Chitosan/nano-TiO2 composite material and preparation method and application thereof

A composite material, chitosan technology, applied in the direction of botanical equipment and methods, applications, rayon manufacturing, etc., can solve the problems of undisclosed bacteria and other microbial inhibition effects, change fiber strength, low safety, etc., to achieve structural Stable, enhanced antibacterial activity, good safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 prepares chitosan solution

[0039] Dissolve chitosan powder with a deacetylation degree of 85% in 1% acetic acid aqueous solution by volume to prepare a solution with a chitosan concentration of 10 mg / ml; adjust the pH to 6.0 with NaOH, and shake at room temperature for 24 hours at 160 rpm ; Sterilize in an autoclave at 121°C for 20 minutes, store at 4°C until use.

Embodiment 2

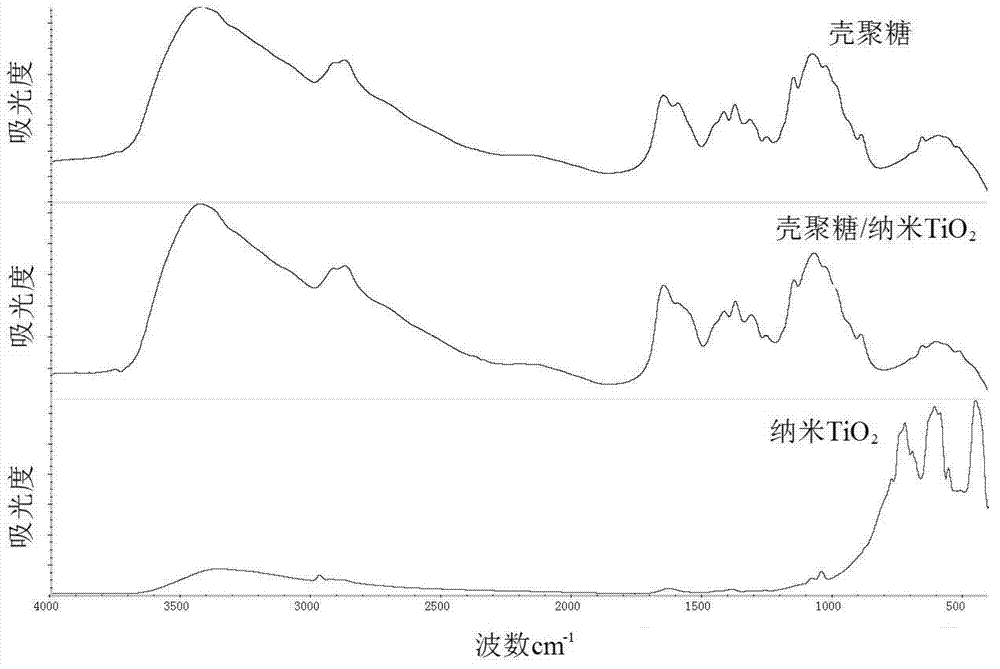

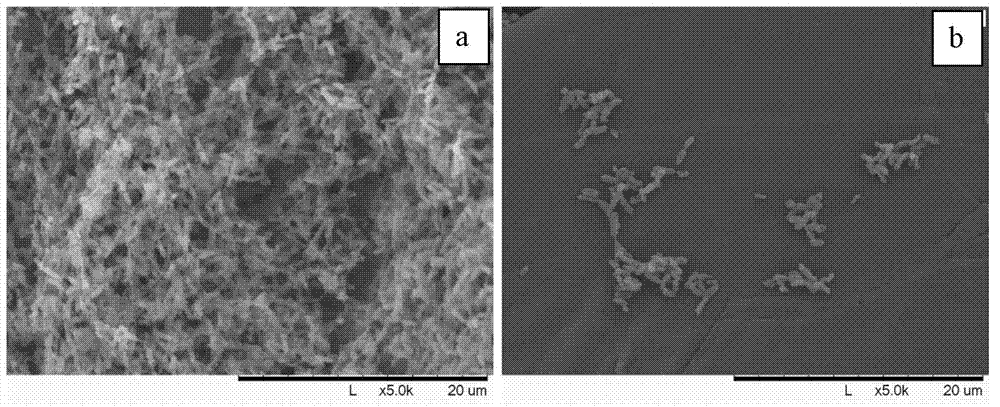

[0040] Embodiment 2 chitosan / nano TiO 2 Composite formulation

[0041] Take an appropriate amount of chitosan solution and nano-TiO 2 The powders were mixed according to the addition ratio in Table 1, and ultrasonically dispersed for 1 min to make TiO 2 The powder is completely dispersed in the chitosan solution and formulated as chitosan / nano-TiO 2 of emulsion. Move the emulsion to an autoclave, seal it, put it in an oven, react at 160°C-180°C for 2 hours, and then put it in a 4°C refrigerator for use.

[0042] Table 1 Chitosan / nano-TiO with different concentrations 2 Composite formulation

[0043]

[0044] Note: The concentration of each raw material is the concentration of the raw material in the emulsion.

Embodiment 3

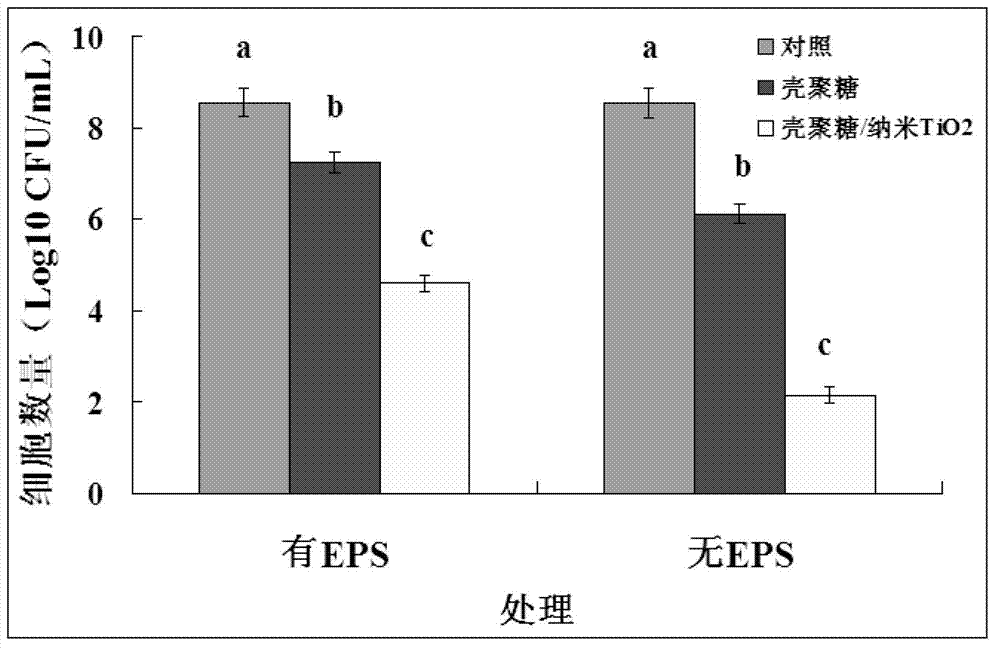

[0045] Activation and cultivation of embodiment 3Xoo

[0046] Activate the Xoo strain stored at -70°C on NA (beef extract 1g, peptone 5g, yeast extract 5g, sodium chloride 5g, sucrose 10g, agar 20g, water 1000ml; pH 6.8-7.0) plate, and incubator Put it in the medium for 24-48h, check the purity of the bacteria, and use a sterilized transfer loop to pick up pure cultured bacteria with the same colony shape on a sterile ultra-clean bench, streak them on a new NA plate, and culture for 24 hours. Pick a single colony and inoculate it into LB liquid medium, shake and culture it in a shaker at 28°C and 160r / min for 24 hours to make a seed liquid, so that the concentration of bacteria in the seed liquid is 10 9 CFU / ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com