Anti-aging hydrolysis-resistant PU synthetic leather fabric and preparation method thereof

A hydrolysis-resistant, synthetic leather technology, applied in the fields of biochemical fiber processing, textile and papermaking, fiber processing, etc., can solve the problems of limited application of PU synthetic leather products, poor anti-aging ability of leather, and influence of leather use range, etc. Achieving good anti-mildew effect, good solubility, and easy production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

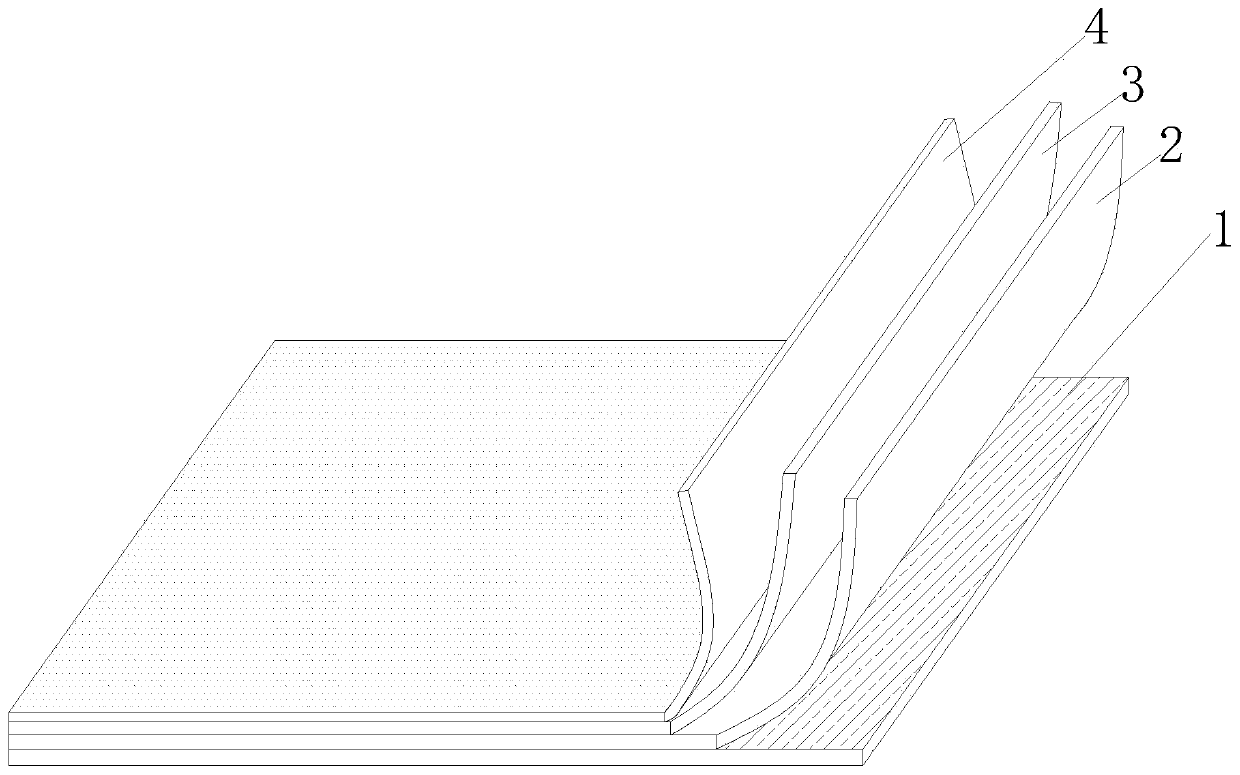

[0032] See figure 1 The anti-aging and hydrolysis-resistant PU synthetic leather fabric provided by the embodiments of the present invention includes a base fabric layer 1, a wet polyurethane layer 2, a dry polyurethane layer 3, and an antibacterial layer 4. The wet polyurethane layer 2 is coated on the base fabric layer On the top of 1, the dry polyurethane layer 3 is coated on the top of the wet polyurethane layer 2, the antibacterial layer 4 is coated on the top of the dry polyurethane layer 3, the surface of the antibacterial layer 4 is provided with vents, and the vents penetrate the dry polyurethane Layer 3, wet-process polyurethane layer 2 and base fabric layer 1. Base fabric layer 1 is a micro-fleece with a thickness of 0.8mm, the back of base fabric layer 1 is smooth, and antibacterial layer 4 is leather antibacterial and antifungal agent, and leather is antibacterial and antifungal The agent is formed by chemical reaction of antibacterial macromolecular organic biguan...

Embodiment 2

[0042] The anti-aging and hydrolysis-resistant PU synthetic leather fabric and the preparation method thereof provided by the embodiment of the present invention are basically the same as that of Embodiment 1, and the difference lies in:

[0043] The preparation method of the anti-aging and hydrolysis resistant PU synthetic leather fabric includes the following steps: step one, mixing liquid preparation; step two, preparing wet polyurethane layer emulsion; step three, wet bass production; step four, back treatment; step Five, dry polyurethane layer mixture ingredients; step six, dry veneer treatment; step seven, inspection; among them:

[0044] In step 1, 1.1 parts of 1,4-butenediol, 1 part of heptamethyltrisiloxane and 0.05 parts of catalyst metal platinum were added to the reaction flask, and then 400 parts of toluene were added and nitrogen protection was applied. While stirring, the temperature was raised to 110°C, and the reaction was stirred for 6 hours. After the reaction, t...

Embodiment 3

[0052] The anti-aging and hydrolysis-resistant PU synthetic leather fabric and the preparation method thereof provided by the embodiment of the present invention are basically the same as that of Embodiment 1, and the difference lies in:

[0053] A preparation method of anti-aging and hydrolysis resistant PU synthetic leather fabric, comprising the following steps: step one, mixing liquid preparation; step two, preparing wet polyurethane layer emulsion; step three, wet bass production; step four, back treatment; step Five, dry polyurethane layer mixture ingredients; step six, dry veneer treatment; step seven, inspection; among them:

[0054] In step 1, 1.2 parts of 1,4-butenediol, 1.2 parts of heptamethyltrisiloxane and 0.07 parts of catalyst metal platinum were added to the reaction flask, and then 500 parts of toluene were added and nitrogen protection was introduced. While stirring, the temperature was raised to 120°C, and the reaction was stirred for 7 hours. After the reaction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com