Web smoothness improvement process

A web, smoothness technology, applied in pulp beating/refining method, papermaking, paper machine, etc., can solve problems such as smoothing and economical method, degradation of strength characteristics, not providing fiber web surface, etc., reaching unit Small loss in weight and thickness, improved smoothness, and improved hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

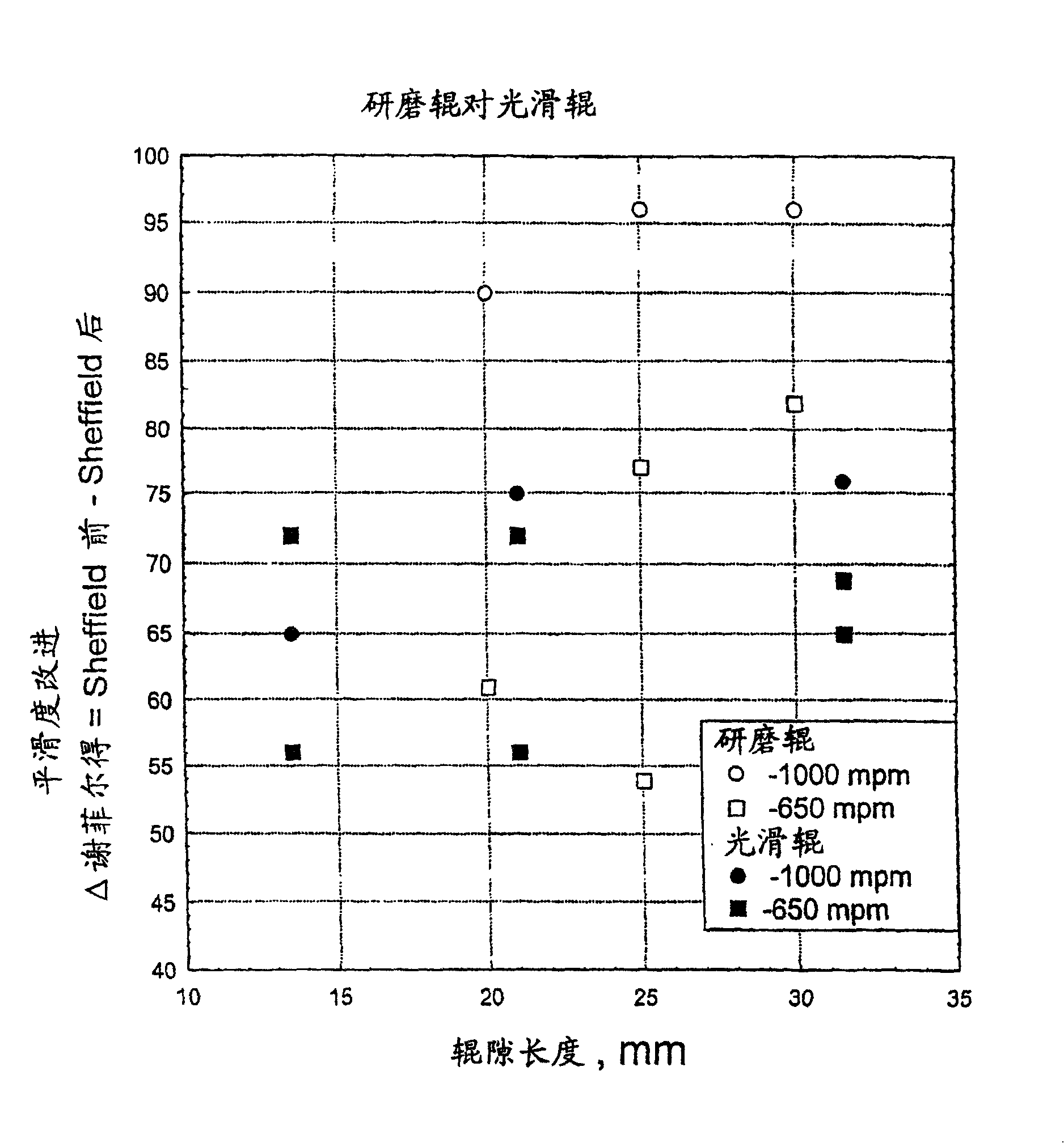

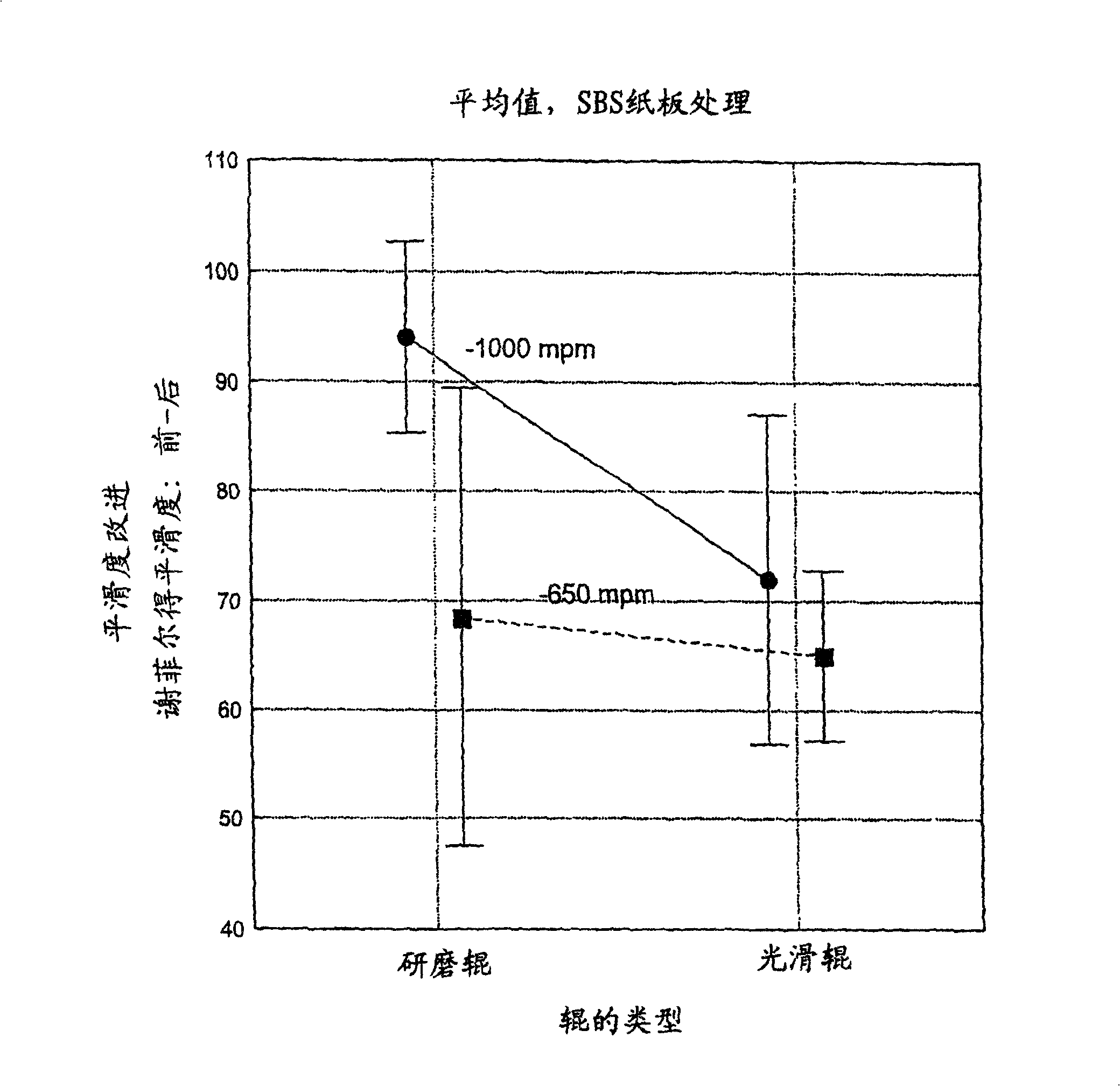

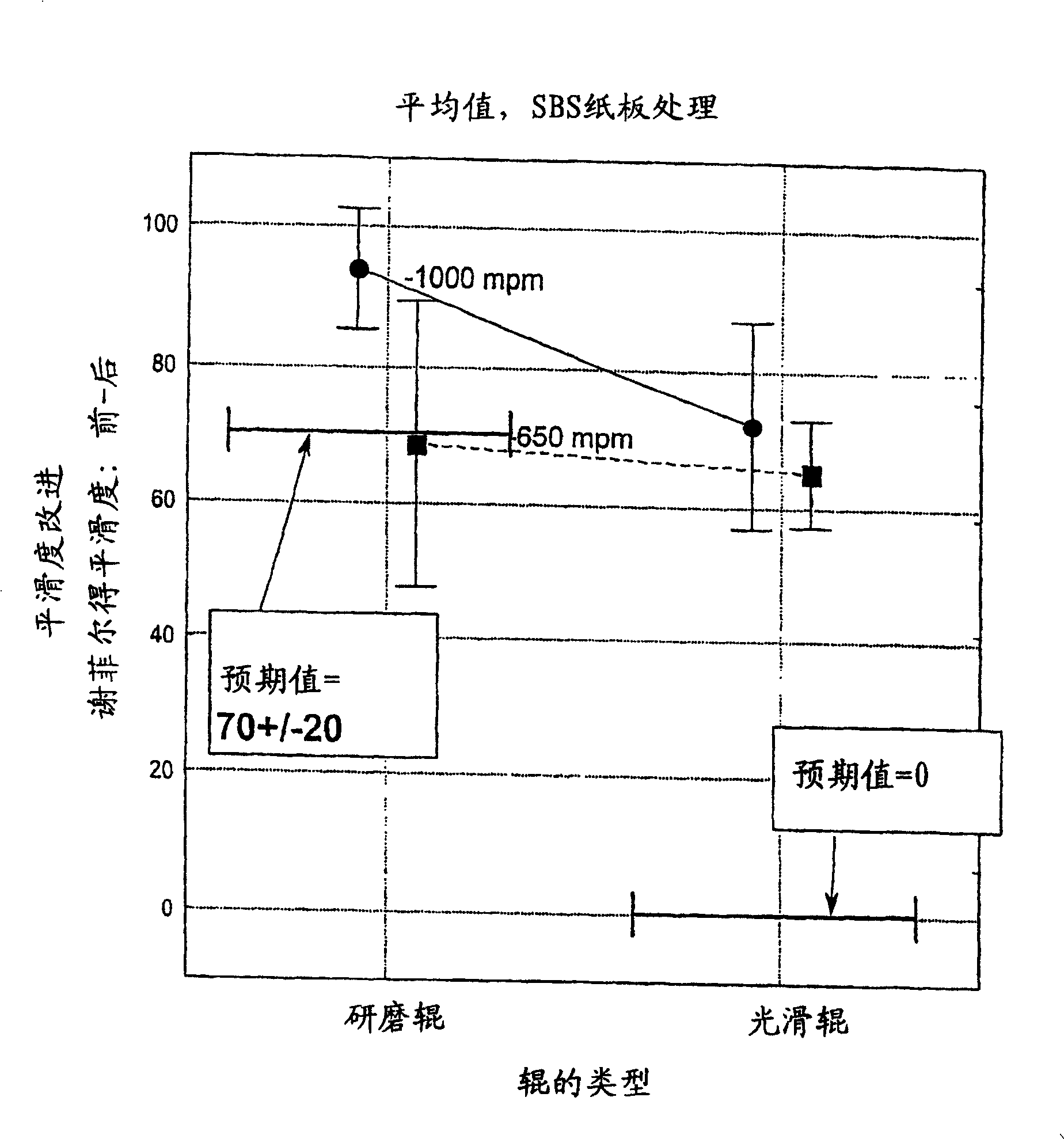

[0025] In the paper industry, rolls are used for different purposes, such as conveying webs, coating and rolling, etc. The present invention is based on the surprising discovery that a smooth roll can be used to generate heat and thus considerably improve the smoothness of the web / board, which was previously thought to require an abrasive cover roll Completed. In particular, the present invention provides a method of improving the smoothness of the web surface by subjecting the web surface to an uncovered smooth roller moving at a different speed from the web, thereby due to The heat generated by the friction plasticizes the uppermost fibers on the paper. Surprisingly, the inventors have discovered that it is not necessary to add any abrasives to the steel rolls to generate the heat required to increase the smoothness.

[0026] The terms "paper / board", "paper" and "board" refer to products formed from sheets containing cellulosic or woody fibers. "Paperboard" is synonymous ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com