Manufacture method of semiconductor device and flash memory device

A manufacturing method and technology of flash memory devices, which are applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as reducing product quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the above-mentioned purpose, characteristics and advantages of the present invention more obvious and understandable, a preferred embodiment is listed below, and in conjunction with the accompanying drawings, the detailed description is as follows:

[0027] The following are examples describing the present invention, which disclose the main technical features of the present invention, but are not intended to limit the present invention.

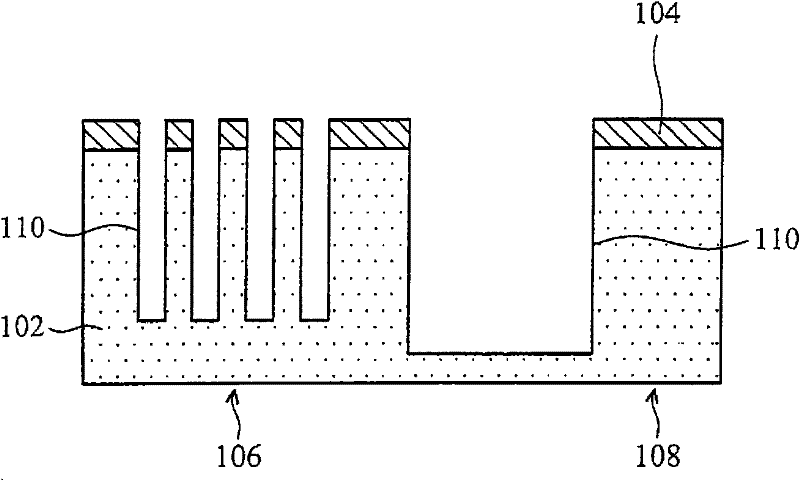

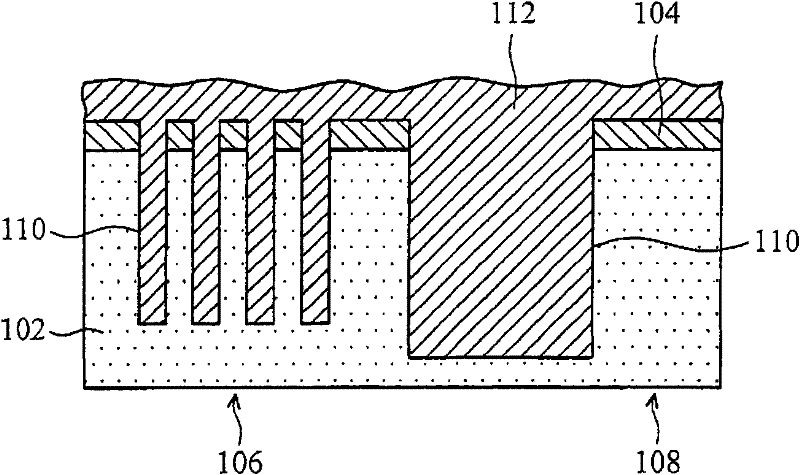

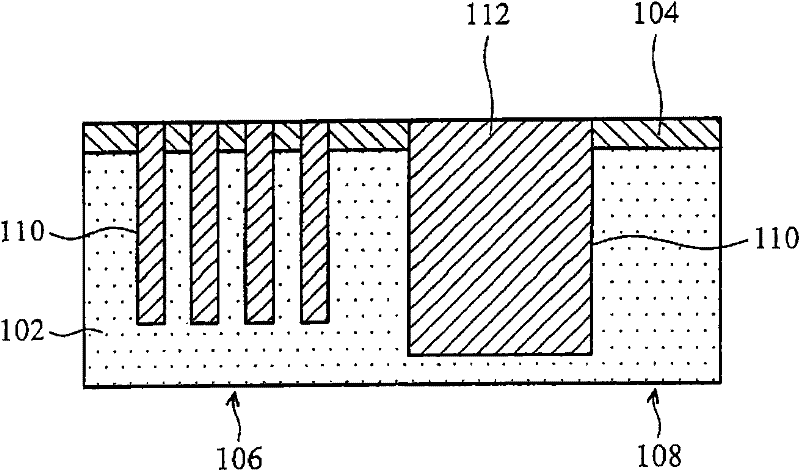

[0028] Please refer to Figure 2A , provide a substrate 202, including an array region 204 and a peripheral region 206, the material of the substrate 202 is silicon, for example. A pad layer 210 such as silicon oxide is formed on the substrate 202 , and a hard mask layer 212 such as silicon nitride is formed on the pad layer 210 . Next, pattern the hard mask layer 212 and pad layer 210 , and use the patterned hard mask layer 212 as a mask to etch the substrate 202 to form a plurality of trenches 208 . Please refer to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com