Magnesium base alloy pipes and method of manufacturing the same

a technology of magnesium base alloy and pipe, which is applied in the direction of machines/engines, transportation and packaging, and other domestic objects, can solve the problems of lack of ductility, marked inferiority in plastic workability, and the difficulty of producing magnesium or its alloy pipes so far, and achieves the effect of convenient butting and easy pipe manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

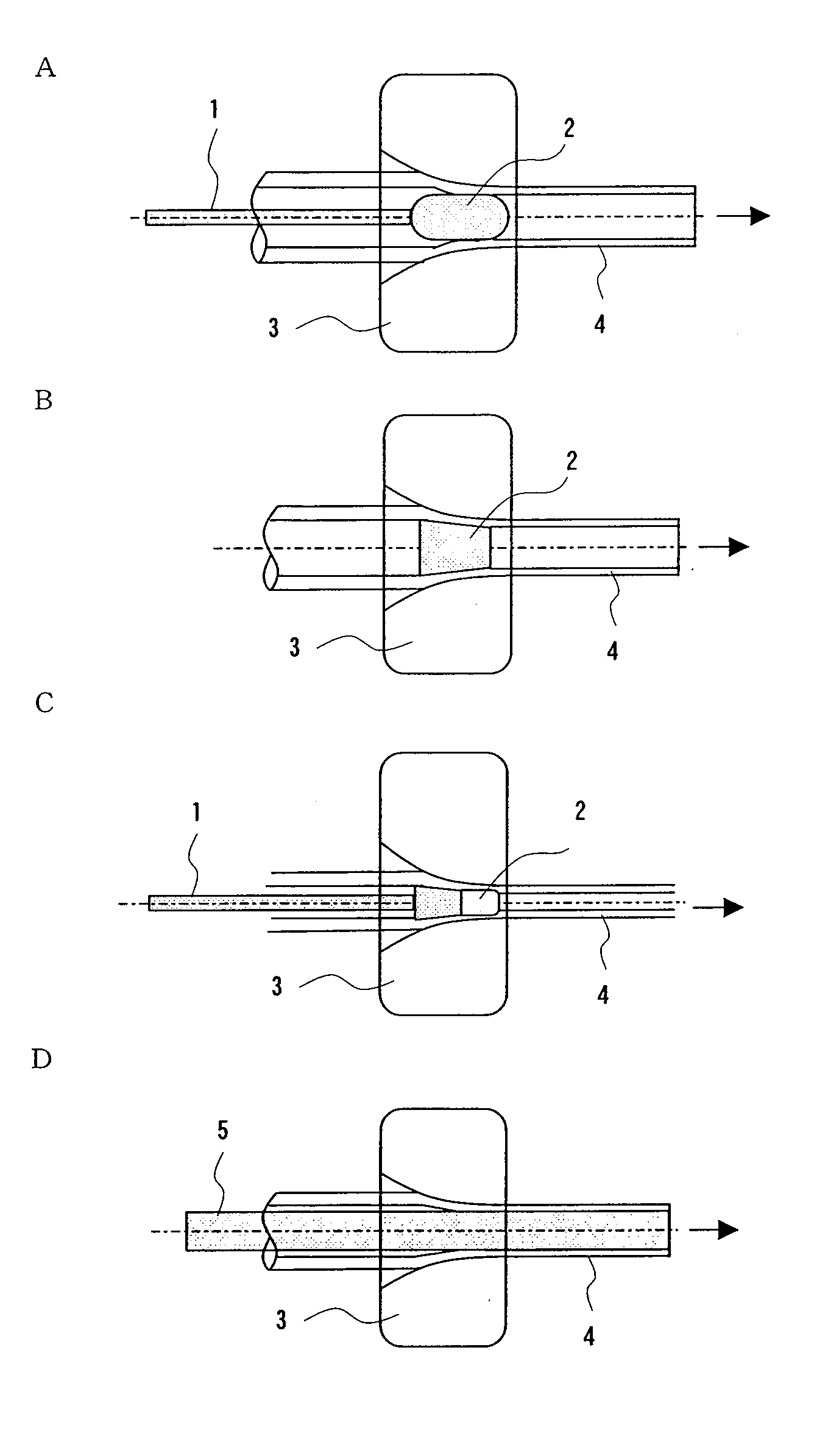

Method used

Image

Examples

experimental example 1-1

[0093]An extruded pipe (outside diameter: 15.0 mm, wall thickness: 1.5 mm) of an alloy subject to the ASTM AZ31 (shall be referred to as AZ31 alloy and like nomenclature shall apply hereinafter) and an extruded pipe of an AZ61 alloy having the same configuration as above were drawn, respectively, at varied temperatures to be reduced to 12.0 mm in outside diameter, thus yielding various specimens of drawn magnesium base alloy pipes. The AZ31 alloy of the extruded pipe used was a magnesium base alloy containing 2.9 mass % of Al, 0.77 mass % of Zn and 0.40 mass % of Mn with the balance composed of Mg as a base material and unavoidable impurities, while the AZ61 alloy of the extruded pipe was a magnesium base alloy containing 6.4 mass % of Al, 0.77 mass % of Zn and 0.35 mass % of Mn with the balance likewise comprising Mg and unavoidable impurities. The drawing was accomplished in two passes of plain drawing, with the first pass reducing the outside diameter to 13.5 mm and the second pa...

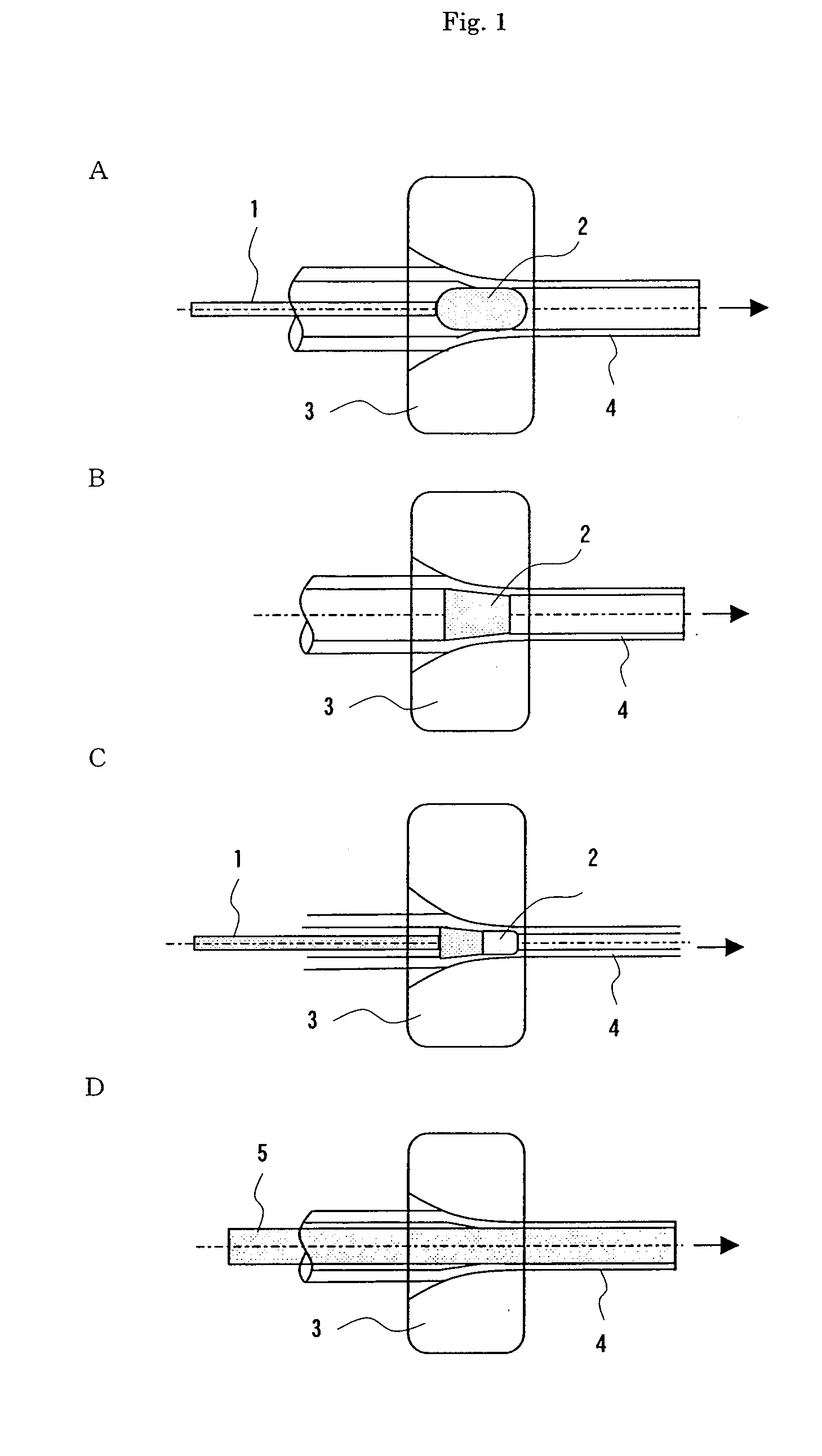

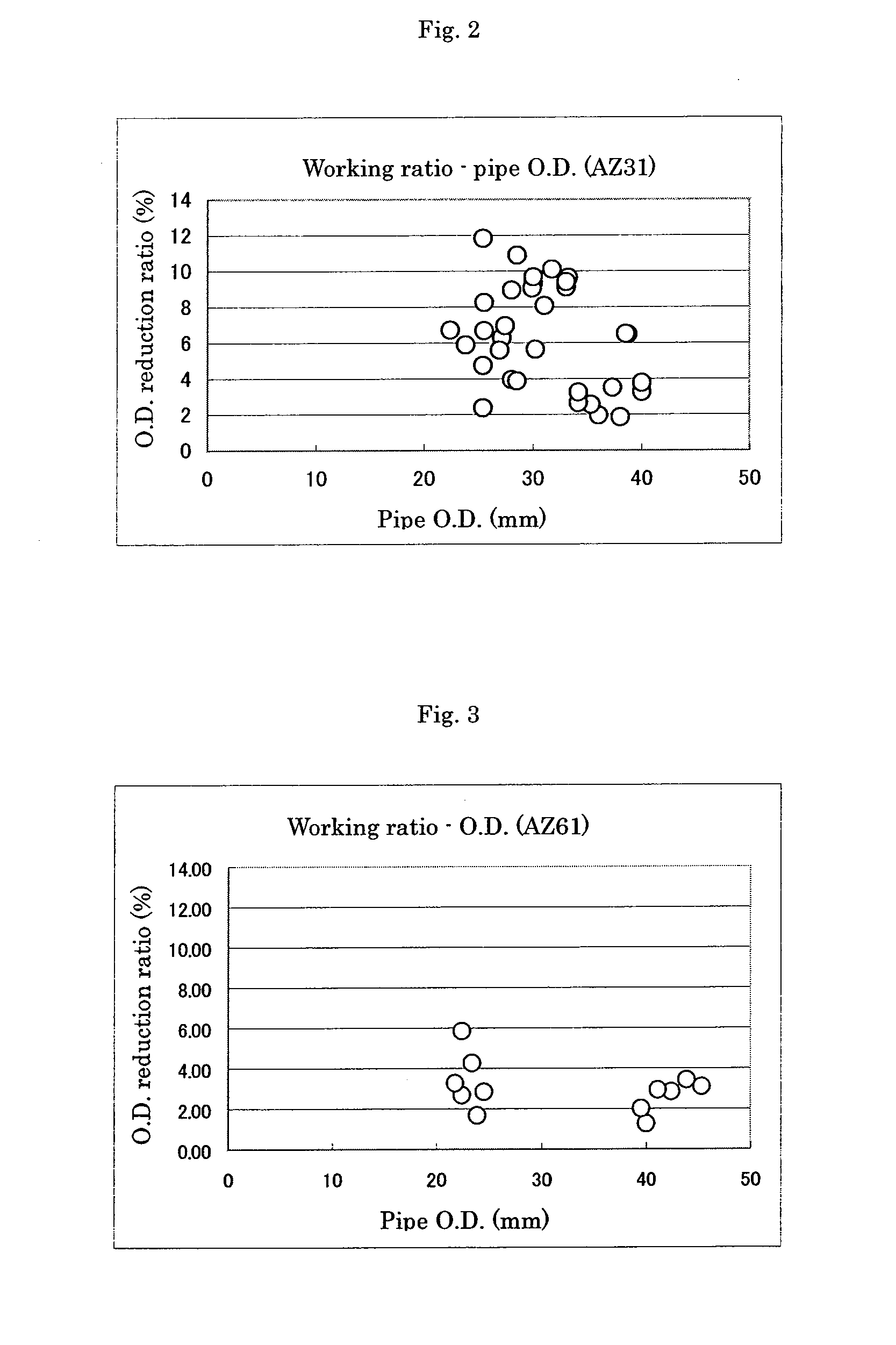

experimental example 1-2

[0096]An extruded pipe (outside diameter: 15.0 mm, wall thickness: 1.5 mm) of an AZ31 alloy and an extruded pipe of an AZ61 alloy having the same configuration as above were drawn, respectively, with varied reduction ratios, consequently yielding various specimens of drawn magnesium base alloy pipes having different outside diameters. The AZ31 alloy of the extruded pipe used was a magnesium base alloy containing 2.9 mass % of Al, 0.77 mass % of Zn and 0.40 mass % of Mn with the balance composed of Mg as a base material and unavoidable impurities, while the AZ61 alloy of the extruded pipe was a magnesium base alloy containing 6.4 mass % of Al, 0.77 mass % of Zn and 0.35 mass % of Mn with the balance likewise comprising Mg and unavoidable impurities. The drawing was accomplished in one pass of plain drawing by using varied area reduction ratios of 5.5% (O.D. after a drawing: 14.20 mm), 10.0% (O.D. after a drawing: 13.5 mm) and 21.0% (O.D. after a drawing: 12.0 mm), respectively. The d...

experimental example 1-3

[0099]In this experimental example, to prepare drawn magnesium base alloy pipes, three types of extruded pipes were drawn at 150° C. to be reduced in outside diameter to 12.0 mm, respectively, including an extruded pipe of a magnesium base alloy (AZ10 alloy) containing 1.2 mass % of Al, 0.4 mass % of Zn and 0.3 mass % of Mn with the balance composed of Mg as a base material and unavoidable impurities, an extruded pipe of an AS41 magnesium base alloy containing 4.2 mass % of Al, 1.0 mass % of Si and 0.40 mass % of Mn with the balance likewise comprising Mg and unavoidable impurities and an extruded pipe of an AS21 magnesium base alloy containing 1.9 mass % of Al, 1.0 mass % of Si and 0.45 mass % of Mn with the balance likewise comprising Mg and unavoidable impurities. Each extruded pipe subjected to drawing was 15.0 mm in outside diameter and 1.5 mm in wall thickness. The drawing was performed in the same manner and under the same conditions as in the experimental example 1-1 above, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com