Ceramic smashing mechanism

A pulverizing mechanism and ceramic technology, applied in the field of ceramics and pulverization, can solve the problems of acid and alkali resistance, acid and alkali resistance, expensive metal materials, difficult to clean, etc., and achieve the effects of low cost, high mechanical strength, and simple production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

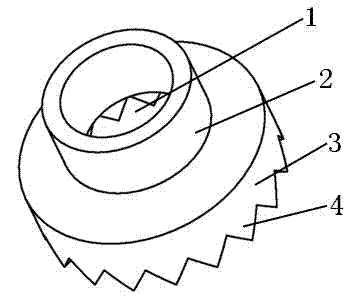

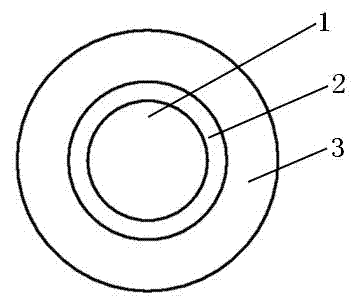

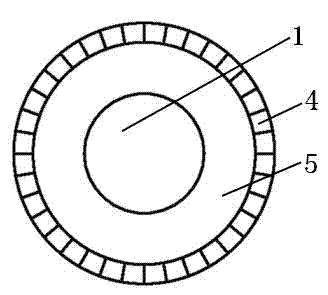

[0021] Please see Figure 1 to Figure 3 , A ceramic crushing mechanism, characterized in that it comprises a connecting part 2 and a crushing part 3 bonded to the connecting part. The connecting part is located above the crushing part and the two are integrally formed; the connecting part is in the shape of a circular cylinder and is connected The hollow part that penetrates the top and bottom of the component is the connecting cavity 1; the inside of the pulverizing component has a hollow container 5, the edge of the pulverizing component is cylindrical and the edge of the pulverizing component has a plurality of teeth 4 distributed along the cylindrical column. The diameter of the object cavity is larger than the diameter of the connecting cavity. The connecting cavity is in communication with the volume cavity, and the volume cavity does not completely penetr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com