Preparing method of fishing pole guide hole

A fishing rod and guide eye technology, applied in the field of fishing equipment, can solve the problems of increasing fishing costs, not easy to feel, and increasing the weight of fishing rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

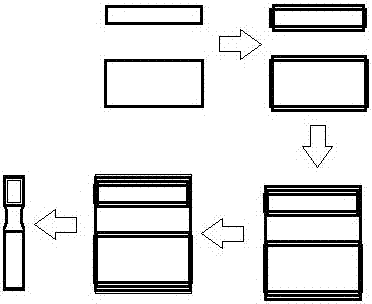

[0037] Such as figure 1 with figure 2 Shown is a method for preparing a fishing rod guide eye, which is characterized in that it comprises the following steps:

[0038] Step 1. Prepare the mold. The mold is composed of at least two rod-shaped molds. The outer diameter of one mold matches the outer diameter of the assembled fishing rod, which is called the fishing rod part mold. The outer diameter of the other mold matches the outer diameter of the fishing rod. The outer diameter of the assembled guide ring matches, which is called the wire part mold;

[0039] Step 2, making tubular embryos, respectively winding carbon fiber cloth (3) on the mold of the fishing rod part and the mold of the wire part to obtain two tubular embryos;

[0040] Step 3, forming the guide eye embryo, fixing the two tubular embryos parallel to each other, and then winding carbon fiber cloth (4) on the outer surface of the two tubular embryos to form the guide eye embryo;

[0041] Step 4, curing trea...

Embodiment 2

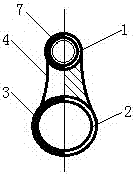

[0045] Such as image 3 , Figure 4 , Figure 5 with Image 6 Shown is a method for preparing a fishing rod guide eye, which is characterized in that it comprises the following steps:

[0046] Step 1. Prepare three rod-shaped molds. The outer diameter of the first mold matches the outer diameter of the assembled fishing rod, which is called the fishing rod part mold. The outer diameter of the second mold matches the assembled guide. The size of the outer diameter of the ring is matched, which is called the mold of the wire part, and the third mold is used to adjust the distance between the mold of the fishing rod part and the mold of the wire part, called the mold of the support part;

[0047] Step 2, making tubular embryos, respectively winding carbon fiber cloth (3) on the mold of the fishing rod part, the mold of the wire part and the mold of the bracket part to obtain three tubular embryos;

[0048] Step 3: Form the guide eye embryo, put the three tubular embryos in pa...

Embodiment 3

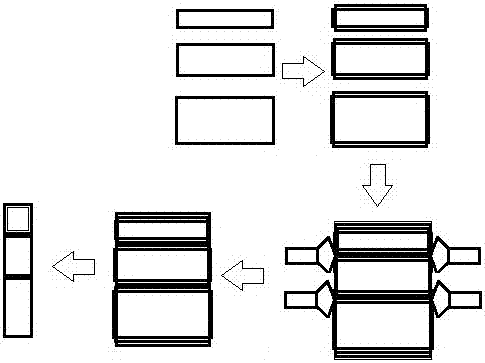

[0053] Such as Figure 7 with Figure 8 Shown is a method for preparing a fishing rod guide eye, which is characterized in that it comprises the following steps:

[0054] Step 1. Prepare the mold. The mold is composed of at least two rod-shaped molds. The outer diameter of one mold matches the outer diameter of the assembled fishing rod, which is called the fishing rod part mold. The outer diameter of the other mold matches the outer diameter of the fishing rod. The outer diameter of the assembled guide ring matches, which is called the wire part mold;

[0055] Step 2, making tubular embryos, respectively winding carbon fiber cloth (3) on the mold of the fishing rod part and the mold of the wire part to obtain two tubular embryos;

[0056]Step 3. Form the guide eye embryo, fix the two tubular embryos parallel to each other and tangentially, fill the two sides of the tangent line of the tubular embryo with carbon fiber cloth (6) or carbon fiber plus binder, and then wind the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com