Patents

Literature

51results about How to "Freeze-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

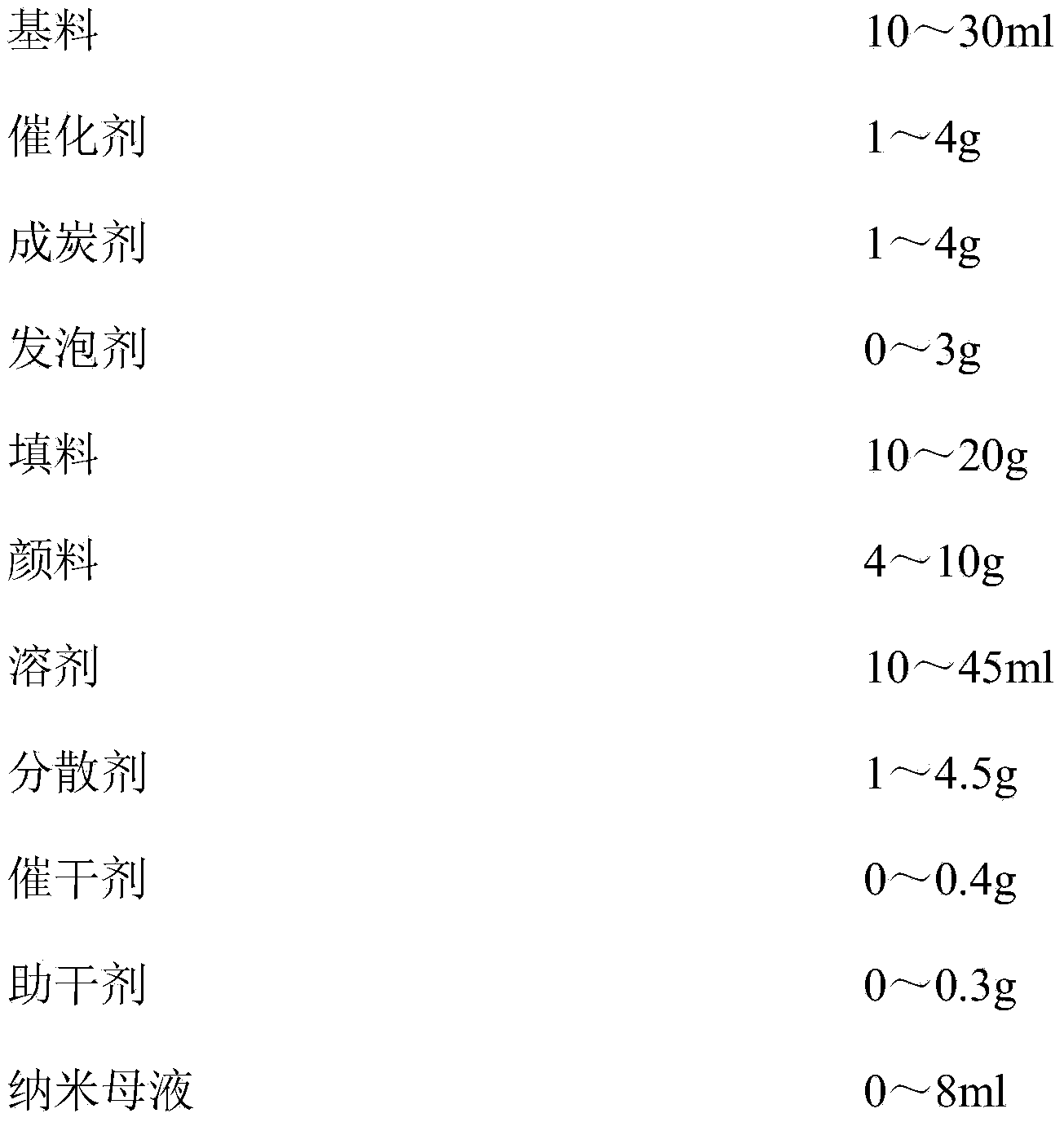

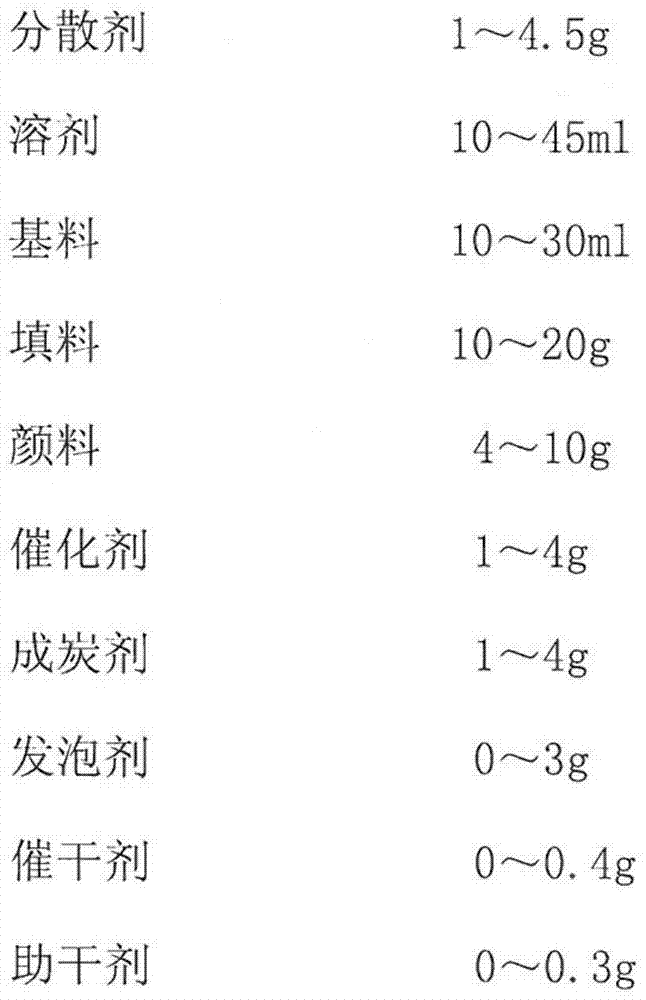

Fire-retardant coating with photo-catalytic performance and preparation method thereof

The invention discloses a fire-retardant coating with photo-catalytic performance and a preparation method thereof, belonging to the field of fire-retardant coatings. The coating comprises a base material, a catalyst, a charring agent, a foaming agent, a filler, a pigment, a solvent, a dispersant, a drier, a drying aid, a nano mother solution and the like, wherein the base material is aluminum dihydrogen phosphate, the catalyst is ammonium polyphosphate, the charring agent is pentaerythritol, the foaming agent is melamine, the filler is ultra-fine slag powder, the pigment is Cu-La / TiO2, the solvent is water, the dispersant is a BYK180 polymeric dispersant, the drier is lead oxide, the drying aid is zinc powder, and the nano mother solution is a nano SiO2 mother solution. The fire-retardant coating disclosed by the invention reduces the environment pollution to the maximum extent by using industrial waste residues as the filler; meanwhile, the coating has a function of realizing photocatalytic degradation of formaldehyde gas under a visible light source to endow conventional fire-retardant coatings with a brand-new function, and the fire-retardant coating accords with the development trend of national green ecological building materials.

Owner:镇江新智生物科技有限公司

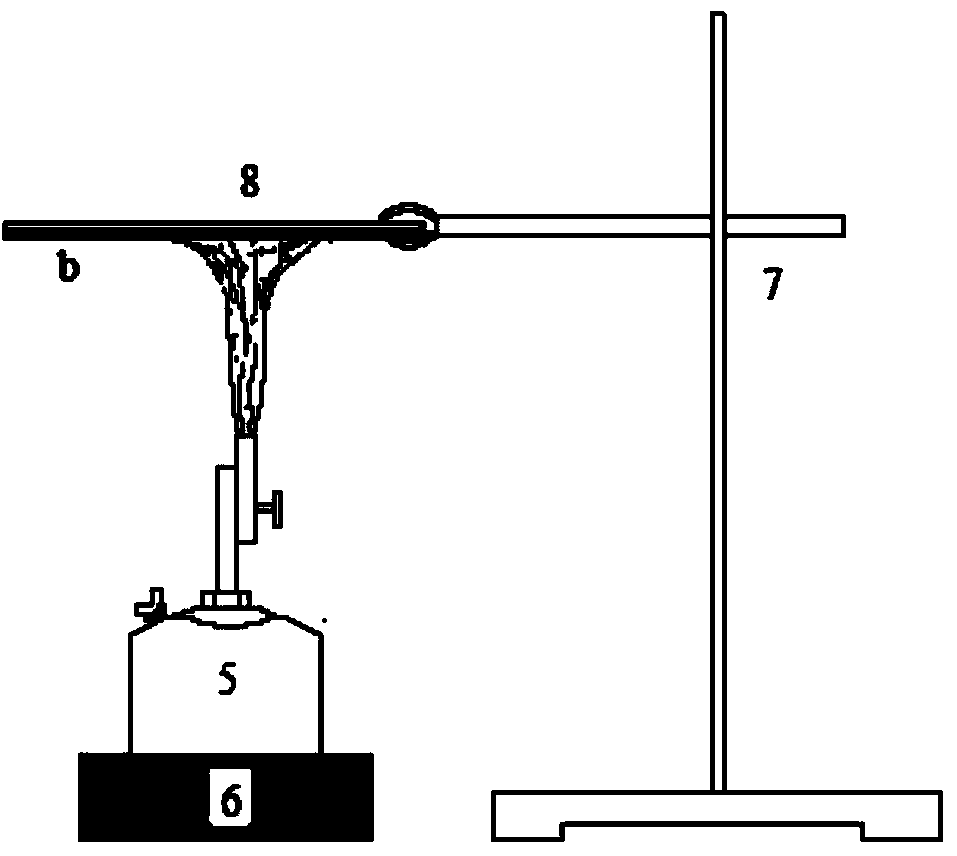

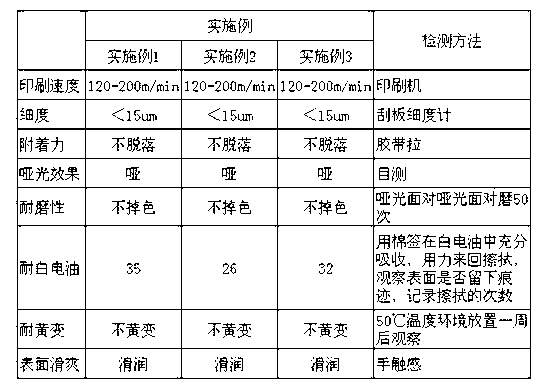

Surface printed solidified matte ink and preparation method thereof

The invention relates to surface printed solidified matte ink and a preparation method thereof. The surface printed solidified matte ink is formed by adding a curing agent into an ink base material according to a ratio of 6-10% and stirring, wherein the ink base material comprises the following ingredients: 23 parts of n-propyl ester, 10 parts of butyl acetate, 8 parts of a polyurethane resin, 10 parts of aldehyde ketone resin, 1 part of a flatting agent, 40 parts of light removing slurry, 7 parts of ternary chlorine vinegar resin, 0.5 part of an antifoaming agent and 0.5 part of a dispersing agent; the n-propyl ester, the butyl acetate, the polyurethane resin, the ternary chlorine vinegar resin and the aldehyde ketone resin are firstly ground, combined with the flatting agent and the light emitting slurry, and are subjected to high-speed dispersion, the ingredients are filtered and packaged into finished products, and 6-10% of the curing agent is added, thus obtaining the ink which can be used for printing. The matte ink can be used for directly printing in a matte manner to form a film, personal hollow printing or conventional covering printing is realized, the adhesive force is high, the surface is smooth, the matte effect is remarkable, and the production cost is lowered. The surface printed solidified matte ink is applicable to printing on coiling drums of wall paper, chrome paper, kraft paper, leatherette paper and various special types of paper, and meanwhile the ink is applicable to printing on PE (Poly Ethylene), PET (Polyethylene Terephthalate), BOPP (Biaxially-oriented Polypropylene), pearly luster films and twisting films with corona layers.

Owner:ZHUANGLI PRINTING CHAOAN COUNTY

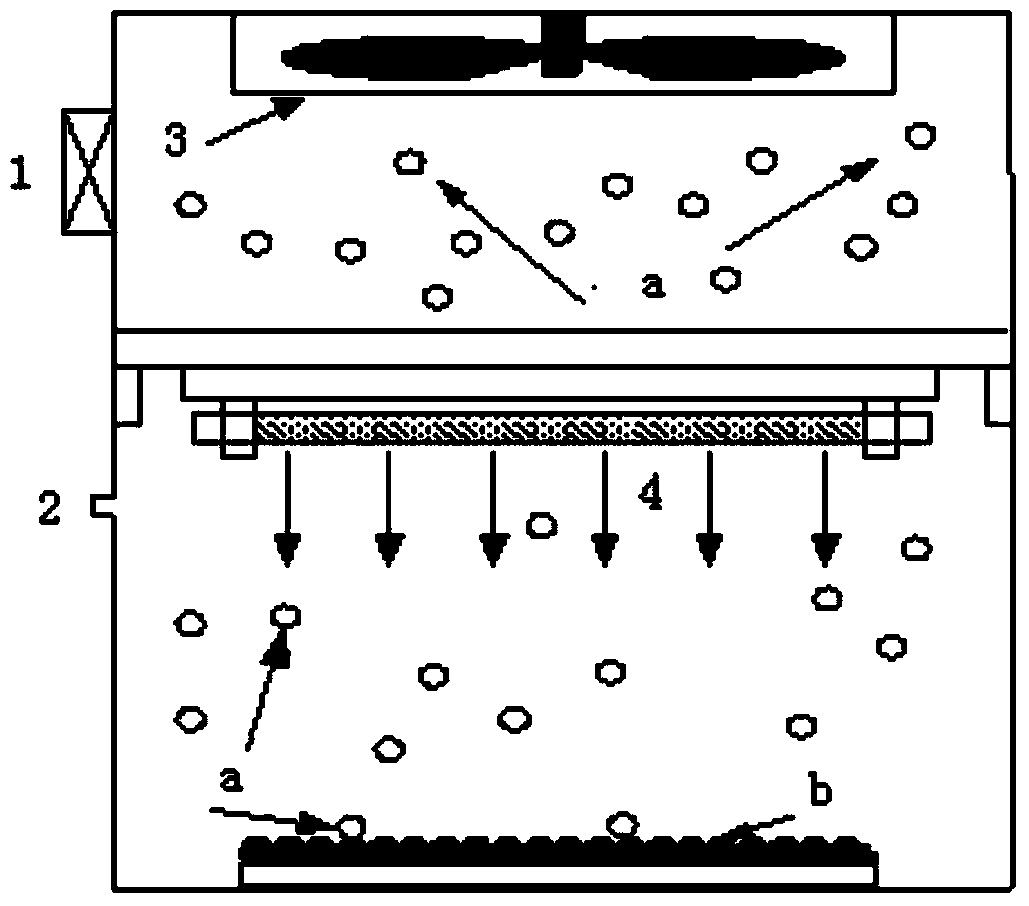

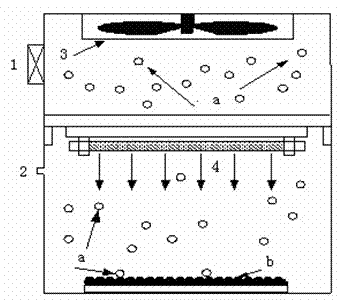

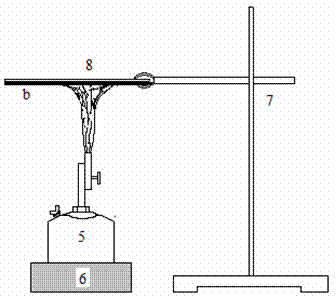

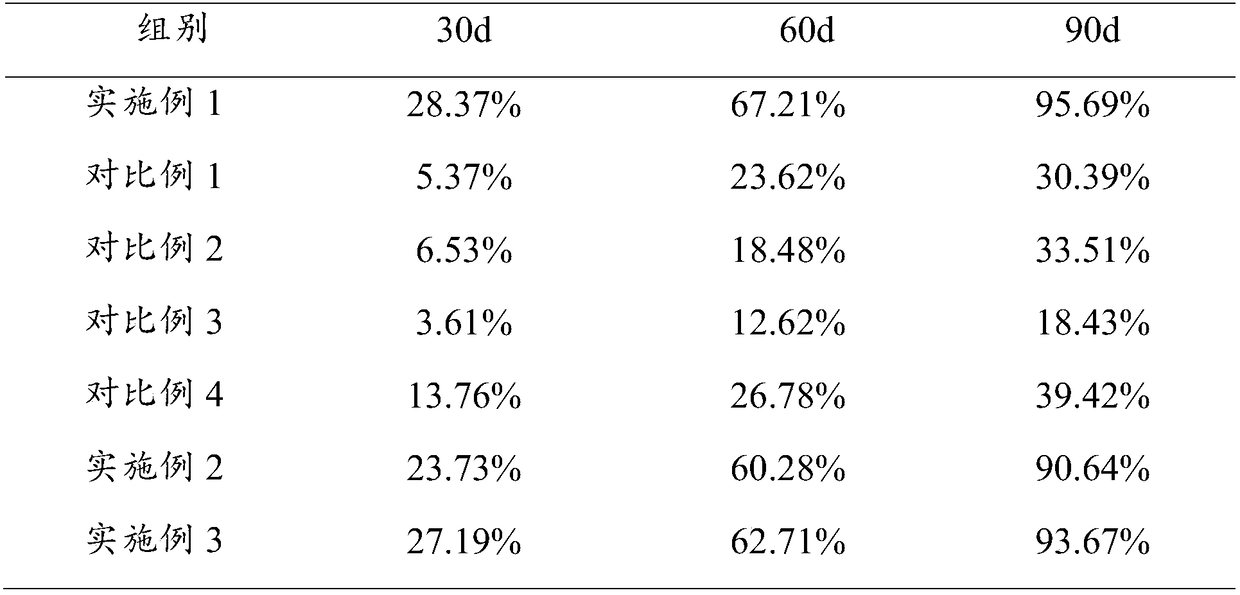

Preparation method of immobilization bacterium for restoring polycyclic aromatic hydrocarbons contaminated soil

InactiveCN101177679AImprove competitivenessIncrease resistanceContaminated soil reclamationOn/in inorganic carrierContaminated soilsEnvironmentally friendly

The invention relates to cell immobilization technology, in particular to a preparation method for immobilized bacteria used in the restoration of polycyclic aromatic hydrocarbons contaminated soil, using 0.25-1.00mm red brick powder, fly ash, vermiculite, peat soil, diatoms Soil or coke powder is used as the carrier material. After sterilization, it is inserted into the bacterial solution, and then multiplied and cultivated to obtain the desired immobilized particles. The immobilized biological product prepared according to the formula of the invention has a good remediation effect on soil polluted by high-molecular-weight polycyclic aromatic hydrocarbons, and is a reliable new environment-friendly biological product.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI

Fire retardant coating with photocatalytic performance and preparation method thereof

InactiveCN104744976AReduce environmental pollutionLow costFireproof paintsPhotocatalytic degradationSolvent

The invention discloses a fire retardant coating with photocatalytic performance and a preparation method thereof. The fire retardant coating is obtained by mixing and stirring a base material, a catalyst, a charring agent, a foaming agent, filler, a pigment, a solvent, a disperser, a dryer, a drying aid and a nano-mother solution. By adopting the preparation method provided by the invention, the environment pollution can be furthest reduced, the recycling economical production of the product can be realized and about 20% of the cost can be reduced; the fire retardant coating prepared by the invention has excellent performances of high strength, rapid hardness, washing resistance, water resistance, alkali resistance and freezing resistance, particularly has an outstanding feature of degrading the formaldehyde gas in the room through photocatalysis and has a natural, non-toxic, pollution-free environment-friendly safety performance.

Owner:CHINA MCC17 GRP

Enamel wok with patterns on outer surface and manufacturing method of enamel wok

InactiveCN105274424AGood insulation performanceSimple manufacturing processPotassium feldsparCast iron

The invention discloses an enamel wok with patterns on the outer surface. The enamel wok comprises a lid and a cast iron enamel wok body. The cast iron enamel wok body is composed of a cast iron blank and a high-temperature glaze material acting on the outer surface of the cast iron blank. The cast iron blank contains carbon, silicon, manganese, phosphorus, sulfur, chromium, molybdenum, vanadium, boron and the balance iron. The glaze material contains cordierite, zircon, kaolin, potassium feldspar, quartz stone, mullite, calcined talc, zinc fluoride, nanometer titania and cerium dioxide. The formula of the glaze material of the produced wok is unique, the patterns rich in beauty can be produced on the outer surface of the wok, and the ornamental value of the wok is increased.

Owner:ANHUI ZAOSHANGHUANG MACHINERY CO LTD

Special glue for cigarettes

InactiveCN102391798AWater resistantHeat resistantMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesHeat resistanceEngineering

The invention provides special glue for cigarettes. The special glue for cigarettes comprises vinyl acetate, polyvinyl alcohol, dibutyl phthalate, a crosslinking agent Me-10, a copolymerization catalyst Zh-4 and water. The special glue for cigarettes provided by the invention has the characteristics of water tolerance, heat resistance, freezing resistance, high initial adhesive strength and the like. The special glue for cigarettes is applicable to the conventional different models of cigarette machines in China to serve as cigarette glue and can also serve as high-performance general milk-white glue.

Owner:陈瑜

Multipurpose redispersible emulsion powder and preparation method thereof

The invention discloses a multipurpose redispersible emulsion powder and a preparation method thereof. The multipurpose redispersible emulsion powder comprises the following components in portions by weight: 120-140 portions of polyvinyl alcohol, 4.0-6.0 portions of emulsifying agent, 1.0-1.2 portions of ammonium persulfate, 300-350 portions of vinyl acetate, 0.5-1.0 portion of sodium bicarbonate, 100-150 portions of vinyl versatate, 20-25 portions of butyl acrylate, 20-30 portions of ethyl acrylate, 0.5-1.5 portions of silicone and 300-450 portions of ethyl acetate-acetic acid copolymer emulsion (CW-718). The emulsion powder has the advantages of good redispersibility, stable performance, high low-temperature construction applicability and wide application, can be used as a high-quality additive of varieties of putty powder, and can be made into three-dimensional modules, external heat-insulating adhesion materials for exterior walls, ceramic tile adhesive, gap-filling cement, flexible cement, plastering and repairing materials, cement mortar capable of flowing by gravity, powder emulsion paint and the like.

Owner:徐永泽

Polycyclic aromatic hydrocarbon contaminated soil remediation material and preparation method thereof

PendingCN108911864AFreeze-resistantWith water absorptionSuperphosphatesAgriculture tools and machinesPolycyclic aromatic hydrocarbonMicrobial agent

The present invention belongs to the technical field of soil remediation and discloses a polycyclic aromatic hydrocarbon contaminated soil remediation material. The polycyclic aromatic hydrocarbon contaminated soil remediation material comprises the following components in parts by weight: diatomaceous earth, peat soil, humic acid, corn cob, nutrients, a surfactant, an oxidant and a compound microbial agent; the nutrients comprise rice bran, (NH4)2HPO4, urea, calcium superphosphate and plant ash; the surfactant is an anionic and non-ionic mixed surfactant; the oxidant is one of hydrogen peroxide activated sodium persulfate, potassium hydrogen persulfate or a Fenton reagent; the compound microbial agent comprises pseudomonadaceae powder, bacillus powder and fusarium powder; and the weight ratio of the pseudomonadaceae powder, bacillus powder and fusarium powder is 3:(1-5):(2-5). Compared with the prior art, beneficial effects are as follows: the polycyclic aromatic hydrocarbon contaminated soil remediation material is capable of degrading polycyclic aromatic hydrocarbons in the soil and also has an improved effect on the soil conditions of the soil.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

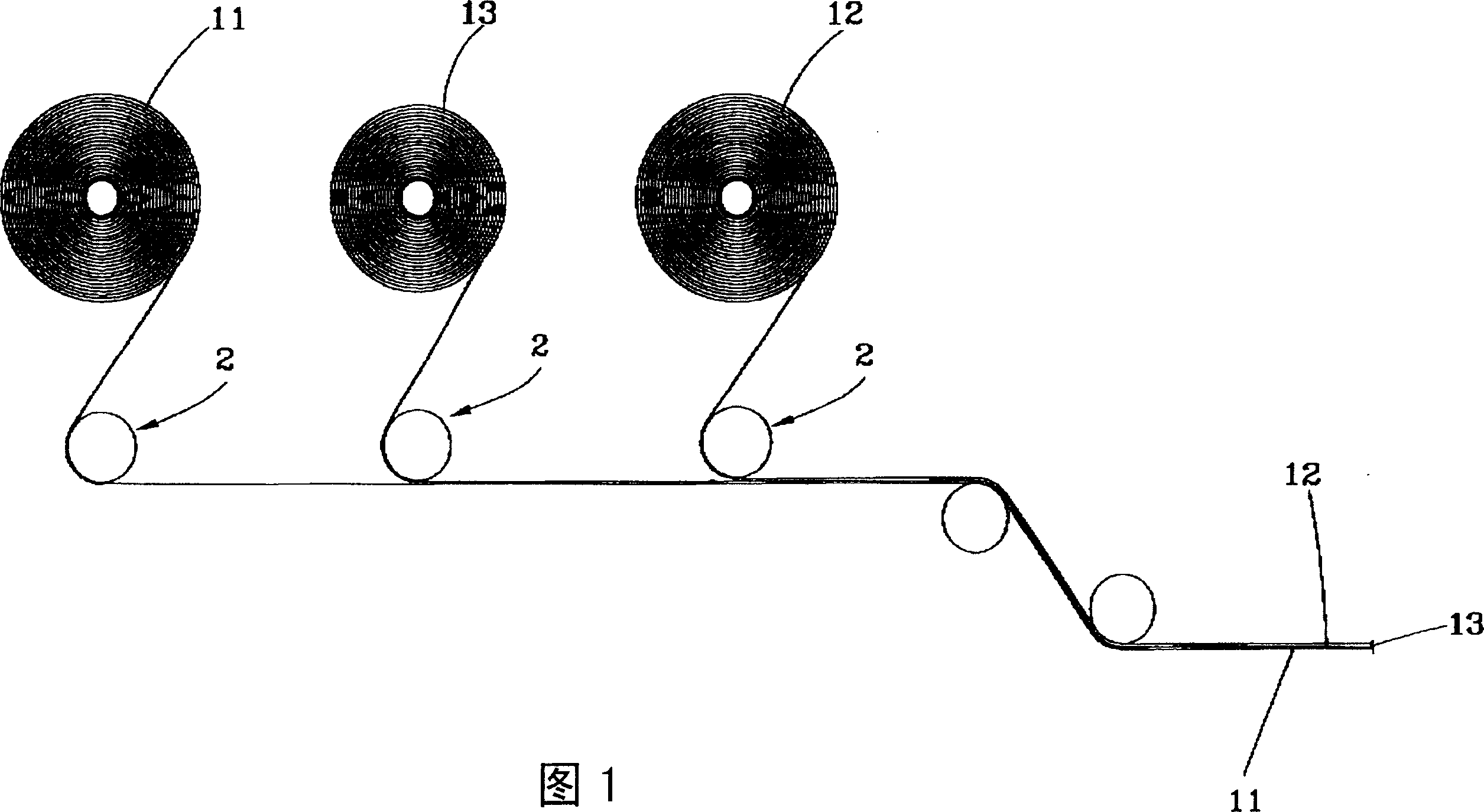

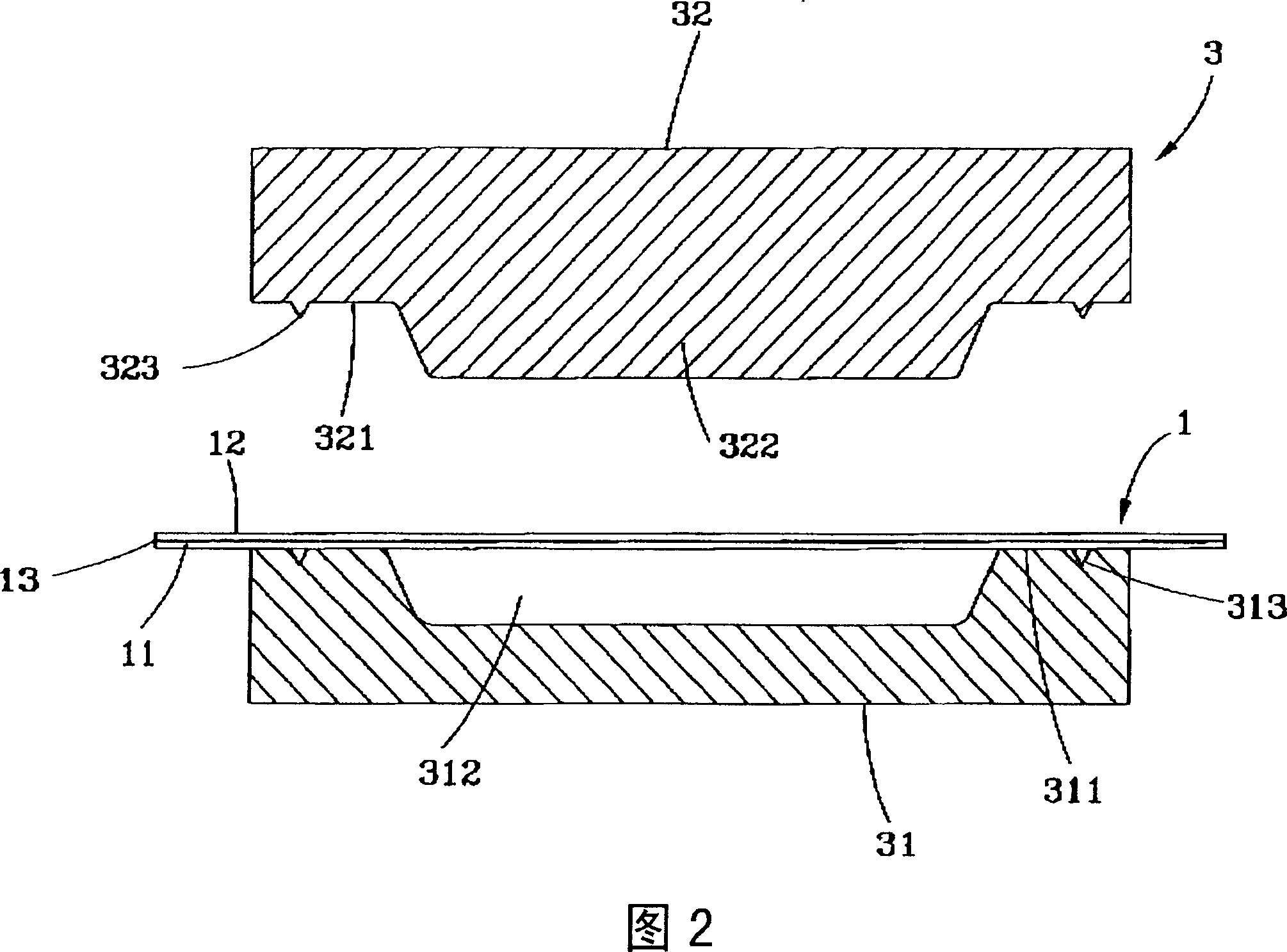

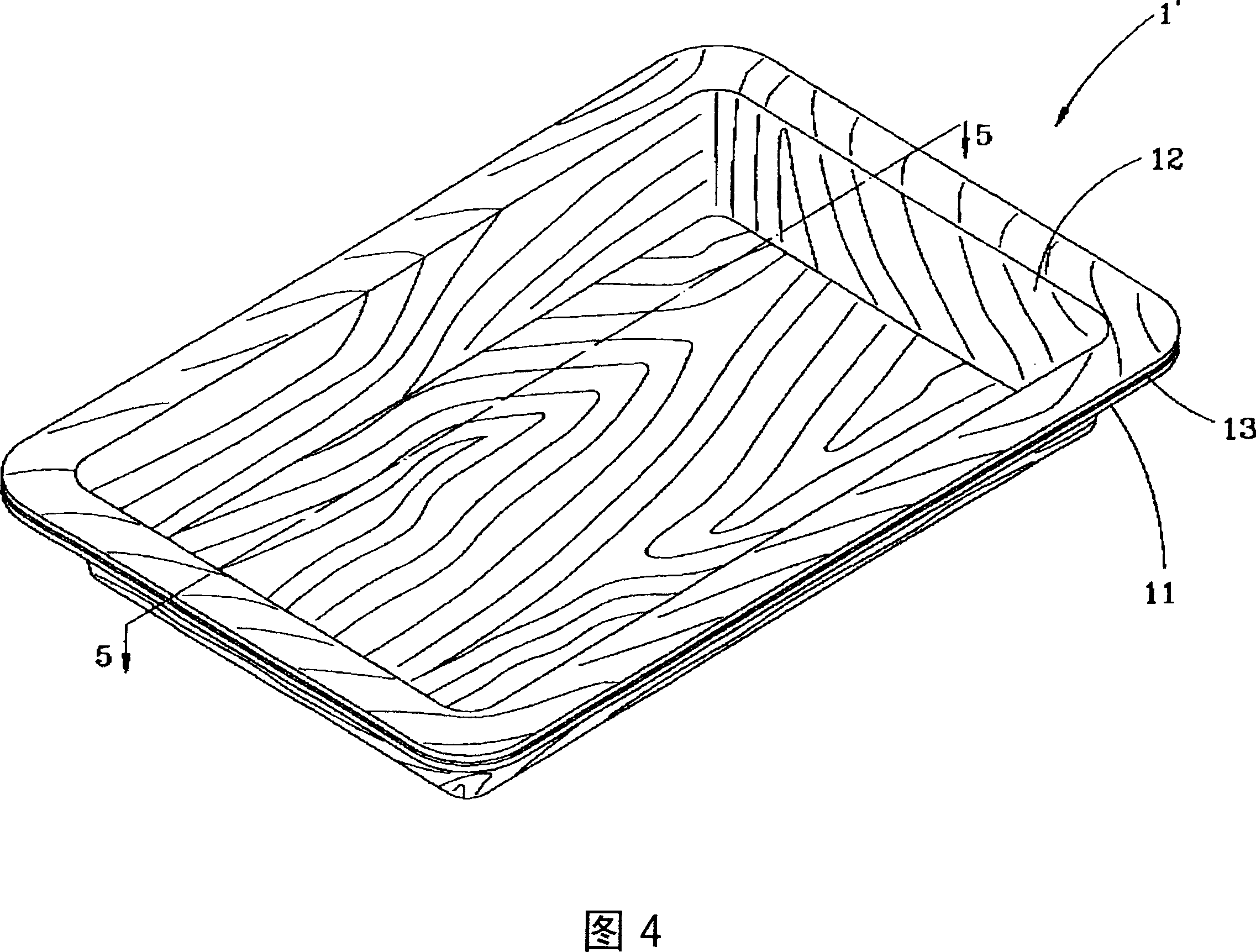

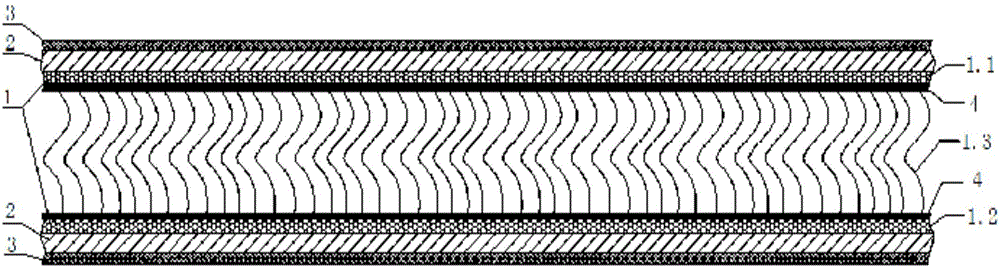

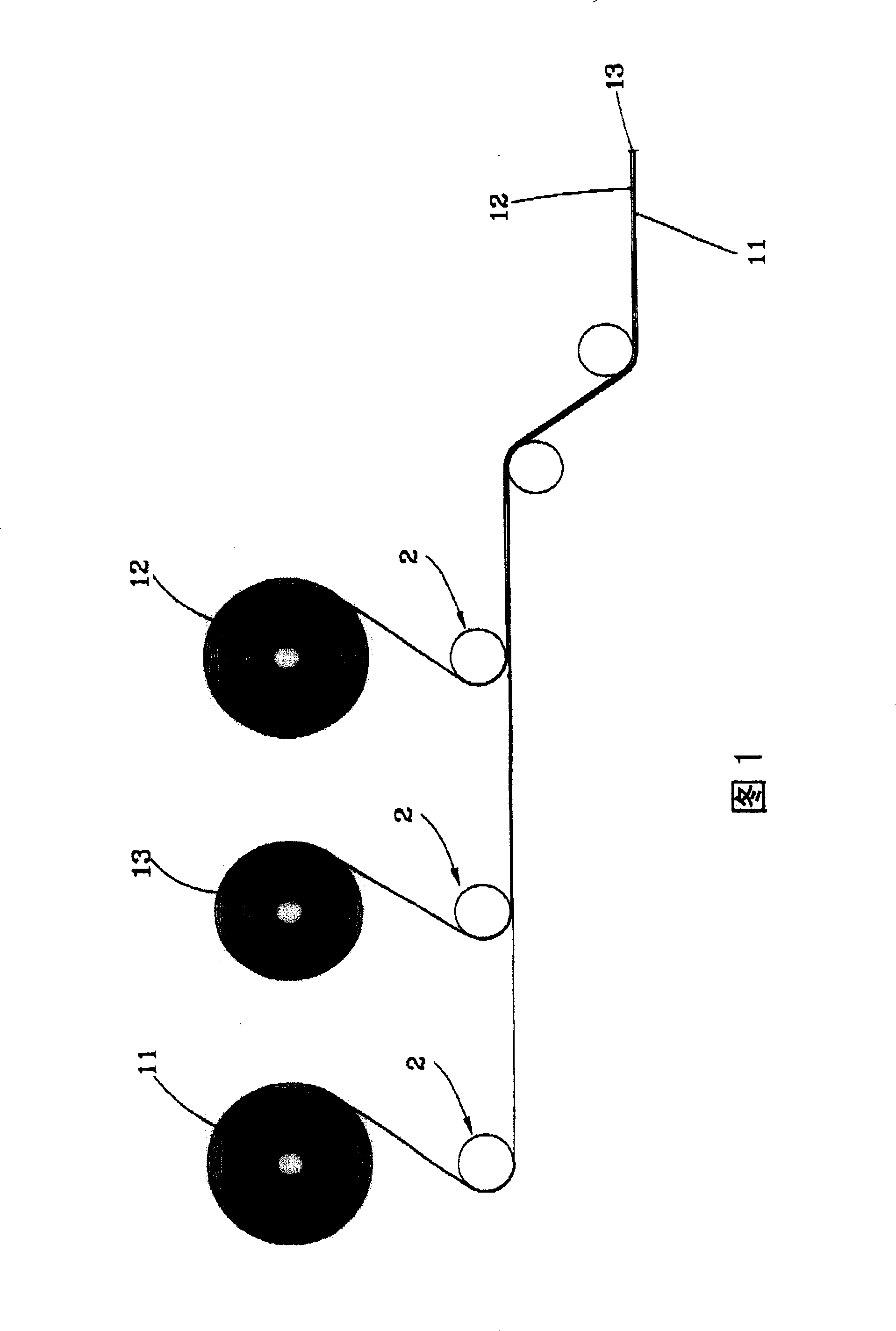

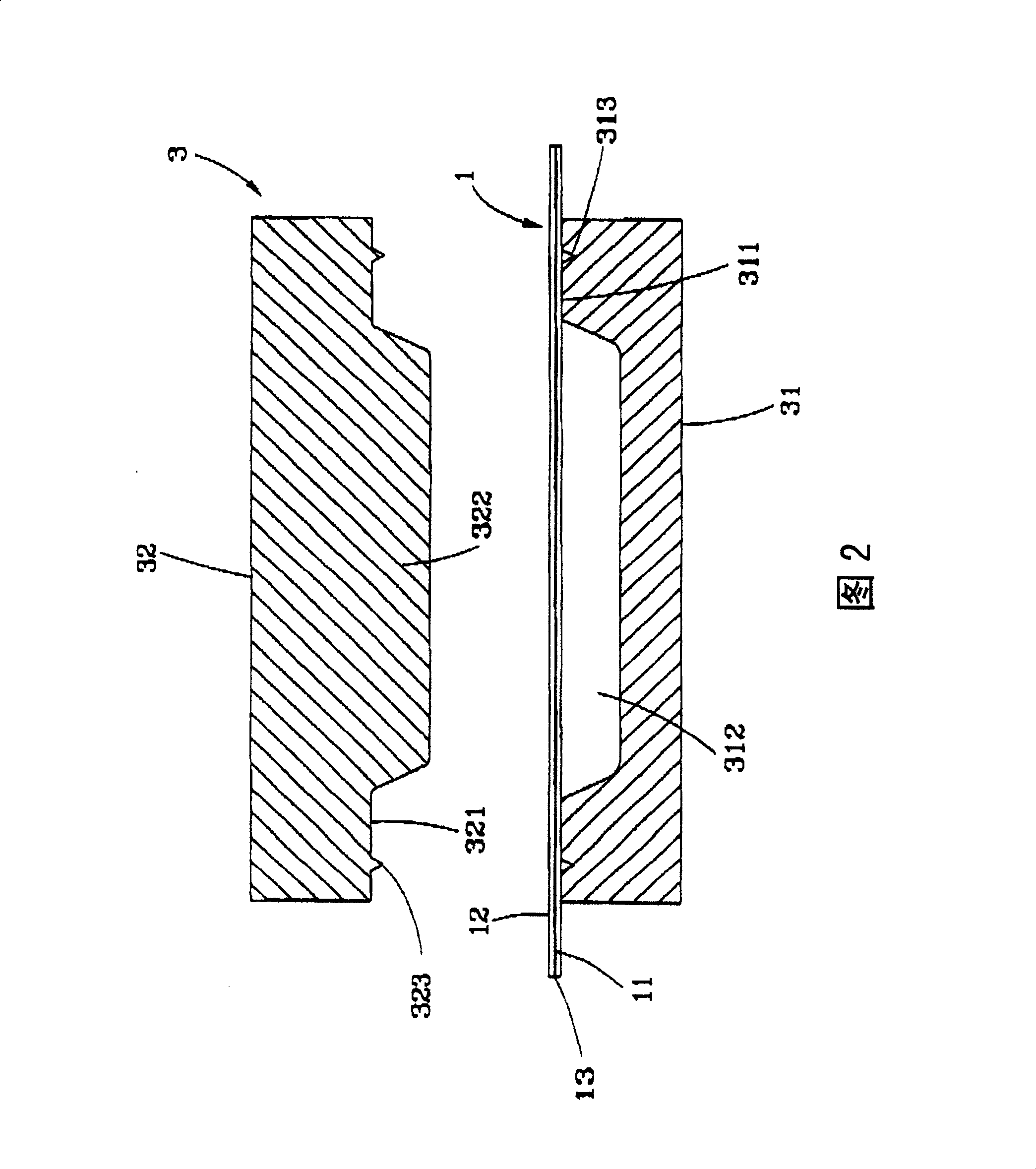

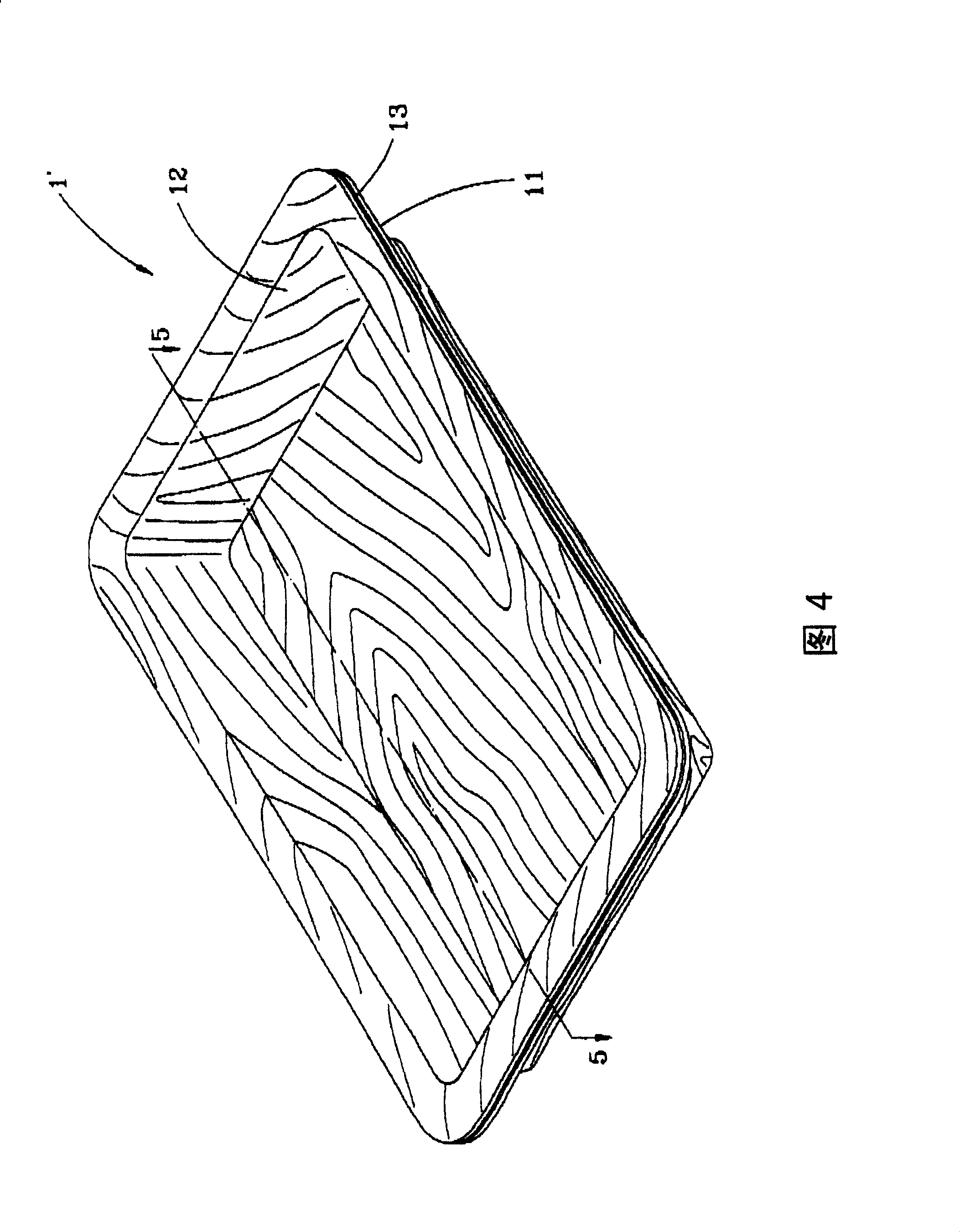

Wooden container and its making method

InactiveCN1919699AMeet the requirements of "green environmental protection"Non-toxic and harmlessFlexible coversWrappersFiberWood veneer

The invention discloses a wood container and preparing method, which is characterized by the following: adopting two wood films to chuck one gluing film, forming glue on the fiber wood surface, integrating mould and wood slice through heat fusing to form wood container.

Owner:HONG GENE TECH

Environmental-protection inorganic glass fiber product and its preparing method

InactiveCN1814564AGood frost resistanceStable weather resistanceSolid waste managementPerliteSaw dust

The invention discloses an environment protecting inorganic glass fiber product and the manufacture method. It uses MgO, MgCl2, fly ash, assistant agent, non alkali glass fiber cloth, glass fiber short thread, saw dust, quartz powder, gesso, perlite, lithopone, hollow ceramic aggregate, floating pearl, sintering clay, and bamboo reinforcement. The process includes mixing, electric whisking, clip casting, modeling, mold carrying preserving, mold removing, mending, coloring, surface treating, maintaining, packaging. The invention has the feature of high temperature endurable, freezing endurable, not easy to broken, non-combustible, non zinc, and non chemical content. It has the advantage of low cost, and it is environment protection product.

Owner:江鸿仪

High density building member and manufacturing method thereof

The invention discloses a high density building member. The building member comprises the following raw materials in part by weight: 70 to 80 parts of base stock of more than 350 meshes, 10 to 20 parts of coarse aggregate of between 10 and 40 meshes, 10 to 20 parts of asphalt powder or cement, 7 to 10 parts of plant glue solution prepared by boiling corn and sticky rice with water, 1 to 2 parts of citric acid curing agent and the like. A method for manufacturing the high density building member comprises the following steps of: mixing coarse and fine base stocks; taking the boiled plant glue solution as a coagulant; and after a blank is formed under a high pressure, solidifying and shaping the building member by microwave heating. The base stock can be prepared by smashing industrial solid waste, building rubbish, tailings, weathered granite and the like by ball milling and screening the smashed product. Screened particles can be taken as the coarse aggregate. A process for manufacturing the building member is energy saving and environmental-friendly, and a product has the advantages of high density, high intensity, water resistance, freezing resistance, high temperature resistance and the like.

Owner:王发东

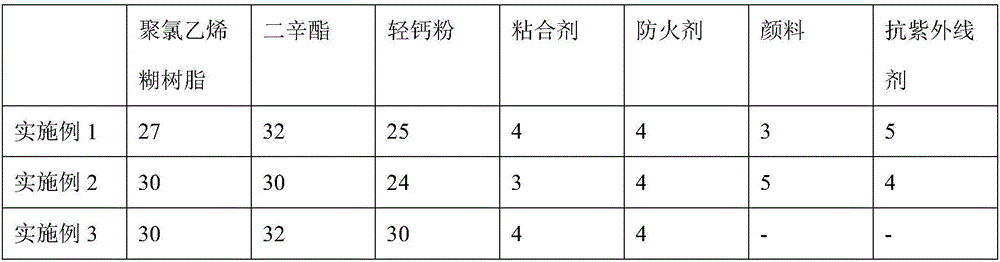

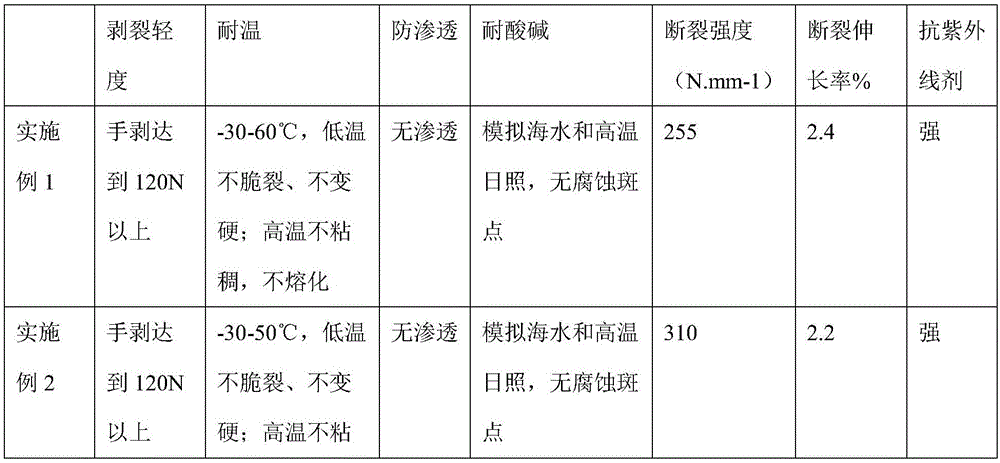

Surfboard canvas and preparation method thereof

InactiveCN106218043AAnti-corrosionImprove air tightnessLamination ancillary operationsSynthetic resin layered productsAging resistancePolyvinyl chloride

The surfboard canvas and a preparation method thereof. The surfboard canvas is characterized by comprising a double-layer wire drawing base cloth; the upper and lower surfaces of the double wire drawing base cloth are coated with a PVC paste resin layer, the outer surface of the PVC paste resin layer is adhered with a polypropylene calendering film; the double-layer wire drawing base cloth comprises an upper base cloth and a lower base cloth; a plurality of terylene connection wires are arranged between the upper base cloth and lower base cloth; the connecting parts of the upper base cloth and lower base cloth with the plurality of terylene connection wires are provided with a viscose layer for bonding the base cloth andterylene connection wires. The product of the invention has the characteristics of no seam, no toxicity, no taste, acid and alkali resistance, impact resistance, high temperature resistance, aging resistance, freezing resistance and permeability resistance, and the advantages of reaching national standard GB 6675, United States ASTMF- 963, and EU EN-71.

Owner:NINGBO TIANDUN WATERPROOF MATERIAL CO LTD

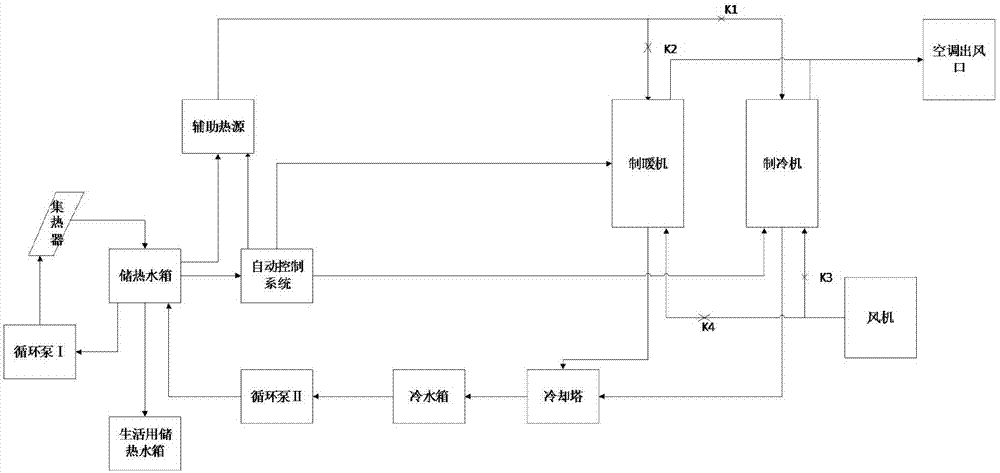

Solar air conditioner system

PendingCN107036214AImprove cooling efficiencyImprove efficiencyMechanical apparatusSpace heating and ventilation safety systemsCooling towerAutomatic control

The invention provides a solar air conditioner system and belongs to the field of solar energy. The solar air conditioner system comprises a heat collector, a circulating pump I, a heat storage water tank, an automatic control system, a circulating pump II, an auxiliary heat source, a heating machine, a refrigerating machine, a cold water tank, a cooling tower, a draught fan and an air conditioner air outlet. The input end of the heat collector is connected with the output end of the circulating pump I. The output end of the heat collector is connected with the heat storage water tank. The input end of the circulating pump I is connected with the heat storage water tank. The output end of the heat storage water tank is connected with the heating machine and the refrigerating machine. The output end of the draught fan is connected with the heating machine and the refrigerating machine. An air outlet of the heating machine and an air outlet of the refrigerating machine are connected with the air conditioner air outlet. A cold water loop of the heating machine and a cold water loop of the refrigerating machine are connected with the cold water tank through the cooling tower. The cold water tank is connected with the heat storage water tank through the circulating pump II.

Owner:广西长奥科技开发有限公司

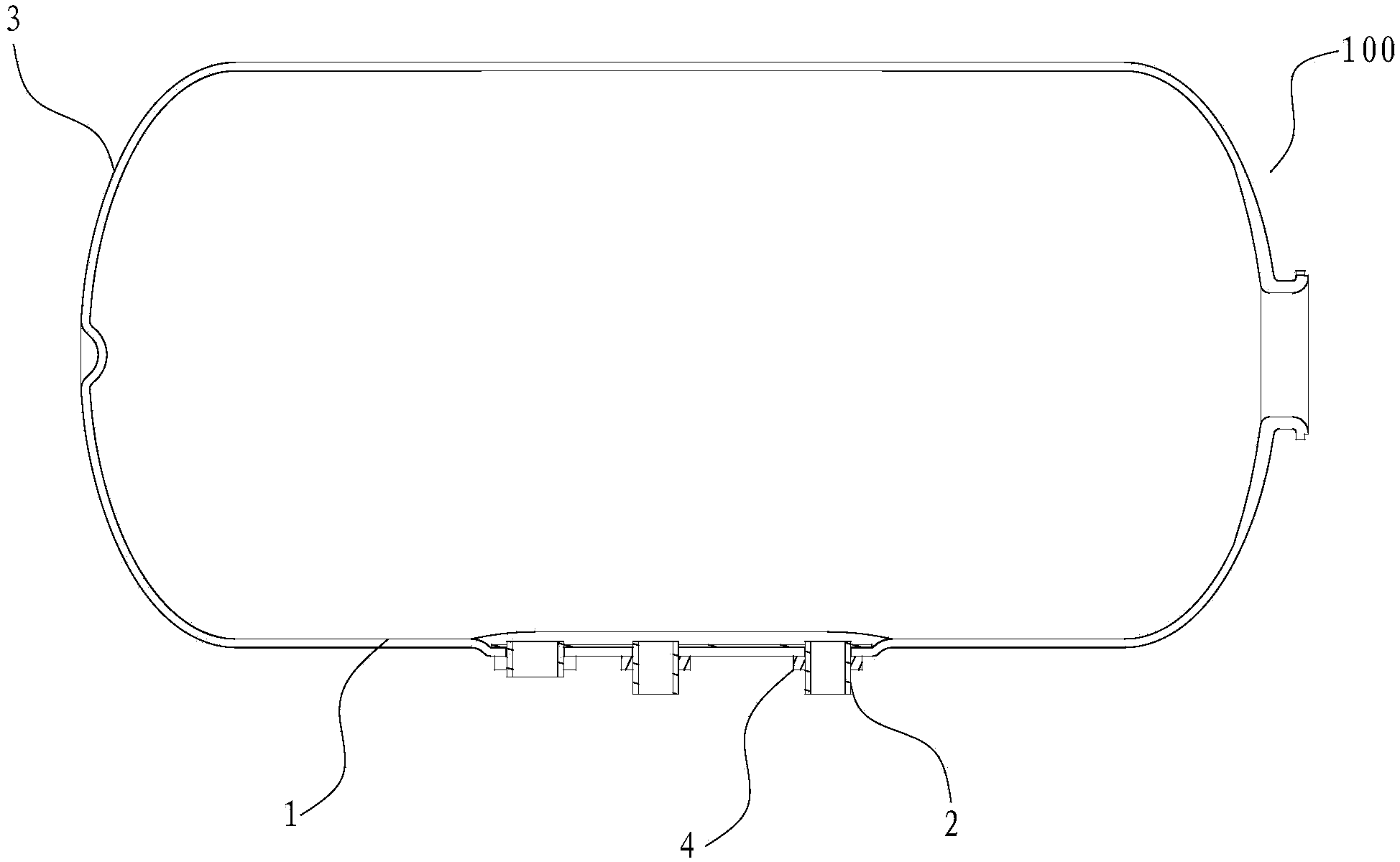

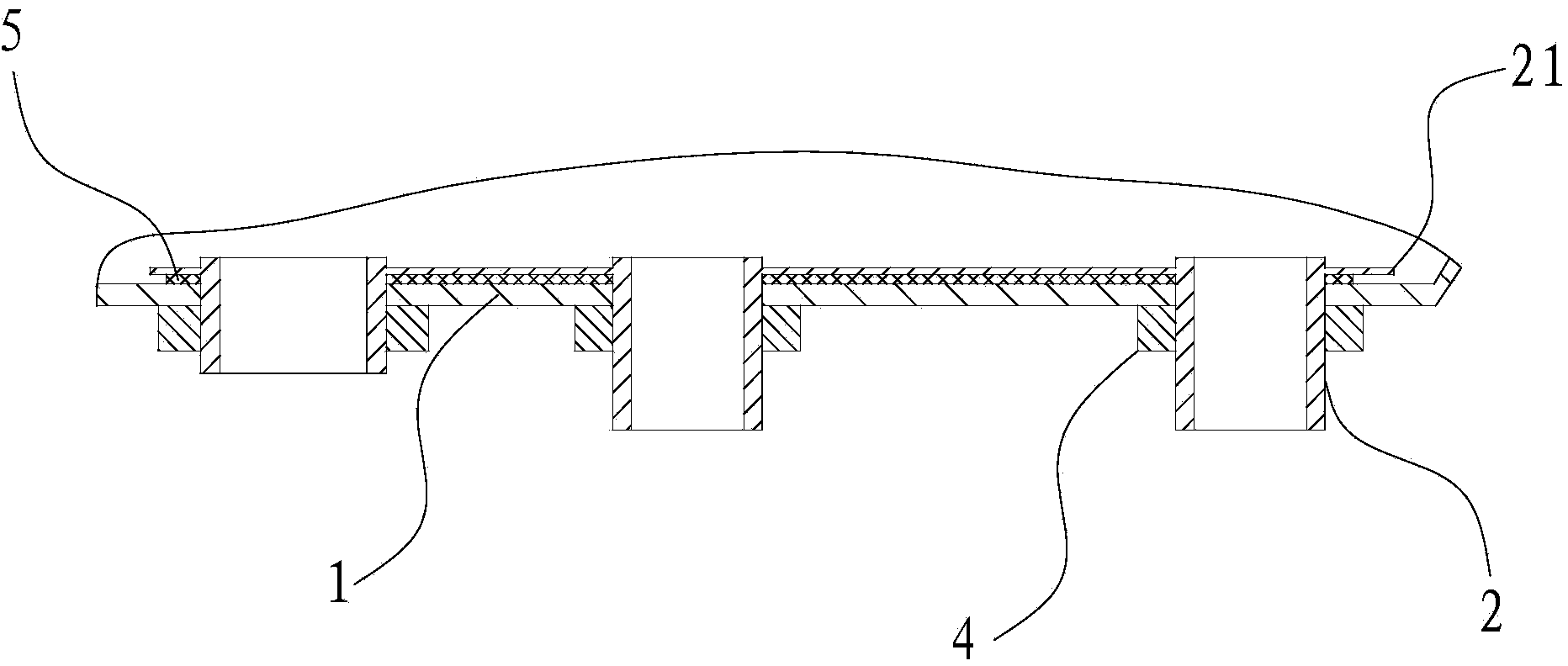

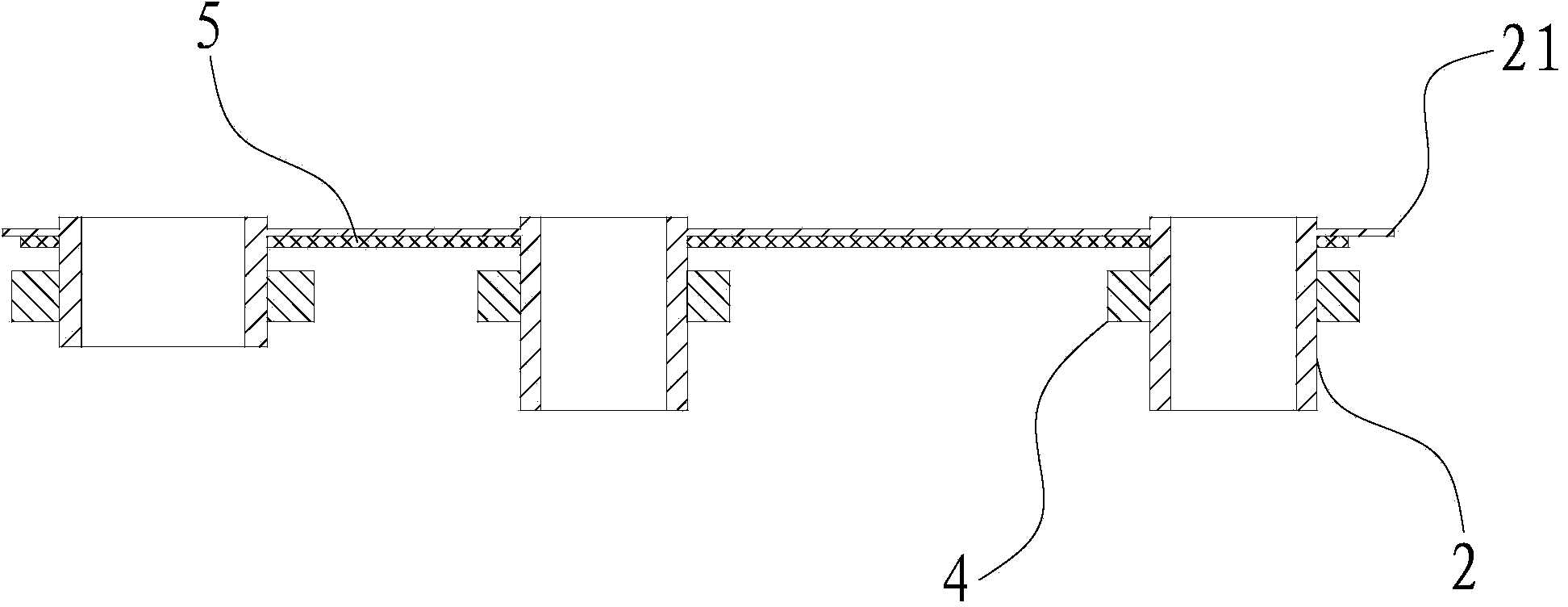

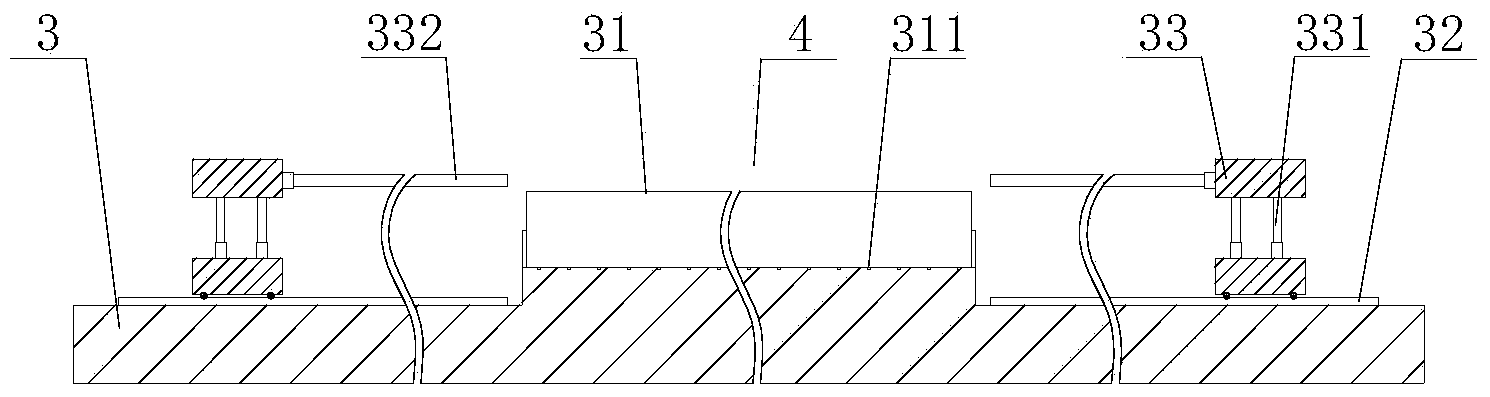

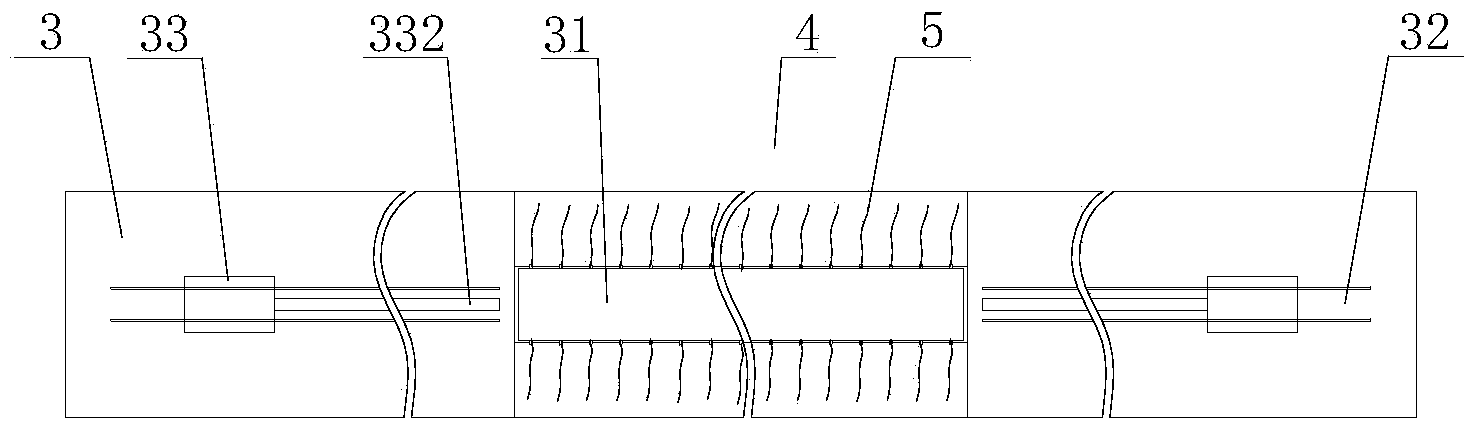

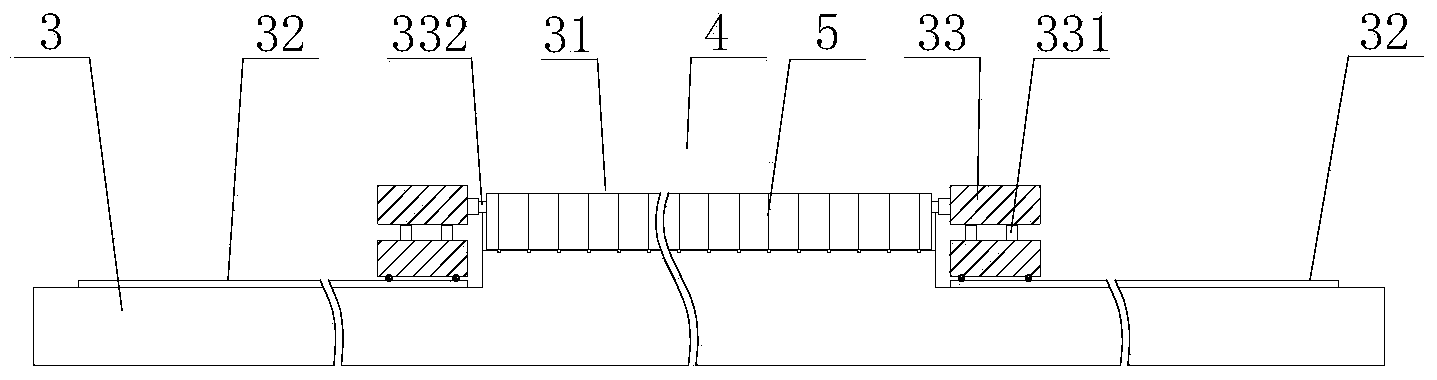

Composite-type inner container and water heater with same

The invention discloses a composite-type inner container and a water heater with the same. The composite-type inner container comprises a plastic inner container body, metal water pipes and a glass fiber member, mounting holes are formed at the bottom of the plastic inner container body, one end of each metal water pipe penetrates the corresponding mounting hole to extend into the plastic inner container body, a boss is arranged on each metal water pipe and positioned in the plastic inner container body, and the glass fiber member is wound on the outer surface of the plastic inner container body. By arranging the bosses on the metal water pipes, after the metal water pipes and the plastic inner container body are assembled in place, water in the plastic inner container body can be effectively prevented from flowing out from gaps between the mounting holes and the metal water pipes; by the inner container body made by plastic, the composite-type inner container is enabled to adapt to changes of pressure of the inner container; by wounding the glass fiber member on the outer surface of the plastic inner container body, the composite-type inner container is enabled to be resistant to high pressure, so that using state of the water heater is met better, and service life of the water heater is prolonged.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

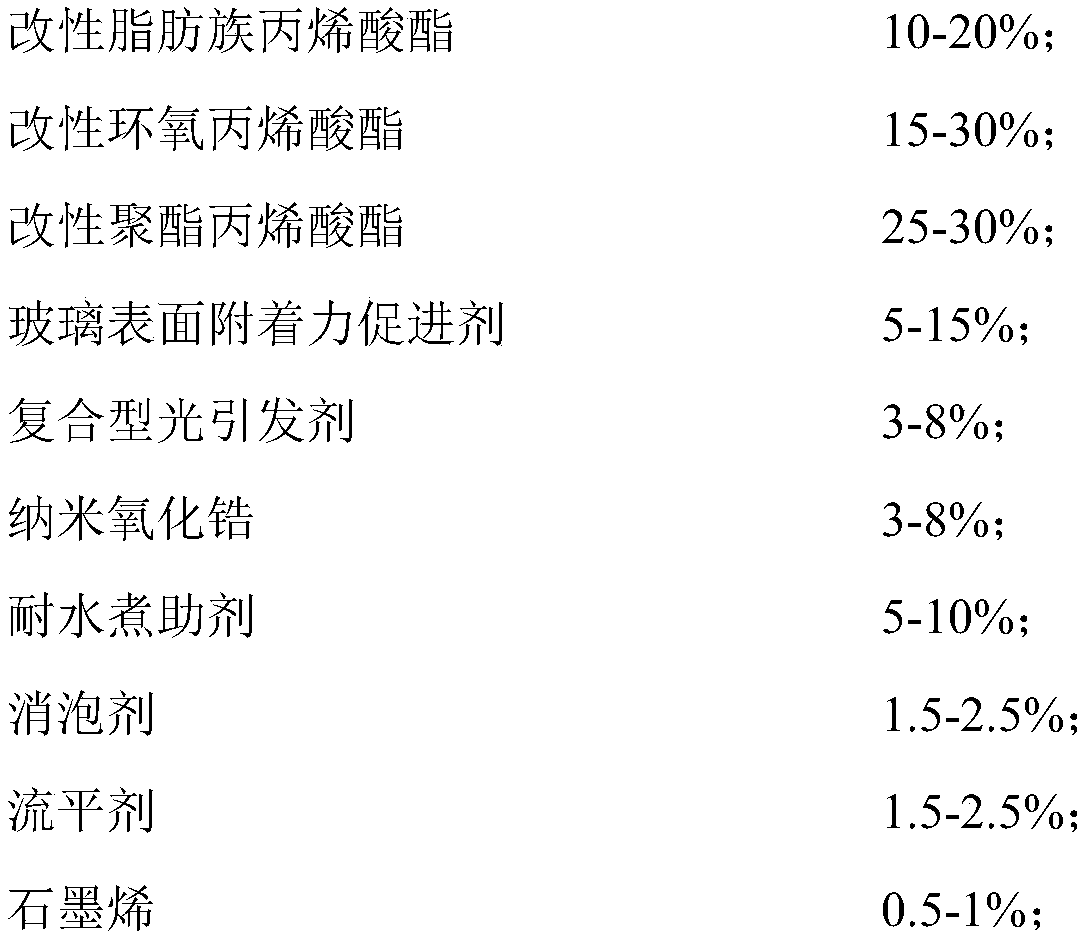

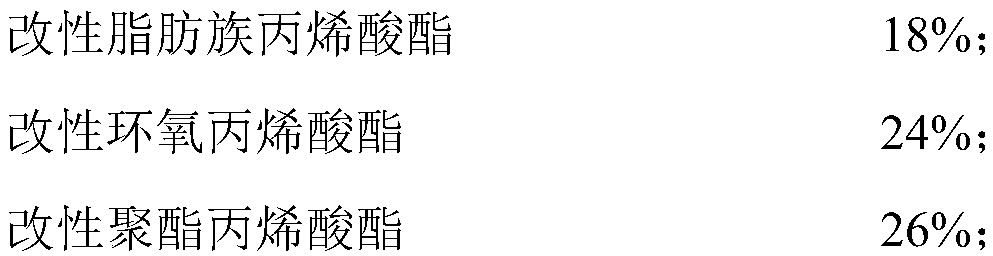

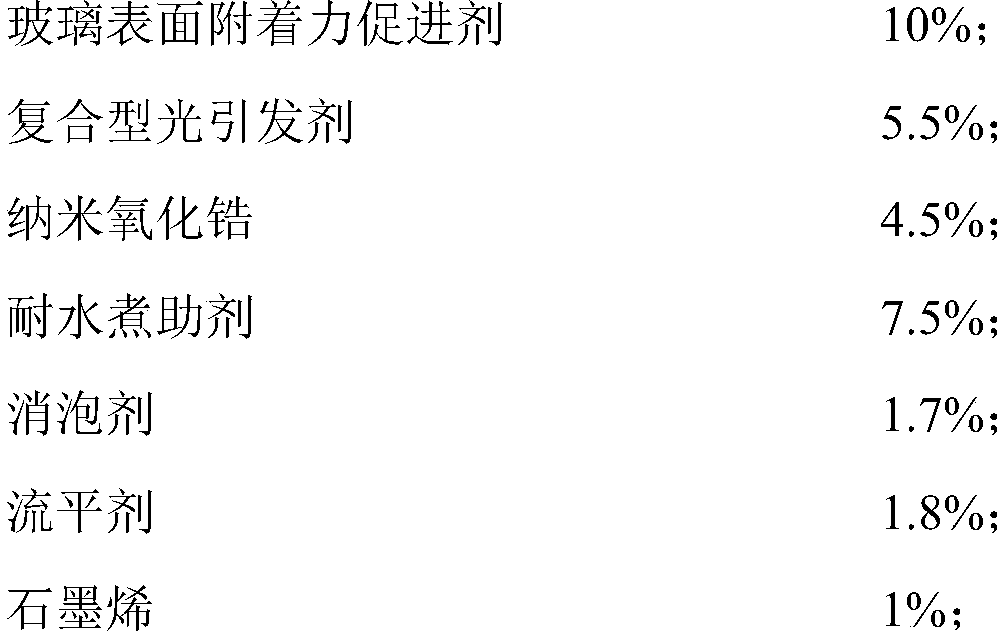

Colorful LED-UV glass coating and preparation method thereof

InactiveCN109337535AImprove performanceImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterDefoaming Agents

The invention belongs to the technical field of coatings and particularly relates to a colorful LED-UV glass coating and a preparation method thereof. The coating is prepared from modified aliphatic acrylate, modified epoxy acrylate, modified polyester acrylate, a glass surface adhesion promoter, a compound photoinitiator, nano zirconia, a boiling resistant aid, a defoaming agent, a leveling agent, graphene, pigment and a diluent. The glass surface adhesion promoter capable of improving glass surface adhesion as well as resin, the initiator and various aids capable of improving boiling resistance of cured films are added to the colorful LED-UV glass coating, these substances are crosslinked through reactions and are instantly cured to form a film under irradiation of an LED-UV lamp, the adhesion to the glass surface is enhanced, the performance of the glass coating is greatly improved, and the formed film has the characteristics of high gloss, high hardness, high adhesion, freezing resistance, boiling resistance, organic solvent resistance, acid-base resistance and salt mist resistance. The preparation method is simple and feasible.

Owner:李汉青

Corn stalk plant fiber synthetic resin and preparation technology thereof

The invention relates to the field of chemical materials, in particular to corn stalk plant fiber synthetic resin and a preparation technology thereof. The corn stalk plant fiber synthetic resin is prepared from the following raw materials: corn stalk powder, carnauba wax, arabia gum, adipic acid, cassava starch, diethylene glycol, colophony powder, organic acid ferric salt and polylactic acid fiber. The preparation technology comprises the following steps: (1) preparing fine-particle corn stalk powder; (2) preparing a preliminarily mixed material; (3) preparing corn stalk fiber powder; (4) preparing a mixed addition material; (5) evenly stirring the mixed addition material and the polylactic acid fiber, blending and extruding, and carrying out injection molding to obtain the corn stalk plant fiber synthetic resin. In order to avoid the waste of resources such as crop waste materials and the like, the preparation technology of the corn stalk plant fiber synthetic resin fully utilizes the crop waste materials, and reduces the pollution to the environment; the preparation technology is low in production cost and very wide in application, and can give play to the advantages of rural resources, so that an effective method and means can be provided for the reasonable utilization of waste crops.

Owner:安徽科邦树脂科技有限公司

Multi-layer special-material integrated pipe and manufacturing technique thereof

ActiveCN103912735ATraffic resistanceEasy to scaleRigid pipesTubular articlesEngineeringThermal expansion

Disclosed are a multi-layer special-material integrated pipe and a manufacturing technique thereof. The integrated pipe comprises an outer primary pipe and an inner secondary pipe which are produced and integrated through on-line production equipment, the primary pipe is produced in advance or online, a blank of the secondary pipe is produced online and is composed of a plastic base layer and a solid gum layer, the external diameter of the blank is slightly larger than the internal diameter of the primary pipe, the blank forms a frozen body via U-shaped deformation, and finally the frozen body is inserted into an inner cavity of the primary pipe subjected to thermal expansion to be integrated. When an integrated body is used in high temperature or extremely cold environment, the primary pipe and the secondary pipe are still firmly connected without cracking and layering. By the technical scheme, the defects of lack of smoothness and high passing resistance, or proneness to scaling and falling off, or proneness to layering and deforming, or high manufacturing difficulty and high input cost, or poor applicable temperature-difference environmental function and the like of a protective coating on the inner wall of an existing hard pipe used for water supply, gas supply and oil supply and delivery are overcome; the integrated pipe is suitable for water, gas and oil delivery of various municipal works and industrial and mining establishments, and particularly suitable for pipe products for water supply of the municipal works.

Owner:HUNAN ZHENHUI PIPE IND

Peanut hull plant fiber synthetic resin and preparation technology thereof

The invention relates to the field of chemical materials, in particular to peanut hull plant fiber synthetic resin and a preparation technology thereof. The resin is prepared from peanut hull powder, polyanionic cellulose, alginate, aliphatic polycarbonate, cassava starch, glycerinum, Arabic gum powder, calcium carbonate and polylactic acid fiber. The preparation method includes the following steps that firstly, fine granular peanut hull powder is prepared; secondly, a primarily mixed material is prepared; thirdly, peanut hull fiber powder is prepared; fourthly, a mixed additive is prepared; fifthly, the mixed additive and polylactic acid fiber are stirred evenly, mixed and extruded, injection molding is conducted, and the peanut hull plant fiber synthetic resin is obtained. The resin and the method aim to prevent crop waste and other resources from being wasted, fully use the resources and reduce environment pollution. Production cost is low, application range is wide, rural resource advantages can be achieved, and an effective method and a means are provided for reasonable utilization of waste crops.

Owner:安徽科邦树脂科技有限公司

Highly abrasion resistant brake pad and preparation method thereof

InactiveCN103644229AImprove buffering effectImprove wear resistanceOther chemical processesFriction liningFiberGlass fiber

The invention discloses a highly abrasion resistant brake pad which comprises, by weight, 13-16% of modified phenolic resin, 28-33% of fiber materials, 45-55% of filling materials and 3-6% of Sinkiang white vermiculite, wherein the fiber materials are composed of one or more of mineral fibers, glass fibers and paper fibers. The invention further discloses a preparation method of the highly abrasion resistant brake pad. The highly abrasion resistant brake pad is stable in high-temperature friction coefficient and good in abrasion resistance, and the preparation method is simple, low in cost and suitable for Yunan, Guizhou and Sichuan regions and other regions with high mountains, steep roads and large brake loads.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Saussurea involucrate culture dropping pill and preparation method thereof

ActiveCN109350633AHeat resistantAcid resistantMetabolism disorderDigestive systemInulinPolyethylene glycol

Owner:DALIAN PRACTICAL BIOTECH

Straw plant fiber synthetic resin and preparation technology thereof

The invention relates to the field of chemical materials, in particular to a straw plant fiber synthetic resin and a preparation technology thereof. The straw plant fiber synthetic resin is prepared from straw powder, rice bran wax, cellulose, aliphatic polycarbonate, corn starch, sorbitol, gum Arabic powder, superfine aluminum silicate and polylactic acid fiber. The preparation technology comprises the following steps that 1, fine particle straw powder is prepared; 2, a preliminary mixing material is prepared; 3, straw fiber powder is prepared; 4, a mixed addition material is prepared; 5, after the mixed addition material and polylactic acid fiber are stirred to be uniform, and blending extrusion and injection molding are performed to obtain straw plant fiber synthetic resin. In order to avoid waste of resources such as crop waste, the resources are sufficiently utilized, and environmental pollution is lowered; the production cost is low, the application range is quite wide, the advantage of rural resources can be brought into play, and effective methods and ways are provided for reasonably utilizing waste crops.

Owner:安徽科邦树脂科技有限公司

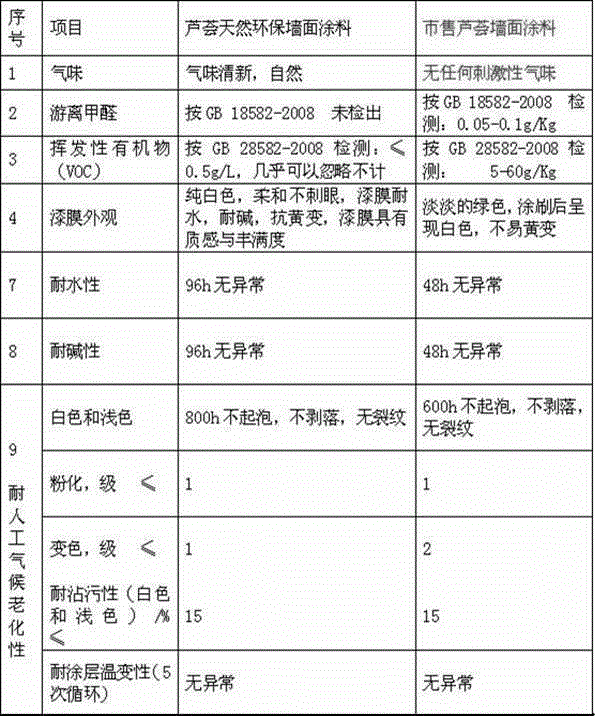

Aloe natural environmental-protection wall coating

InactiveCN105623424AUnique natural propertiesExcellent anti-corrosion and anti-bacterial functionAntifouling/underwater paintsPaints with biocidesEmulsionPlant Gums

The invention discloses an aloe natural environmental-protection wall coating, which is characterized by being mainly prepared from the following ingredients (by weight): 200-340 parts of water, 130-250 parts of titanium dioxide, 20-80 parts of talcum powder, 1-4 parts of alkaloid, 2-8 parts of a dispersant, 1-4 parts of a wetting agent, 1-8 parts of an antifoaming agent, 100-240 parts of aloe-gel, 150-320 parts of an acrylic emulsion and 20-80 parts of vegetable glue. The coating has full film, has excellent effects in aspects of smell, environmental protection and performance, has good decorative function and environmental protection function, and is an aloe natural environmental-protection wall coating with excellent comprehensive properties.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Composite gel food and preparation method thereof

The present invention relates to the technical field of food processing, and discloses a composite gel food, which comprises a gel and a content, the gel comprises curdlan, pectin, gellan gum, sodiumalginate, gelatin, carrageenan and konjaku flour, and is formed by compounding, and the content is a mixture of one or more foods. The invention also discloses a processing method of the composite gelfood. The gel food is resistant to high temperature and can be subjected to secondary processing.

Owner:SHANGHAI SONGJIANG BAOLI FOODSTUFF

Tea stalk plant fiber synthetic resin and preparation process thereof

The invention relates to the field of chemical materials, in particular to tea stalk plant fiber synthetic resin and a preparation process thereof. The tea stalk plant fiber synthetic resin comprises the following raw materials: tea stalk powder, polyanionic cellulose, arabia resin, adipic acid, wheat starch, diethylene glycol, rosin powder, talcum powder and polylactic acid fibers. The preparation process comprises the following steps: (1) preparing fine-grain tea stalk powder; (2) preparing preliminary mixing materials; (3) preparing tea stalk fiber powder; (4) preparing mixed additive materials; and (5) stirring the mixed additive materials and the polylactic acid fibers uniformly, performing blending extrusion and performing injection moulding to obtain the tea stalk plant fiber synthetic resin. The tea stalk plant fiber synthetic resin and the preparation process thereof have the advantages that resources, such as crop waste and the like, are completely utilized to avoid waste of the resources, and environmental pollution is reduced; and the production cost is low, wide application is realized, the advantages of rural resources can be exploited, and effective method and approach are provided for reasonable utilization of waste crops.

Owner:安徽科邦树脂科技有限公司

Walnut shell plant fiber synthetic resin and preparation process thereof

The invention specifically relates to a walnut shell plant fiber synthetic resin and a preparation process thereof, belonging to the field of chemical materials. The walnut shell plant fiber synthetic resin comprises the following raw materials: walnut shell powder, methyl cellulose, polyvinyl alcohol, aliphatic dicarboxylic acid, amino resin, sorbitol, gelatin powder, alkyl sulfonate and polylactic acid fiber. The preparation process comprises the following steps: (1) preparing fine-grain walnut shell powder; (2) preparing a preliminarily mixed material; (3) preparing walnut shell fiber powder; (4) preparing a mixed additive; and (5) uniformly mixing the mixed additive and the polylactic acid fiber under stirring and carrying out blending, extrusion and injection molding so as to obtain the walnut shell plant fiber synthetic resin. According to the invention, resources like waste crop materials are prevented from wasting and made full use of, and environmental pollution is reduced; and the preparation process is low in production cost and wide in an application scope, can give full play to the resource advantage of rural areas and provides an effective method and approach for rational utilization of waste crops.

Owner:安徽科邦树脂科技有限公司

Tapioca pearls preserved by sugar solution and preparation method thereof

InactiveCN113412930AFreeze resistantNo deformationSugar food ingredientsClimate change adaptationBiotechnologyHigh-fructose corn syrup

The invention relates to the technical field of snack food production and preparation, and discloses tapioca pearls preserved by a sugar solution, the tapioca pearl comprises pearl tapioca and the sugar solution, the pearl tapioca is prepared from cassava native starch and / or modified starch, sugar and a composite colloid, the sugar solution comprises one sugar selected from white granulated sugar, high fructose corn syrup, malt syrup and brown sugar, and an acidity regulator and / or perfume, and water. The invention also discloses a preparation method of the tapioca pearls preserved by the sugar solution. The tapioca pearls are more convenient to use, the storage limitation range is narrowed, energy can be saved, and the method is energy-saving and environment-friendly.

Owner:SHANGHAI SONGJIANG BAOLI FOODSTUFF

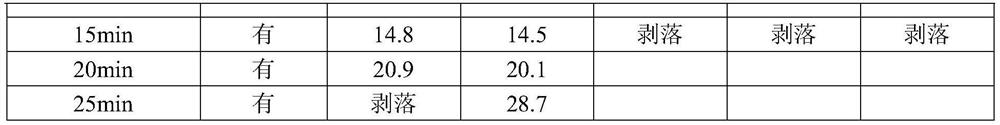

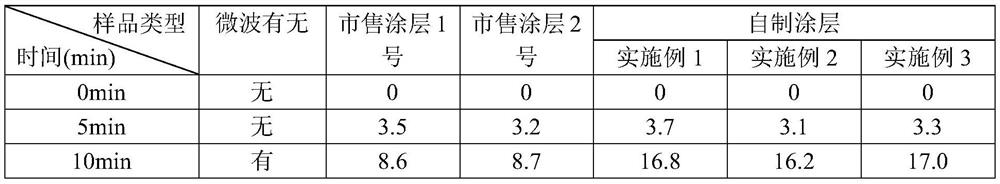

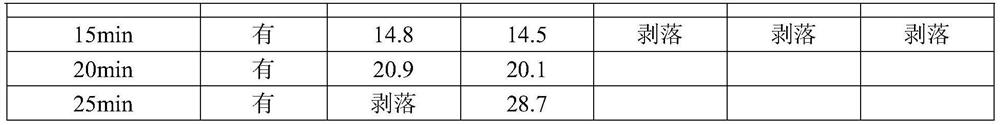

Wave-absorbing and heat-generating coating for ice melting of wind power blade and preparation method thereof

ActiveCN114085609ASelf-cleaningResistant to heat and humidityMachines/enginesPolyurea/polyurethane coatingsThermodynamicsMicrowave

The invention provides a wave-absorbing and heat-generating coating for ice melting of a wind power blade and a preparation method thereof. The surface of the wind power blade is coated with the material, and an ice layer on the surface of the wind power blade is removed in cooperation with microwaves. The coating provided by the invention adopts environment-friendly chemical components, can be sprayed on the wind power blade in a large area, has the advantages of self-cleaning, damp heat resistance, freezing resistance and the like, and does not corrode the wind power blade. In cooperation with microwave deicing, microwave energy can be better absorbed and converted into heat energy, ice at an interface is rapidly melted, and the ice surface is loosened and disengaged. The coating has the advantages of strong microwave absorption, wide frequency band, high wear resistance, strong adhesive force, good thermal stability and the like.

Owner:XIAN THERMAL POWER RES INST CO LTD

A wave-absorbing and heat-generating coating for melting ice of wind power blades and its preparation method

ActiveCN114085609BSelf-cleaningResistant to heat and humidityMachines/enginesPolyurea/polyurethane coatingsMicrowaveChemical composition

Owner:XIAN THERMAL POWER RES INST CO LTD

Making method of wooden container

InactiveCN100460289CMeet the requirements of "green environmental protection"Non-toxic and harmlessFlexible coversWrappersFiberWood veneer

The invention discloses a wood container and preparing method, which is characterized by the following: adopting two wood films to chuck one gluing film, forming glue on the fiber wood surface, integrating mould and wood slice through heat fusing to form wood container.

Owner:HONG GENE TECH

Cotton seed hull plant fiber synthetic resin and preparation process thereof

The invention relates to the technical field of chemical materials, and in particular to cotton seed hull plant fiber synthetic resin and a preparation process thereof. The cotton seed hull plant fiber synthetic resin is prepared from the following raw materials: cotton seed hull powder, ethyecellulose, polycaprolactone, aliphatic dicarboxylic acid, modified amino resin, pentaerythritol, wood glue powder, light calcium carbonate and polylactic acid fiber. The preparation process comprises the following steps: (1) preparing fine granular cotton seed hull powder; (2) preparing a primary mixed material; (3) preparing cotton seed hull fiber powder; (4) preparing a mixed added material; (5) uniformly stirring the mixed added material and polylactic acid fiber, co-mixing, extruding, and performing injection molding, thereby obtaining the cotton seed hull plant fiber synthetic resin. By adopting the cotton seed hull plant fiber synthetic resin, waste of resources such as waste crop materials can be avoided, the waste crop materials can be sufficiently utilized, and environment pollution can be reduced, the production cost is low, the application is very wide, resource advantages of rural areas can be brought into good play, and effective methods and ways are provided for reasonable utilization of waste crops.

Owner:安徽科邦树脂科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com