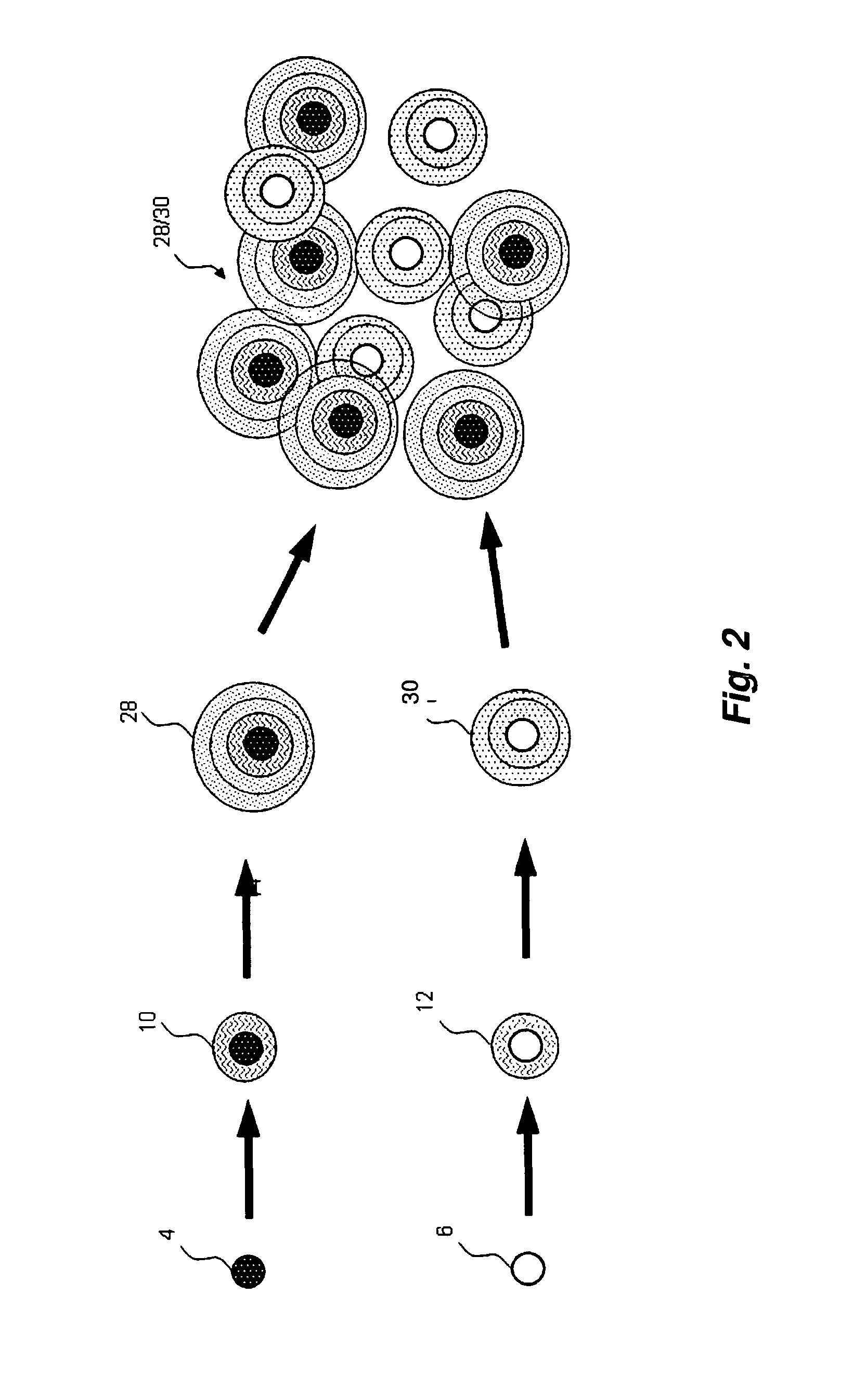

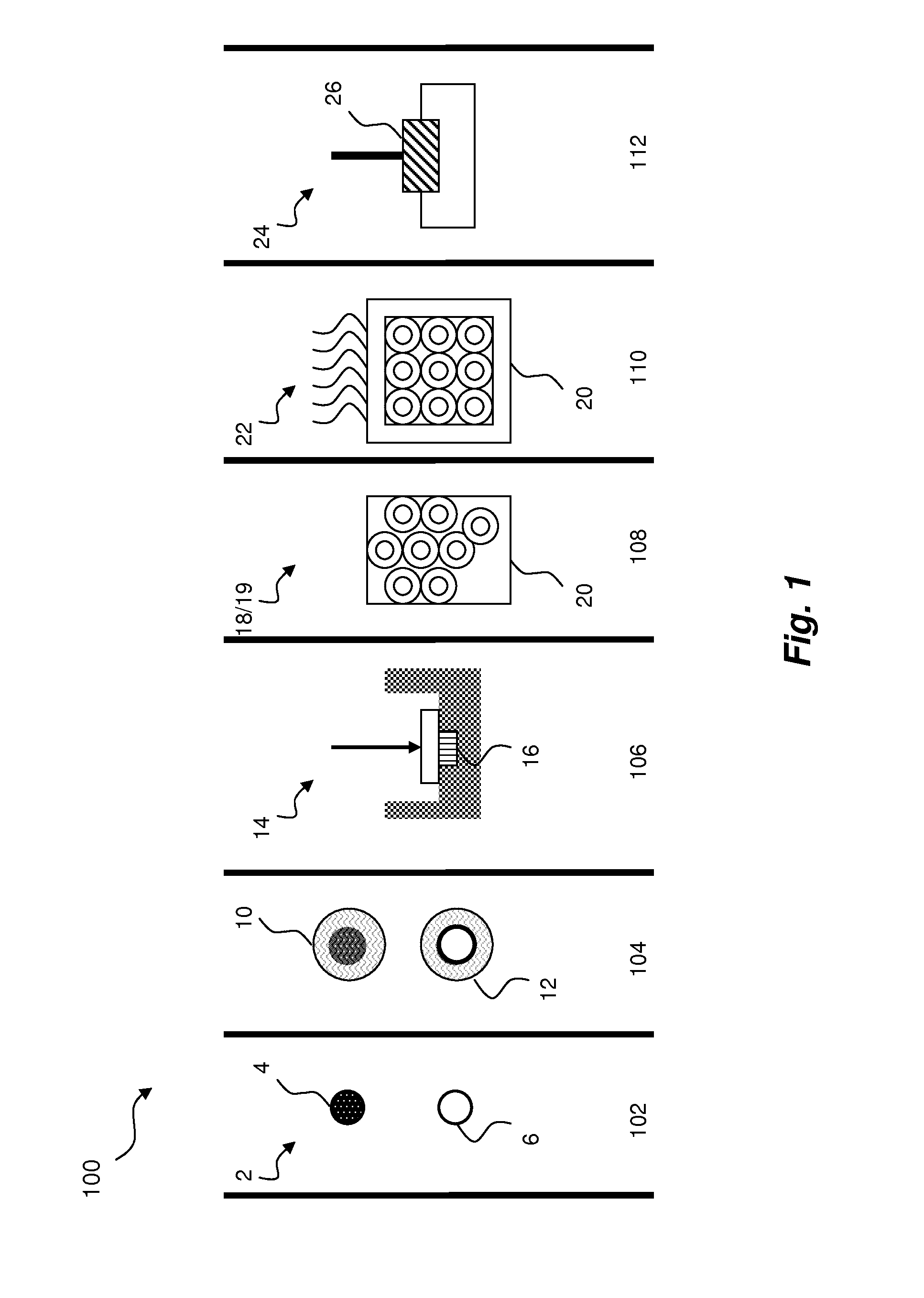

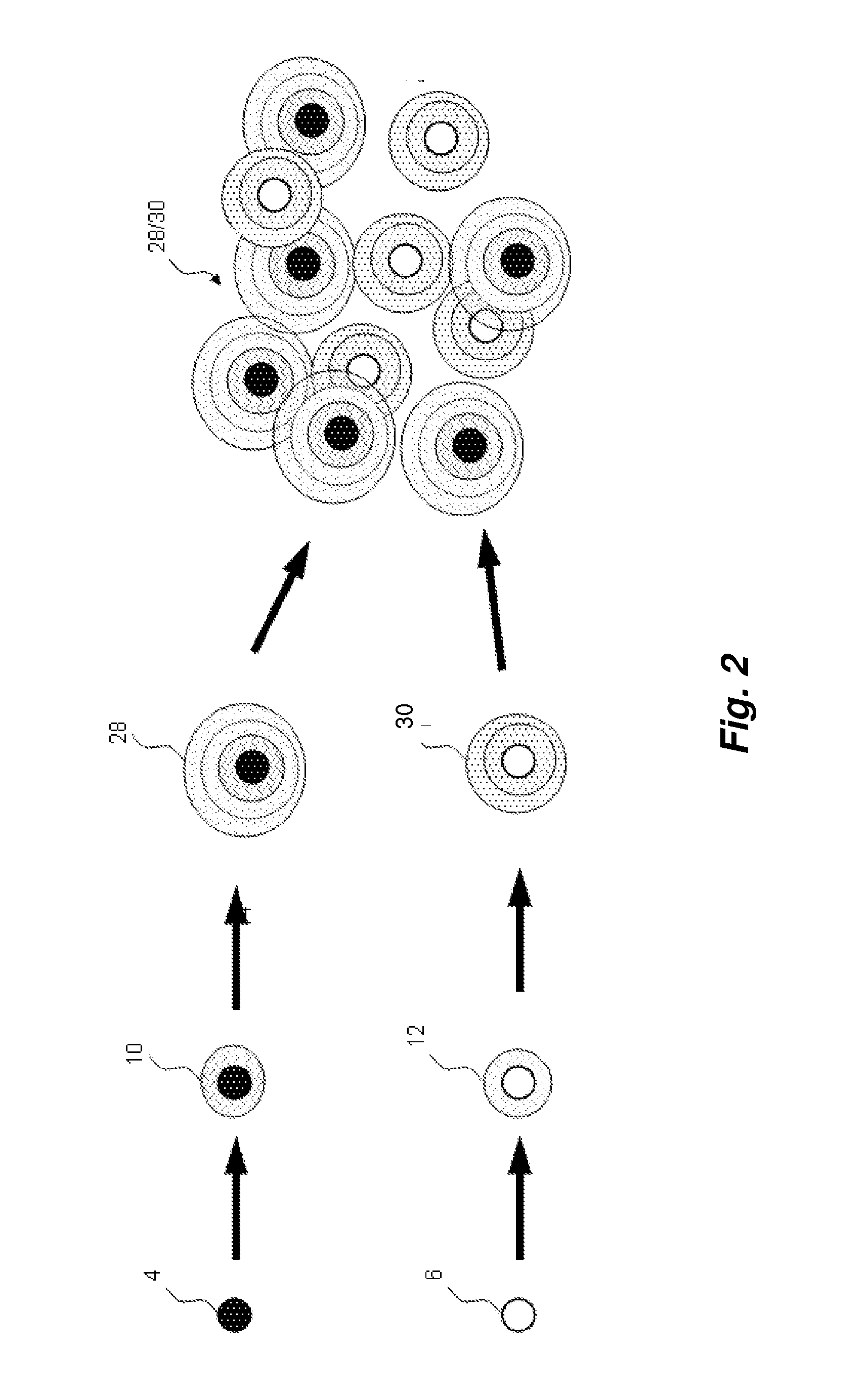

A method of producing composites of micro-engineered, coated particulates embedded in a matrix of metal, ceramic powders, or combinations thereof, capable of being tailored to exhibit application-specific desired thermal, physical and mechanical properties to form substitute materials for nickel, titanium, rhenium, magnesium, aluminum, graphite epoxy, and beryllium. The particulates are solid and / or hollow and may be coated with one or more layers of deposited materials before being combined within a substrate of powder metal, ceramic or some combination thereof which also may be coated. The combined micro-engineered nano design powder is consolidated using novel solid-state processes that prevent melting of the matrix and which involve the application of varying pressures to control the formation of the microstructure and resultant mechanical properties.

Owner:AMARANTHINE RESOURCES LLC

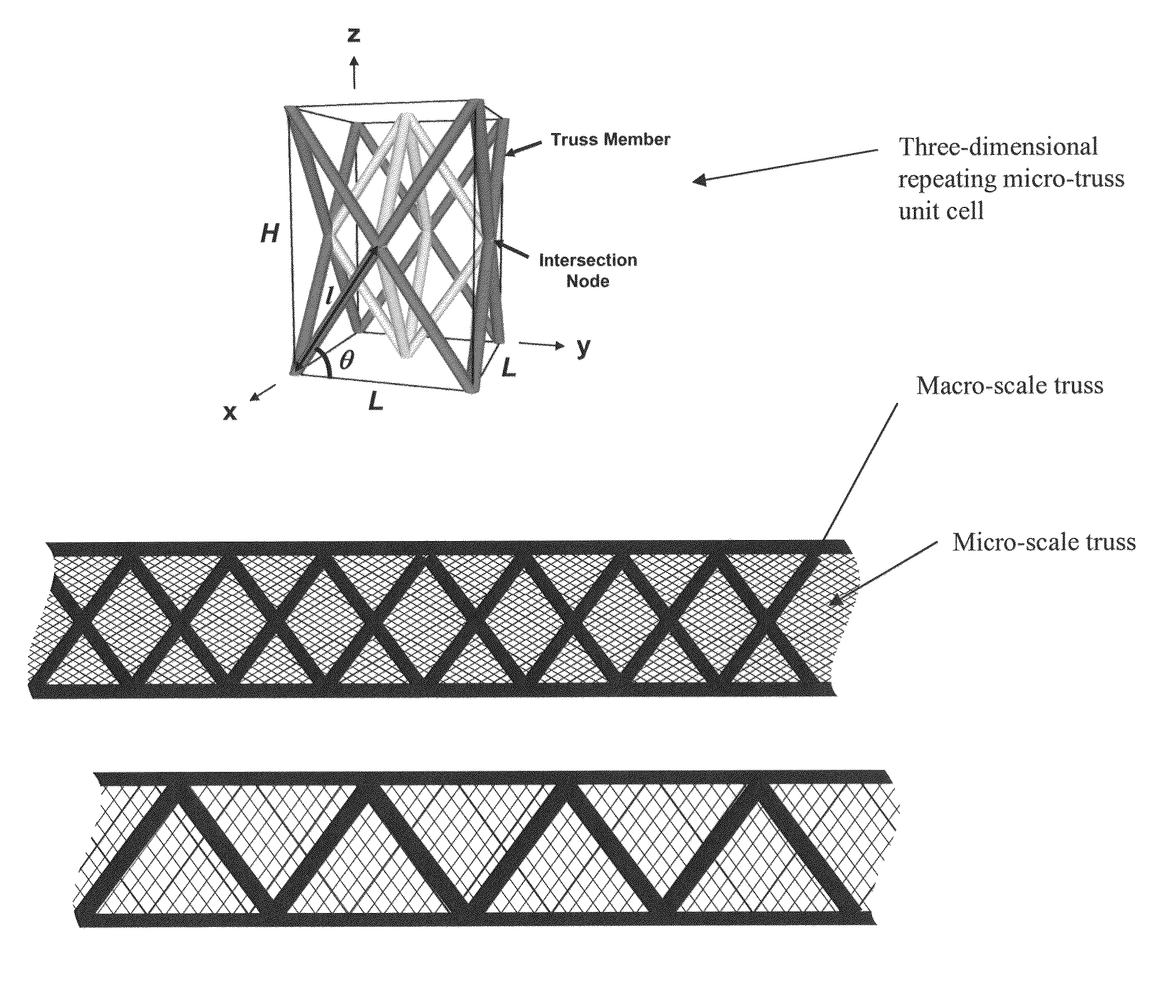

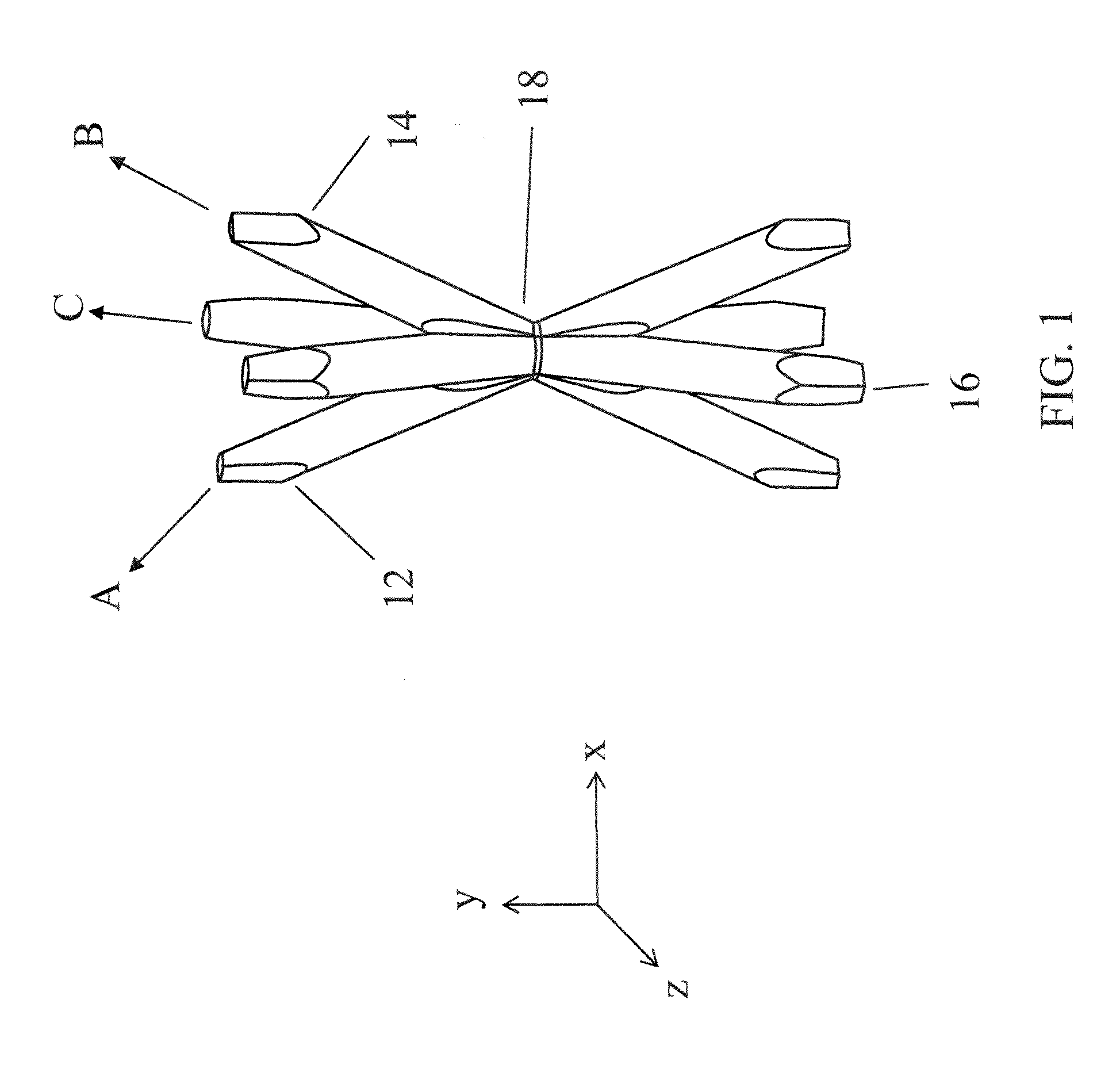

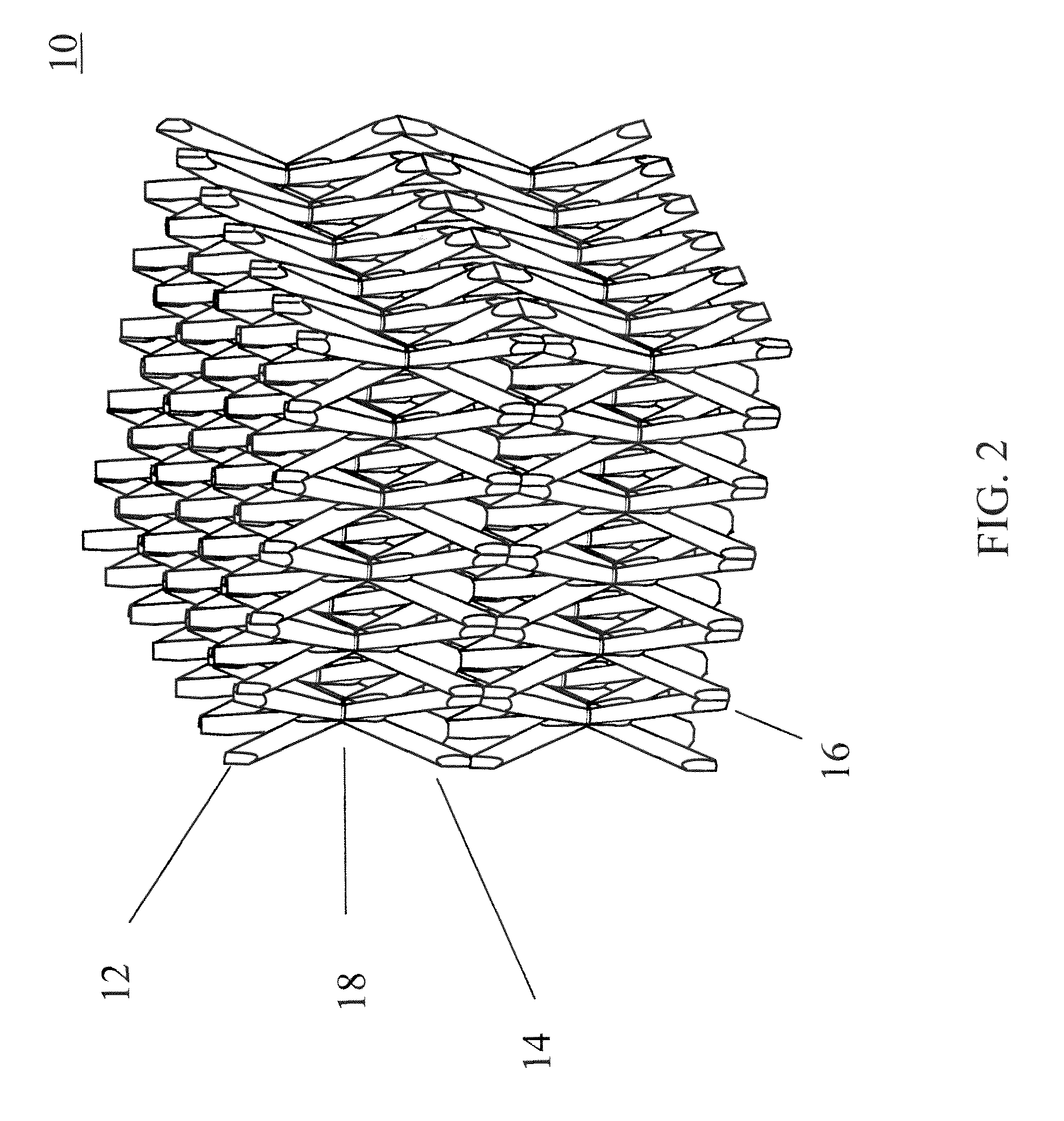

Micro-truss based energy absorption apparatus

ActiveUS9116428B1Significant densificationReduced mechanical propertiesLayered productsArmour platesEnergy absorptionEngineering

A micro-truss based blast protection apparatus. In one embodiment, the blast protection apparatus includes a three-dimensional (3D) ordered truss core between a first face plate and a second face plate. The 3D ordered truss core includes first truss elements defined by first self-propagating polymer waveguides and extending along a first direction, second truss elements defined by second self-propagating polymer waveguides and extending along a second direction, and third truss elements defined by third self-propagating polymer waveguides and extending along a third direction. The first, second, and third truss elements interpenetrate each other at a plurality of nodes to form a continuous material. The first, second, and third truss elements define an open space for providing a densification in response to a force applied to the first face plate and / or the second face plate, and the 3D ordered truss core is self-supporting.

Owner:HRL LAB

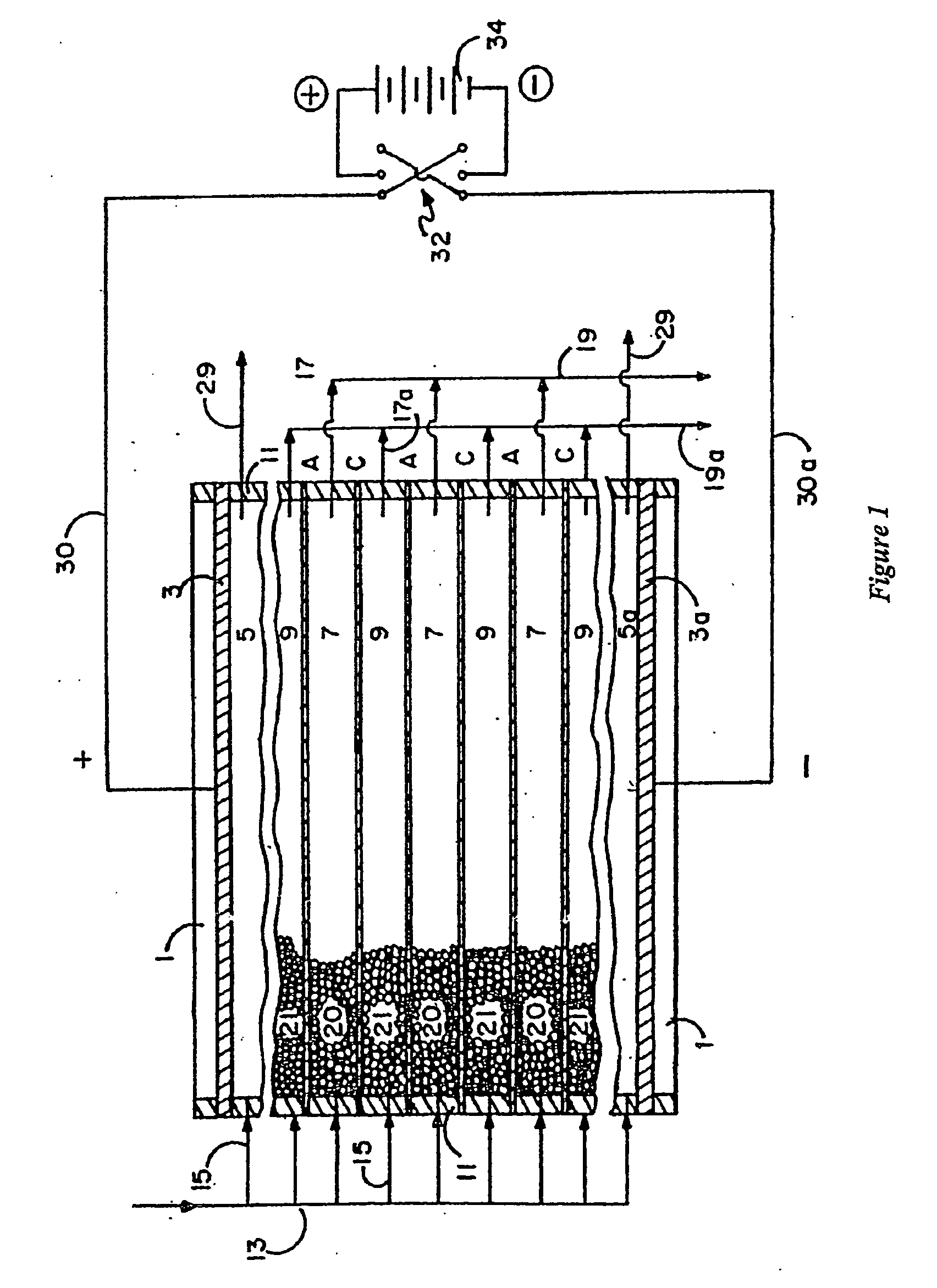

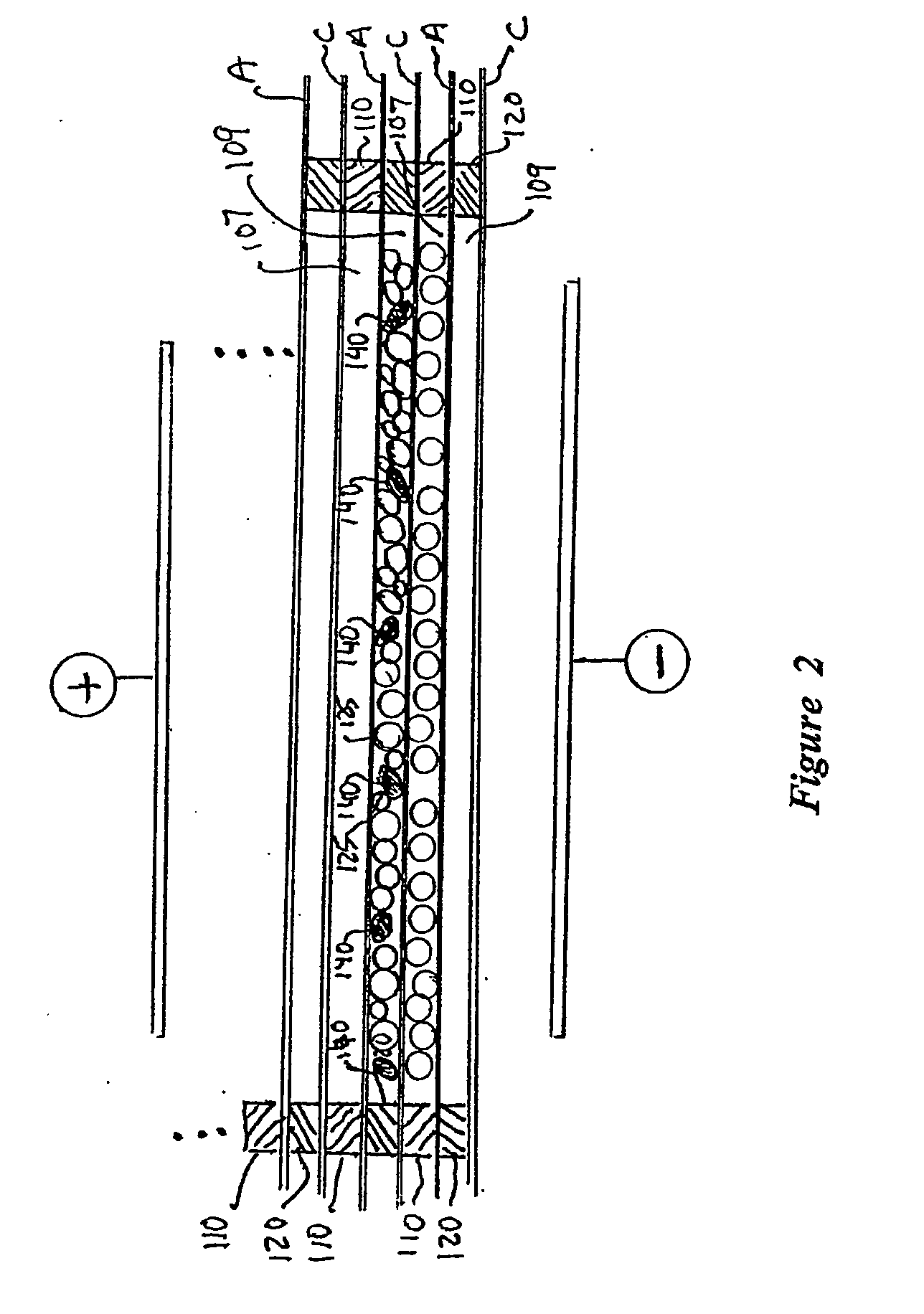

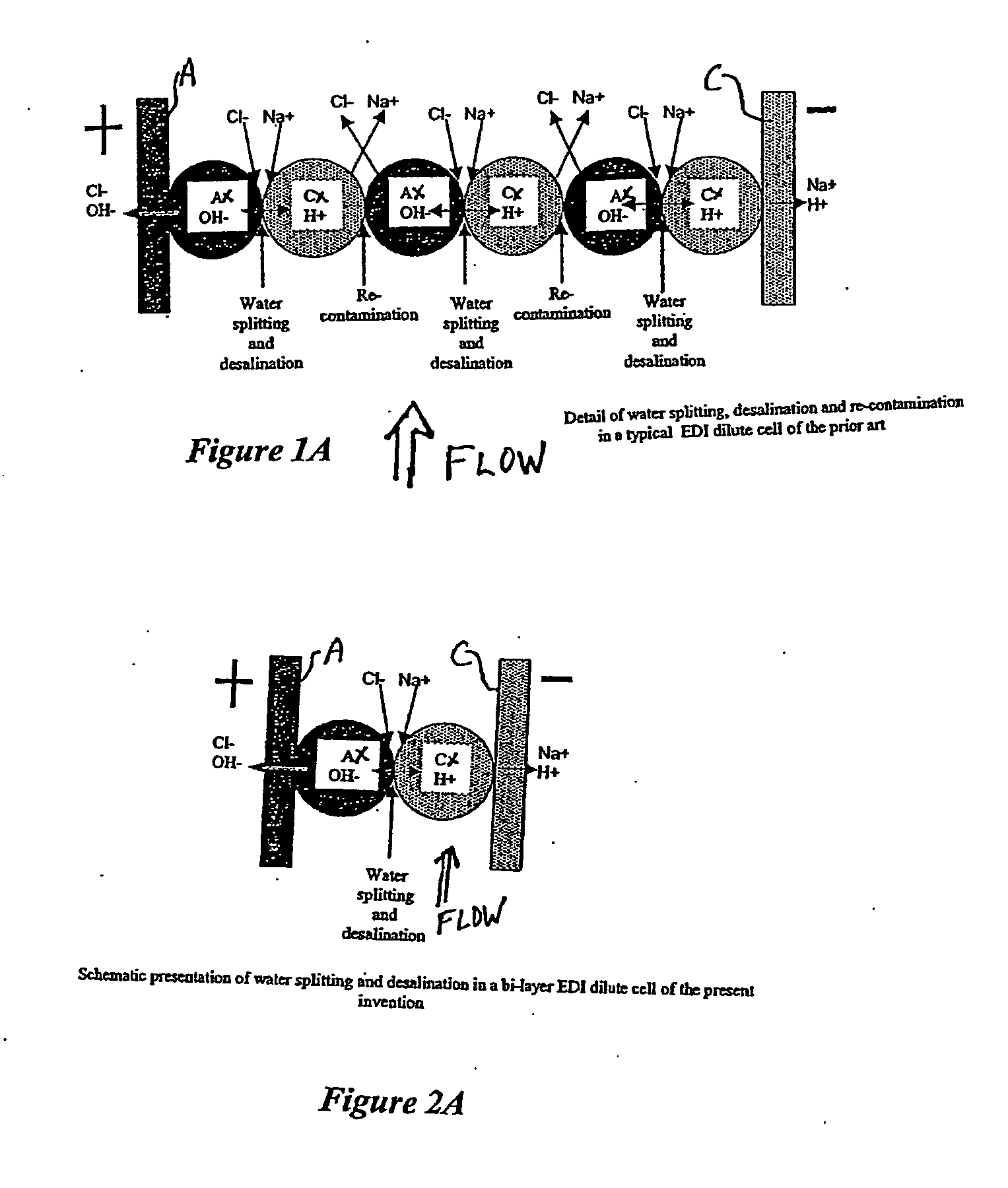

Sparse media edi apparatus and method

An electrodeionization, (EDI) apparatus has flow cells with a sparse distribution of ion exchange (IX) material or beads. The beads extend between membranes defining opposed walls of the cell to separate and support the membranes, and form a layer substantially free of bead-to-bead dead-end reverse junctions. The beads enhance capture of ions from surrounding fluid in dilute cells, and do not throw salt when operating current is increased. In concentrating cells, the sparse bead filling provides a stable low impedance bridge to enhanced power utilization in the stack. A monotype sparse filling may be used in concentrate cells, while mixed, layered, striped, graded or other beads may be employed in dilute cells. Ion conduction paths are no more than a few grains long and the lower packing density permits effective fluid flow. A flow cell thickness may be below one millimeter, and the beads may be discretely spaced, form a mixed or patterned monolayer, or form an ordered bilayer, and a mesh having a lattice spacing comparable to or of the same order of magnitude as resin grain size, may provide a distributed open support that assures a stable distribution of the sparse filling, and over time maintains the initial balance of uniform conductivity and good through-flow. The cells or low thickness and this resin layers relax stack size and power supply constraints, while providing treatment efficiencies and process stability. Reduced ion migration distances enhance the ion removal rate without reducing the product flow rate. The sparse resin bed may be layered, graded along the length of the path, striped or otherwise patterned. Inter-grain ion hopping is reduced or eliminated, thus avoiding the occurrence of salt-throwing which occurs at reverse bead junctions of prior art constructions. Conductivity of concentrate cells is increased, permitting more compact device construction, allowing increases in stack cell number, and providing more efficient electrical operation without ion additions. Finally, ion storage within beads is greatly reduces, eliminating the potential for contamination during reversal operation. Various methods of forming sparse beds and assembling the stacks are disclosed.

Owner:IONICS INC

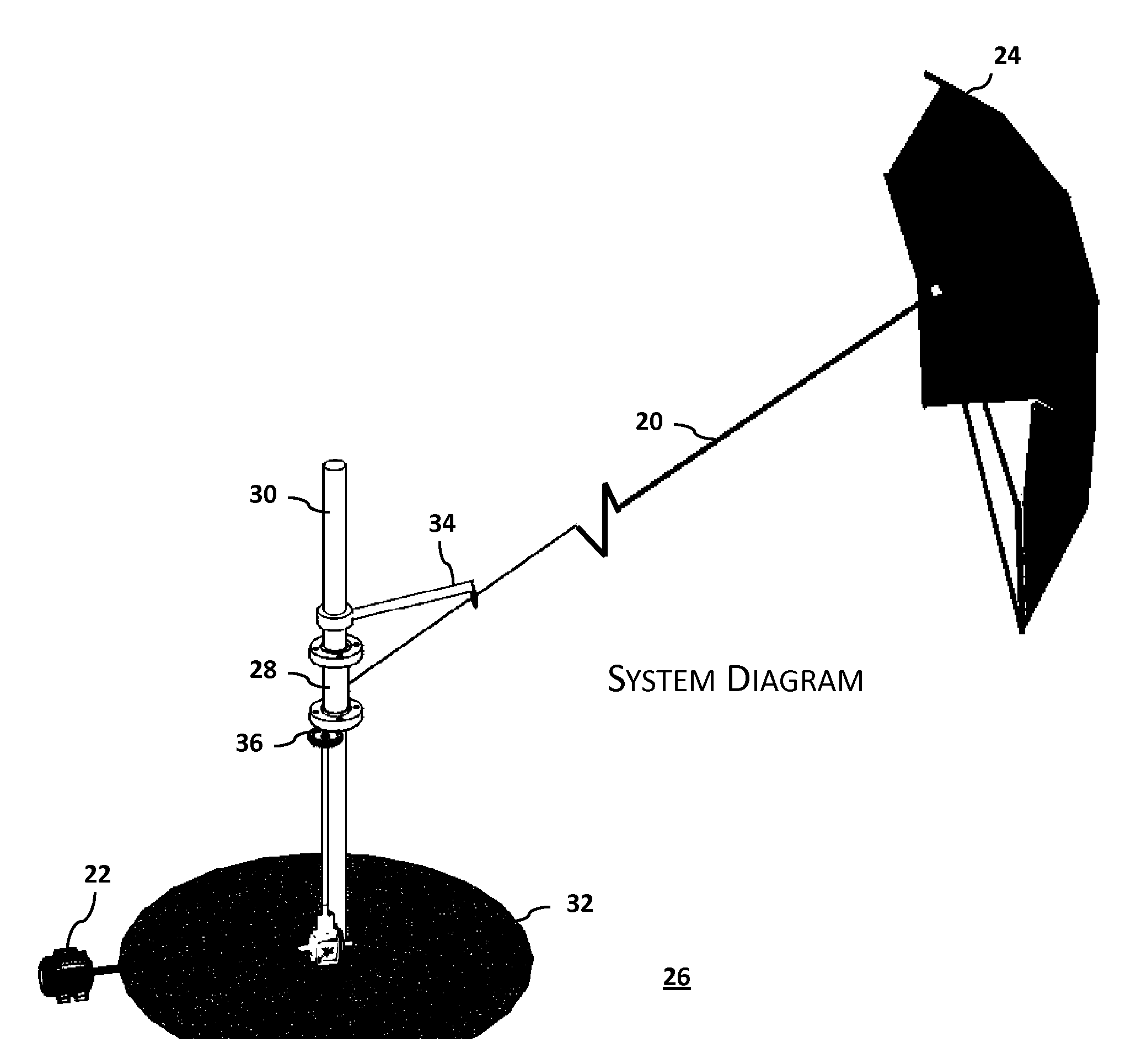

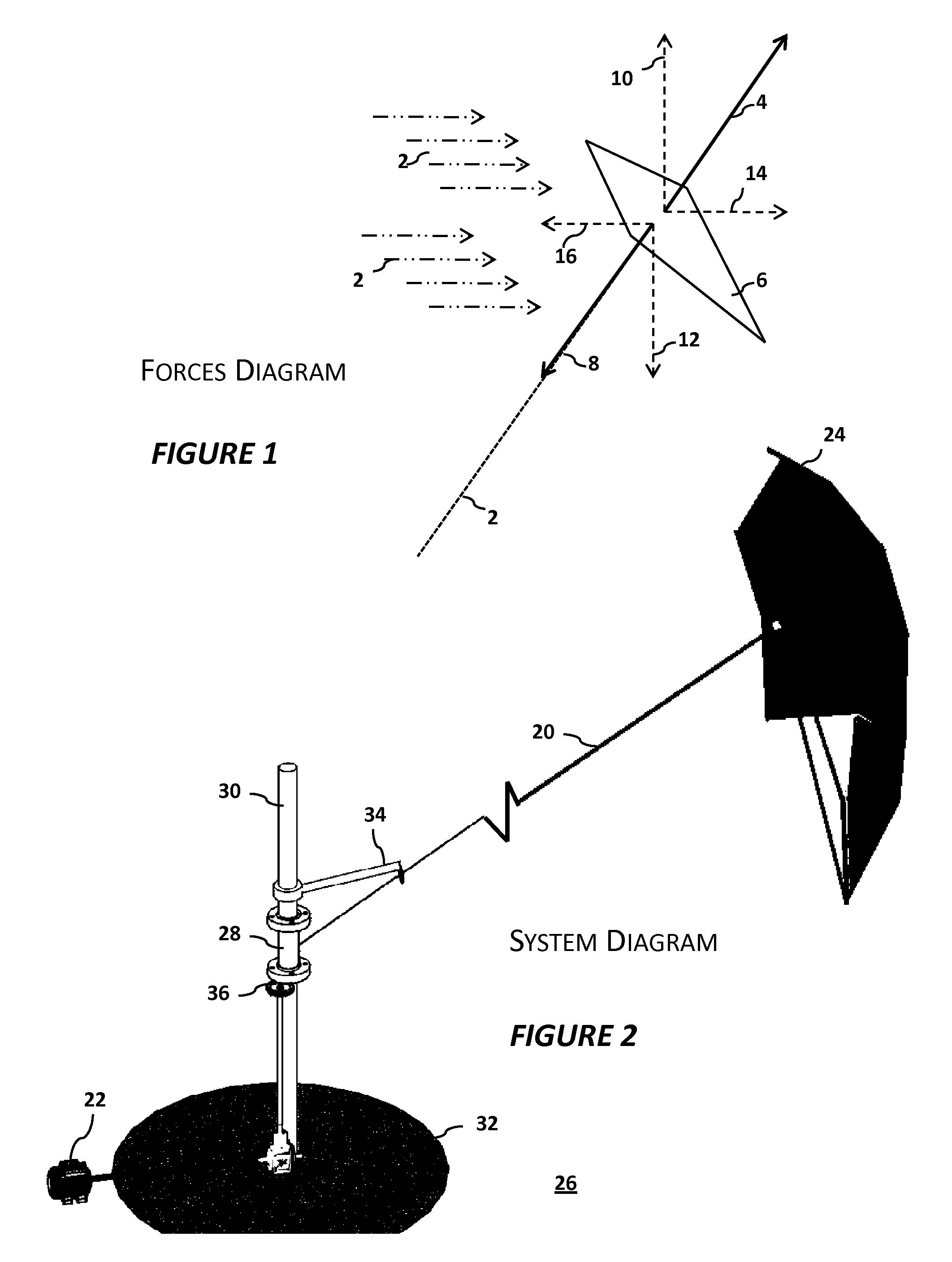

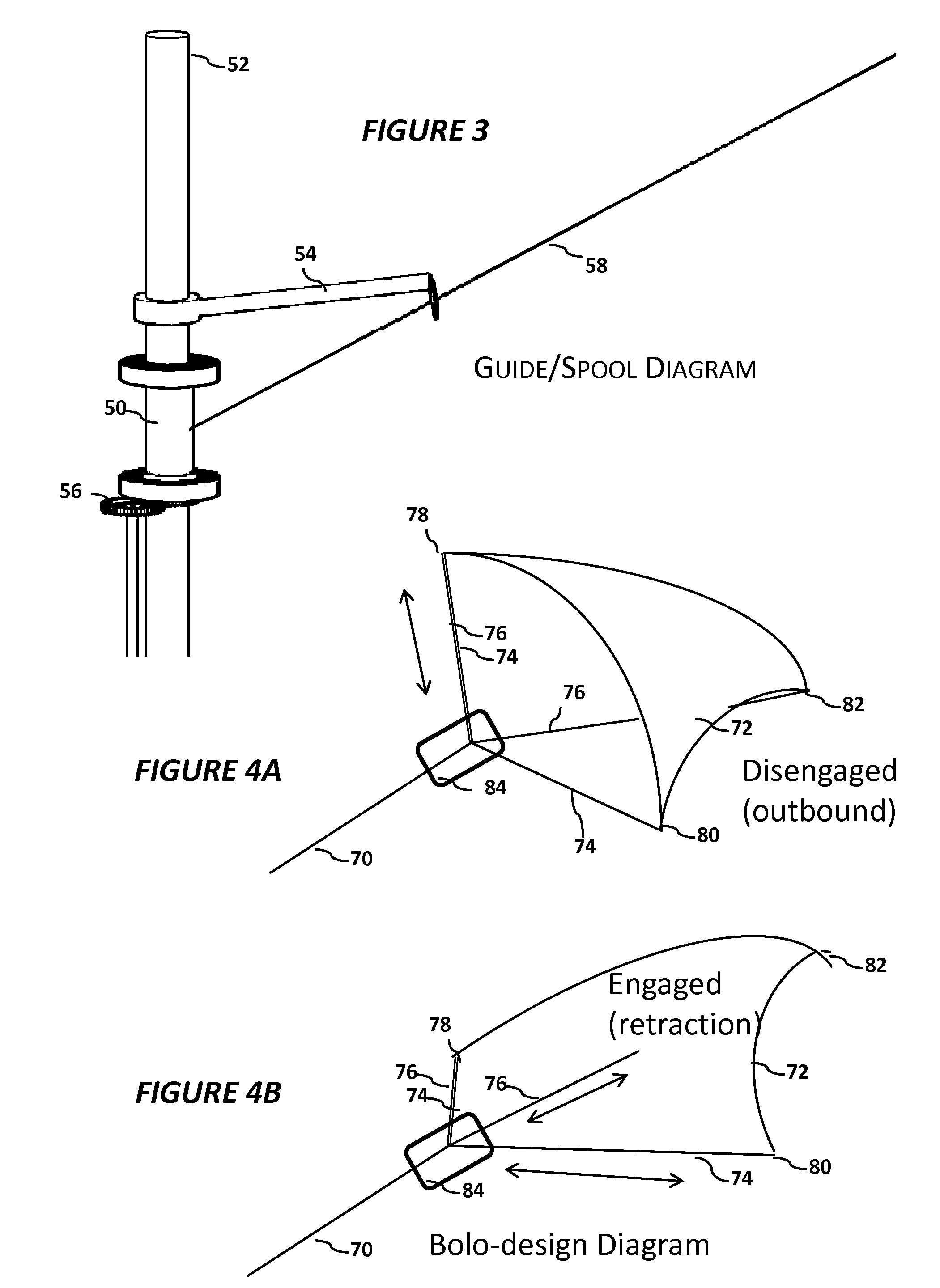

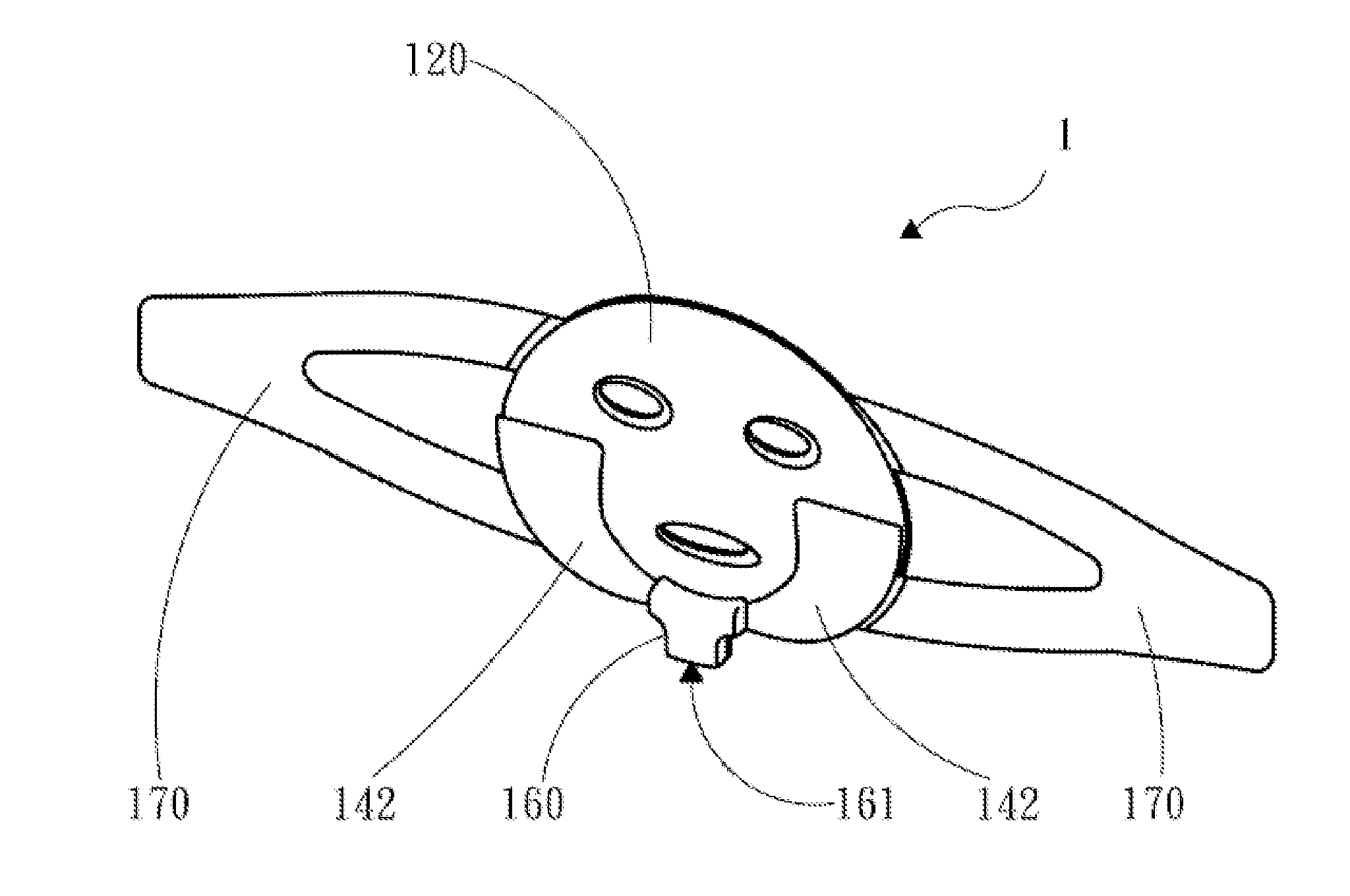

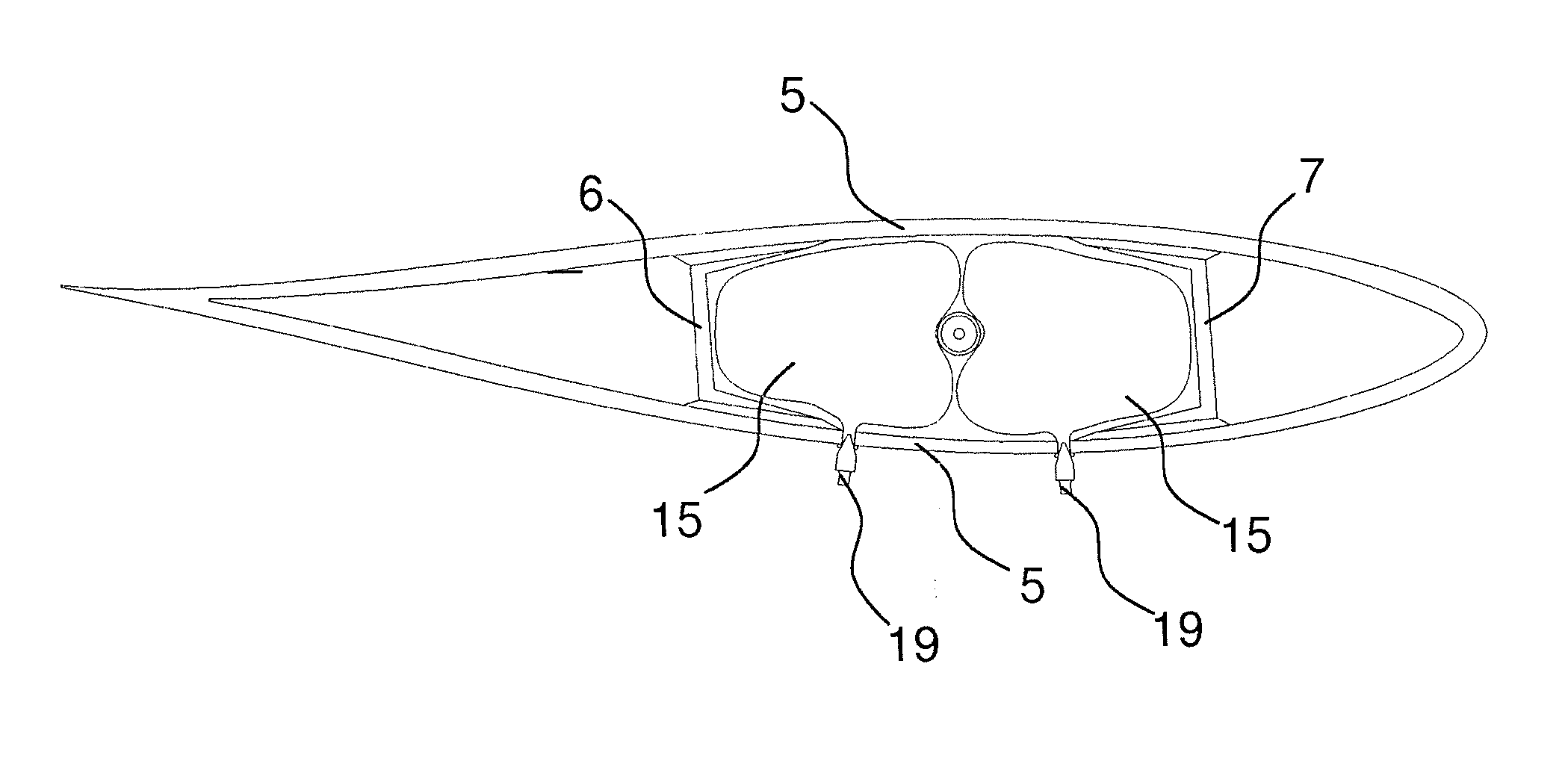

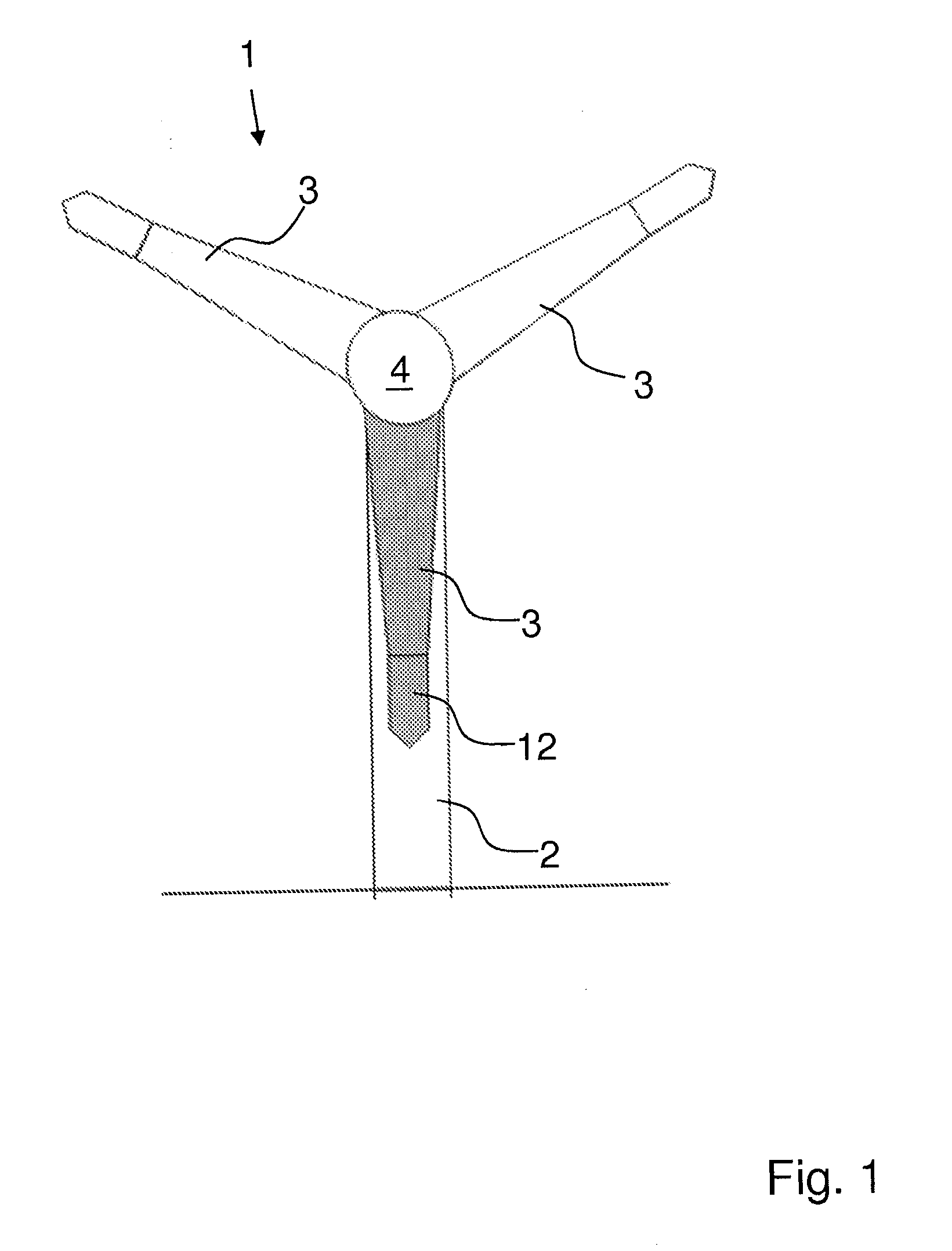

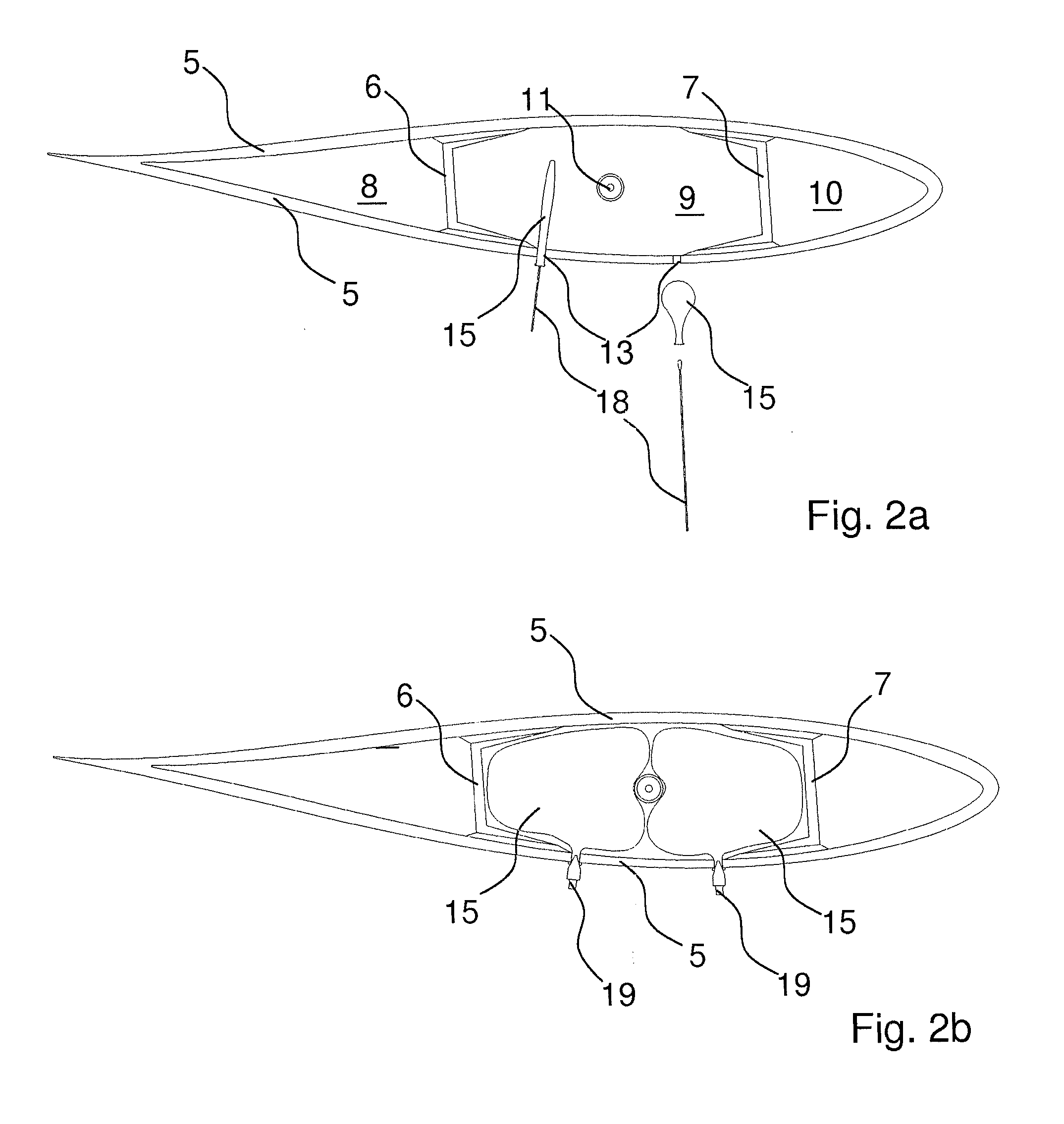

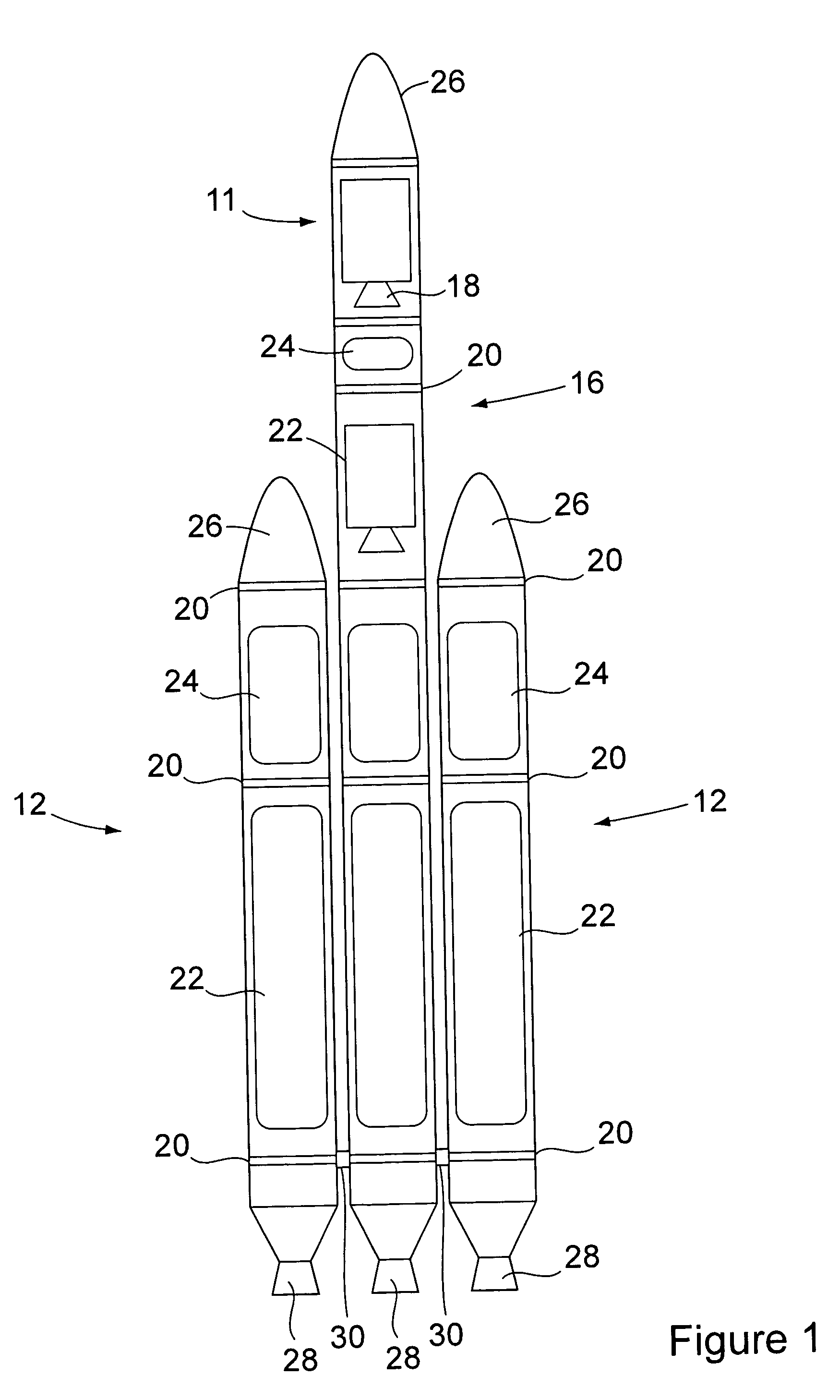

System and method for harnessing wind power at variable altitudes

InactiveUS20100032956A1High tensile strengthHigh strengthWind motor supports/mountsMachines/enginesEngineeringUltimate tensile strength

A system for harnessing power from wind using a wind capturing structure. An axis of rotation could be central to the system, and the lines could rotate around this axis. Features for the wind capturing structure include effective downwind power generation using a durable, lightweight, inexpensive structure that may be safe in the event of a crash, and easily modified to reduce drag for retraction. The capturing structure creates lift in a low altitude environment, capable of operating in high wind conditions. The lines include minimal mass to permit lift at low altitudes, and are constructed with maximum tensile strength to prevent failure in high winds. A versatile wind capturing structure could include a kite operable in variable conditions for efficient and consistent production of force. The power producing cycle of a system capturing power from wind should maximize the efficiency of the system.

Owner:CMNA POWER

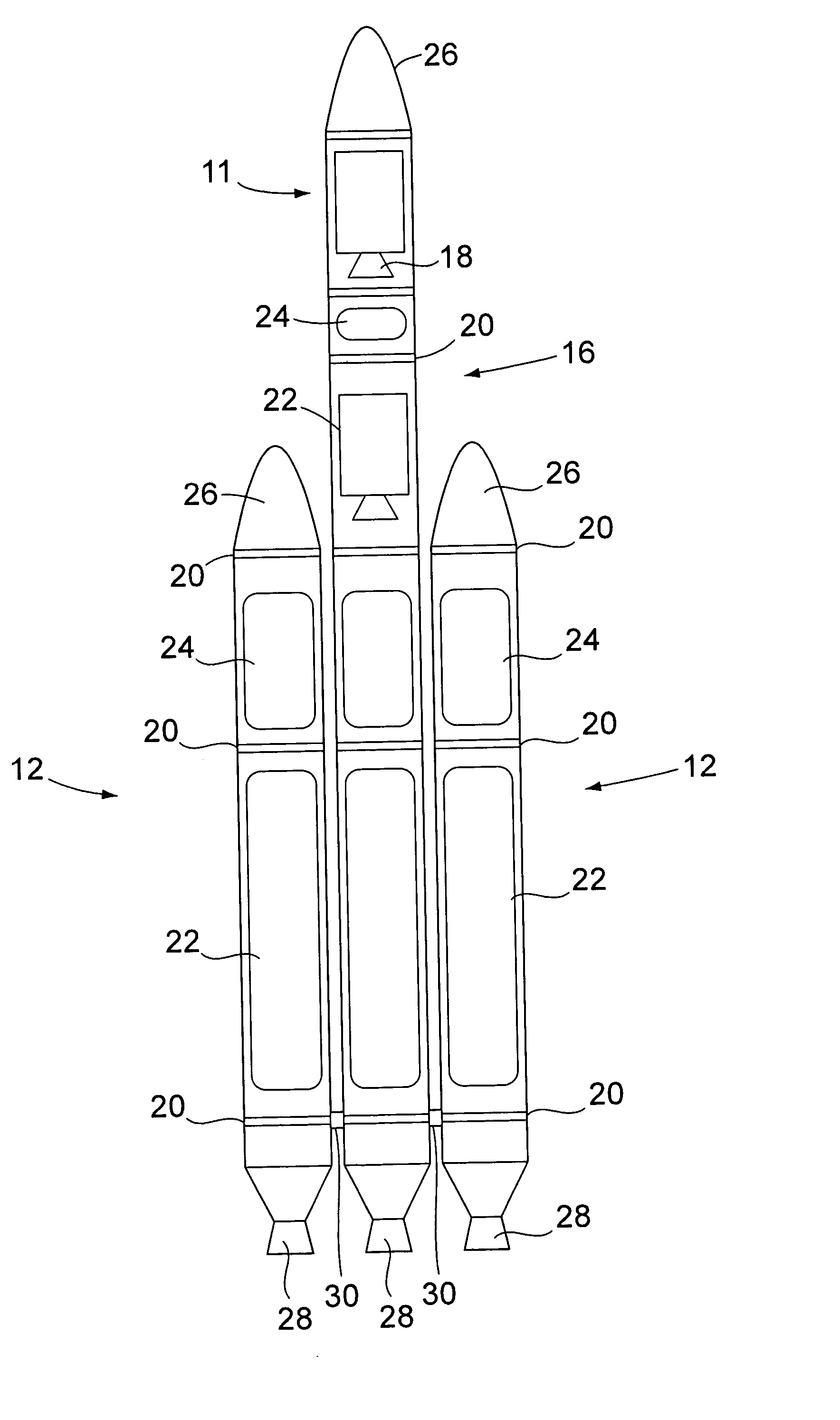

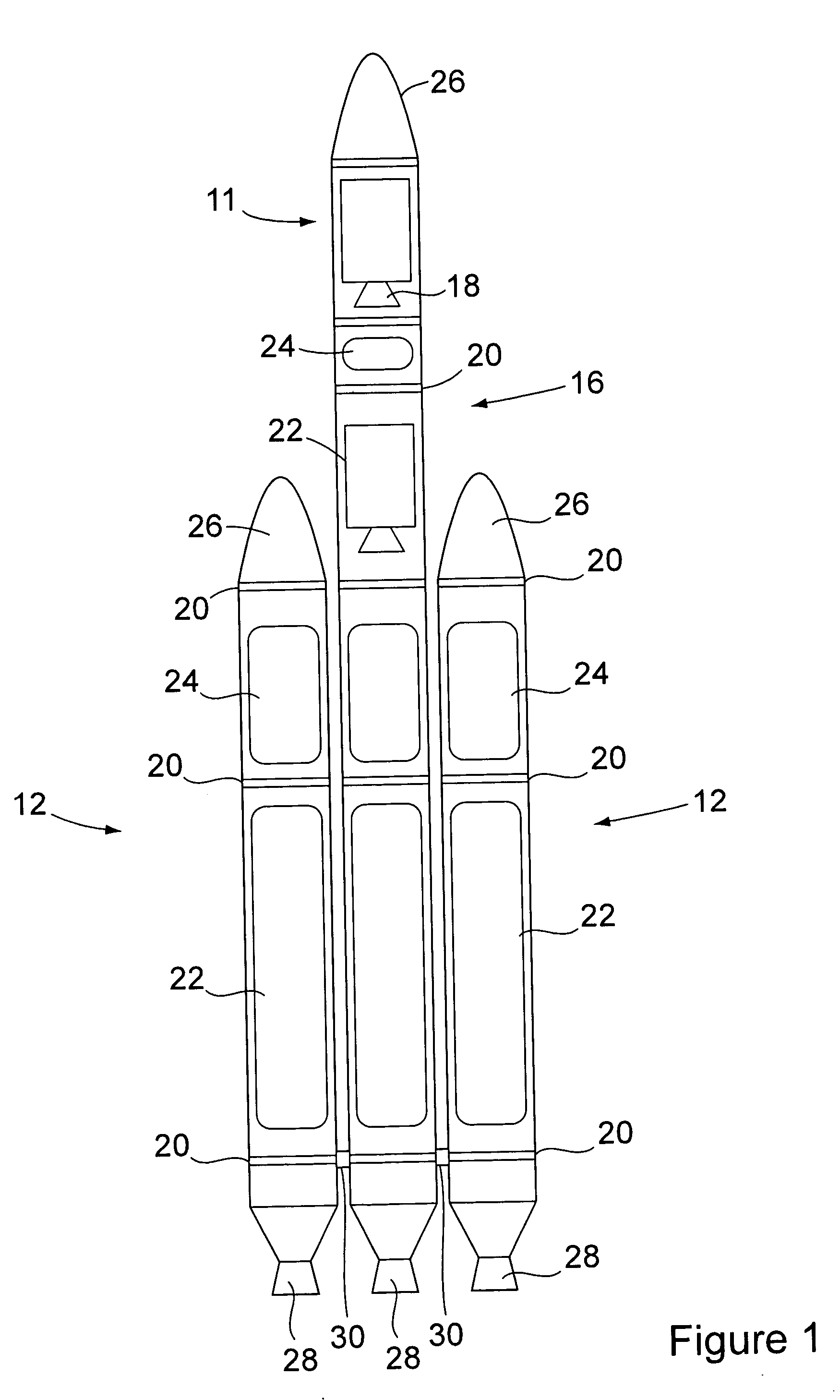

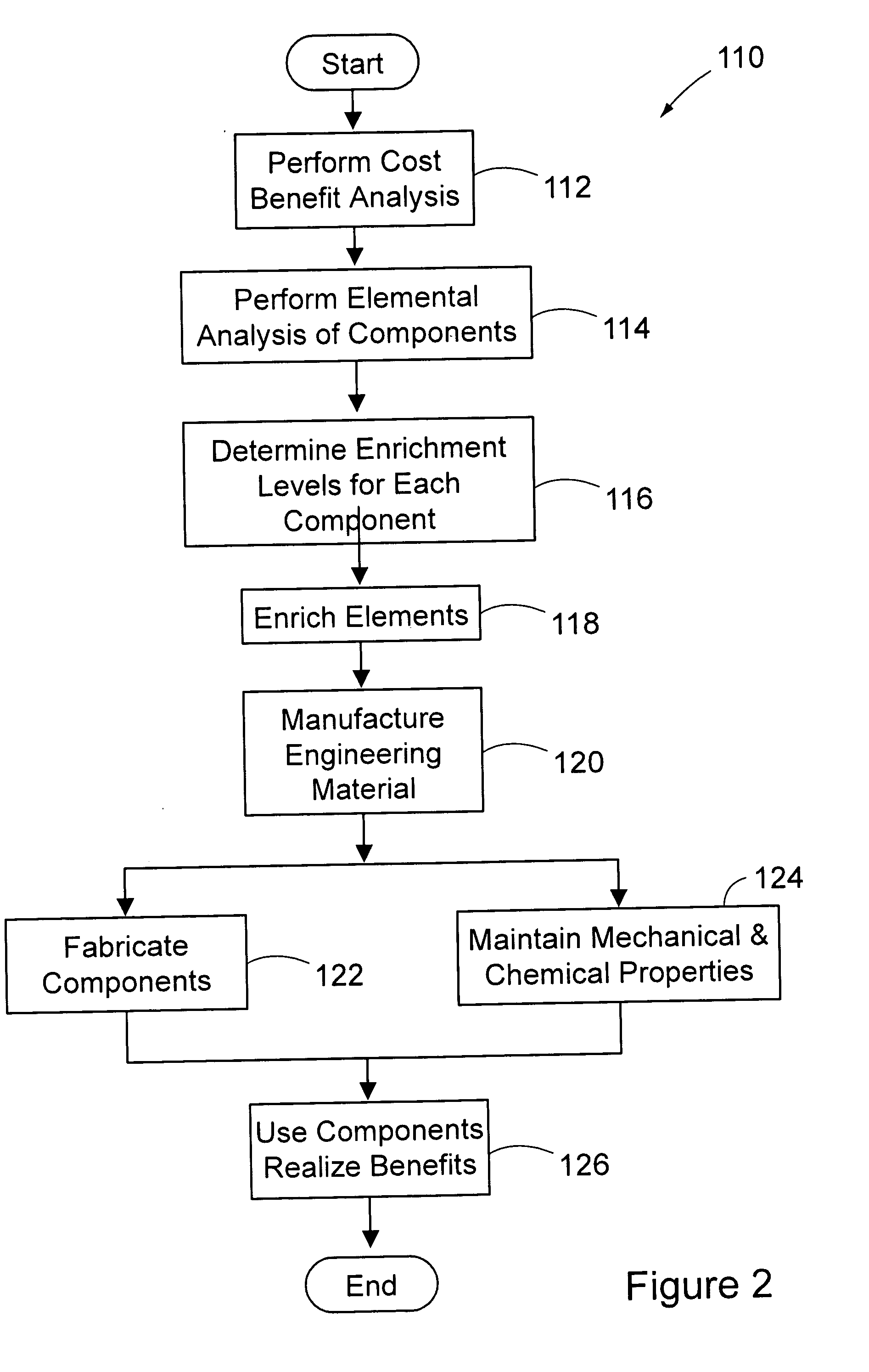

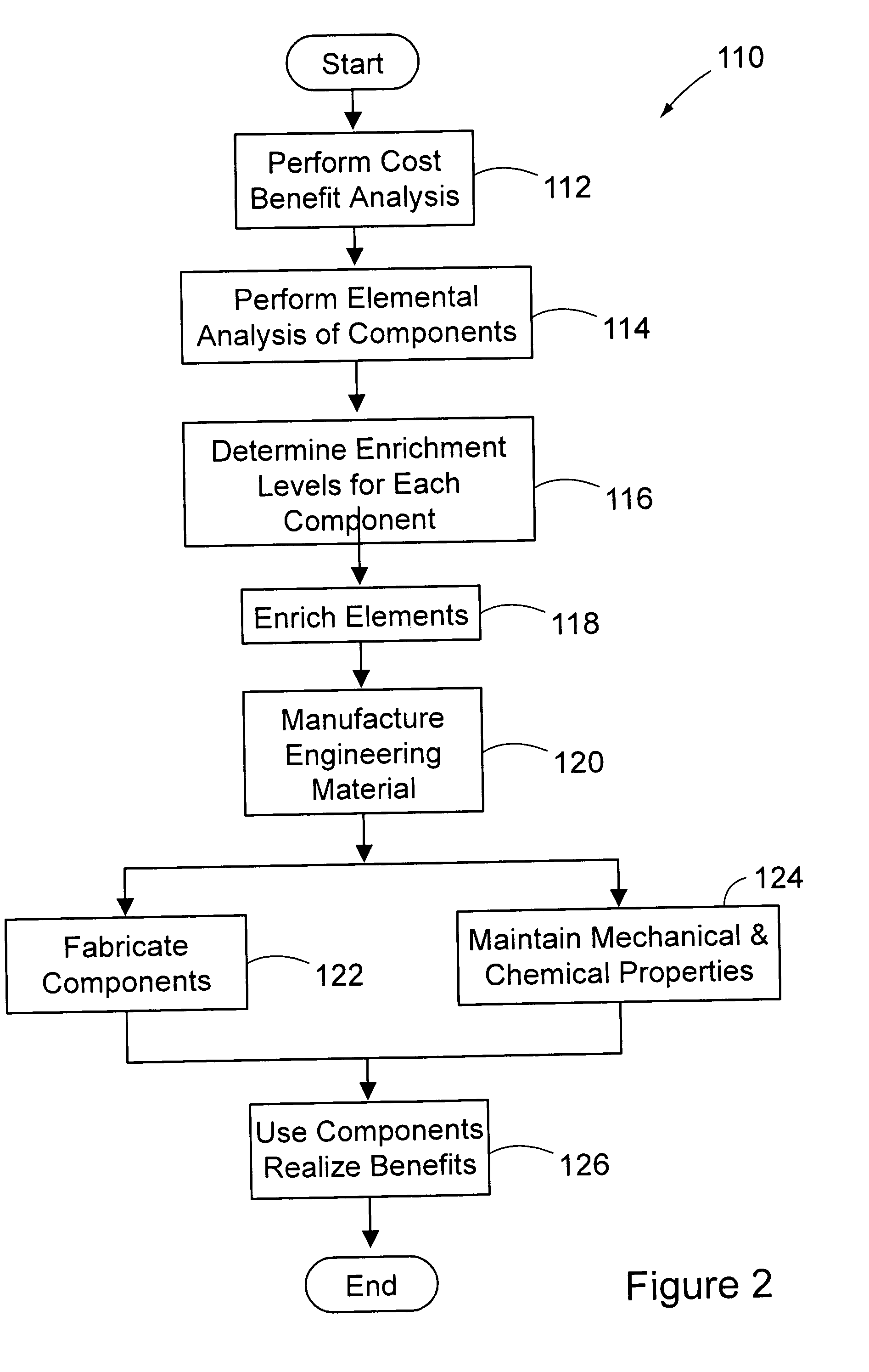

Isotopic lightening

ActiveUS20060102464A1Low densityLight weightTransuranic element compoundsLaunch systemsLithiumHydrogen

A method of manufacturing a component. In a preferred embodiment, the method includes enriching an element with an isotope and using the enriched element as a material of the component. A property of the first isotope being the same as a property of a second isotope and is preferably a mechanical, chemical, or electrical property. A second element can also be used as a material of the component, for instance, where the material is an alloy or a composite material. Further, the first isotope can be a lighter isotope of the element. Lightweight components may be manufactured using the method such that mobile platforms (e.g. spacecraft) can be assembled from the component(s). In other exemplary embodiments, the element can be hydrogen, lithium, boron, magnesium, titanium, or iron. Additionally, the component may carry a load. Components including isotopically enriched elements are also provided.

Owner:THE BOEING CO

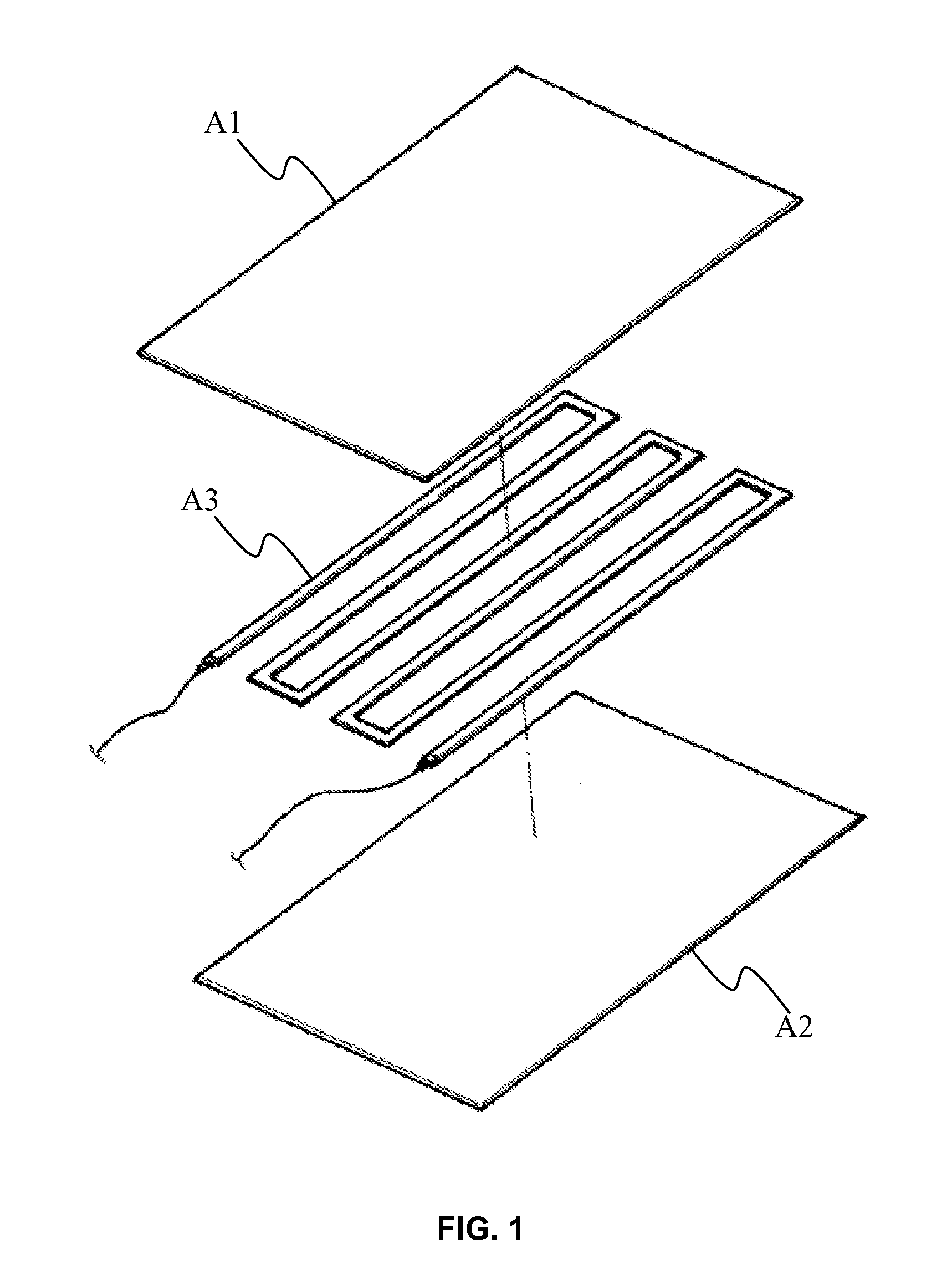

Skin-cover Structure

InactiveUS20120022411A1Specific strengthGood effectElectrotherapyChiropractic devicesElectricityEngineering

The present invention discloses a skin-cover structure comprising: a heating layer comprising a sheet of conductive rubber and at least one conductive and low-impedance material, wherein the sheet of conductive rubber can produce heat energy; a first insulating layer and a second insulating layer being disposed on the two surfaces of the heating layer respectively; at least one vibration module being disposed on the surface of the first insulating layer and able to produce vibration with specific strength when receiving electricity; and at least one electrode module being disposed on the surface of the second insulating layer and able to produce electric shock with specific strength when receiving electricity.

Owner:TOP BOUND ENTERPRISE +1

Special material for wood plastic extrusion foaming and preparation method thereof

The invention relates to a special material for wood plastic extrusion foaming in the technical field of high polymer materials. The composite material is mainly compounded by polypropylene, a foaming agent, a blowing promotor, a cross-linking agent, an assistant crosslinker, a compatilizer, a coupling reagent, a nucleating agent and wood powder. The preparation method of the composite material comprises the following steps of carrying out activating treatment on the wood powder, blending the wood powder and polypropylene as well as various addition agents uniformly through a high mixing machine, extruding by a twin screw and foaming once to prepare the material. The special material for polypropylene or wood powder extrusion foaming has the characteristics of light weight, specific strength, waterproofing, anticorrosion and heat preservation, and the prepared product has the processing characteristic that the timber can be nailed, sawed and planed; the special material not only has good mechanical property and thermal property, but also has excellent environmental protection properties such as being recyclable and degradable and the like; the special material can be widely used in fields of construction, transportation and packaging as well as household decoration and daily necessities markets; the special material can be recycled directly, does not damage the surface of the packed objects due to the soft texture of the material, can be used as a packaging material for electrical equipment, computers, cameras and the like, can be used for skin packaging of glass ware, precise workpieces and quick-wear parts, and can substitute for a PS (polystyrene) foam material.

Owner:TIANJIN DEHAO NEW MATERIALS

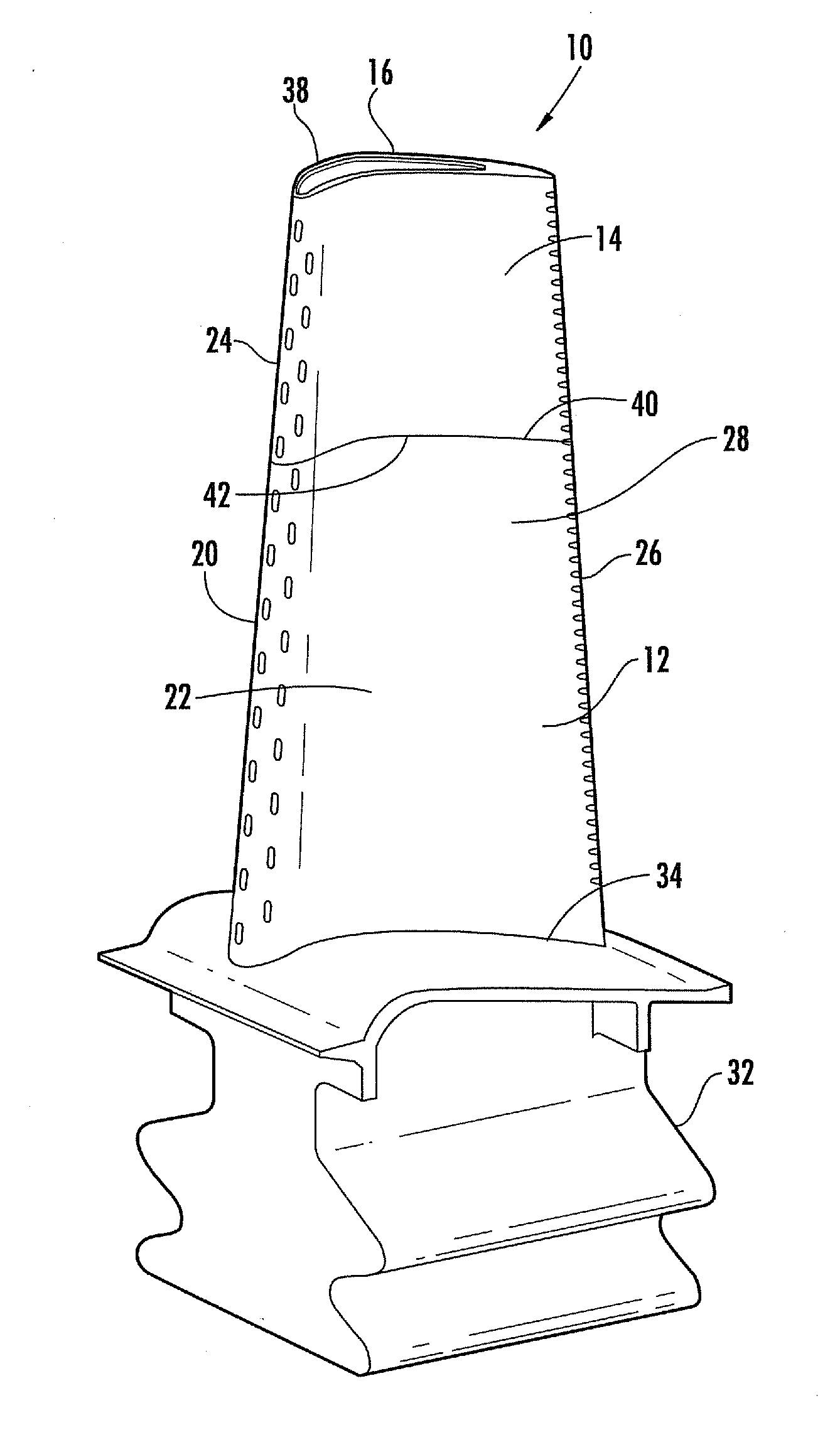

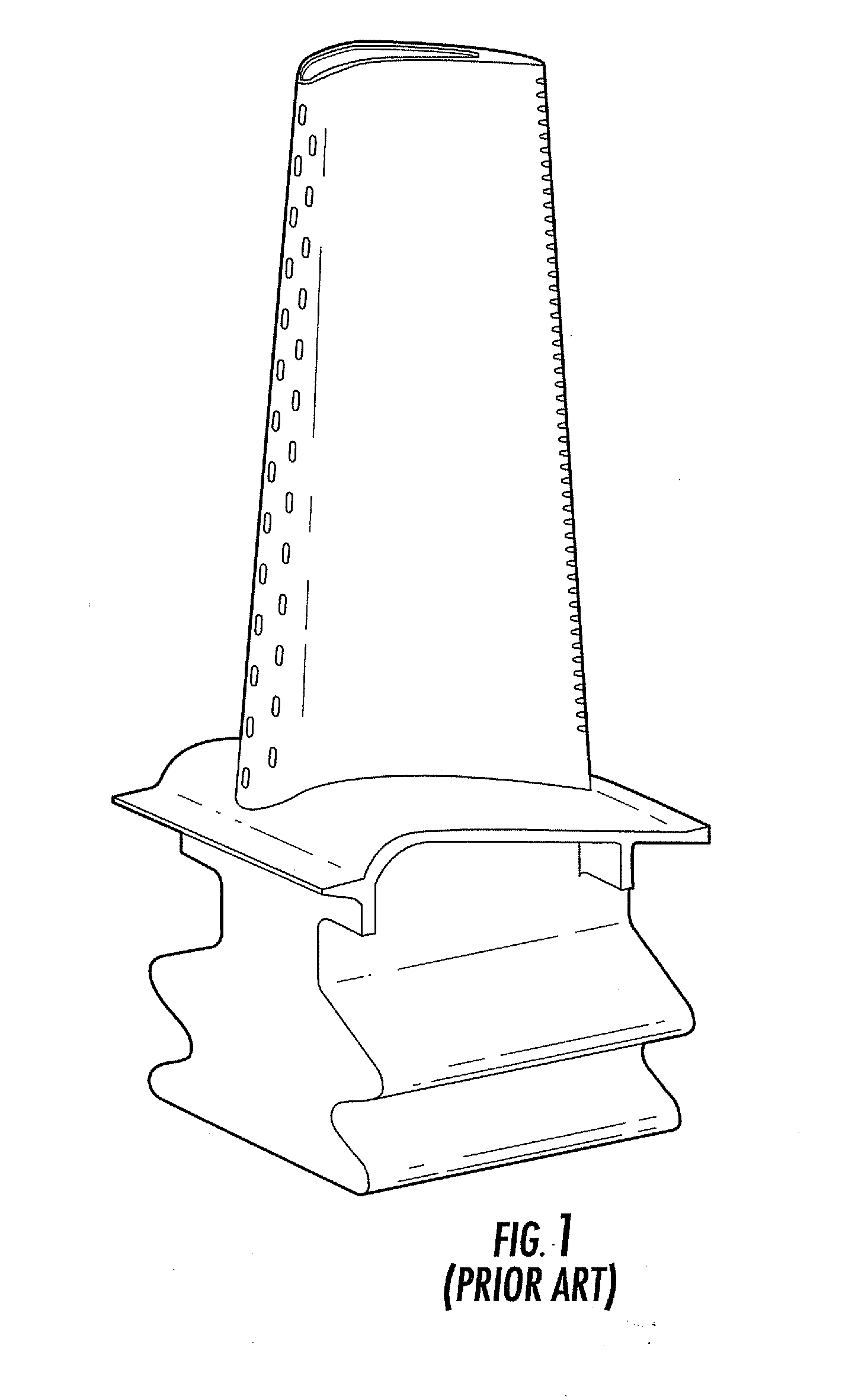

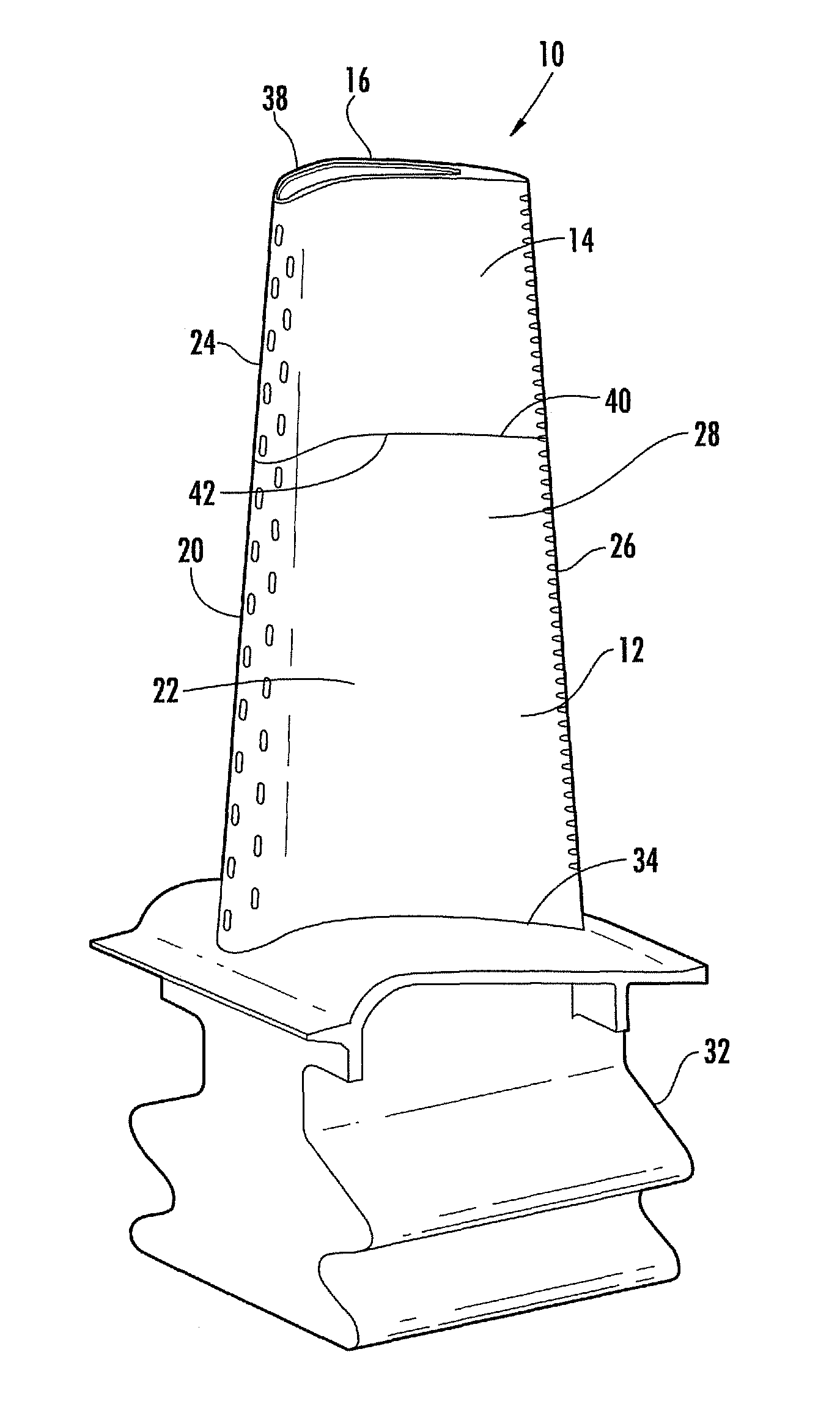

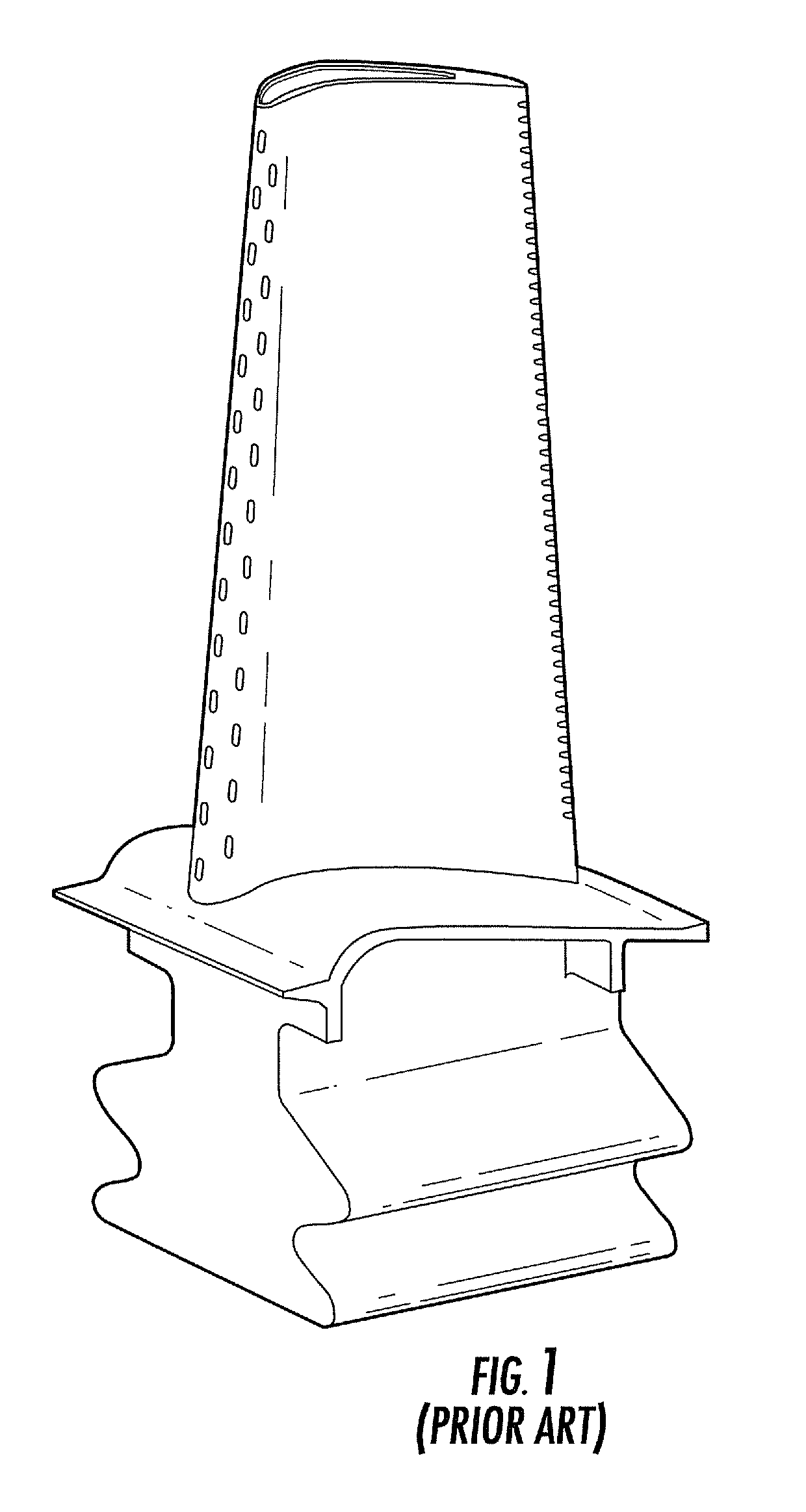

Turbine airfoil having outboard and inboard sections

A turbine airfoil usable in a turbine engine and formed from at least an outboard section and an inboard section such that an inner end of the outboard section is attached to an outer end of the inboard section. The outboard section may be configured to provide a tip having adequate thickness and may extend radially inward from the tip with a generally constant cross-sectional area. The inboard section may be configured with a tapered cross-sectional area to support the outboard section.

Owner:SIEMENS ENERGY INC

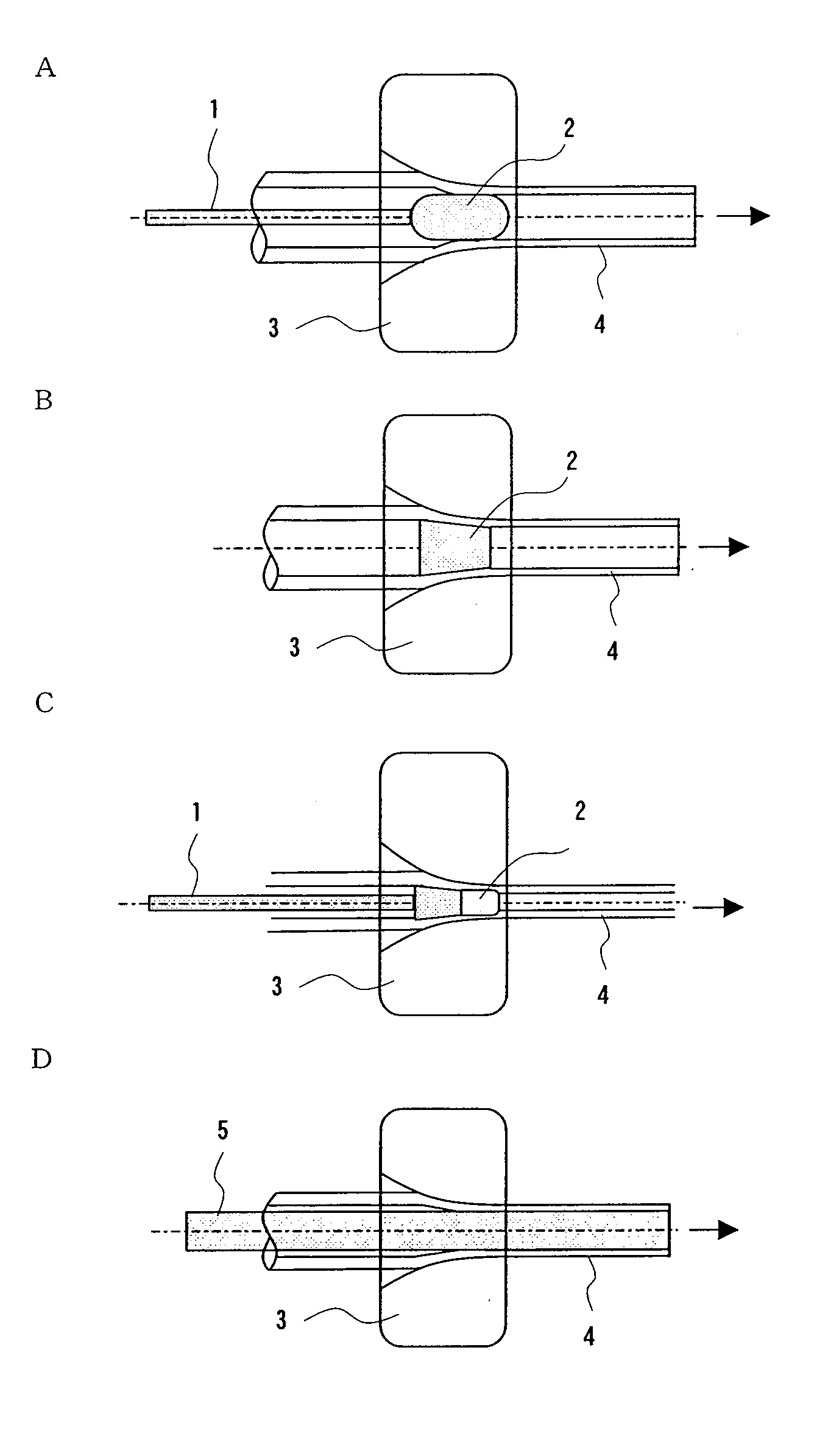

Providing a transverse filling inside and elongated narrow cavity

InactiveUS20110225796A1Without compromising structural propertySpecific densityUmbrellasEngine manufacturePower stationEngineering

A method for performing a task in a tight place in an elongated profile, preferably in a wing blade with an outer shell for a wind power plant, whereby at least one barrier is formed transversely of at least one elongated channel in the profile and a balloon for use in performing the task. The method may include the following steps: establishing a number of inspection and mounting holes in the surface of the shell, mounting at least one inflatable balloons in the at least one channel, filling the balloon(s) with air, and applying at least one first material layer between the sidewalls of the elongated channel and across the balloon(s), the layer preferably being expanding polyurethane foam. The applied layer of material fills cracks and gaps between balloons and wing parts, providing a load-bearing layer between these parts. An additional layer may subsequently be laid upon the former layer.

Owner:LM GLASSFIBER

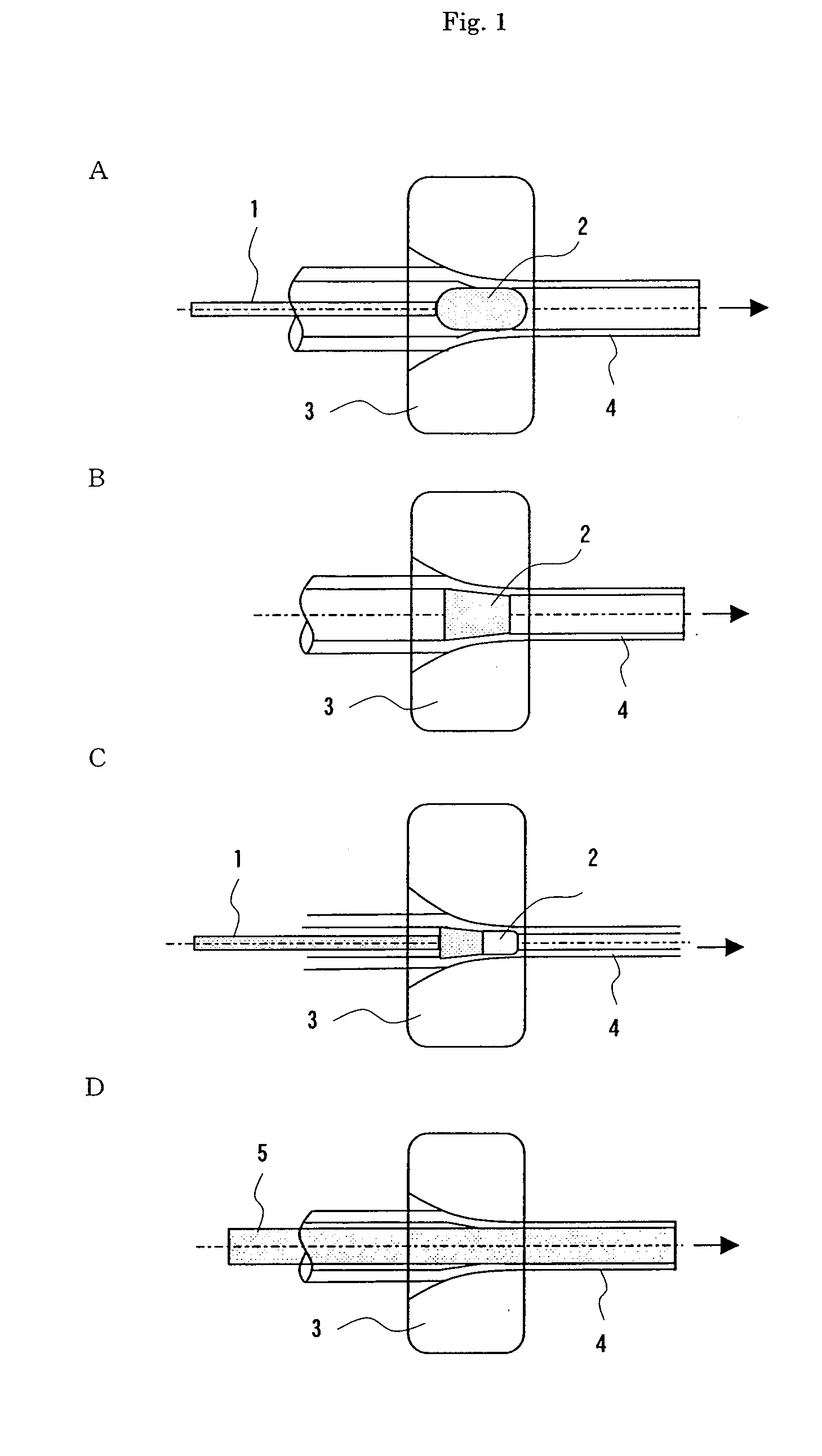

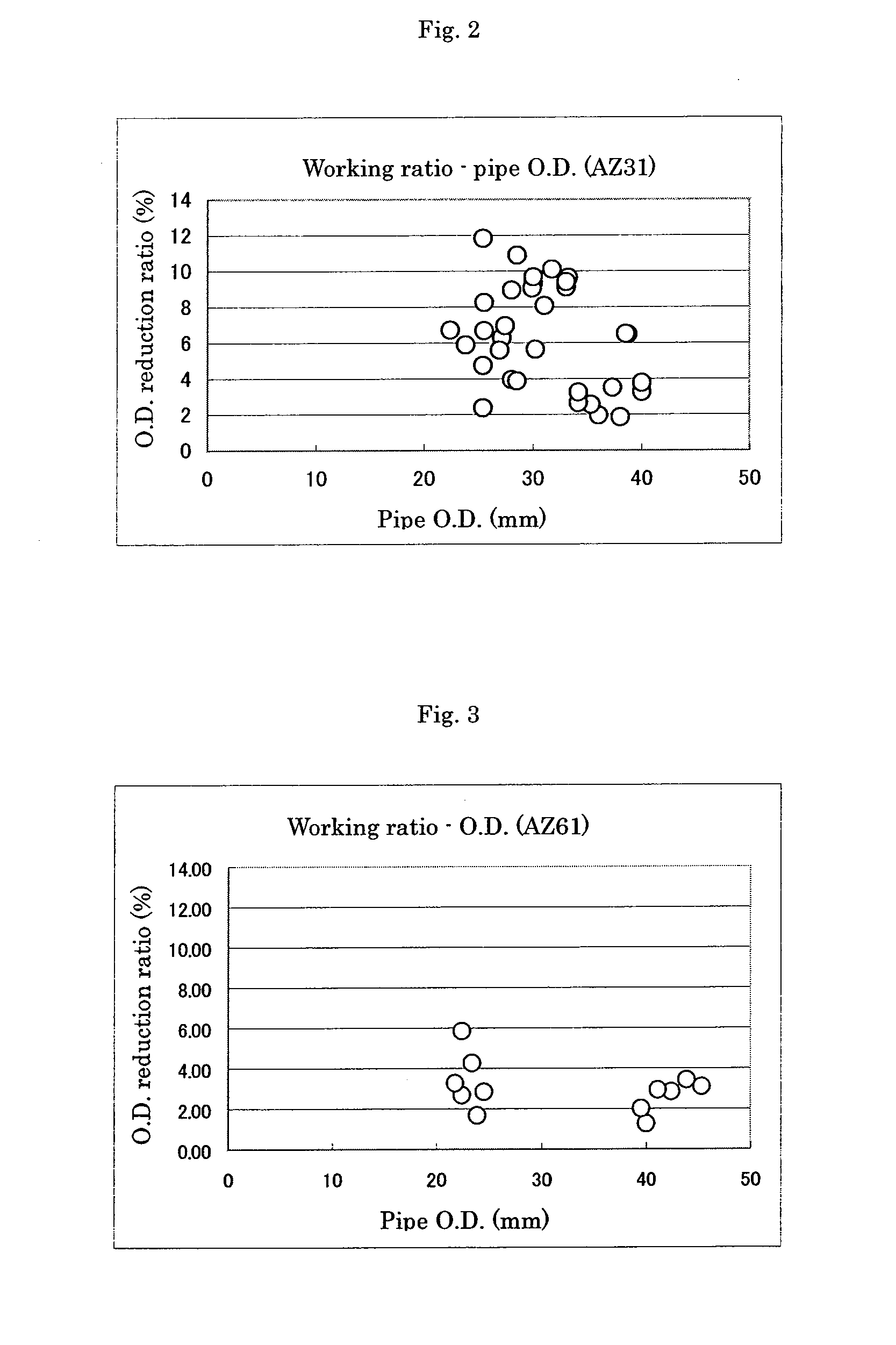

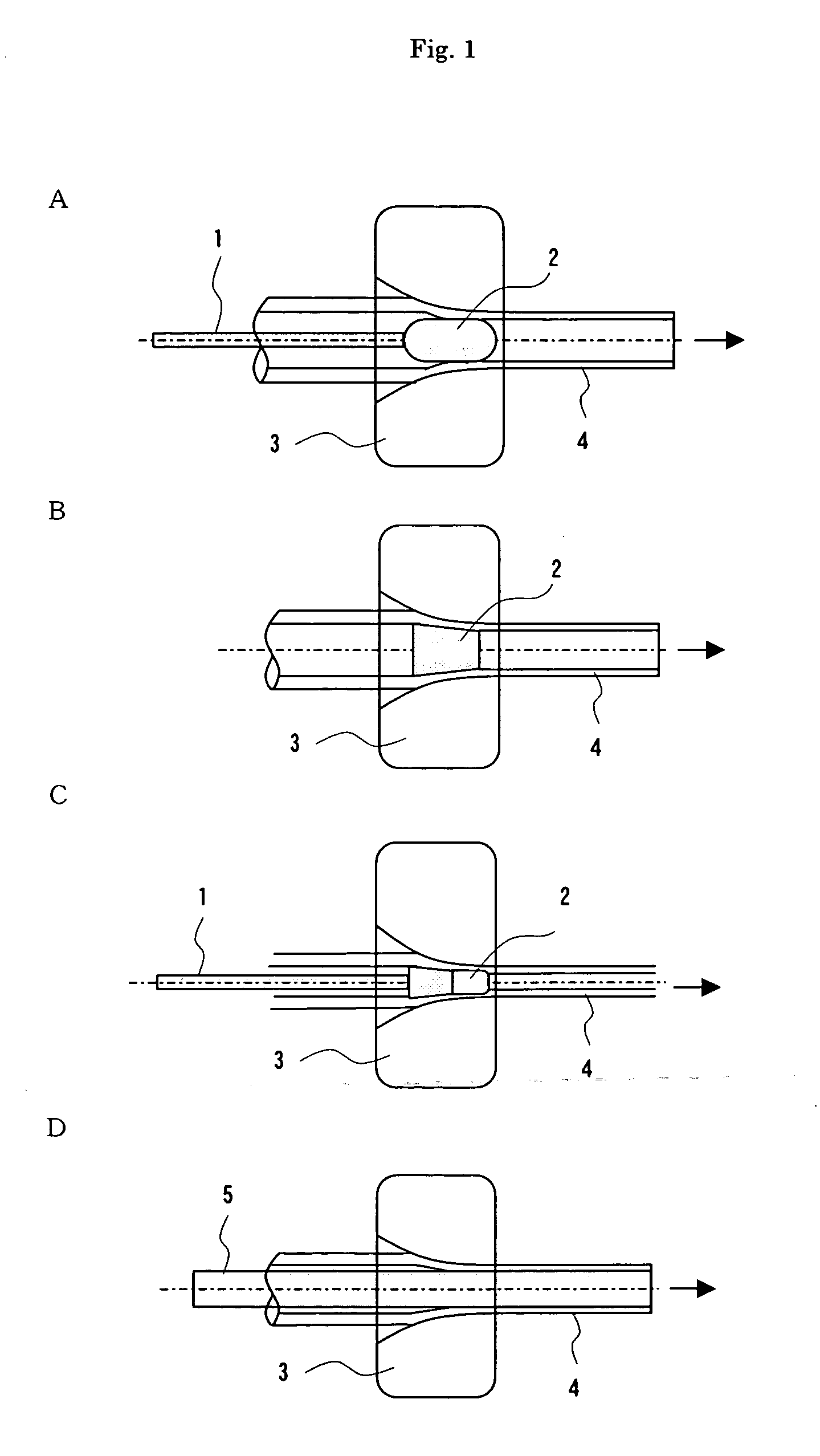

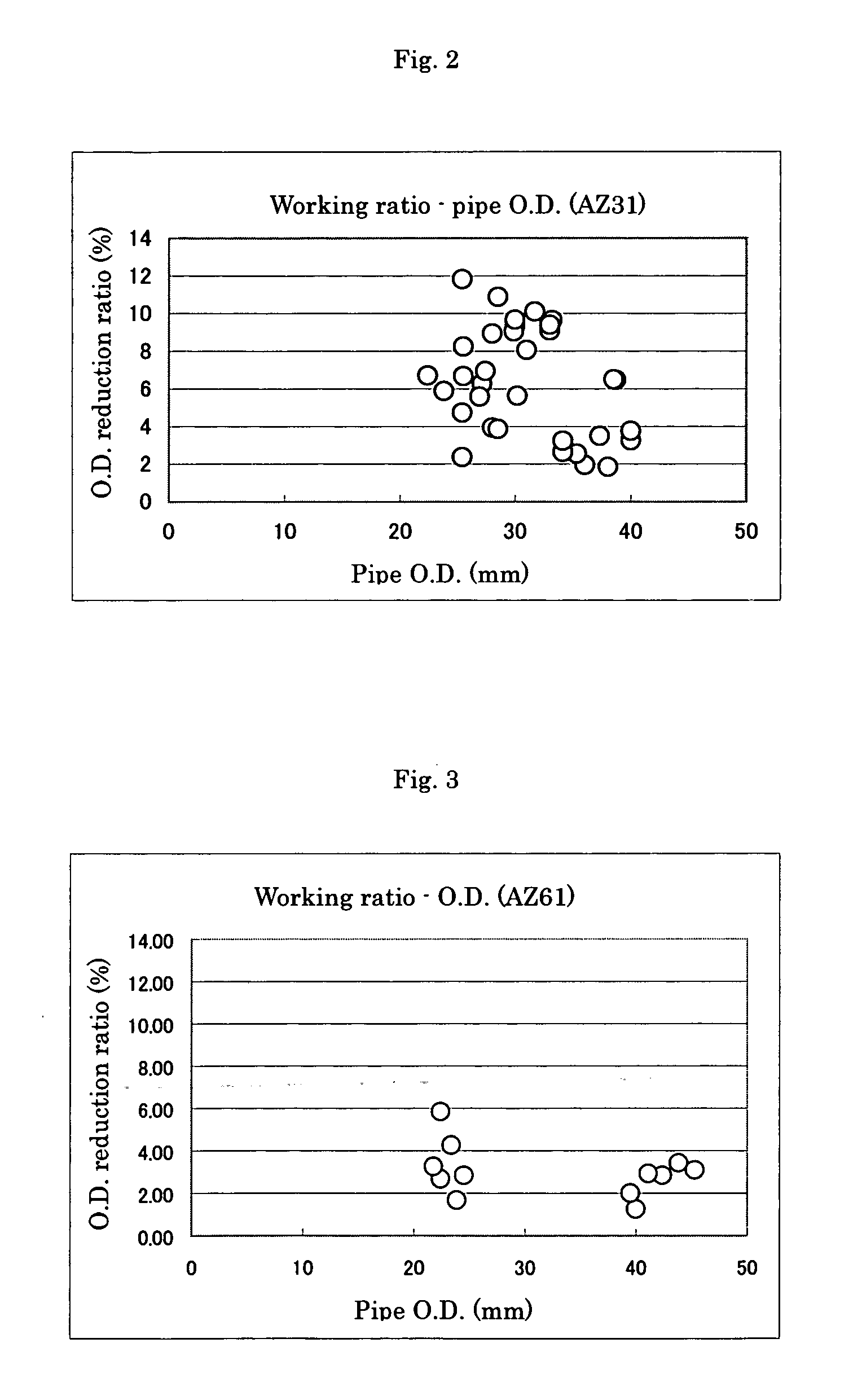

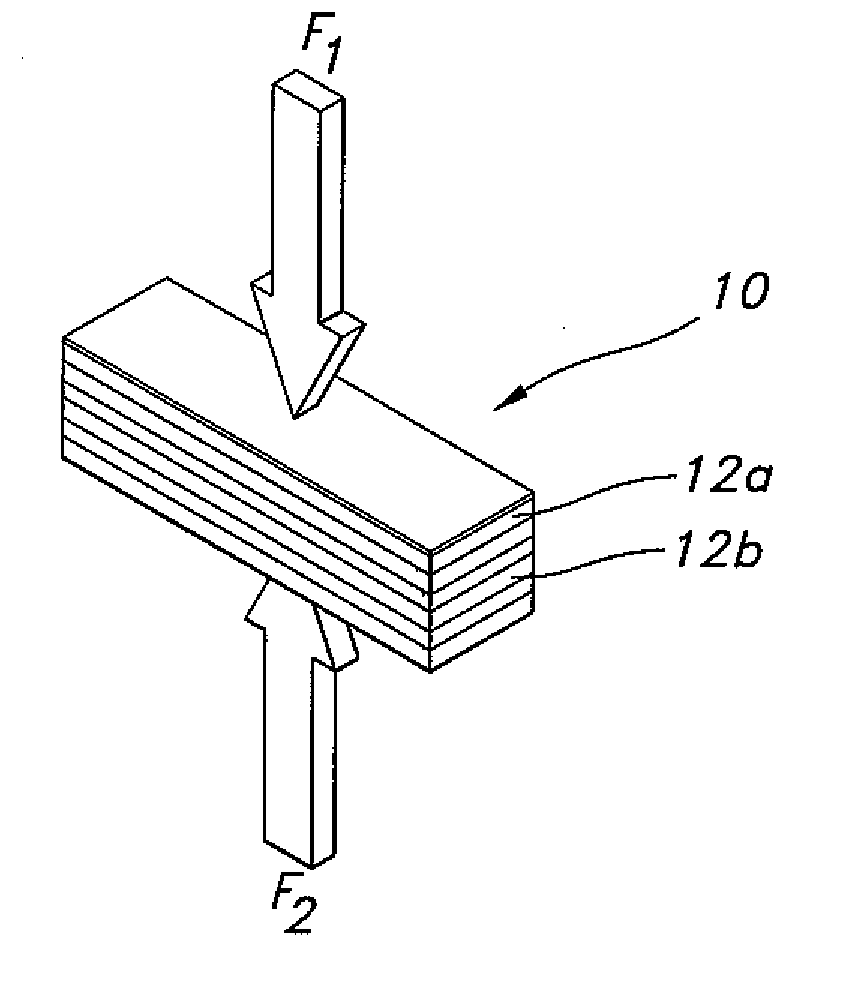

Magnesium base alloy pipes and method of manufacturing the same

InactiveUS20090032151A1High strengthImprove toughnessBlade accessoriesMachines/enginesAlloyHigh intensity

Owner:SUMITOMO ELECTRIC IND LTD

Turbine airfoil having outboard and inboard sections

Owner:SIEMENS ENERGY INC

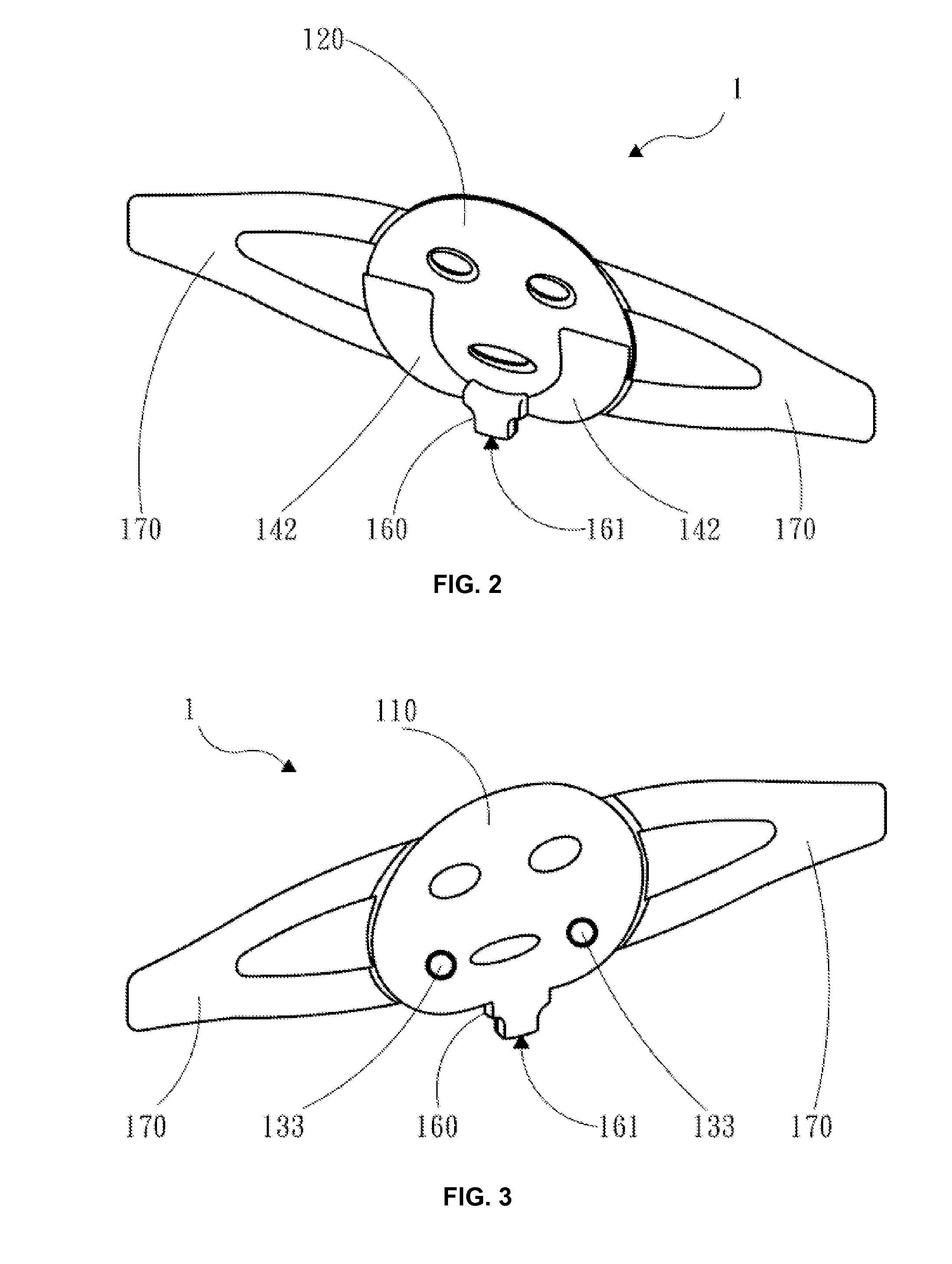

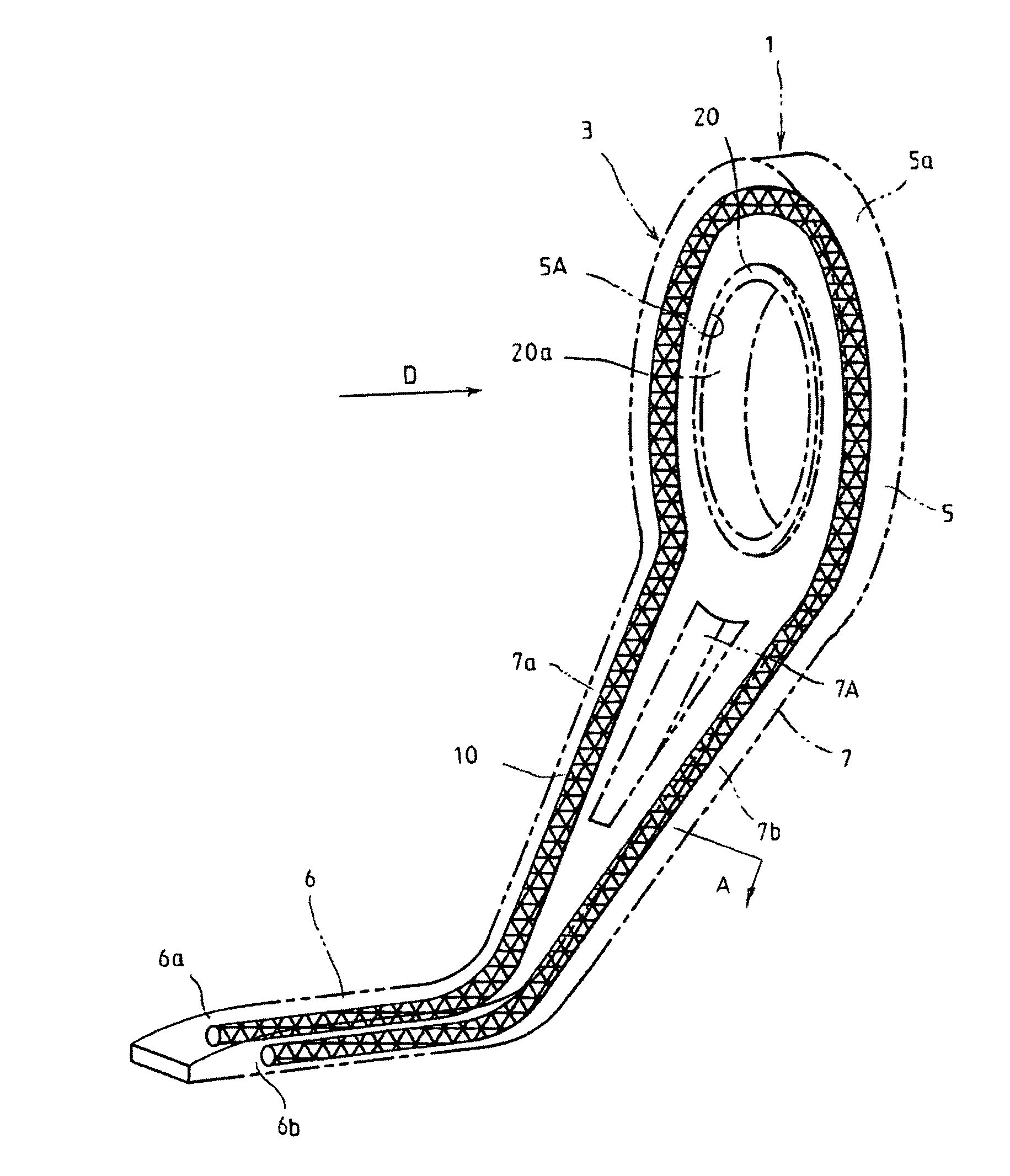

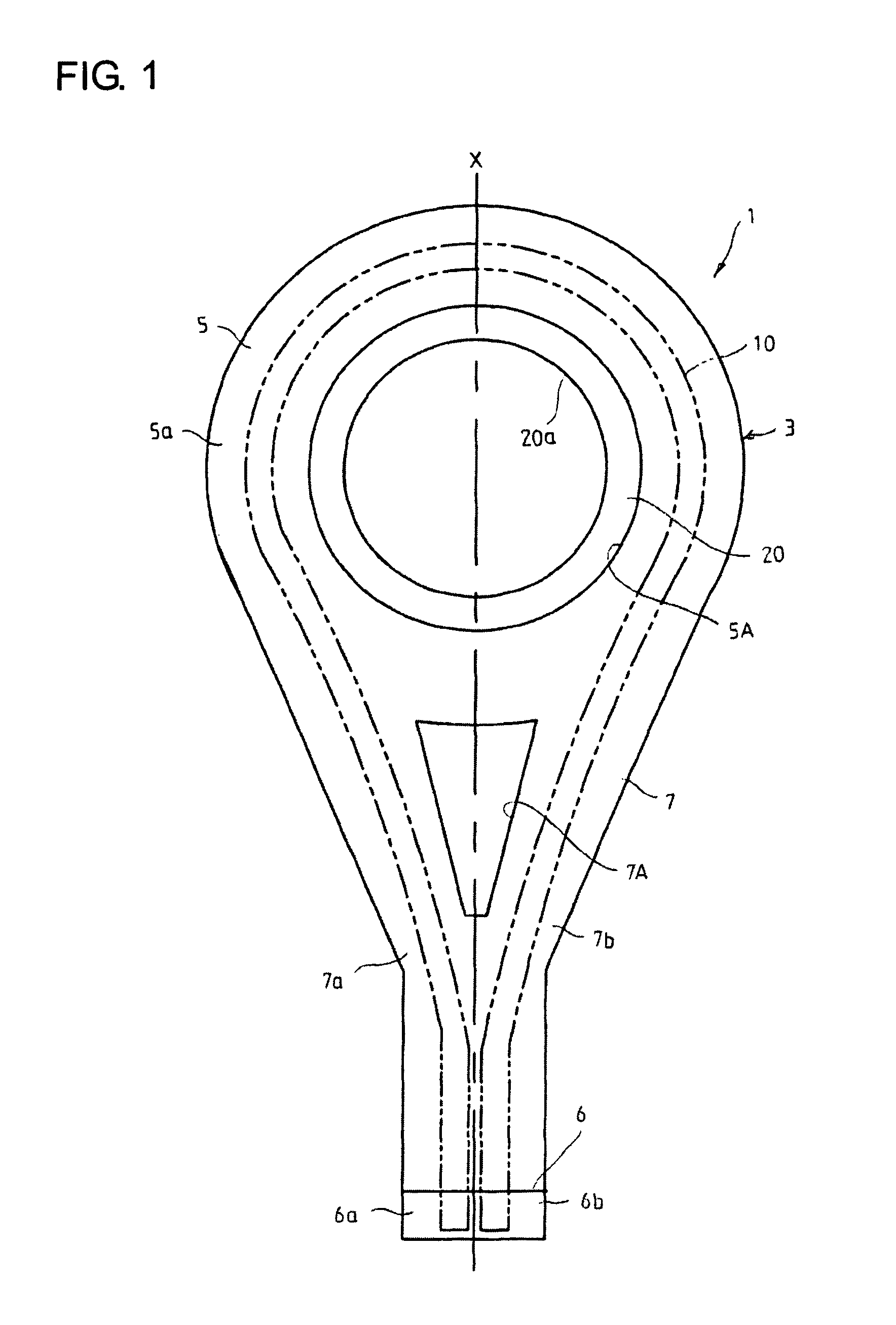

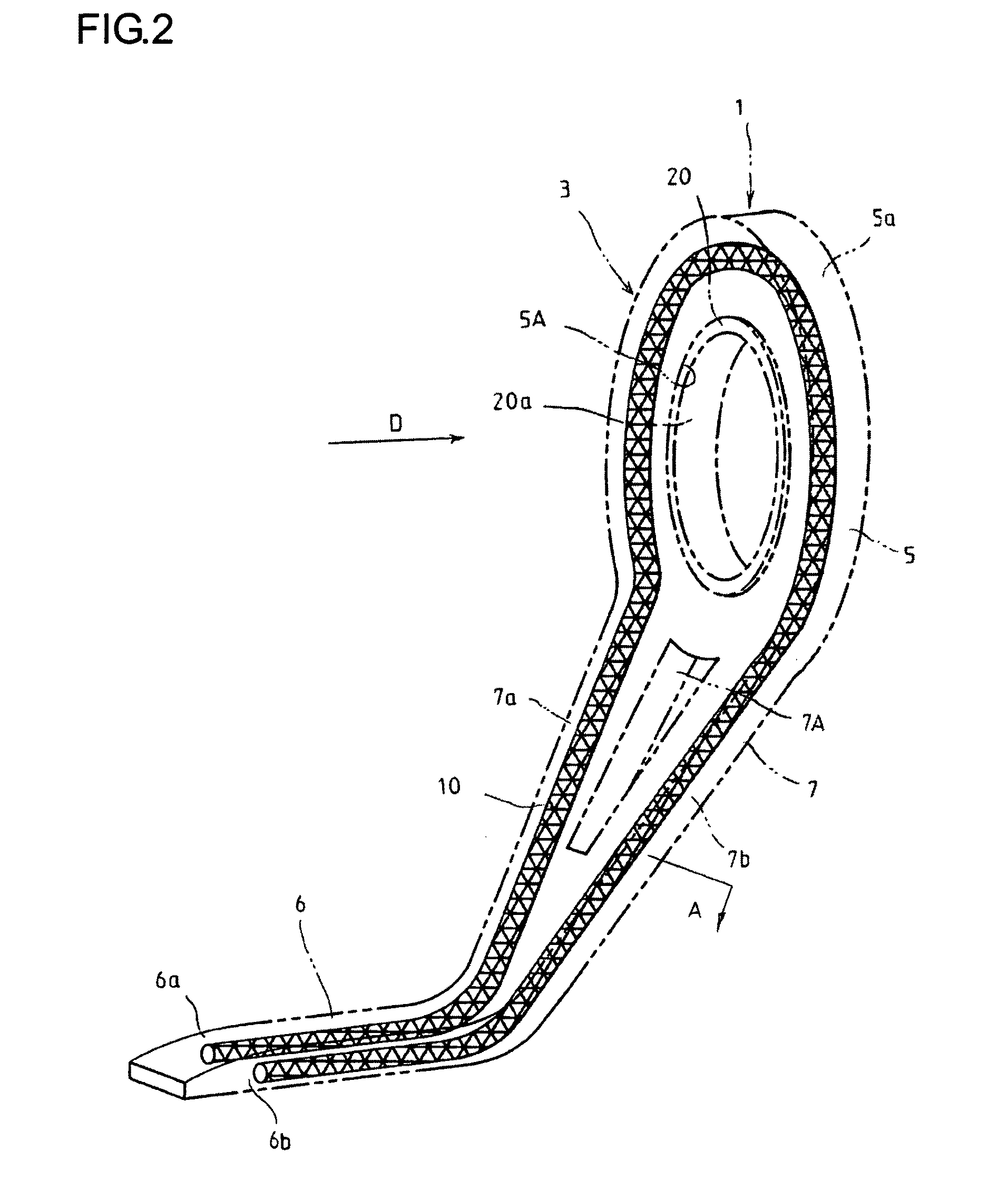

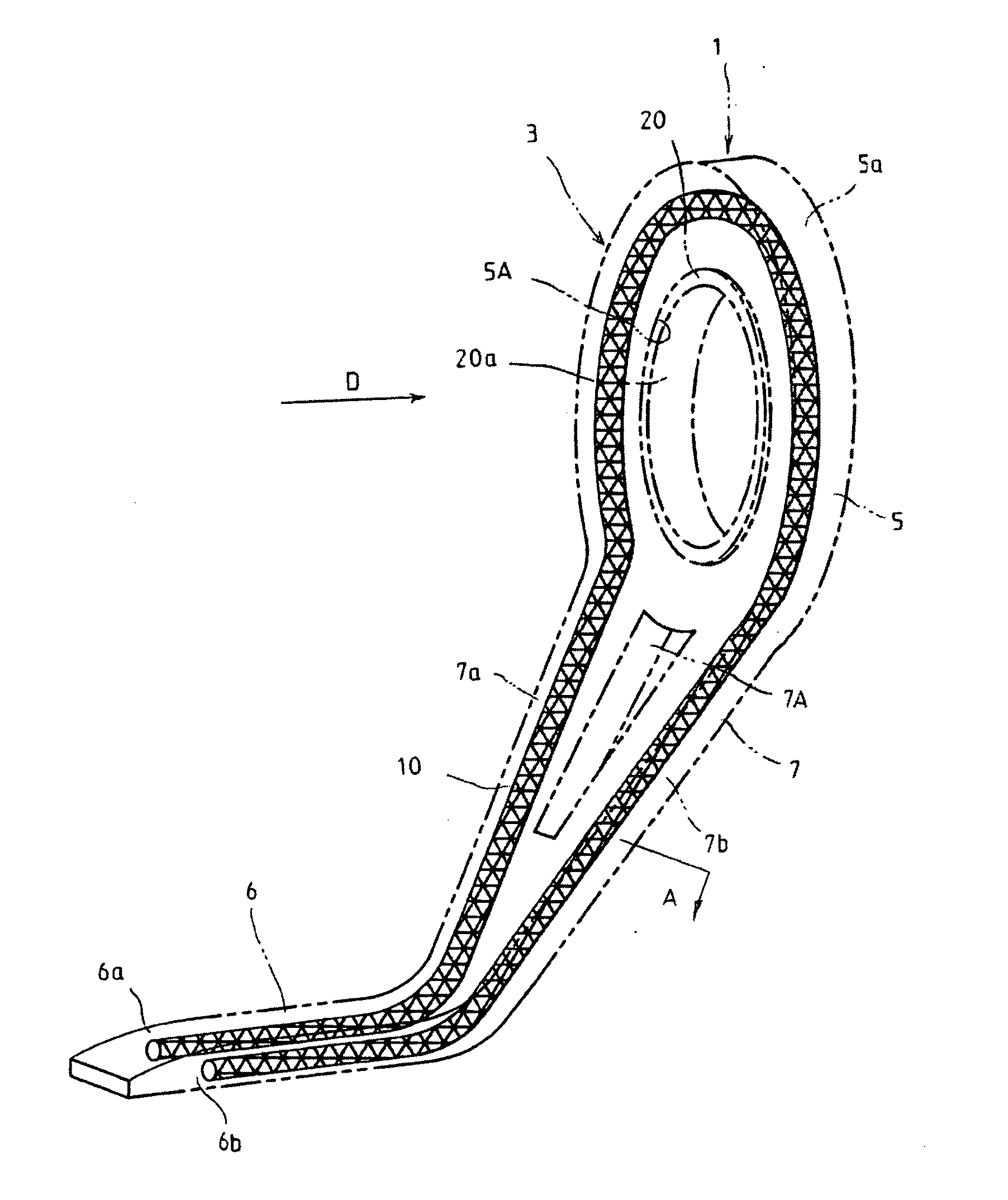

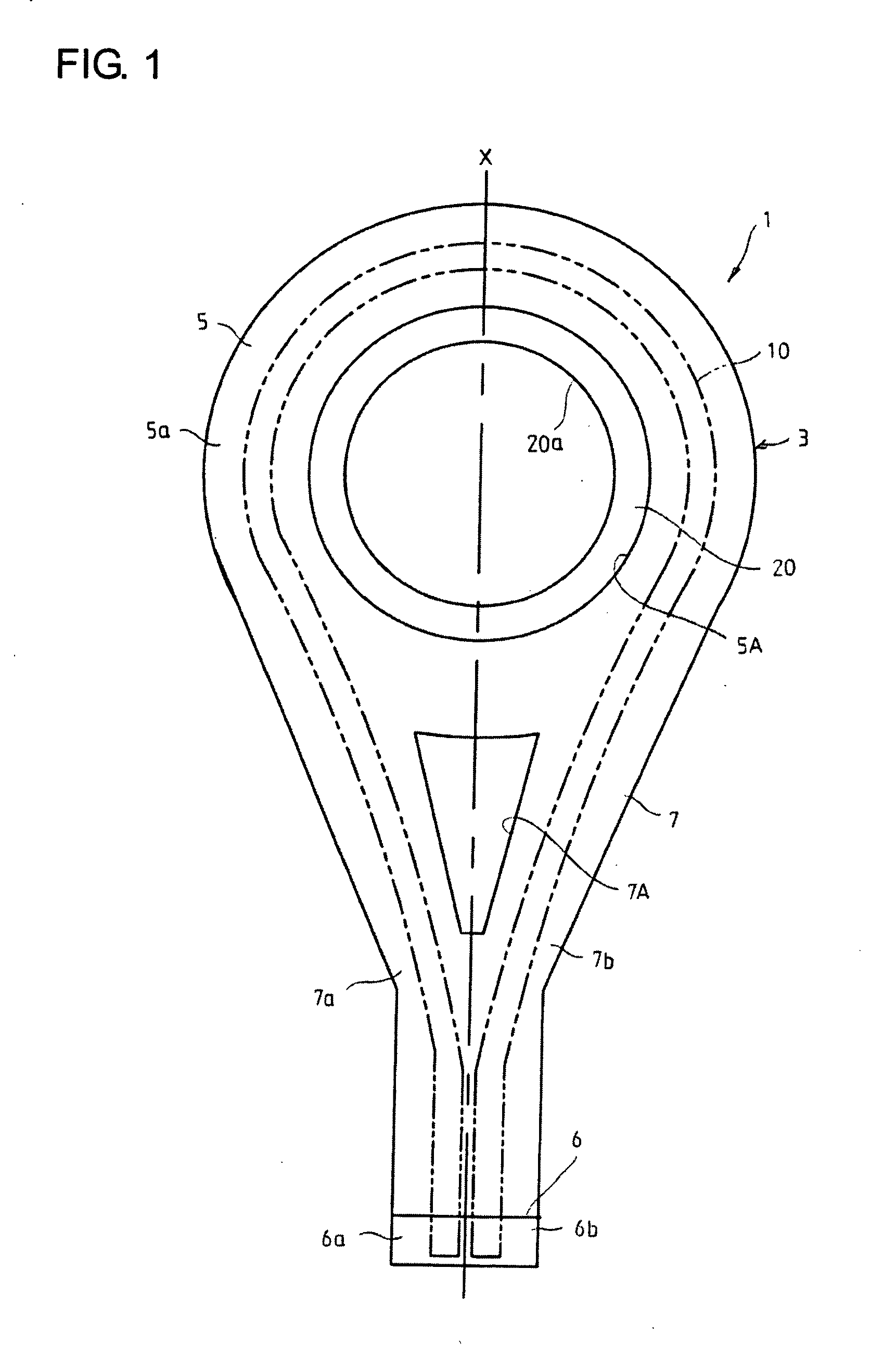

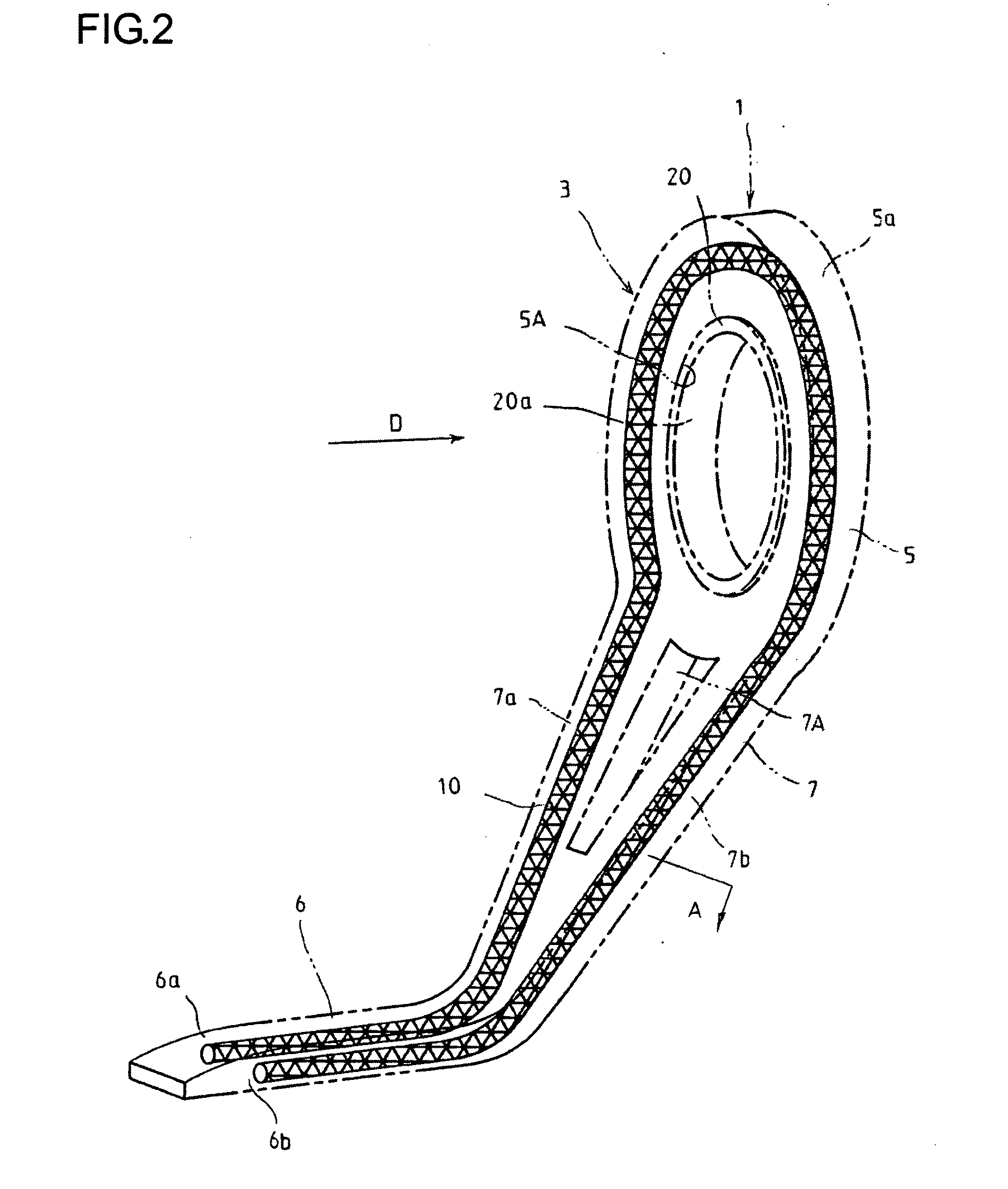

Fishing line guide and method of manufacturing fishing line guide

A fishing line guide to be attached to a fishing rod includes a frame that includes a fixing part to be fixed to an exterior surface of the fishing rod, a holding part which holds a ring-shaped guide ring through which a fishing line is to pass, and a connecting part connecting the fixing portion to the holding part. The frame includes a fiber reinforced synthetic resin including a fiber bundle including a plurality of reinforced fibers extending in an extending direction of a part forming the holding part and the connecting part.

Owner:DAIWA SEIKO CORPORATION

Reinforcing Fiber Bundle and Method for Producing Same

InactiveUS20170145627A1Satisfies texture and convergence performanceHigh resin impregnation ratioCarbon fibresWater soluble polymersMelt viscosity

A fiber reinforcing bundle with a sizing agent adhering to the surface thereof is provided, in which the sizing agent contains a thermoplastic resin as a main component and an emulsion or a dispersion, and in which a melt viscosity of a solid content of the sizing agent at 150° C. and at a shear rate of 10 s−1 is 50 to 300 Pa·s; and a method for producing the fiber reinforcing bundle. Preferably, the sizing agent contains a water-soluble polymer, the sizing agent contains a hardly water-soluble polymer, and the reinforcing fiber bundle is a carbon fiber bundle.

Owner:TEIJIN LTD

Manesium base alloy tube and method for manufacture thereof

InactiveUS20050208324A1Easy to manufactureEfficiently formedThin material handlingMetal layered productsAdditive ingredientAlloy

A magnesium base alloy pipe having high strength and toughness is provided along with a method of manufacturing such pipes. A magnesium base alloy pipe, wherein the pipe is produced by drawing a pipe blank of a magnesium base alloy comprising containing either of the following ingredients (1) or (2): (1) about 0.1-12.0 mass % of Al; or (2) about 1.0-10.0 mass % of Zn and about 0.1-2.0 mass % of Zr. The novel alloy pipe is manufactured by a method comprising steps of providing the above-described pipe blank, pointing the pipe blank, and drawing the pointed pipe blank. The drawing step is executed at a drawing temperature above approx. 50 ° C.

Owner:SUMITOMO (SEI) STEEL WIRE CORP

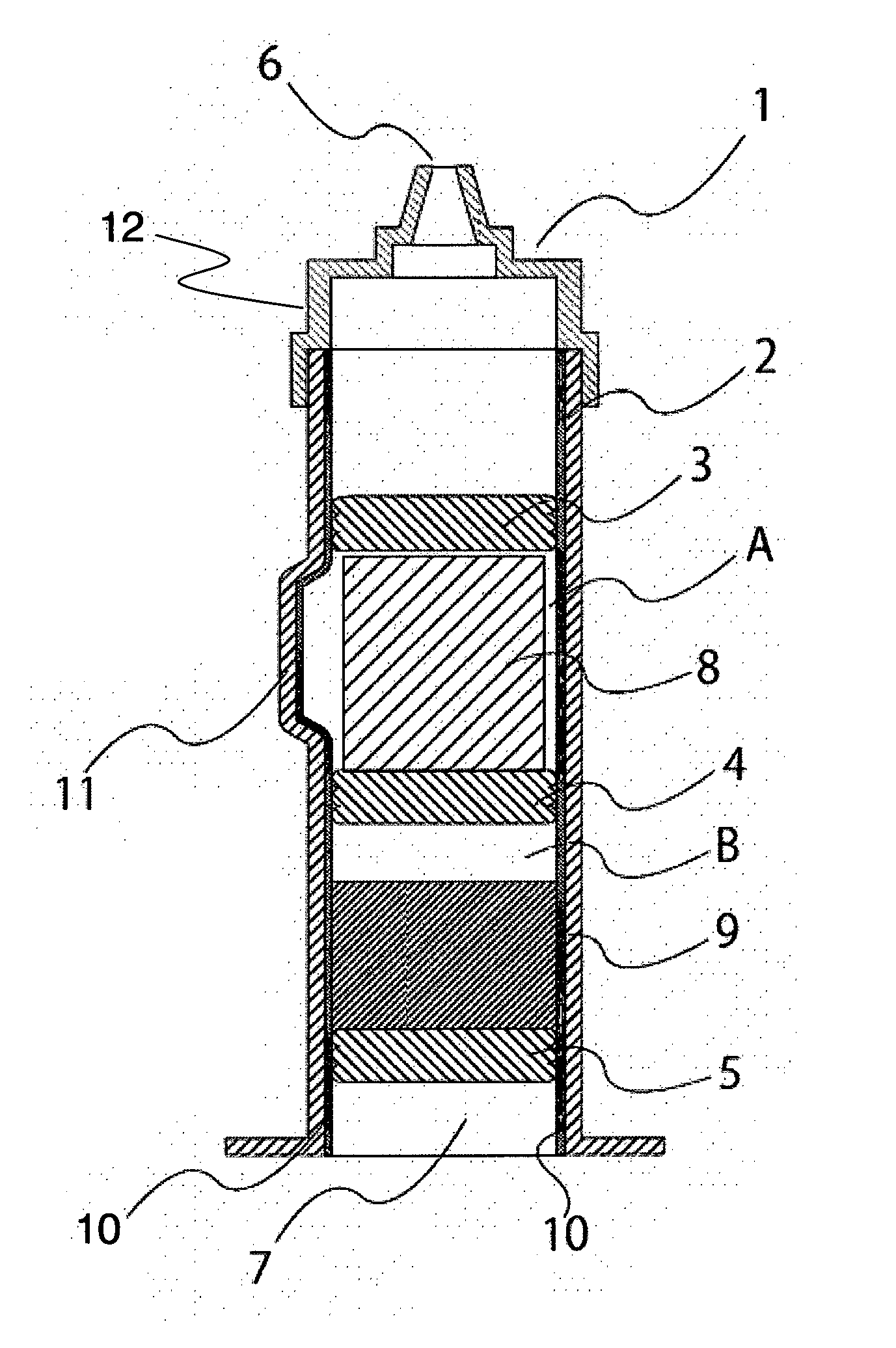

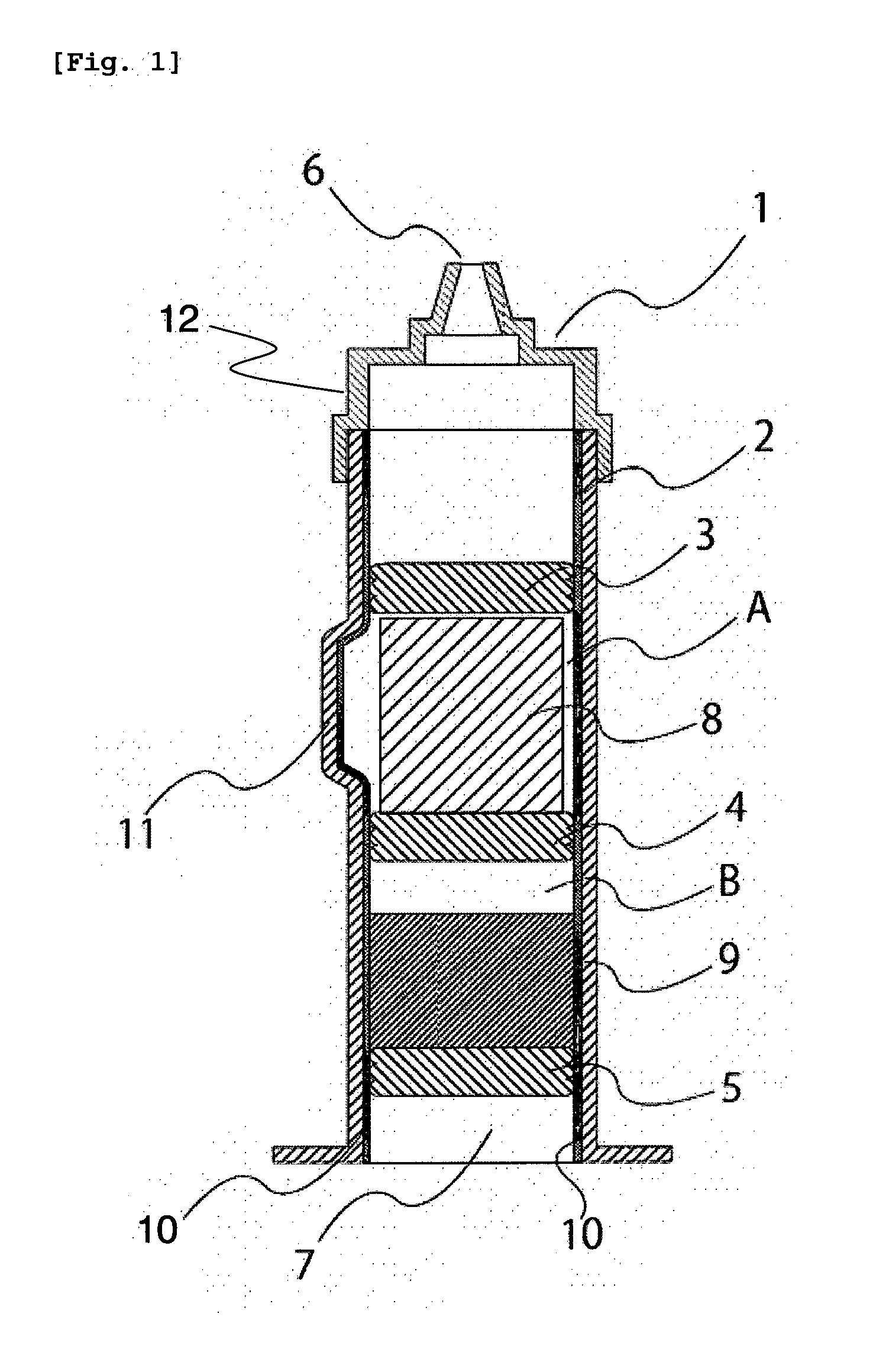

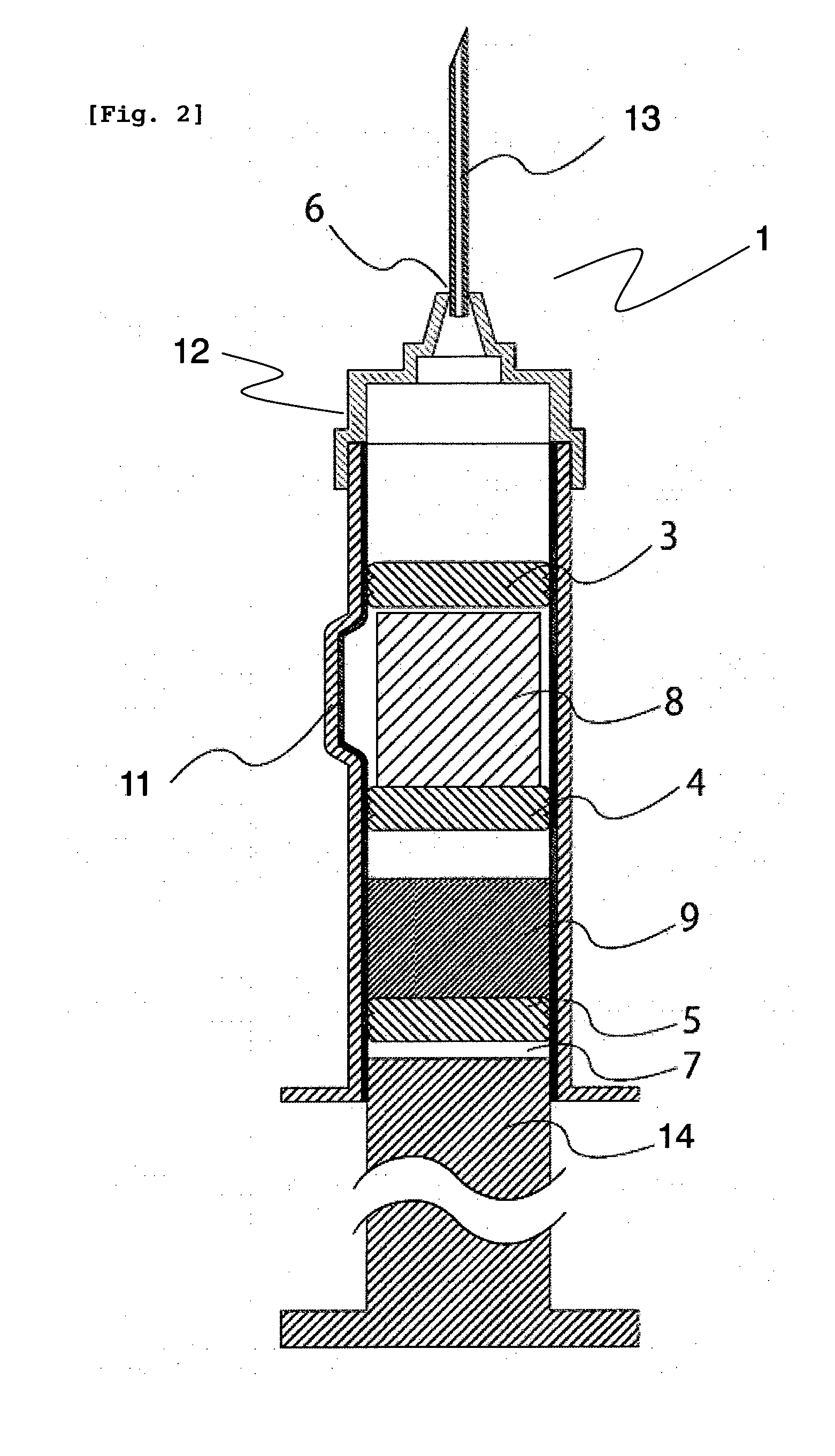

Medical device containing a cake composition comprising aripiprazole as an active ingredient, and a cake composition comprising aripiprazole as an active ingredient

ActiveUS20130302384A1Reduce riskReduce exposureOrganic active ingredientsPowder deliveryMedicineFreeze-drying

The present invention provides a medical device containing a cake composition comprising aripiprazole as an active ingredient and capable of suppressing agglomeration of aripiprazole in a suspension obtained by resuspending a freeze-dried substance; and a cake composition comprising aripiprazole as an active ingredient. The present invention relates to a medical device containing, in a storage container whose inner wall is treated with silicone, a freeze-dried cake composition comprising separately prepared aripiprazole as an active ingredient, wherein there is a space between the inner wall and the cake composition; and a cake composition comprising aripiprazole as an active ingredient and having a strength of 5 to 100 N.

Owner:OTSUKA PHARM CO LTD

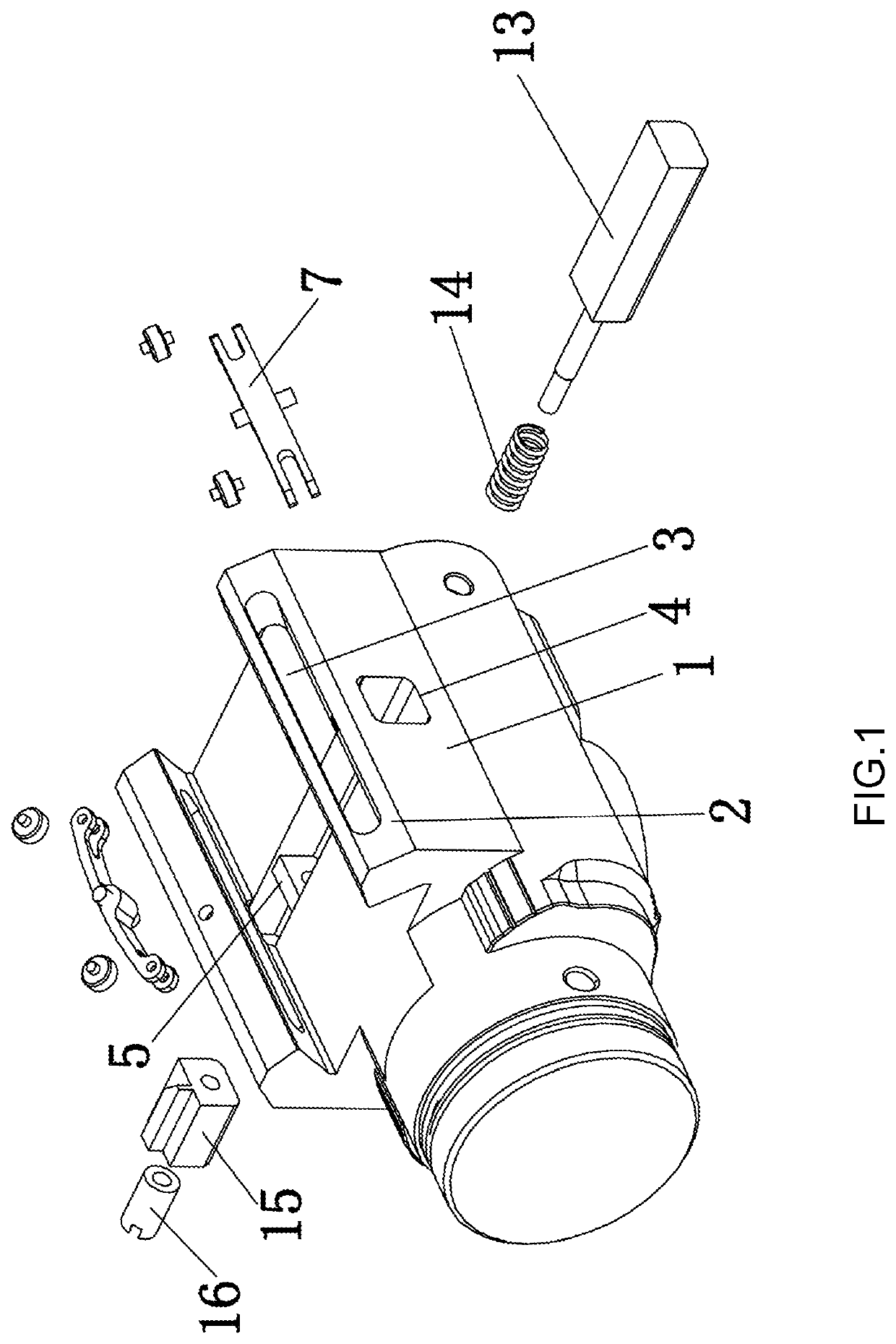

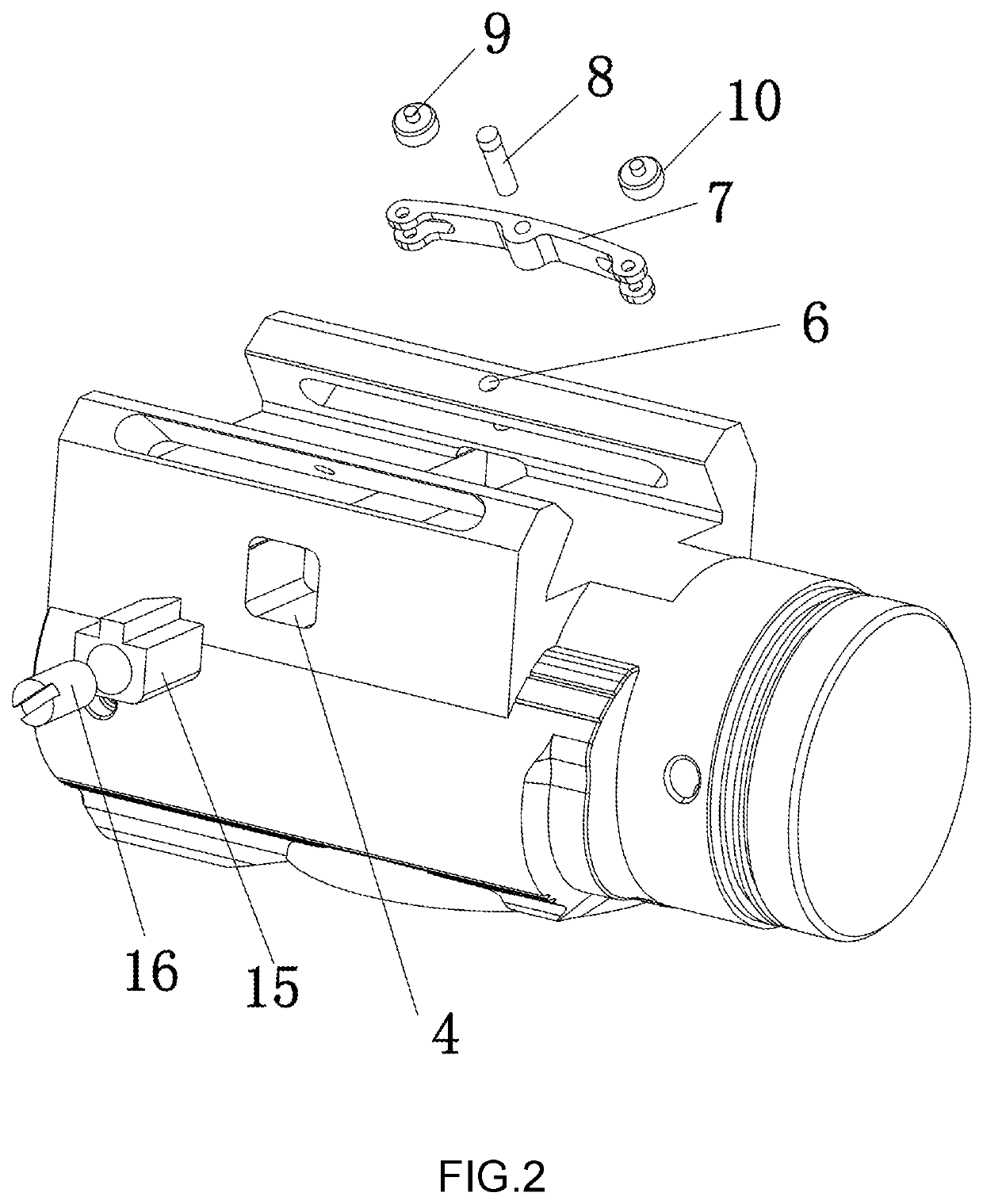

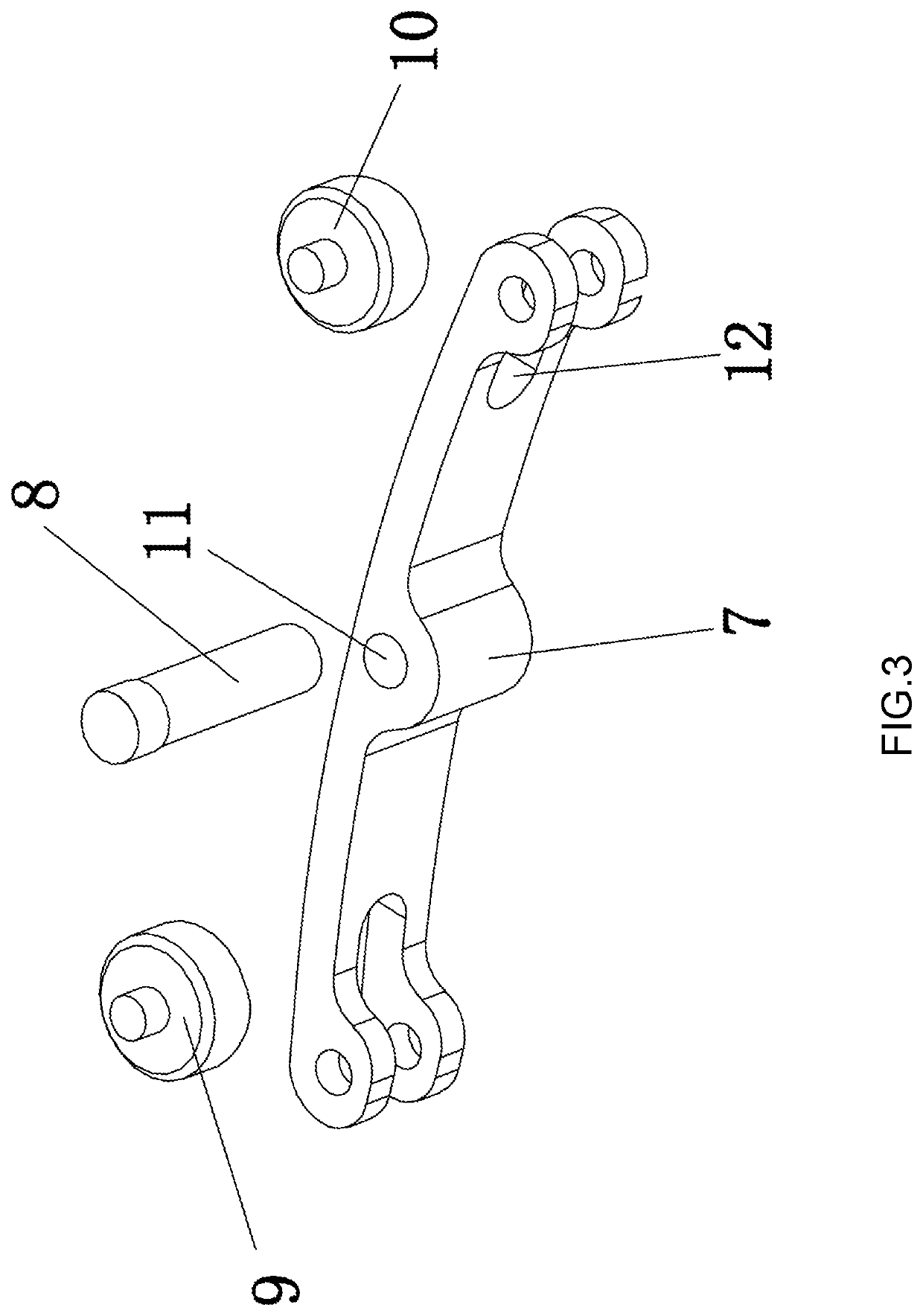

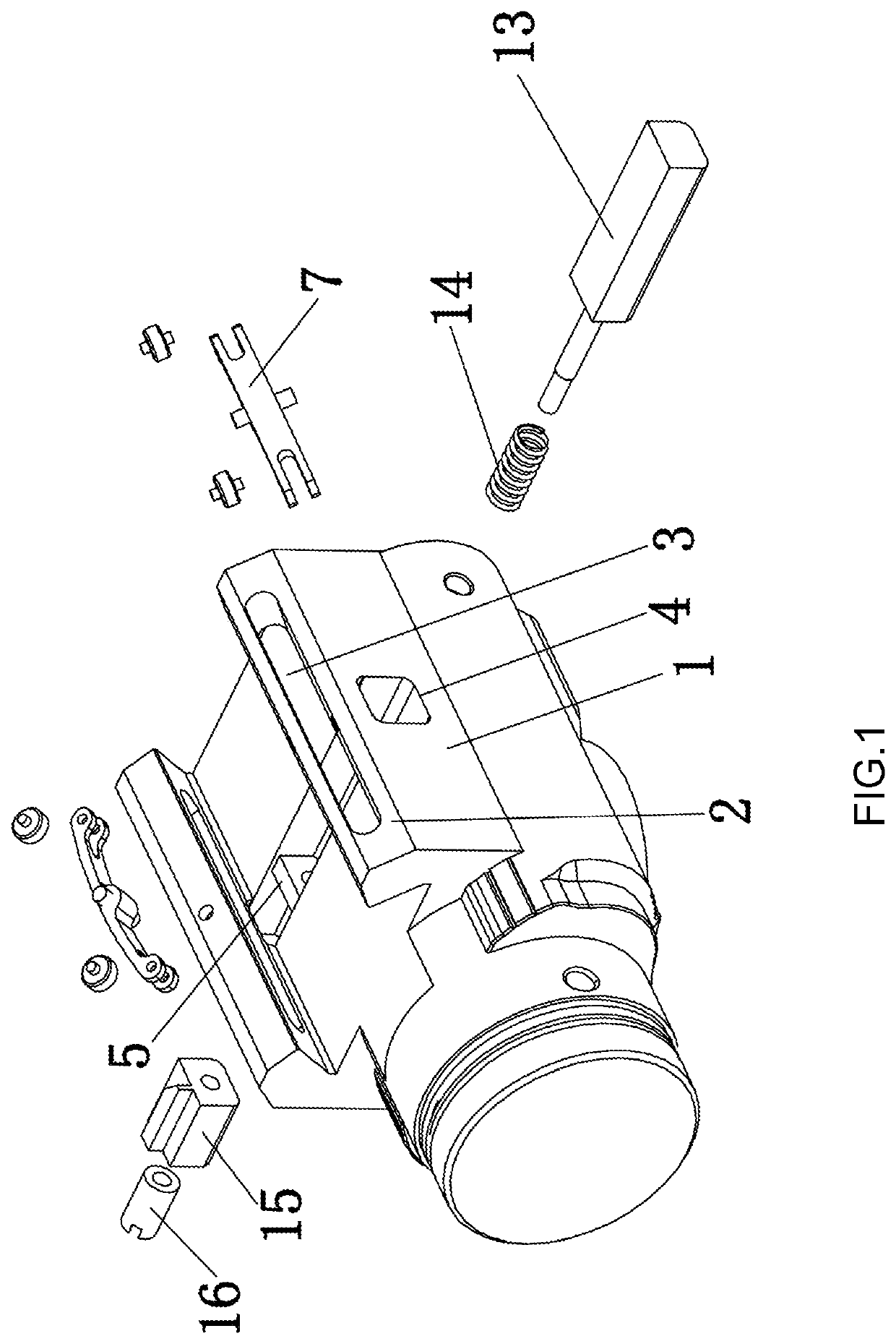

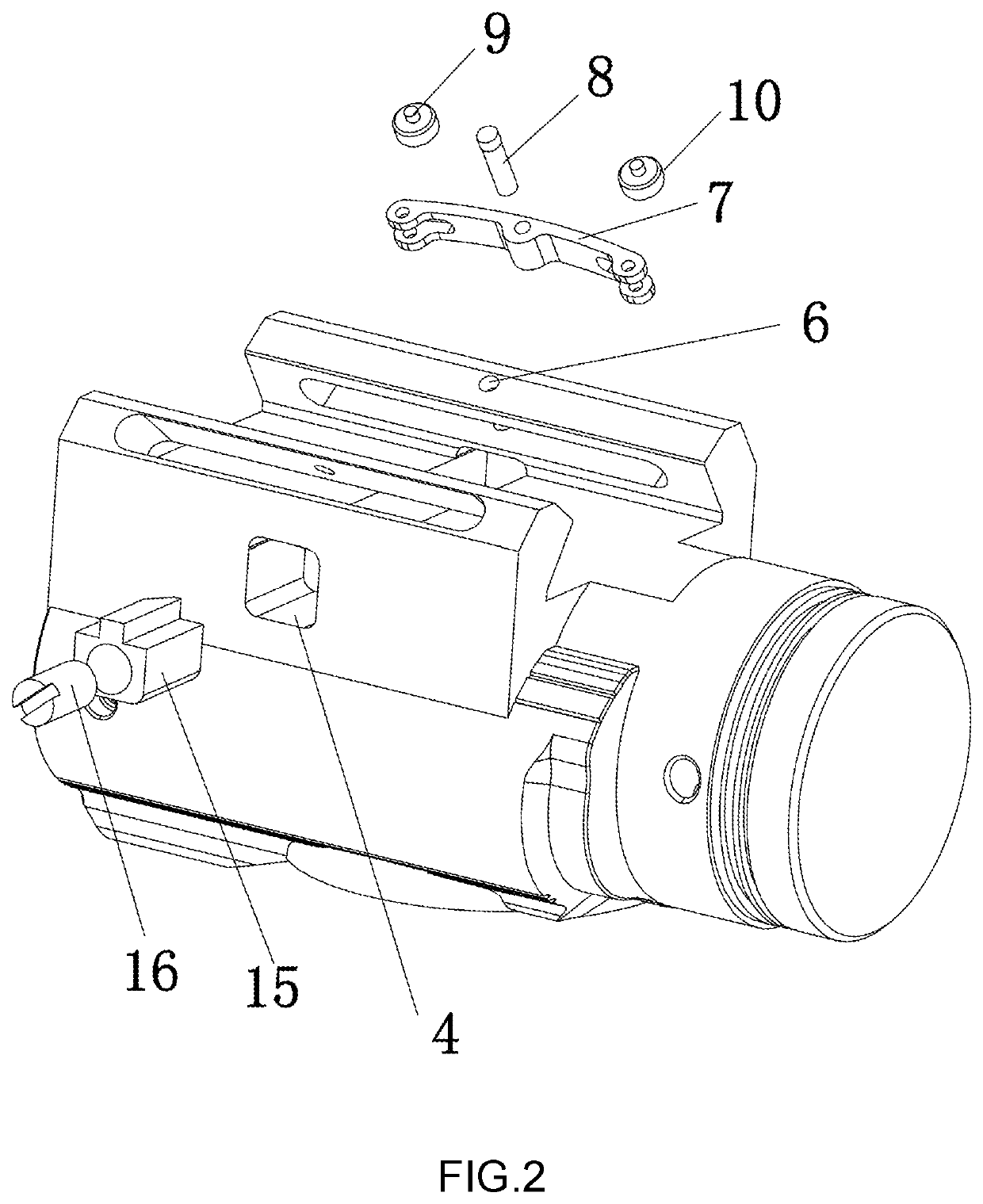

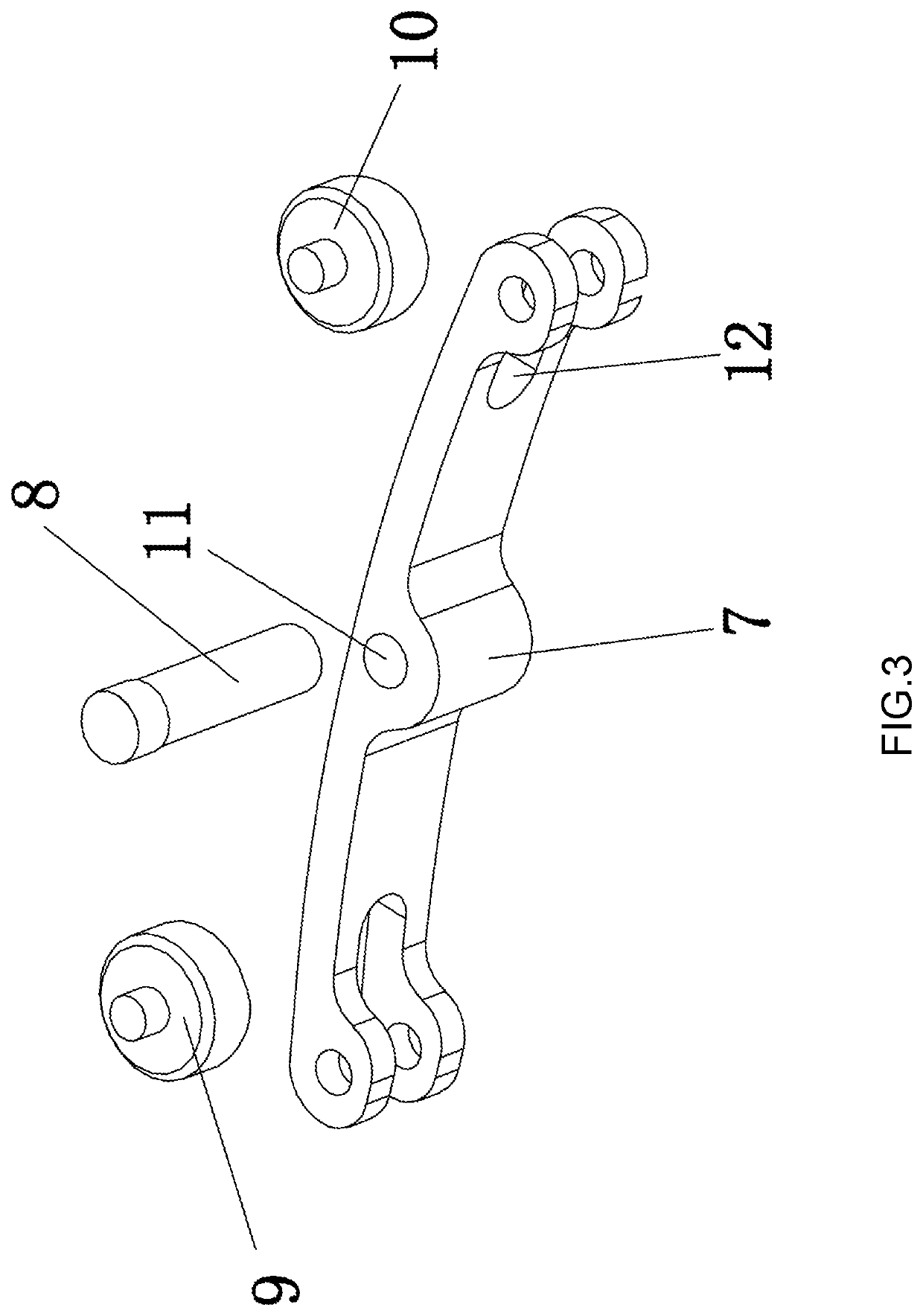

Quick detaching device for handgun tectical light

ActiveUS20210108892A1Quick mountQuick detachmentLighting support devicesWeapon componentsEngineeringStructural engineering

This invention provides a quick detaching device for handgun tactical light which includes a tactical light base, two locking members correspondingly disposed on two sides of a top end of the tactical light base, sliding members and a pressing mechanism; a sliding slot is correspondingly mounted in a middle part of each of the sliding members; the sliding members are respectively mounted in the sliding slots; a through slot which passes through the tactical light base is provided in the tactical light base; a stopping plate is provided in a middle part of the through slot; the pressing mechanism is mounted in the through slot and corresponds to the stopping plate. This invention can quickly mount and detach the tactical light without the help of tools and great effort, and is convenient to use.

Owner:SHENZHEN OLIGHT E COMMERCE TECH CO LTD

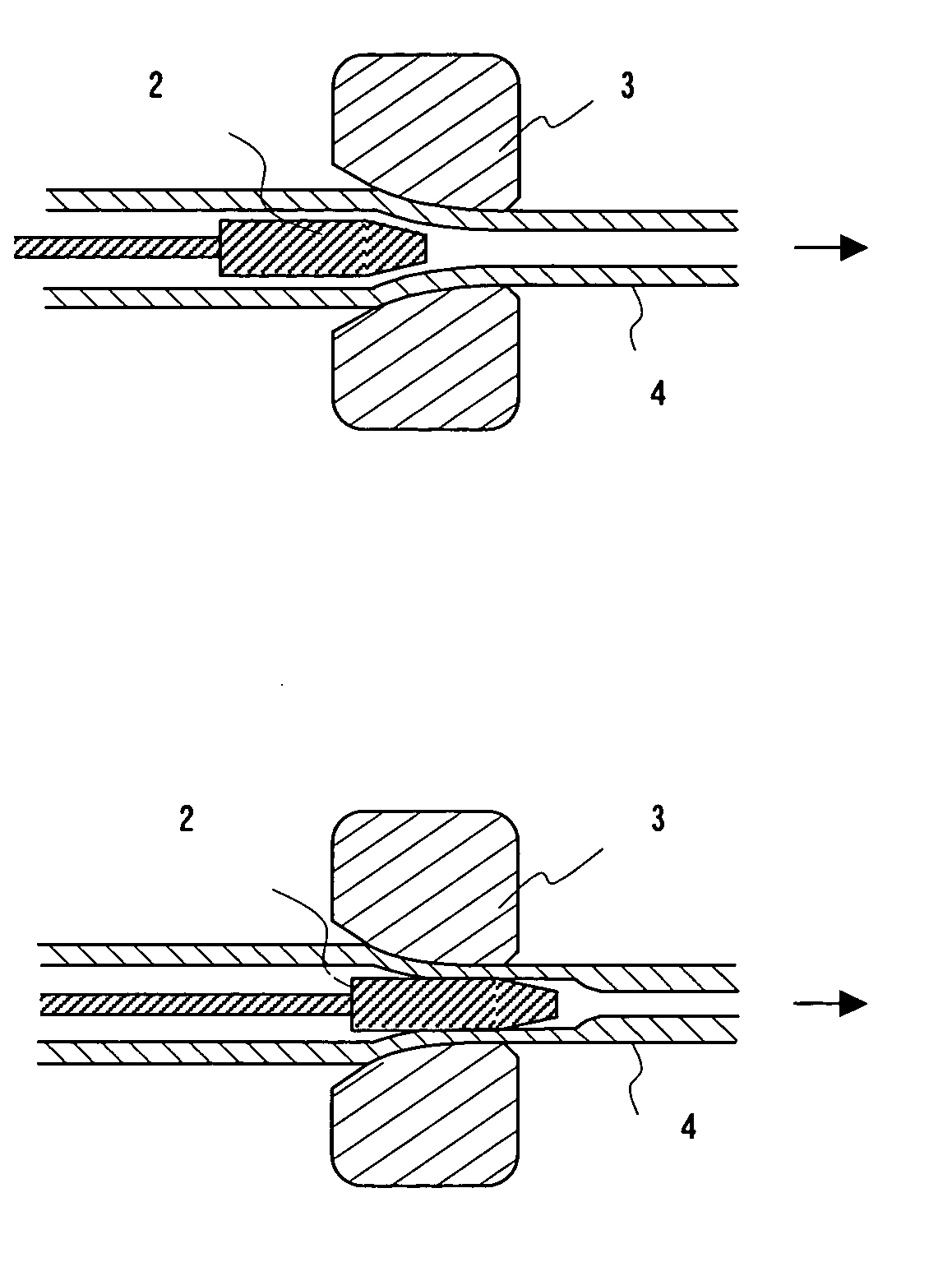

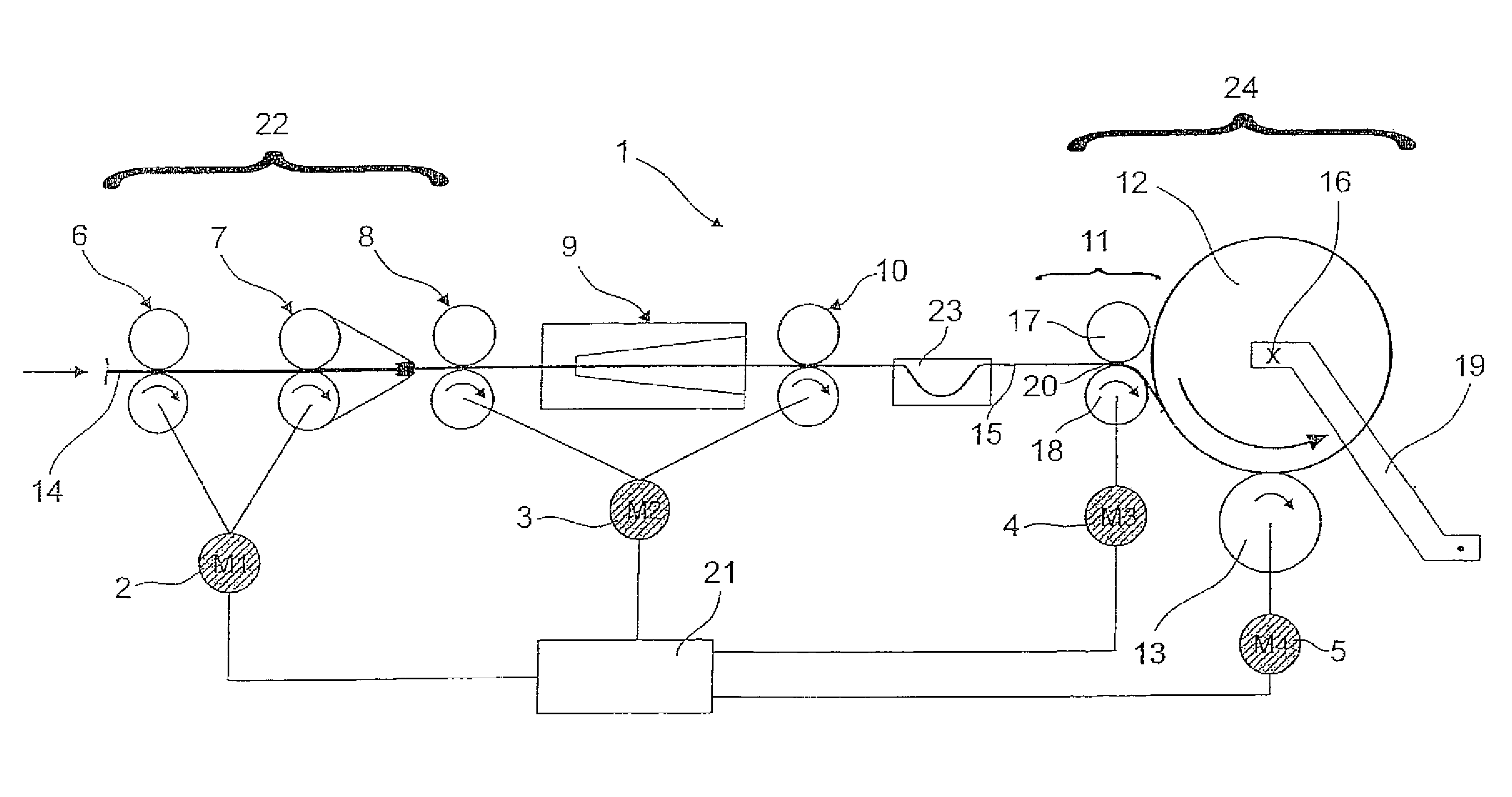

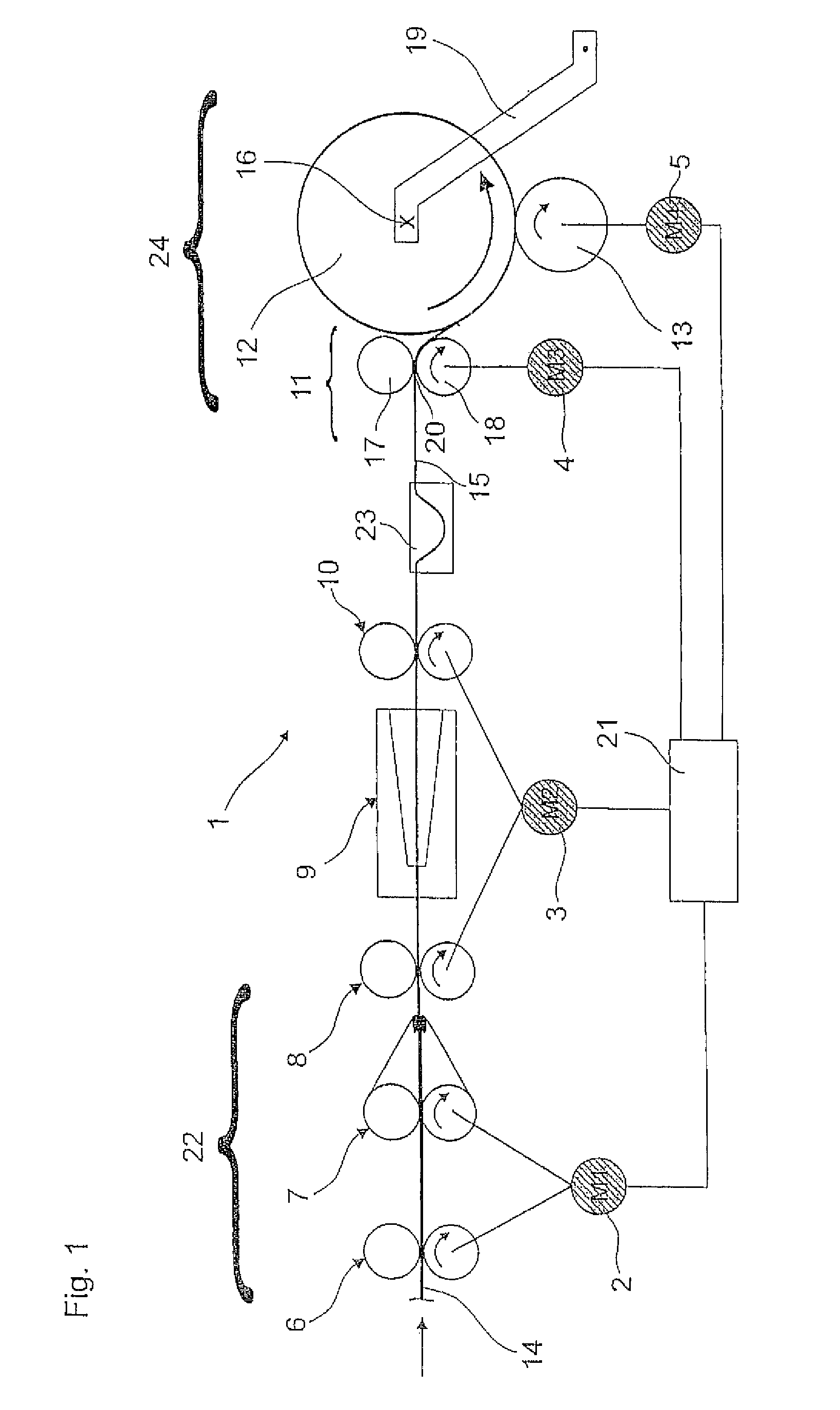

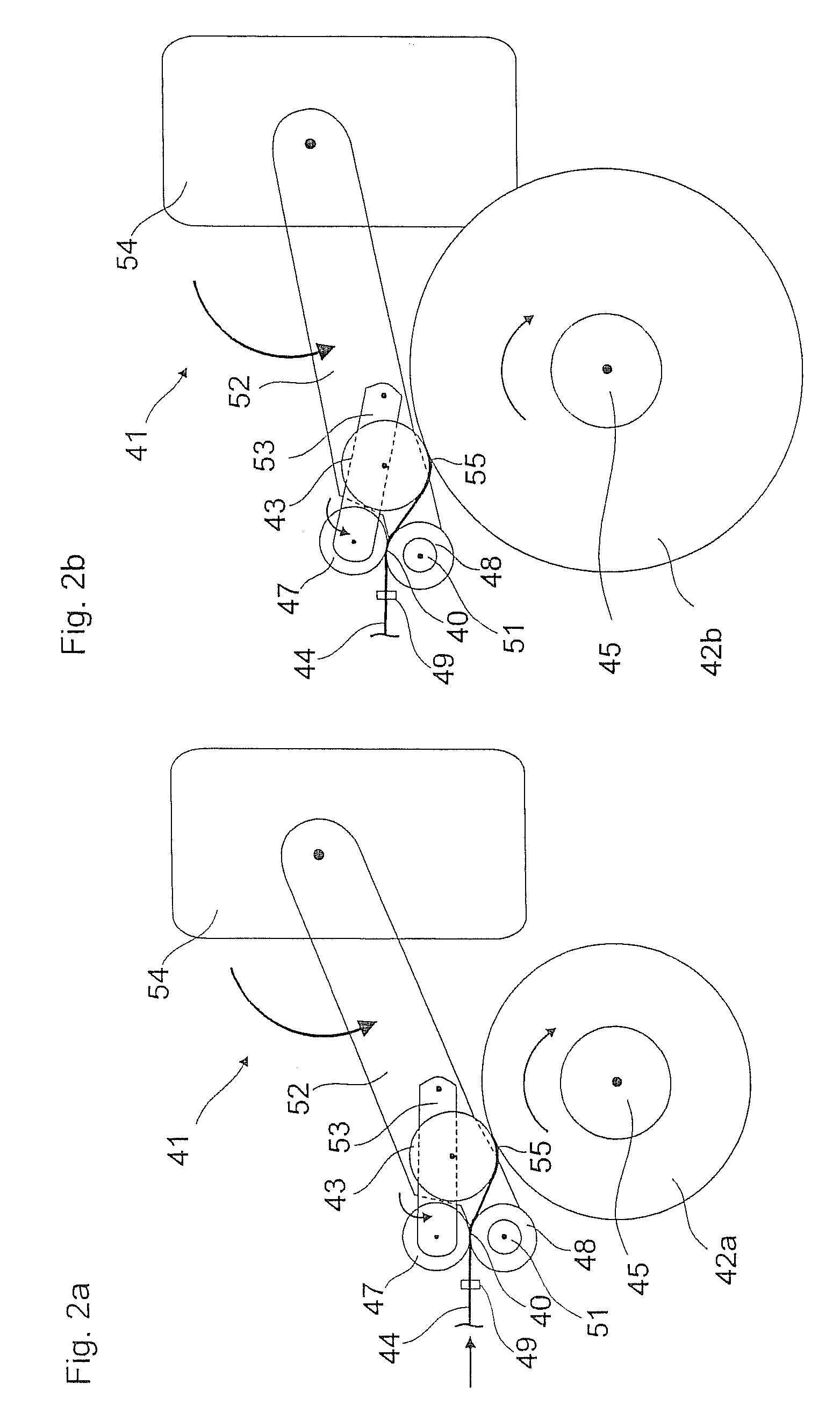

Apparatus and method for winding a roving onto a bobbin

The invention relates to an apparatus for winding a roving provided with a protective twist onto a roving bobbin, containing a bobbin mounting for the rotatable mounting of a roving bobbin and a traversing device for traversing in the bobbin axial direction the roving to be wound. The traversing device comprises a driven pair of winding delivery rollers arranged directly in front of the roving bobbin and having a nip line through which the roving to be wound is guided.

Owner:MASCHINENFABRIK RIETER AG

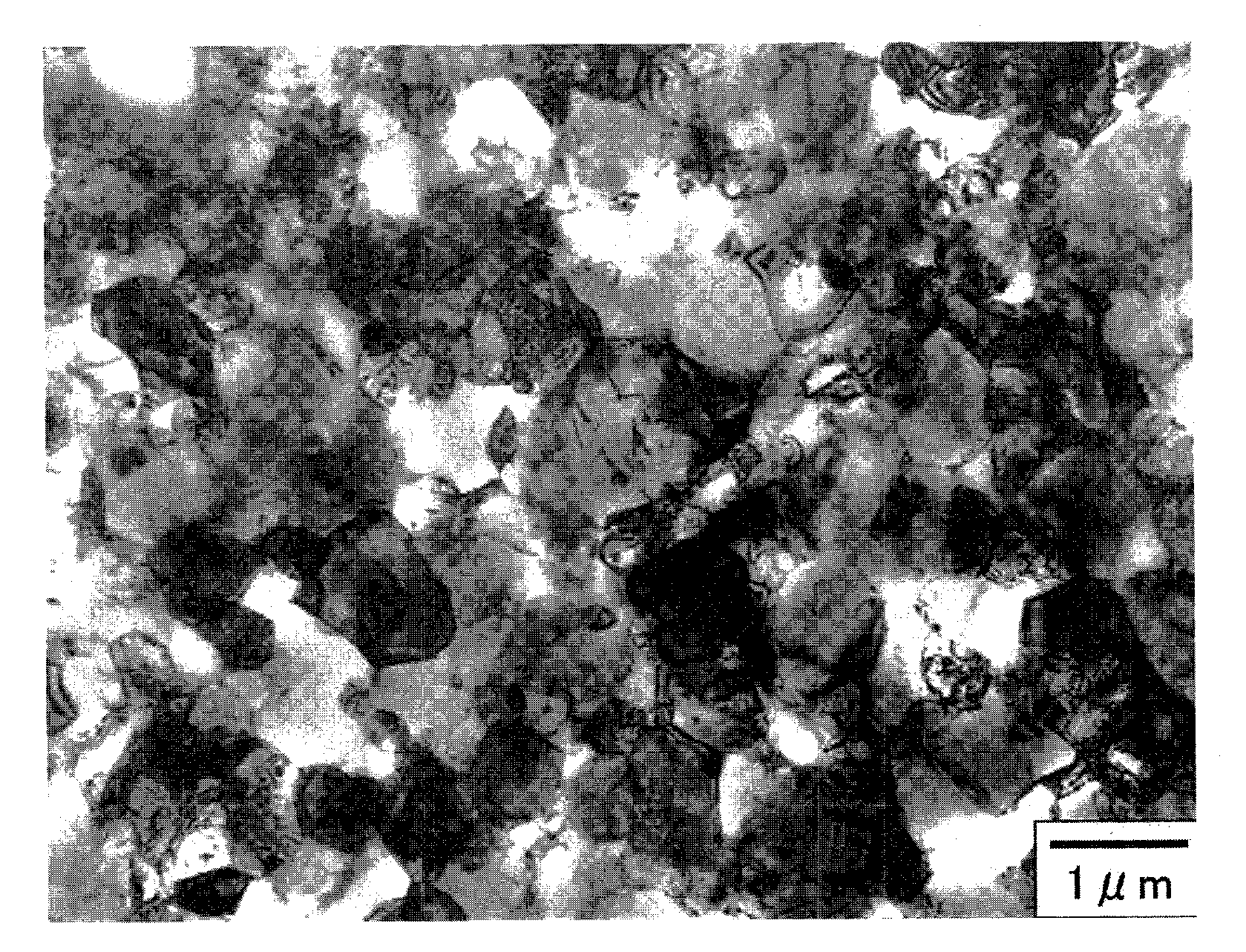

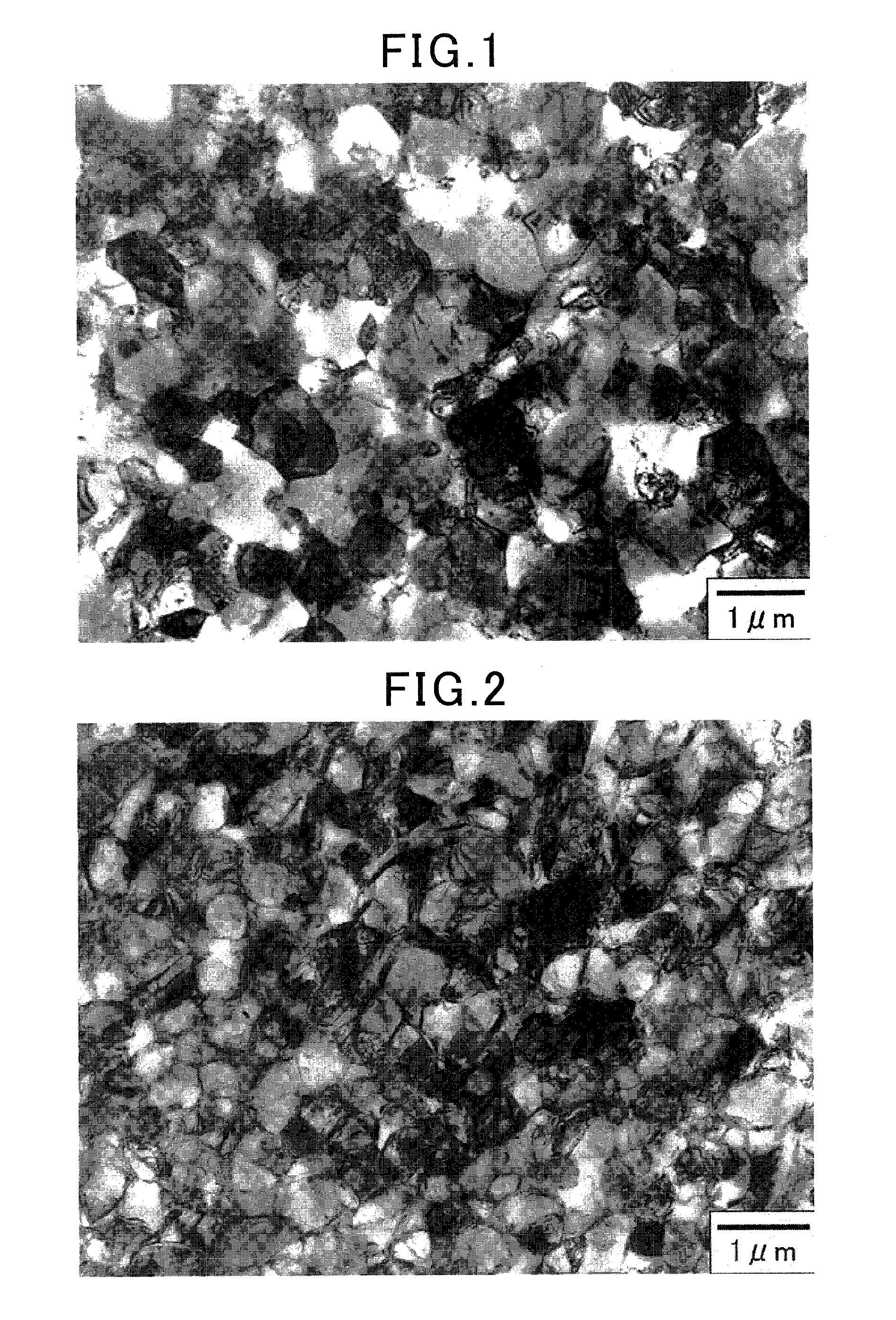

Thick steel plate for high heat input welding and having great heat-affected area toughness and manufacturing method therefor

ActiveUS20180363091A1Great toughnessGood impact toughnessFurnace typesQuenching agentsSteel platesChemical composition

A thick steel plate for high heat input welding and having great heat-affected area toughness and a manufacturing method therefor, comprising the steps of smelting, casting, rolling, and cooling. Chemical composition is properly controlled for the steel plate and satisfies 1≤Ti / N≤6 and Mg / Ti>0.017, where effective S content in steel=S−1.3 Mg−0.8 Ca−0.34 REM−0.35 Zr, and effective S content in steel: 0.0003-0.003%; finely dispersed inclusions may be formed in the steel plate, and the amount of composite inclusion MgO+Ti2O3+MnS in the steel plate is controlled at a proportion greater than or equal to 5%. The tensile strength of a base material so acquired is ≥510 MPa, insofar as welding input energy is 200−400 kJ / cm, the average Charpy impact work of the steel plate at −40 ° C. is 100 J or more, at the same time, the average Charpy aging impact work of the base material of ½ thickness at −40° C. is 46 J or more.

Owner:BAOSHAN IRON & STEEL CO LTD

Quick detaching device for handgun tactical light

ActiveUS11307000B2Quickly mount and detachEasy to useLighting support devicesWeapon componentsStructural engineeringMechanical engineering

Owner:OLIGHT GRP CO LTD

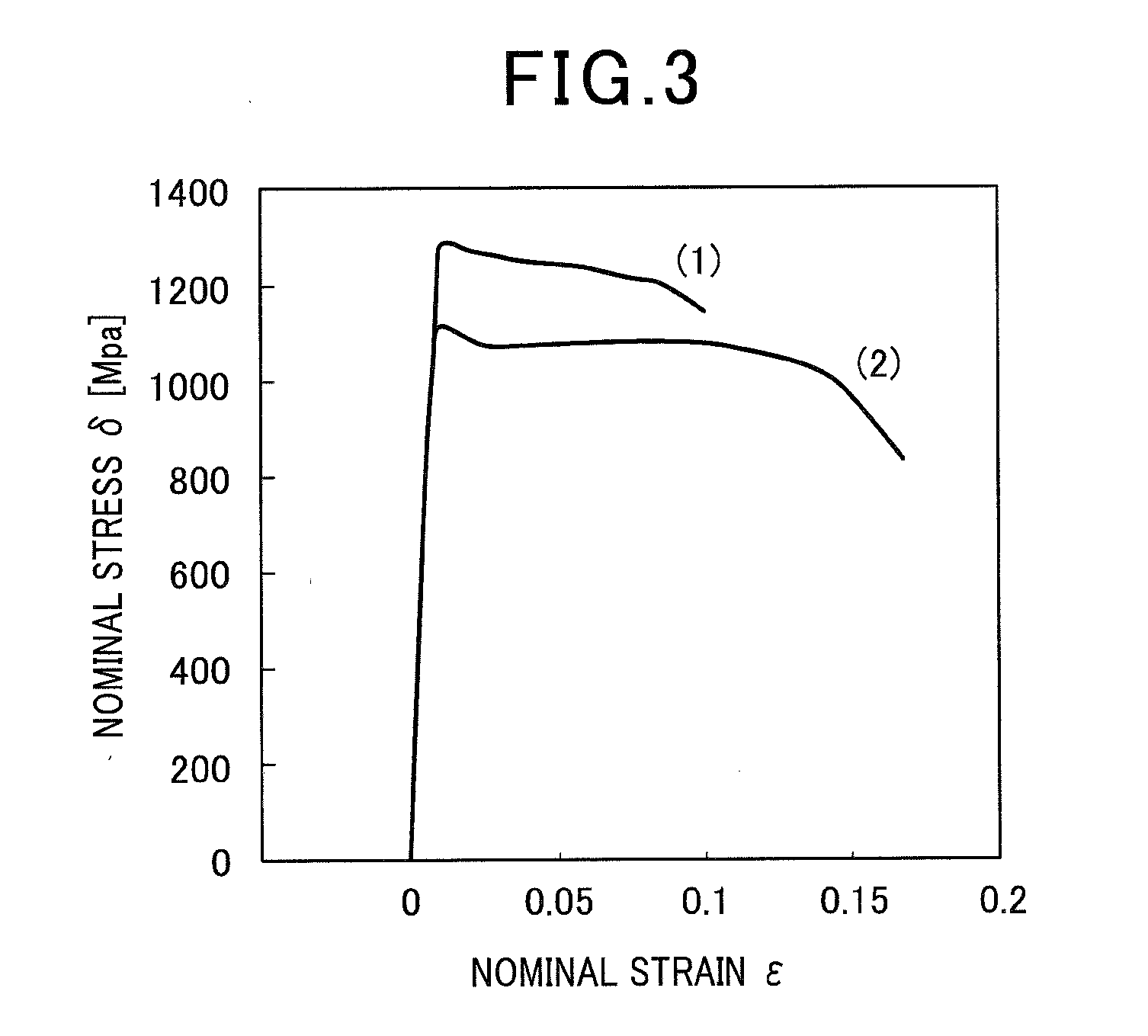

Titanium alloy, method of manufacturing high-strength titanium alloy, and method of processing titanium alloy

Titanium alloy that is formed by subjecting titanium alloy to a treatment containing a hydrogen storing step for making the titanium alloy store hydrogen therein, a solution-treatment step for heating the titanium alloy having the hydrogen stored therein in the hydrogen storage step to apply a solution treatment to the hydrogen-stored titanium alloy, a cooling step for cooling the heated hydrogen-stored titanium alloy to develop martensitic transformation in the hydrogen-stored titanium alloy, a hot rolling step for heating the martensitic-transformed titanium alloy to a temperature which is not more than a predetermined transformation point and hot-rolling the martensitic-transformed titanium, and a dehydrogenation step for dehydrogenating the hot-rolled titanium alloy, thereby bringing the titanium alloy with the superplastic property.

Owner:HONDA MOTOR CO LTD +1

Isotopic lightening

ActiveUS7687025B2High strengthRaise the ratioLaunch systemsTransuranic element compoundsLithiumHydrogen

Owner:THE BOEING CO

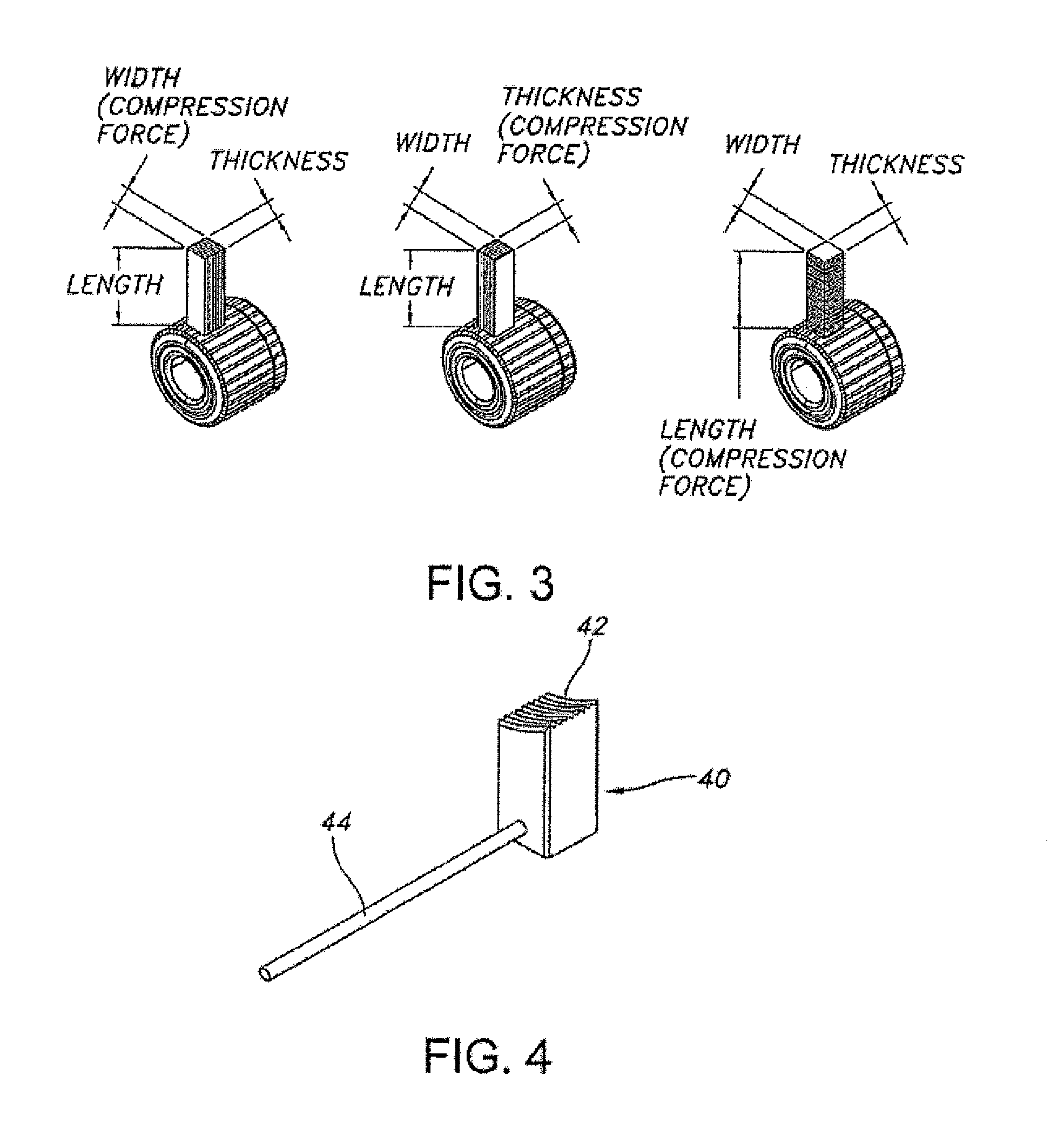

Grain orientation control through hot pressing techniques

InactiveUS20080086875A1High densityIncreased durabilityRotary current collectorManufacturing dynamo-electric machinesApparent densityEngineering

Owner:ENERGY CONVERSION SYST HLDG

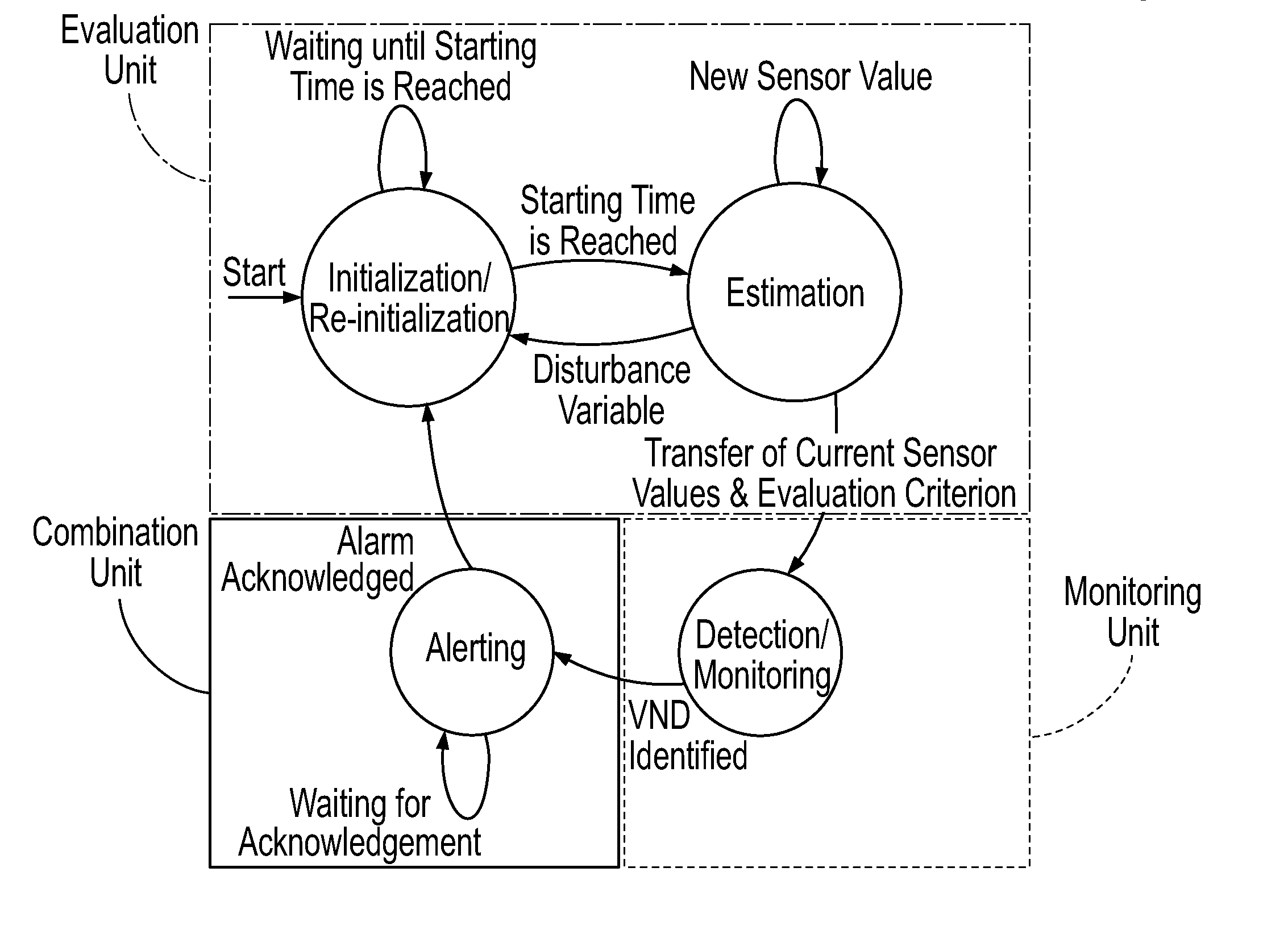

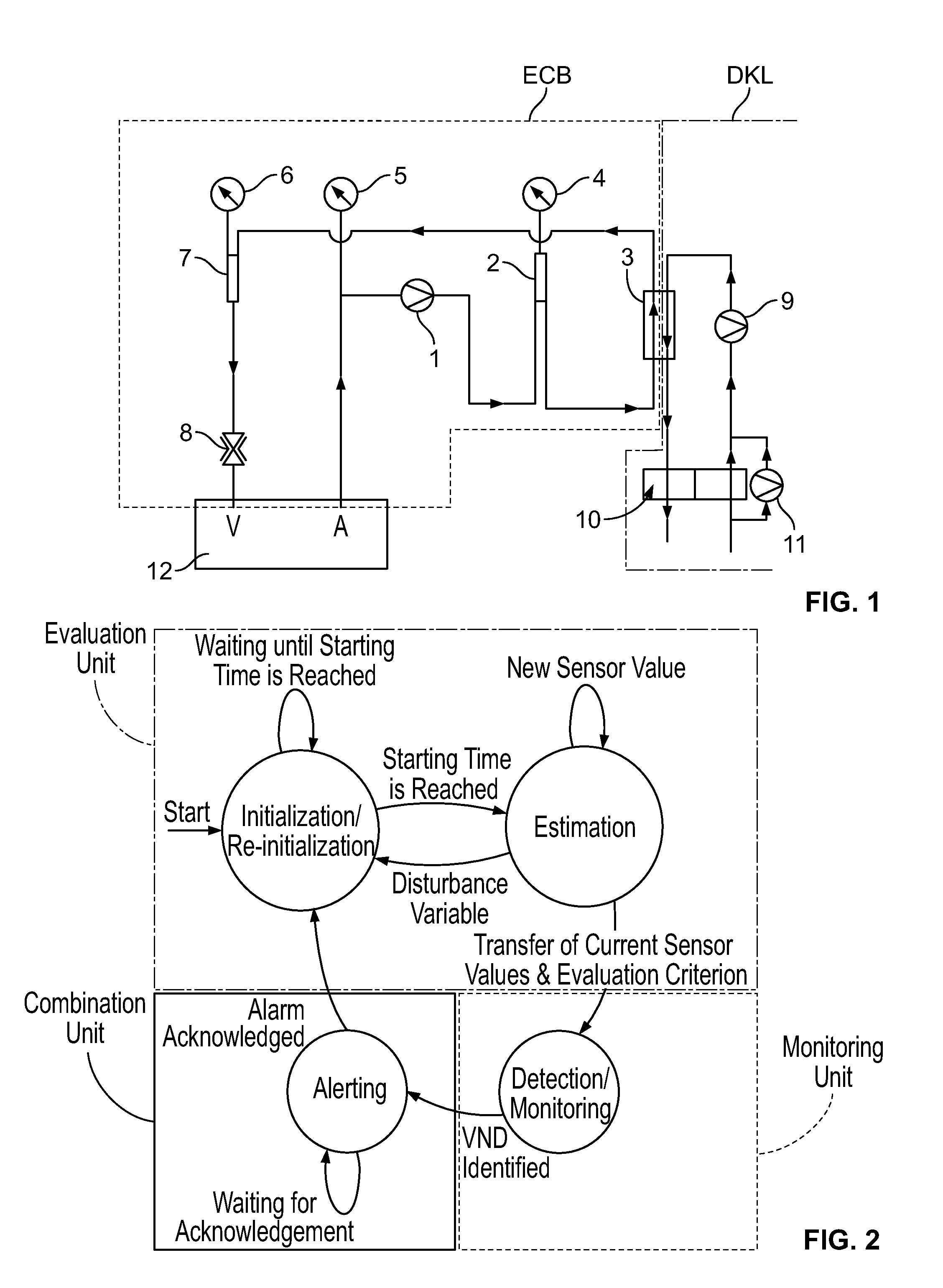

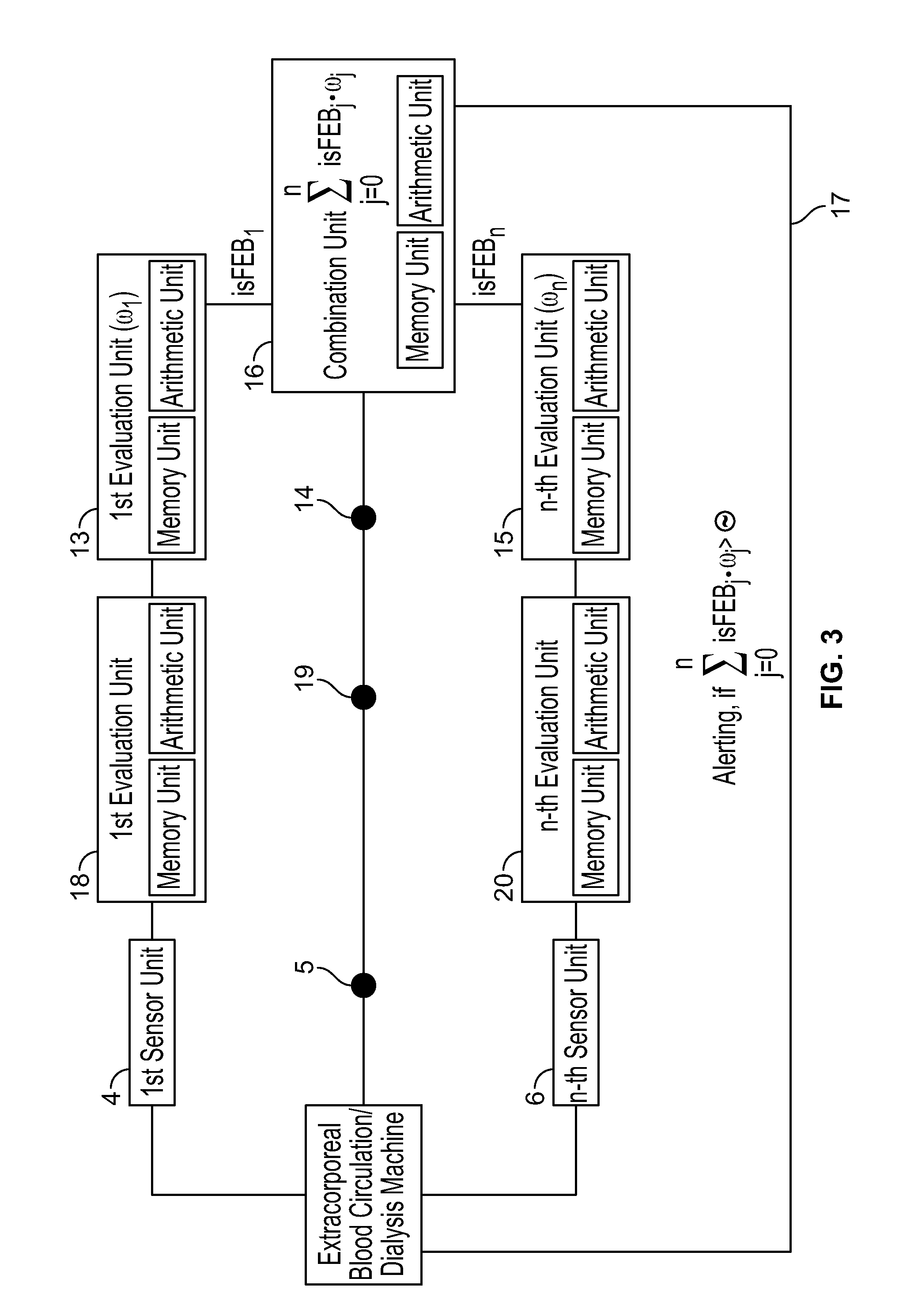

Device and method for identifying a malfunction in an extracorporeal blood circulation

ActiveUS20150306301A1Improve securityImprove reliabilityMechanical/radiation/invasive therapiesOther blood circulation devicesExtracorporeal circulationState parameter

Methods and systems for identifying a malfunction in the extracorporeal blood circulation of a dialysis machine are disclosed. The malfunction may be identified by detecting at least one state parameter; determining a first evaluation criterion for identifying a malfunction in the extracorporeal blood circulation (FEB); using the first evaluation criterion, making a decision with respect to the presence of a malfunction in the extracorporeal blood circulation, generating a first error signal, and monitoring the detected state parameter; determining at least one further evaluation criterion; using the at least one further evaluation criterion, making a decision with respect to the presence of a malfunction in the extracorporeal blood circulation and generating at least one further error signal; combining the first error signal and the at least one further error signal to result in a combined error signal; and triggering an alarm if the combined error signal exceeds a predetermined limit value.

Owner:B BRAUN AVITUM

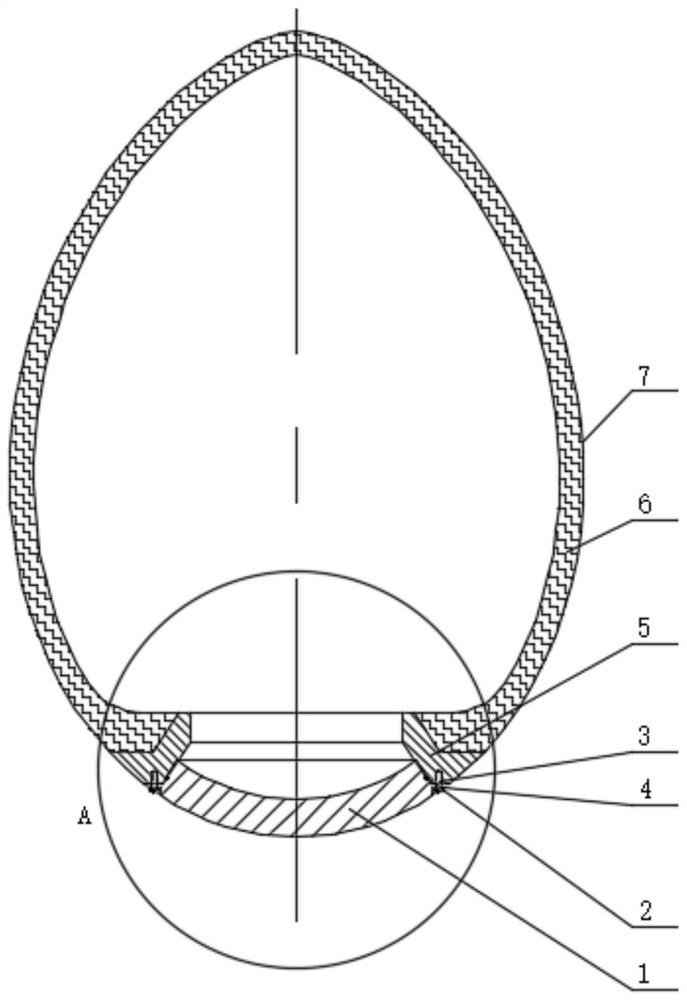

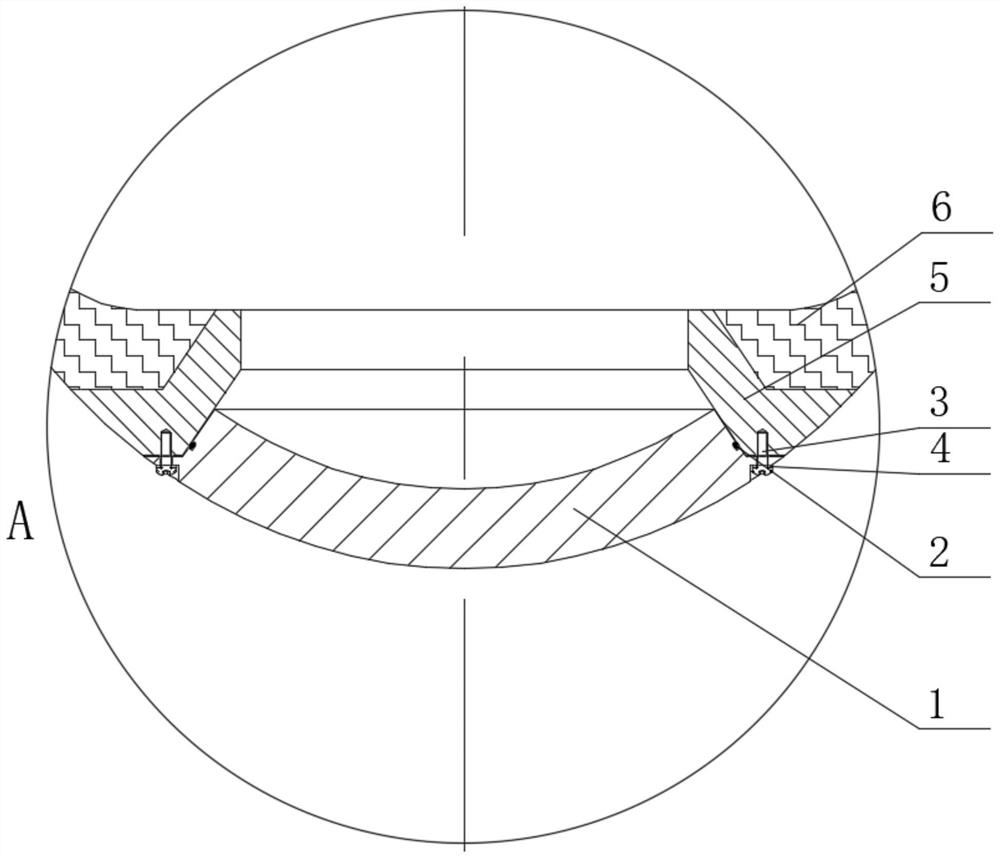

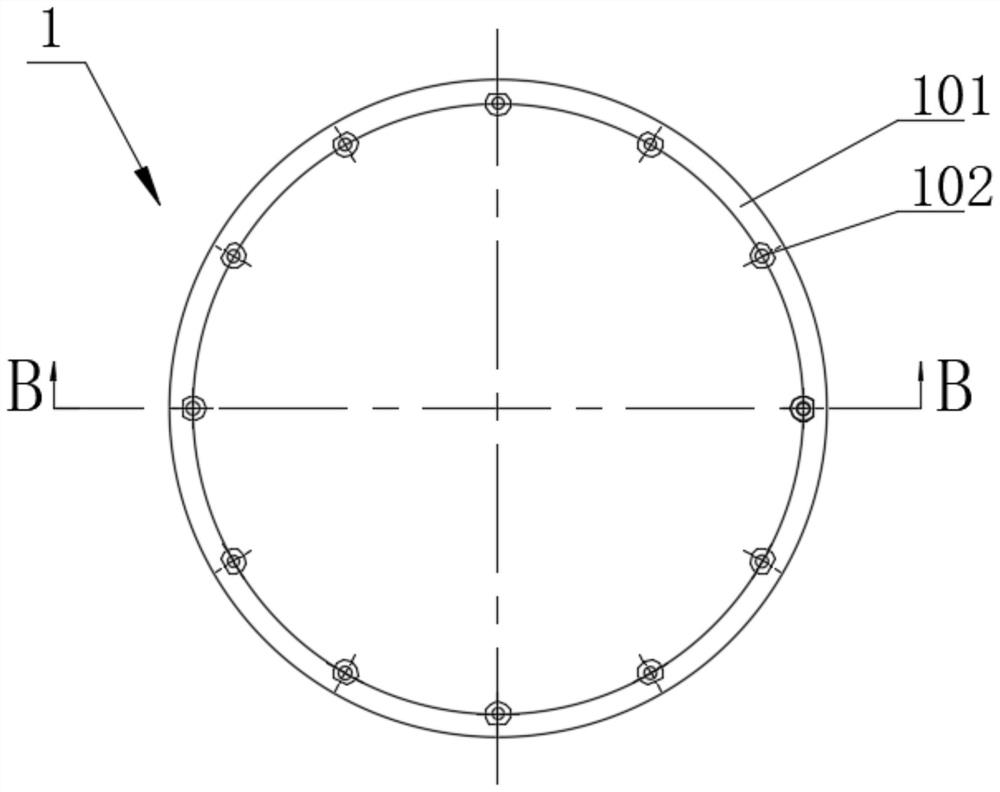

A deep-sea long-term pressure-resistant composite structure and its manufacturing method

ActiveCN113581361BCompact structureReasonable structureWaterborne vesselsClimate change adaptationFiberCarbon fibers

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

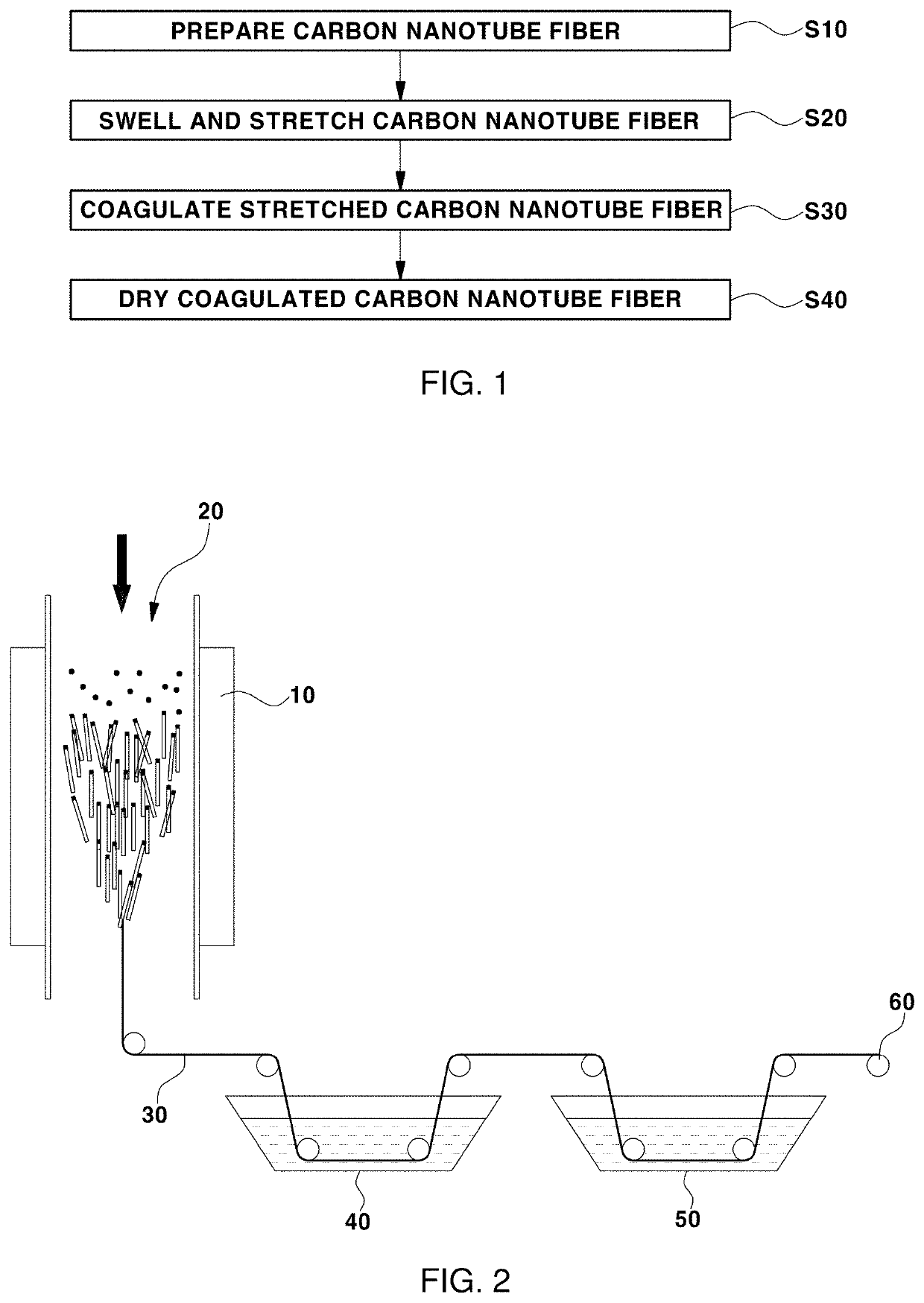

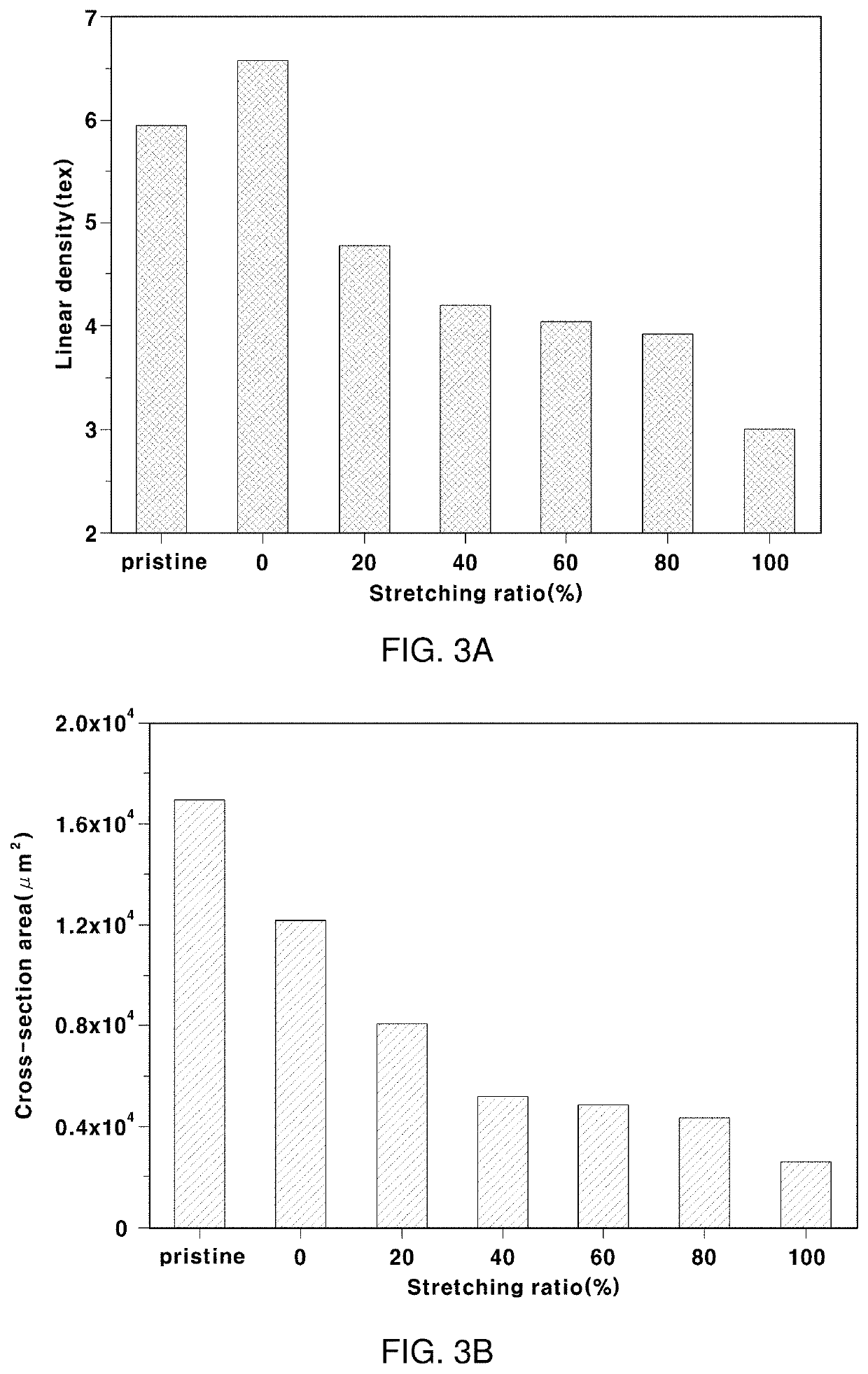

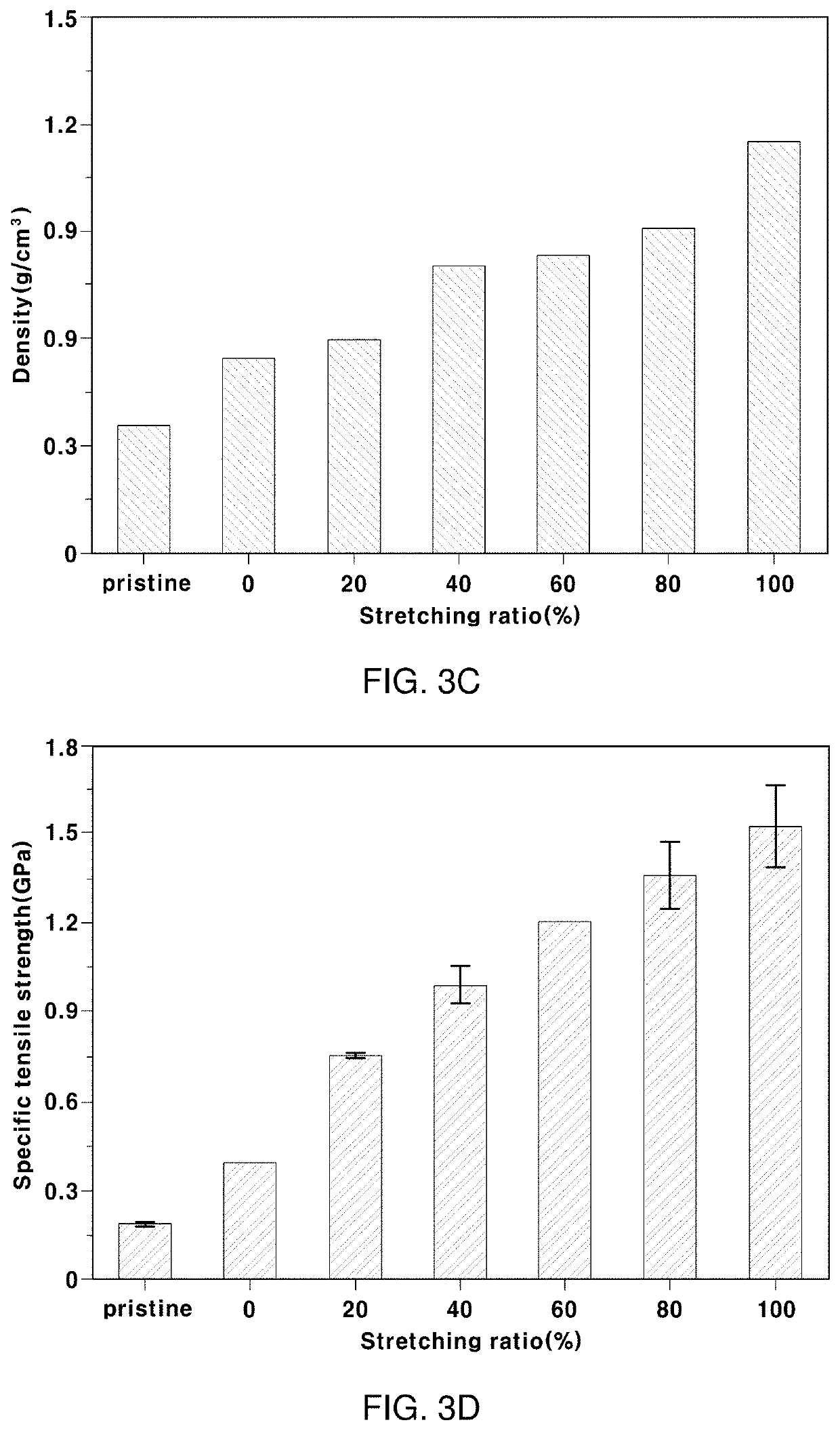

Method for producing densified carbon nanotube fiber

PendingUS20210323826A1Maintain good propertiesIncrease production capacityCarbon compoundsCarbon fibresFiberPolymer science

Owner:KOREA INST OF SCI & TECH

Multifunctional high strength metal composite materials

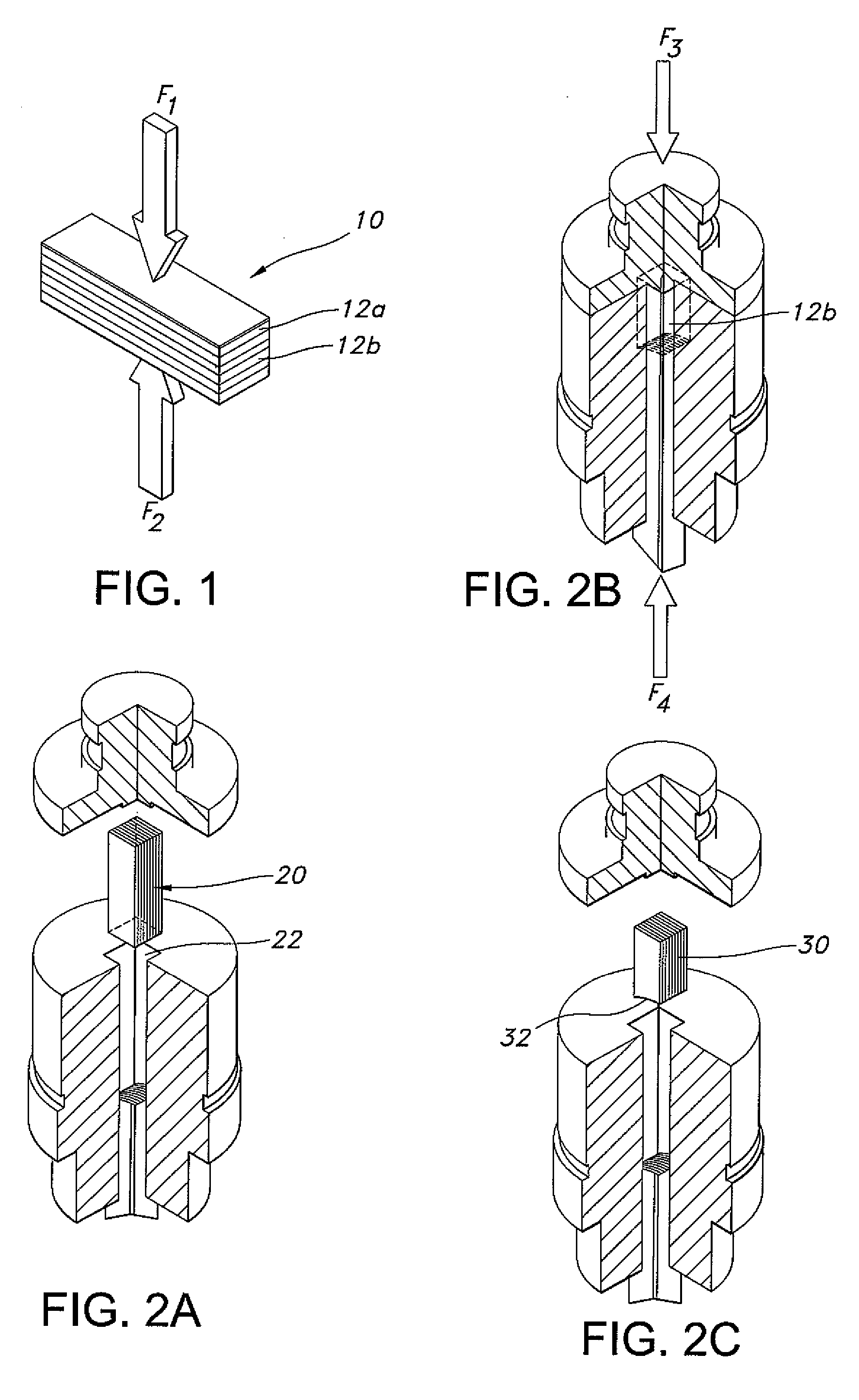

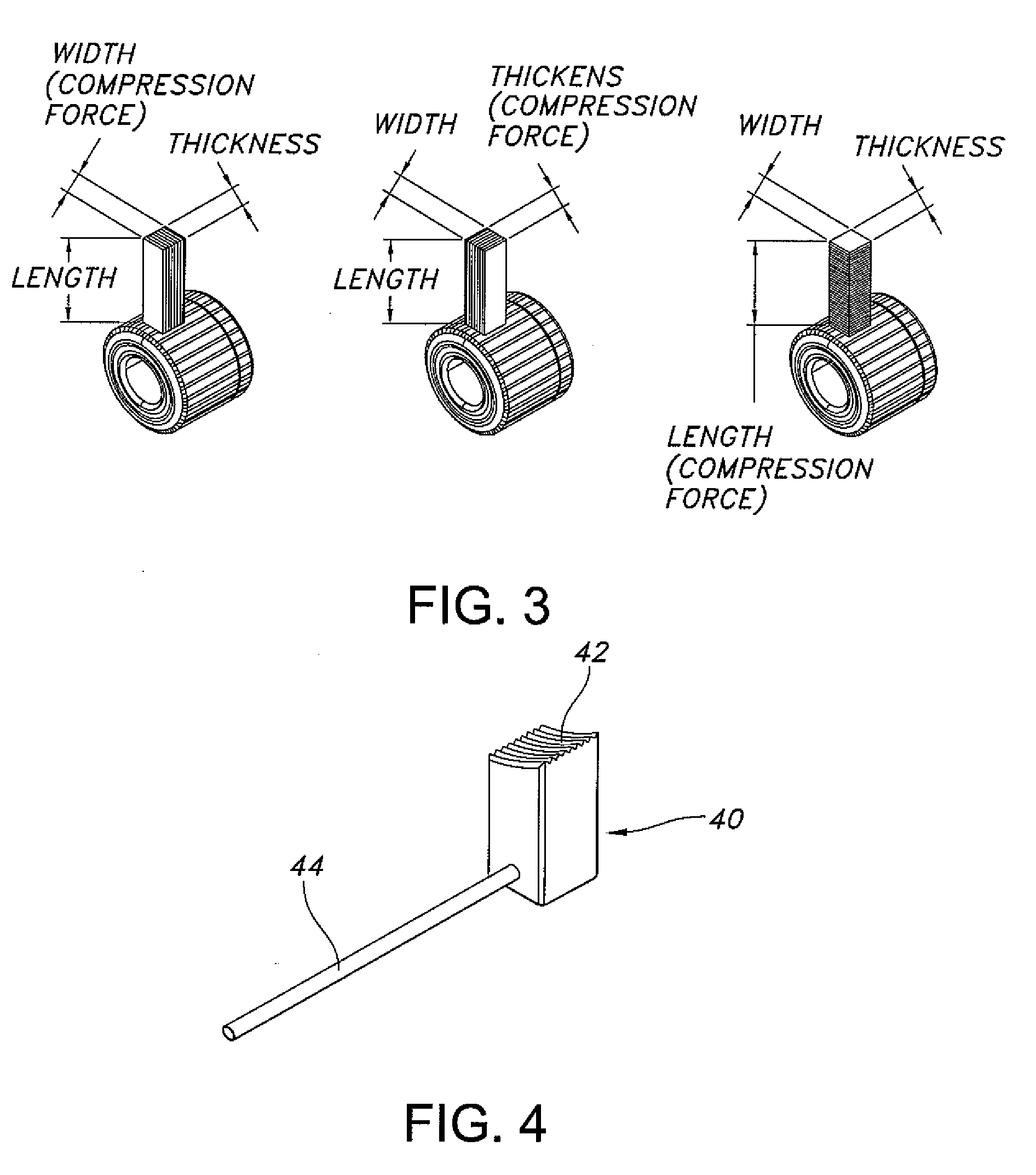

A method of producing composites of micro-engineered, coated particulates embedded in a matrix of metal, ceramic powders, or combinations thereof, capable of being tailored to exhibit application-specific desired thermal, physical and mechanical properties, such as High Altitude Exo-atmospheric Nuclear Standard (HAENS) I, II or III radiation protection, to form substitute materials for nickel, titanium, rhenium, magnesium, aluminum, graphite epoxy, and beryllium. The particulates are solid and / or hollow and may be coated with one or more layers of deposited materials before being combined within a substrate of powder metal, ceramic or some combination thereof which also may be coated. The combined micro-engineered nano design powder is consolidated using novel solid-state processes that prevent melting of the matrix and which involve the application of varying pressures to control the formation of the microstructure and resultant mechanical properties.

Owner:AMARANTHINE RESOURCES LLC +1

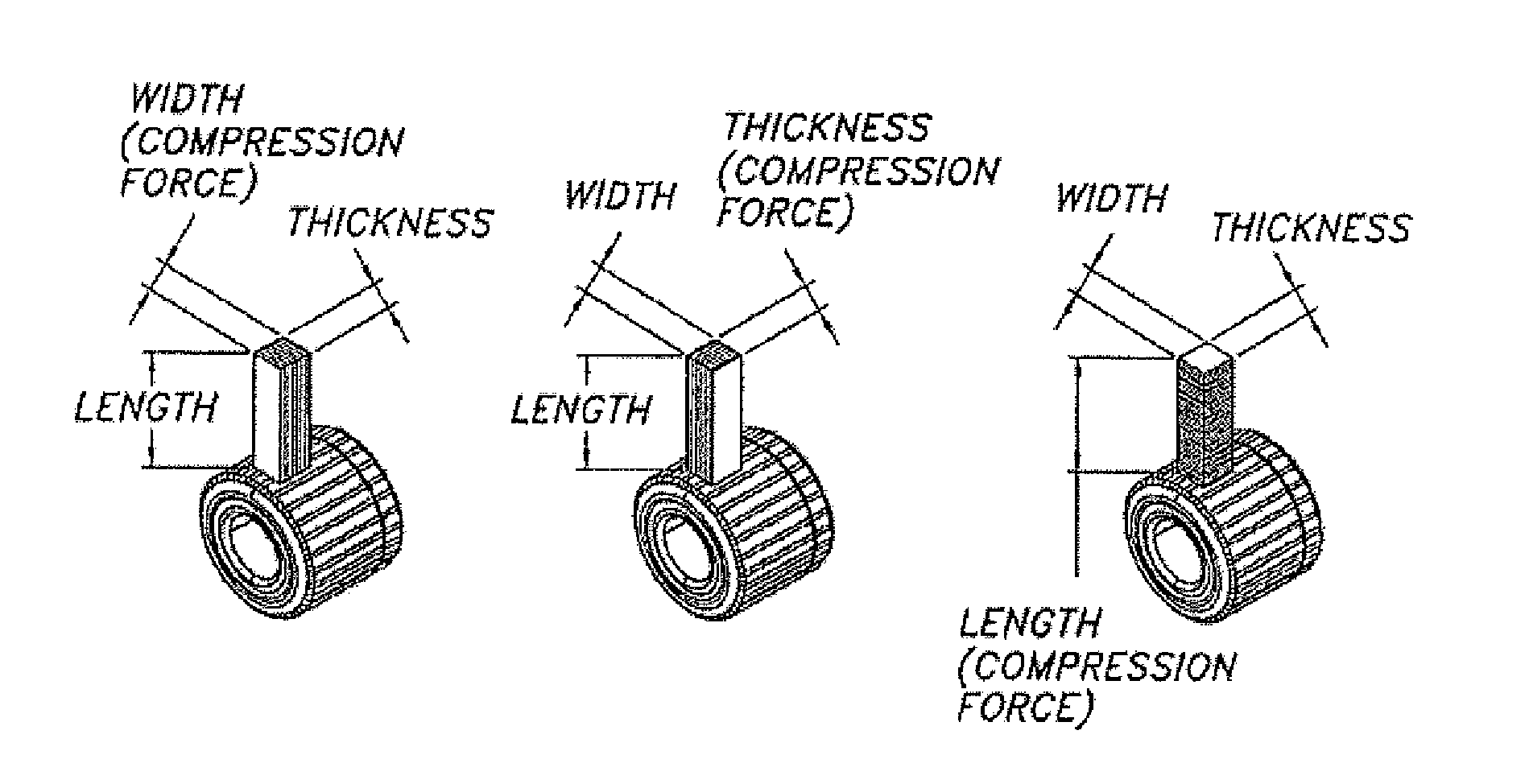

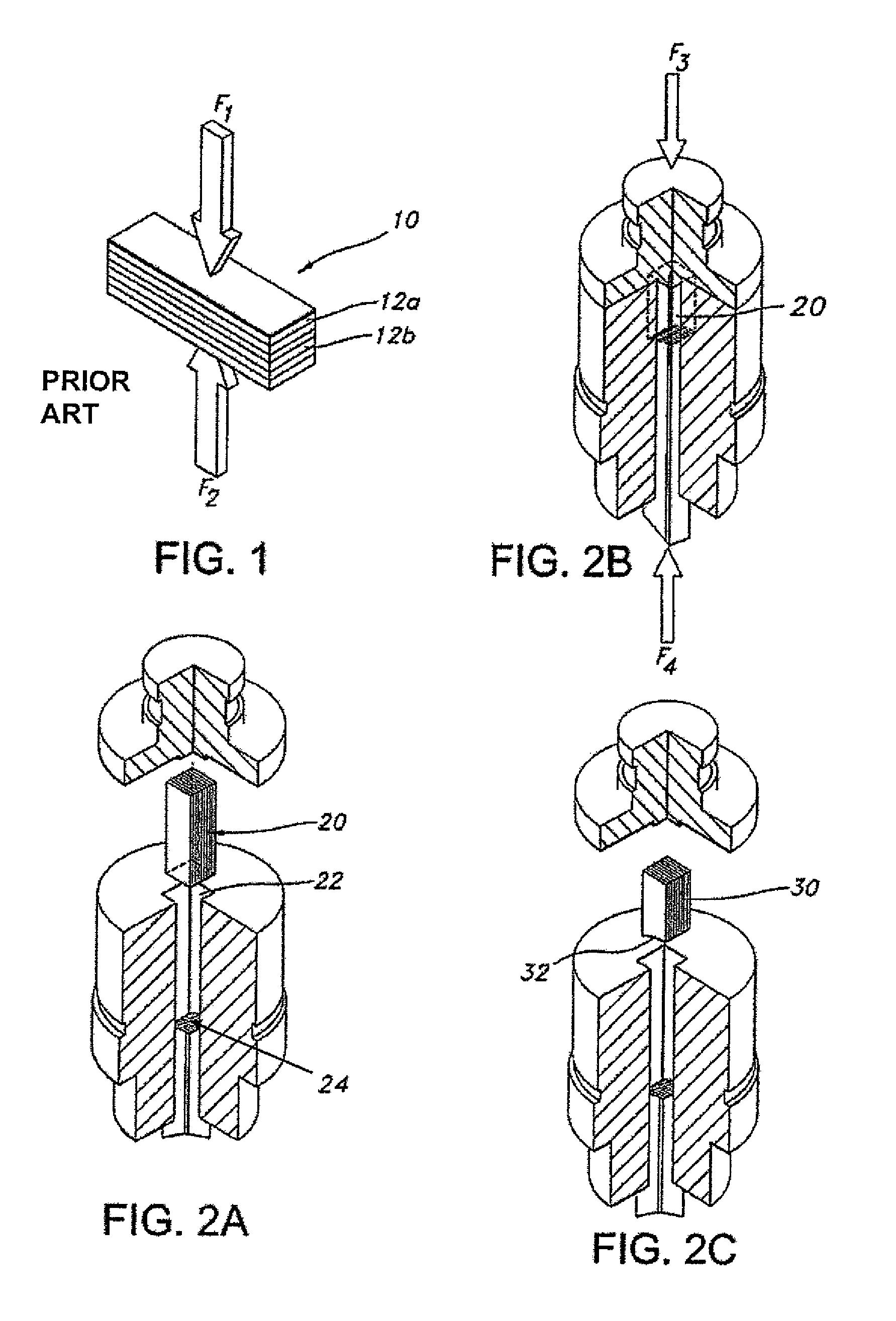

Grain orientation control through hot pressing techniques

InactiveUS7498712B2High densityIncreased durabilityRotary current collectorCeramic shaping apparatusElectronic componentScrub brushes

Systems and methods for electrical component, e.g., brush, manufacture are provided that control grain orientation. The systems and methods utilize hot pressing techniques to enhance the properties and functionalities of the electrical components / brushes. An intermediate work product characterized by a grain orientation is initially formed through a conventional pressing technique. The conventionally-pressed intermediates are positioned within a cavity / die with the grain orientation in a predetermined orientation relative to the hot press force to be applied thereto. The hot pressed final product exhibits superior resistivity, strength and apparent density / durability. Surface features may be formed on the face(s) of the final work product during the hot pressing step that cannot be achieved in conventional processing techniques. Advantageous articles of manufacture, e.g., brushes and brush assemblies, are also disclosed.

Owner:ENERGY CONVERSION SYST HLDG

Thick steel plate for high heat input welding and having great heat-affected area toughness and manufacturing method therefor

ActiveUS20180371587A1High strengthSpecific strengthFurnace typesQuenching agentsChemical compositionHeat-affected zone

A thick steel plate for high heat input welding and having great heat-affected area toughness and a manufacturing method therefor, comprising the steps of smelting, casting, rolling, and cooling. Also, the chemical composition of the steel plate satisfies 1≤Ti / N≤6 and (Ca+REM+Zr) / Al≥0.11, where the effective S content in steel=S-0.8Ca-0.34REM-0.35Zr. and the effective S content in steel: 0.0006-0.005%; finely dispersed inclusions may be formed, and the amount of composite inclusion CaO+Al2O3+MnS+TiN in the steel plate is at a proportion of ≥12%. With respect to welding in which the thickness of the steel plate is 50-70 mm, the tensile strength of a base material is ≥510 MPa. and welding input energy is 200-400 kJ / cm, the average Charpy impact work of a welding heat-affected area of the steel plate at −40 ° C. is 100 J or more, and at the same time, the average Charpy aging impact work of the base material of ½ thickness at −40° C. is 46 J or more.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com