Local positioning anti-fake multiple-color paper board and its making process

A kind of cardboard and partial technology, which is applied in the field of local positioning anti-counterfeiting multi-color cardboard and manufacturing, can solve the problems of being unable to prevent counterfeiting and being easily counterfeited, and achieve the effect of intuitive anti-counterfeiting identification, easy identification and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

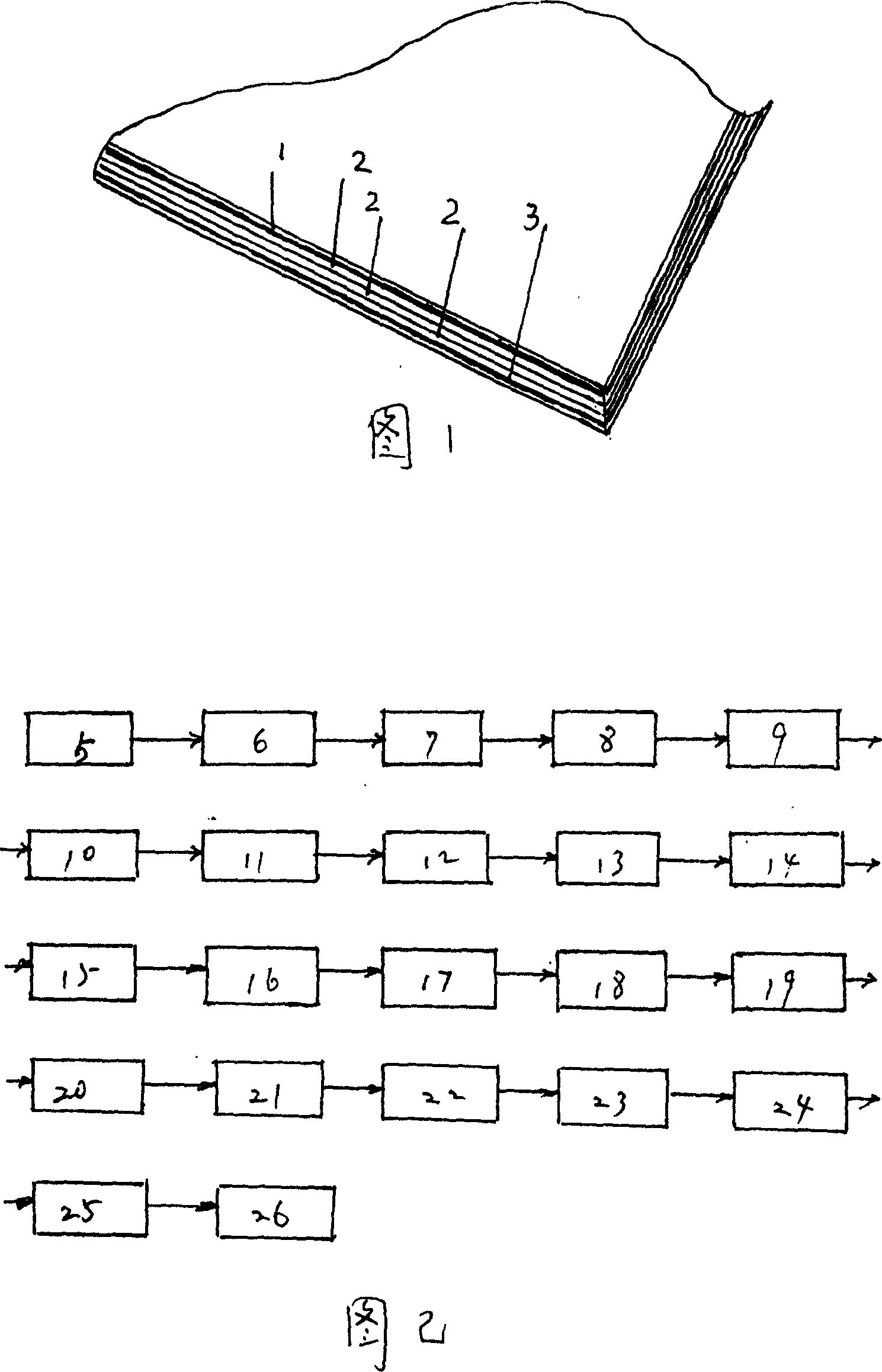

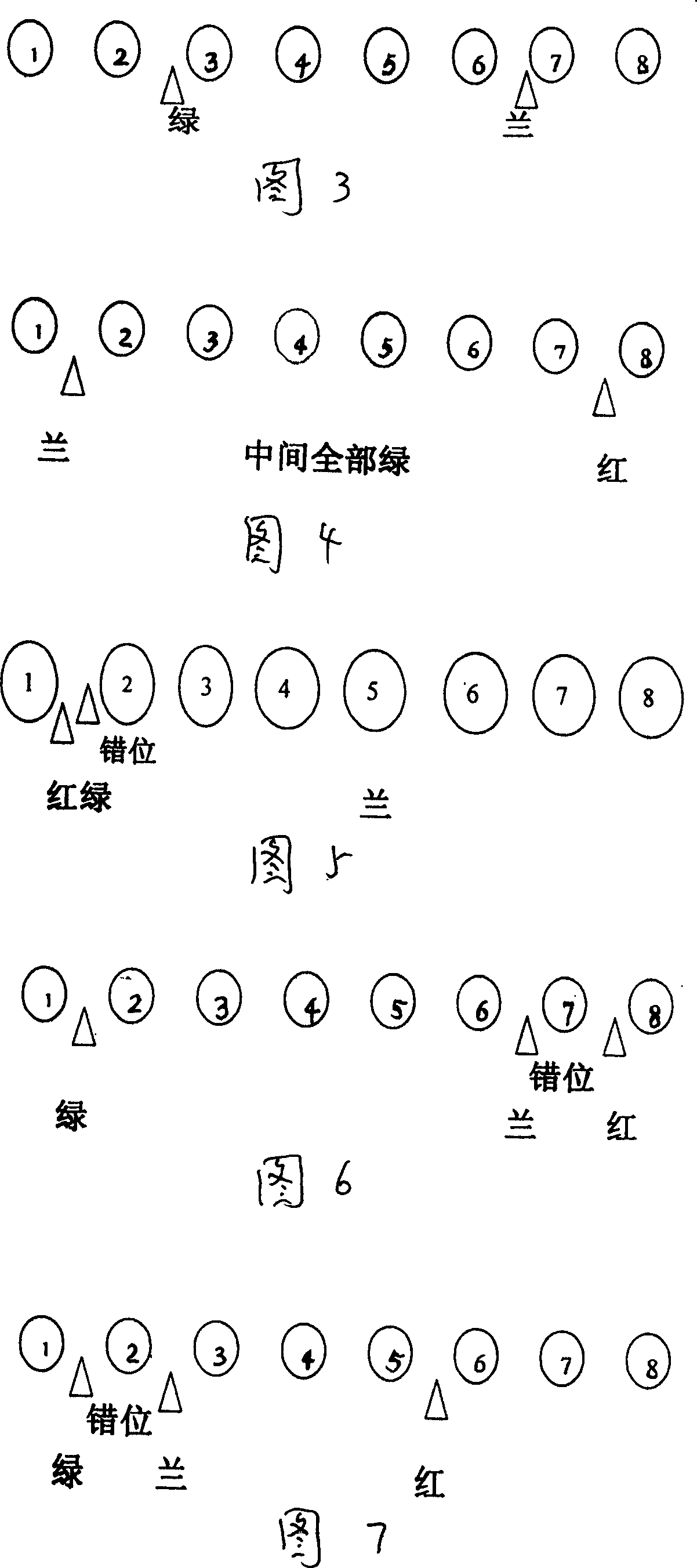

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings: the local positioning anti-counterfeiting multi-color cardboard of the present invention, it at least consists of a face pulp 1, a core pulp 2 and a base pulp 3 to form a multi-layer pulp through a paper machine to make a cardboard, Fig. 1 Shown is five layers of slurry. In other embodiments, the multi-layer slurry has at least three layers, including at least one layer of surface slurry 1, at least one layer of bottom slurry 3, at least one layer of core slurry and so on. In the surface paste and / or base paste of multi-layer paste, at least one paste layer is positioned and sprayed with at least one pigment and is compounded between the multi-layer paste; and in the face paste and / or base paste of multi-layer paste at least one At least two pigments are positioned and sprayed in the paste layer and are compounded between multiple layers of paste.

[0023] The multi-la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com