Volatile antirust synthetic paper and preparation method thereof

A gas-phase anti-rust and synthetic paper technology, applied in the field of gas-phase anti-rust, can solve problems such as waste, white pollution of petroleum resources, environmental hazards, etc., and achieve the effects of reducing waste water, solving white pollution, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

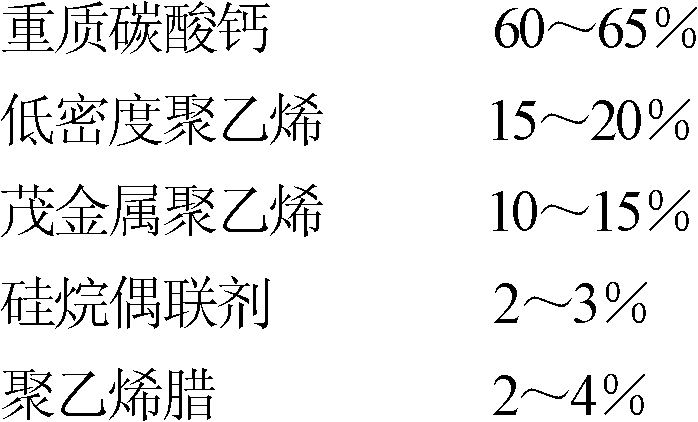

[0025] Vapor-phase antirust synthetic paper, the components and their percentages are:

[0026]

[0027] Among them: the vapor phase corrosion inhibitor for inhibiting metal corrosion consists of: 1 part of benzotriazole; 2 parts of sodium benzoate, 1 part of sodium acetate; 1 part of sodium nitrite;

[0028] Heavy calcium carbonate is 2500 mesh; low density polyethylene resin is blown film grade low density polyethylene with a density of 0.923g / cm 3 , the melt flow rate is 1.0g / 10min; the density of metallocene polyethylene resin (mLDPE) is 0.917g / cm 3 , The melt flow rate is 0.5g / 10min; the silane coupling agent is vinyltrimethoxysilane; the polyethylene wax is a low molecular weight polyethylene wax with a molecular weight of 3500-4000.

[0029] Preparation method: mix gas phase corrosion inhibitor, heavy calcium carbonate, silane coupling agent, and polyethylene wax at 25°C for 5 minutes according to the above formula, then add low-density polyethylene and metallocene ...

Embodiment 2

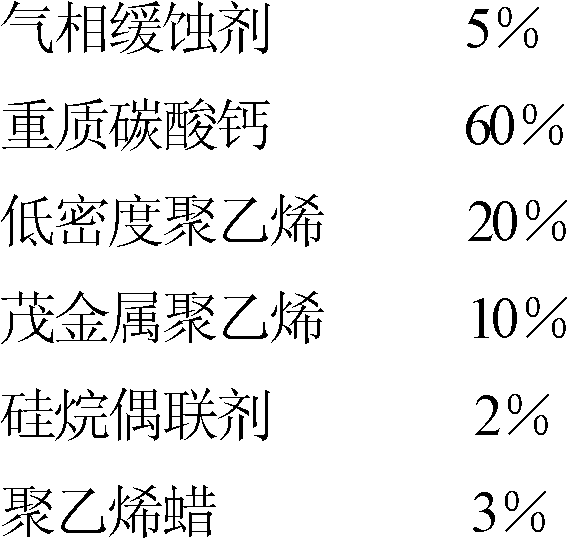

[0031] Vapor phase antirust synthetic paper, composed of the following components:

[0032]

[0033] Among them: the vapor phase corrosion inhibitor for inhibiting metal corrosion consists of: 1 part of benzotriazole; 2 parts of sodium benzoate, 1 part of sodium acetate; 1 part of sodium nitrite;

[0034] Heavy calcium carbonate is 2500 mesh; low density polyethylene resin is blown film grade low density polyethylene with a density of 0.923g / cm 3 , the melt flow rate is 1.0g / 10min; the density of metallocene polyethylene resin (mLDPE) is 0.917g / cm 3 , The melt flow rate is 0.5g / 10min; the silane coupling agent is vinyltrimethoxysilane; the polyethylene wax is a low molecular weight polyethylene wax with a molecular weight of 3500-4000.

[0035] Preparation method: mix gas phase corrosion inhibitor, heavy calcium carbonate, silane coupling agent, and polyethylene wax at 25°C for 5 minutes according to the above formula, then add low-density polyethylene and metallocene poly...

Embodiment 3

[0037] Vapor phase antirust synthetic paper, composed of the following components:

[0038]

[0039]

[0040] Among them: the vapor phase corrosion inhibitor for inhibiting metal corrosion consists of: 1 part of benzotriazole; 1 part of sodium benzoate; 1 part of sodium cinnamate; 1 part of sodium nitrite;

[0041] Heavy calcium carbonate is 2500 mesh; low density polyethylene resin is blown film grade low density polyethylene with a density of 0.923g / cm 3 , the melt flow rate is 1.0g / 10min; the density of metallocene polyethylene resin (mLDPE) is 0.917g / cm 3 , The melt flow rate is 0.5g / 10min; the silane coupling agent is vinyltrimethoxysilane; the polyethylene wax is a low molecular weight polyethylene wax with a molecular weight of 3500-4000.

[0042] Preparation method: Mix gas phase corrosion inhibitor, heavy calcium carbonate, silane coupling agent, and polyethylene wax at 25°C for 5 minutes, then add low-density polyethylene and metallocene polyethylene and mix o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com