Crystal oil slippery resin used for synthetic leather and preparation method thereof

A technology for synthetic leather and crystal, applied in the field of high-gloss polyurethane varnish and its preparation, can solve the problems of poor temperature resistance, easy stickiness of varnish resin, etc., to overcome easy stickiness, easy yellowing, and anti-aging poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The specific formula is: 41 parts of dimethylformamide, 10 parts of polyether polyol, 5 parts of polyester polyol, 13 parts of diphenylmethane diisocyanate, 0.89 part of 1,4-butanediol, ethyl alcohol 4 parts of glycol, 11.5 parts of toluene, 11.5 parts of ethyl acetate, 3.1 parts of emulsified silicone oil, and 0.01 part of phosphite antioxidant.

Embodiment 2

[0021] Embodiment 2: The specific formula is 41 parts of dimethylformamide, 9 parts of polyether polyols, 6 parts of polyester polyols, 13 parts of diphenylmethane diisocyanate, 0.89 parts of 1,4-butanediol, ethylene glycol 4.0 parts of alcohol, 11.5 parts of toluene, 11.5 parts of ethyl acetate, 3.1 parts of emulsified silicone oil, and 0.01 part of phosphite antioxidant.

Embodiment 3

[0022] Example 3: The specific formula is 40.8 parts of dimethylformamide, 10 parts of polyether polyol, 5.0 parts of polyester polyol, 13 parts of diphenylmethane diisocyanate, 1.5 parts of 1,4-butanediol, ethylene glycol 3.59 parts of alcohol, 11.5 parts of toluene, 11.5 parts of ethyl acetate, 3.1 parts of emulsified silicone oil, and 0.01 part of phosphite antioxidant.

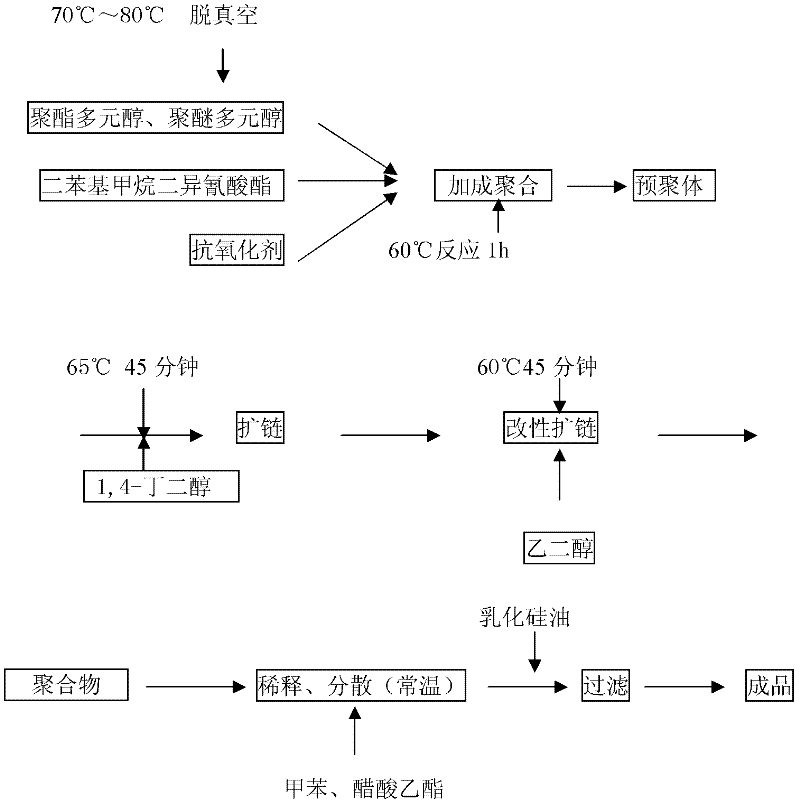

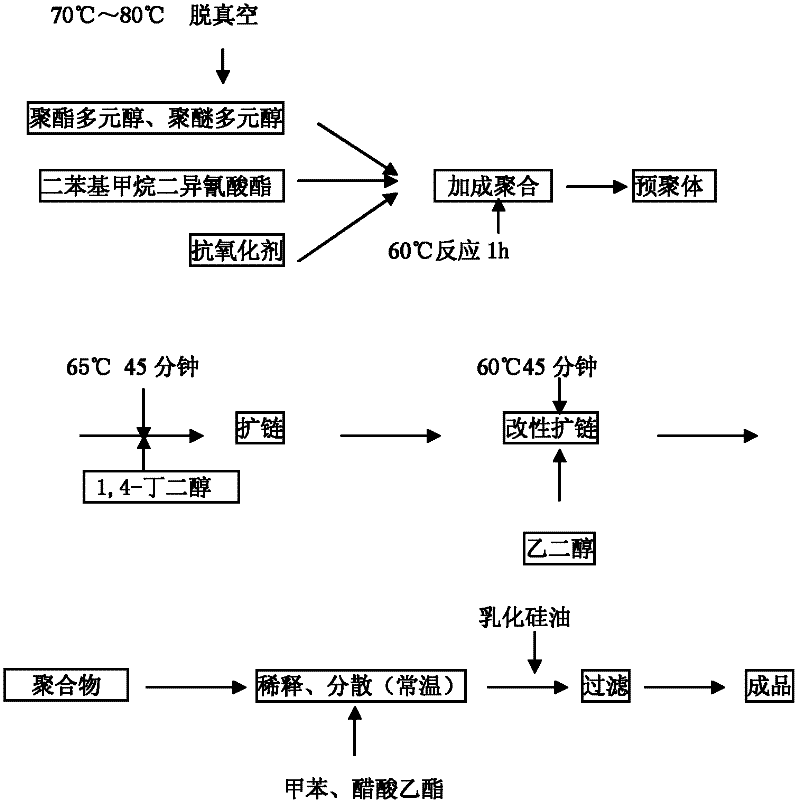

[0023] Such as figure 1 As shown, the preparation method of this crystal oil slippery resin for synthetic leather described in the present invention is first formed by addition polymerization of polyether polyol, polyester polyol, diphenylmethane diisocyanate and antioxidant. The prepolymer is reacted at 60°C for one hour; and then undergoes a chain extension reaction to form a polymer with a relatively high molecular weight. The prepolymer can be prepared by chain extension reactions of diols and polyols Higher quality resin with excellent performance.

[0024] During this addition polymerization proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com