Ice-surface antiskid warm-keeping sole material and preparation method thereof

A shoe sole material and anti-slip technology, which can be applied in other household appliances, household components, applications, etc., can solve the problems of unsatisfactory anti-slip performance, low friction between the sole and the ground, etc., and achieve good heat preservation effect, not easy to slip, and high friction coefficient Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

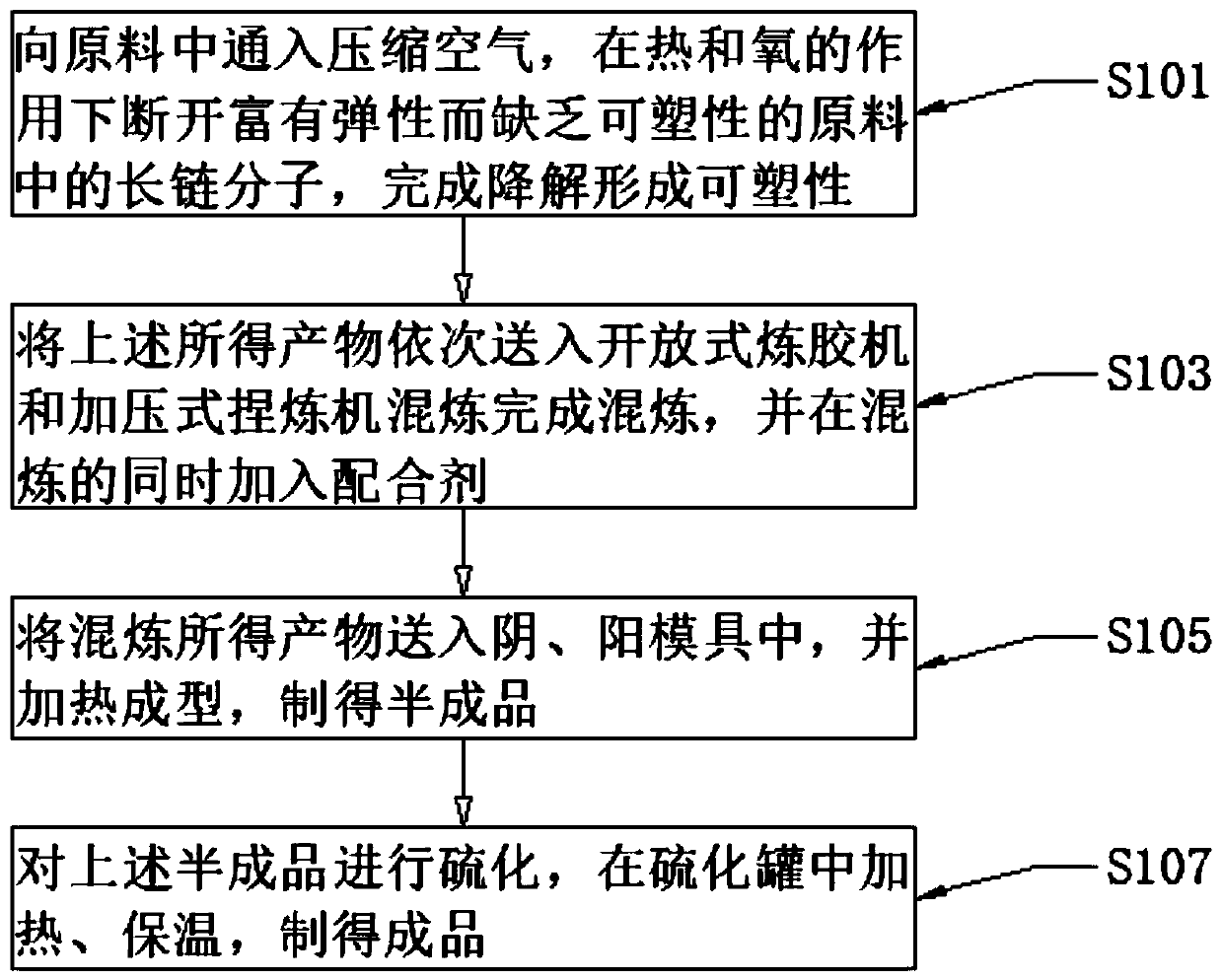

[0033] According to one aspect of the present invention, there is provided a kind of preparation method of anti-slip warming sole on ice, comprising the following steps:

[0034] S101. Thermoplastic refining: inject compressed air into the raw material, under the action of heat and oxygen, break the long-chain molecules in the elastic but lacking plasticity raw material, and complete the degradation to form plasticity;

[0035] S103, mixing: the above-mentioned obtained products are sequentially sent to an open rubber mixer and a pressurized kneader for mixing to complete mixing, and compounding agents are added while mixing;

[0036] S105. Compression molding: put the kneaded product into the male and female moulds, and heat and form it to obtain a semi-finished product;

[0037] S107. Vulcanization: vulcanize the above-mentioned semi-finished products, heat and keep warm in a vulcanization tank to obtain finished products.

[0038] Specifically, the compressed air temperatu...

Embodiment 1

[0058] A kind of ice-surface anti-skid warm-keeping shoe sole material, comprises each component of following mass parts:

[0059] 52 parts of natural rubber, 41 parts of polymer rubber-plastic blended thermoplastic elastomer, 43 parts of polymer thermoplastic rubber, 1 part of butadiene, 13 parts of glass fiber, 6 parts of graphene, 3 parts of reinforcing filler, 2 parts of reinforcing filler , 1.5 parts of structure control agent, 3 parts of modified additive and 6 parts of vulcanizing agent.

Embodiment 2

[0061] A kind of ice-surface anti-skid warm-keeping shoe sole material, comprises each component of following mass parts:

[0062] 65 parts of natural rubber, 46 parts of polymer rubber-plastic blended thermoplastic elastomer, 44 parts of polymer thermoplastic rubber, 3 parts of butadiene, 12 parts of glass fiber, 6 parts of graphene, 5 parts of reinforcing filler, 3 parts of reinforcing filler , 3 parts of structure control agent, 4 parts of modified additive and 6 parts of vulcanizing agent.

[0063] Embodiment two

[0064] A kind of ice-surface anti-skid warm-keeping shoe sole material, comprises each component of following mass parts:

[0065] 78 parts of natural rubber, 49 parts of polymer rubber-plastic blended thermoplastic elastomer, 48 parts of polymer thermoplastic rubber, 5 parts of butadiene, 14 parts of glass fiber, 9 parts of graphene, 8 parts of reinforcing filler, 5 parts of reinforcing filler , 4 parts of structure control agent, 4 parts of modified additive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com