Located multicolour anti false coated white paperboard and production process thereof

A technology of white cardboard and coating, which is applied in the direction of paper, papermaking, fiberboard, etc., can solve the problems of being unable to prevent counterfeiting and being easily counterfeited, and achieve the effect of intuitive anti-counterfeiting identification, easy identification and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

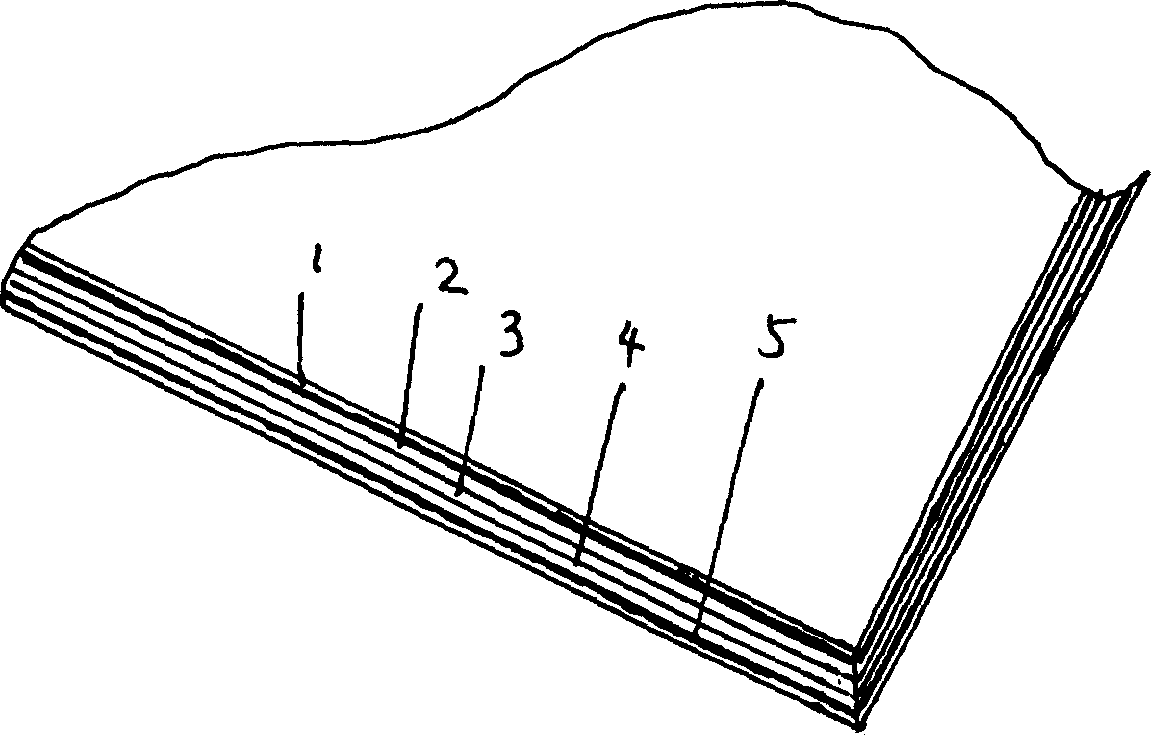

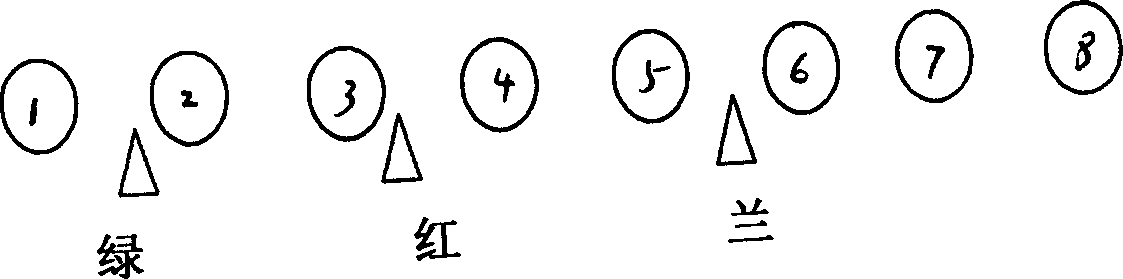

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings: the positioning multi-color anti-counterfeiting coated white paperboard of the present invention, it at least consists of face pulp, core pulp and base pulp to form a multi-layer pulp through a paper machine to make a single-faced white paperboard and through a paper machine. The surface is coated, and at least one pigment is spray-coated on at least one layer of the multi-layer paste and compounded in the middle of the multi-layer paste. The multi-layer slurry also includes at least a lining slurry, and the multi-layer slurry is composed of a face slurry 1, a lining slurry 2, a core slurry 3 and a base slurry 4, figure 1 Five layers of paste are shown, and in other embodiments, there are at least three or more layers of paste.

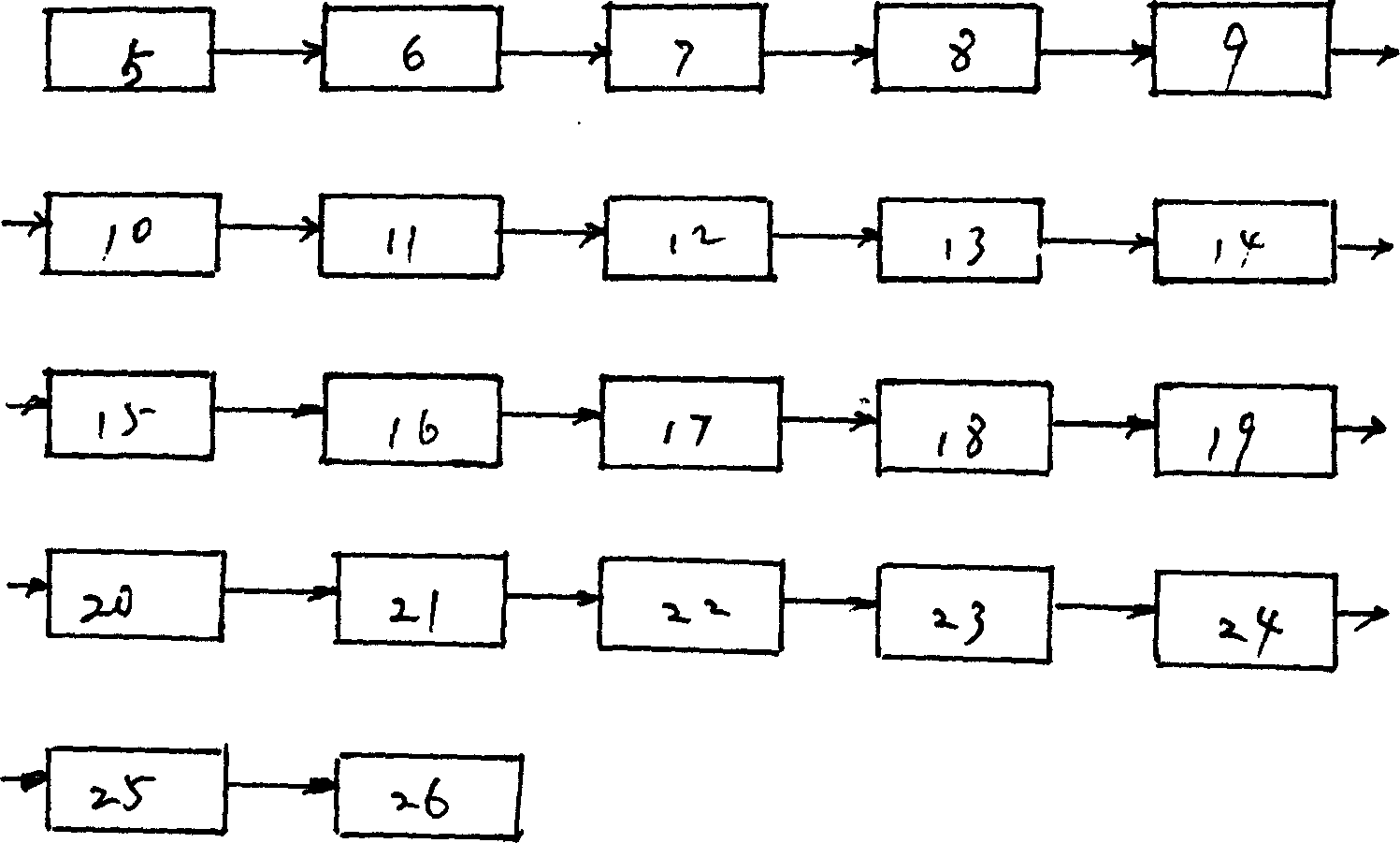

[0019] At least one layer of the multi-layer slurry is sprayed with at least two colors of pigments, figure 1 In the process, pigments of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com