High-strength detonating tube and its preparation method

A detonating tube, high-strength technology, which is applied to blasting tubes, offensive equipment, weapon accessories, etc., can solve the problems of expensive detonating tube equipment, long process routes, and high product costs, achieve good social and economic benefits, and simple production methods. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

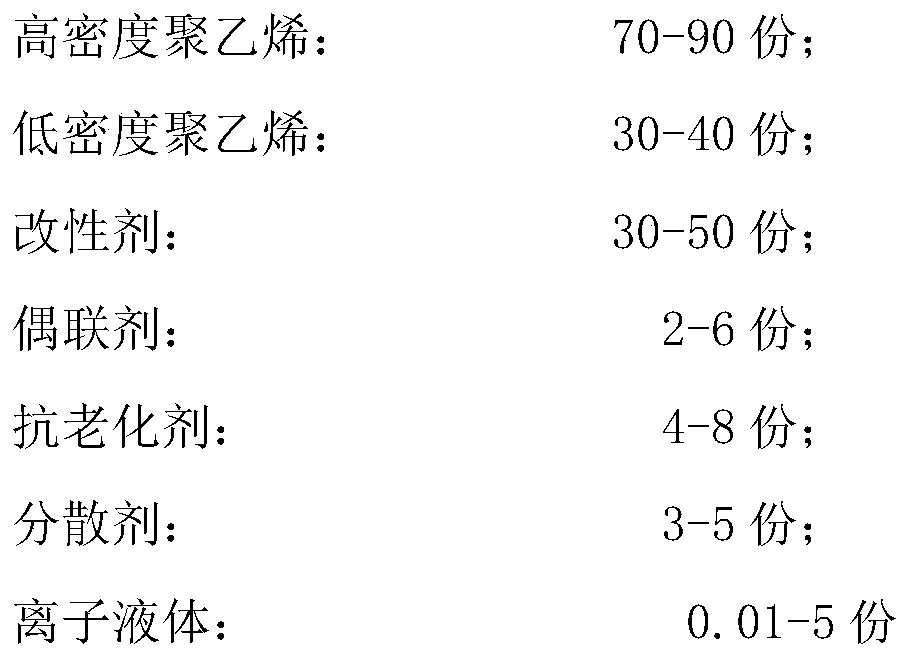

[0038] A high-strength detonator, comprising the following raw materials in parts by weight:

[0039]

[0040] Its preparation method comprises the following steps:

[0041] S1, put the modifier in an oven with a temperature of 80°C, and dry it for 4 hours;

[0042] S2, mixing the dried modifier with the remaining components in a high-speed mixer for 15 minutes at high speed to obtain a mixed material;

[0043] S3, plasticizing the mixed material; the plasticizing temperature is 180°C, and the plasticizing time is 5 minutes;

[0044] S4, extrude the plasticized mixed material into the die head of the extruder after drying, then extrude the single-layer hollow blank tube, and then evenly adhere the explosive fine powder to the inner wall of the blank tube through the inner hole of the die head ;

[0045] S5, cooling and shaping the billet tube to which the fine explosive powder is adhered;

[0046] S6, heating and stretching the blank tube in S5;

[0047] S7, cooling an...

Embodiment 2

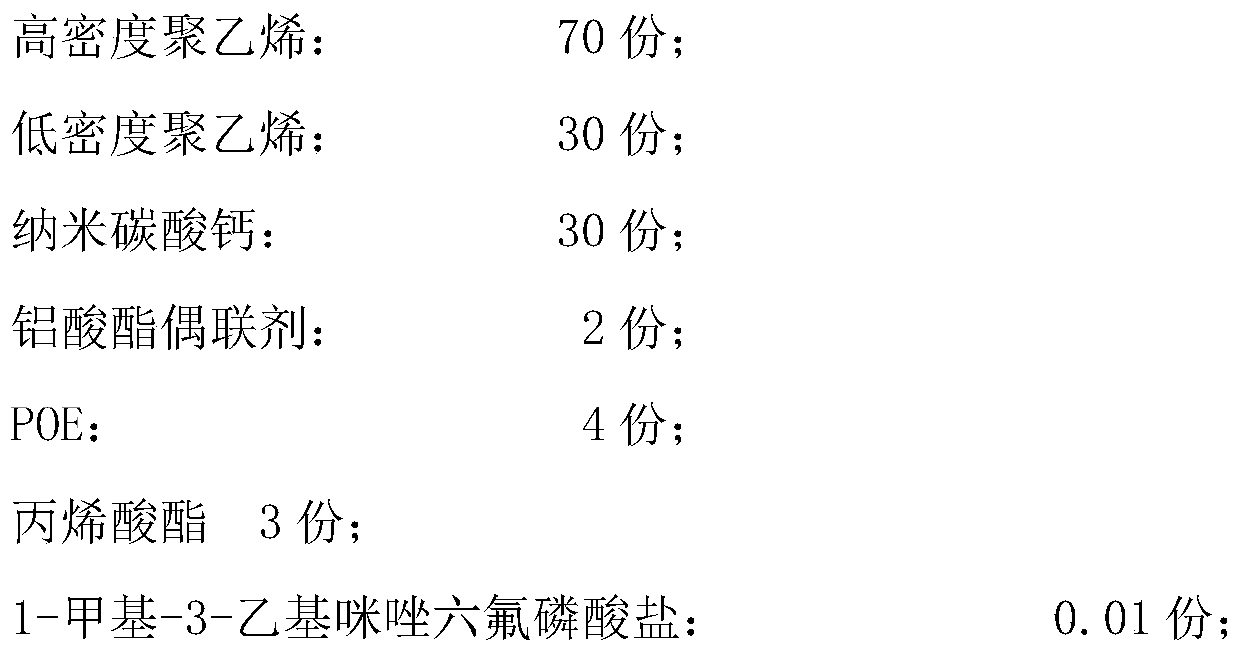

[0050] High-strength detonator, the nano-calcium carbonate modified polyethylene material includes the following raw materials in parts by weight:

[0051]

[0052]

[0053] The ionic liquid: 0.5 part of 1-methyl-3-ethylimidazole tetrafluoroborate, 0.3 part of 1-methyl-3-butylimidazole hexafluorophosphate, 1-methyl-3-butylimidazole 0.8 parts of tetrafluoroborate, 0.2 parts of 1-methyl-3-hexylimidazolium hexafluorophosphate, 0.2 parts of 1-methyl-3-hexylimidazolium tetrafluoroborate, 1,2-dimethyl-3 - 2 parts of ethylimidazolium hexafluorophosphate, 0.3 parts of 1,2-dimethyl-3-ethylimidazolium tetrafluoroborate, 0.7 parts of 1,2-dimethyl-3-butylimidazolium hexafluorophosphate share.

[0054] Its preparation method comprises the following steps:

[0055] S1, put the nano-zinc oxide in an oven with a temperature of 90° C., and perform drying treatment for 5 hours;

[0056] S2, mixing the dried nano-zinc oxide with the rest at high speed in a high-speed mixer for 18 minute...

Embodiment 3

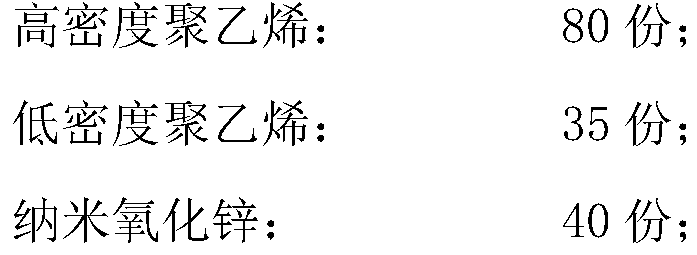

[0064] High-strength detonator, the nano-calcium carbonate modified polyethylene material includes the following raw materials in parts by weight:

[0065]

[0066] Its preparation method comprises the following steps:

[0067] S1, put the modifier in an oven at a temperature of 100°C, and dry it for 6 hours;

[0068] S2, mixing the modifier and other components in a high-speed mixer for 20 minutes at high speed to obtain a mixed material;

[0069] S3, plasticizing the mixed material; the plasticizing temperature is 205° C., and the plasticizing time is 16 minutes;

[0070] S4, extrude the plasticized mixed material into the die head of the extruder after drying, then extrude the single-layer hollow blank tube, and then evenly adhere the explosive fine powder to the inner wall of the blank tube through the inner hole of the die head ;

[0071] S5, cooling and shaping the billet tube to which the fine explosive powder is adhered;

[0072] S6, heating and stretching the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com