Making method of wooden container

A manufacturing method and wood technology, which is applied in the direction of manufacturing tools, wood processing utensils, and the joining of wooden veneers, etc., can solve the problems of unfavorable recycling, easy to be affected by moisture, difficult to store, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

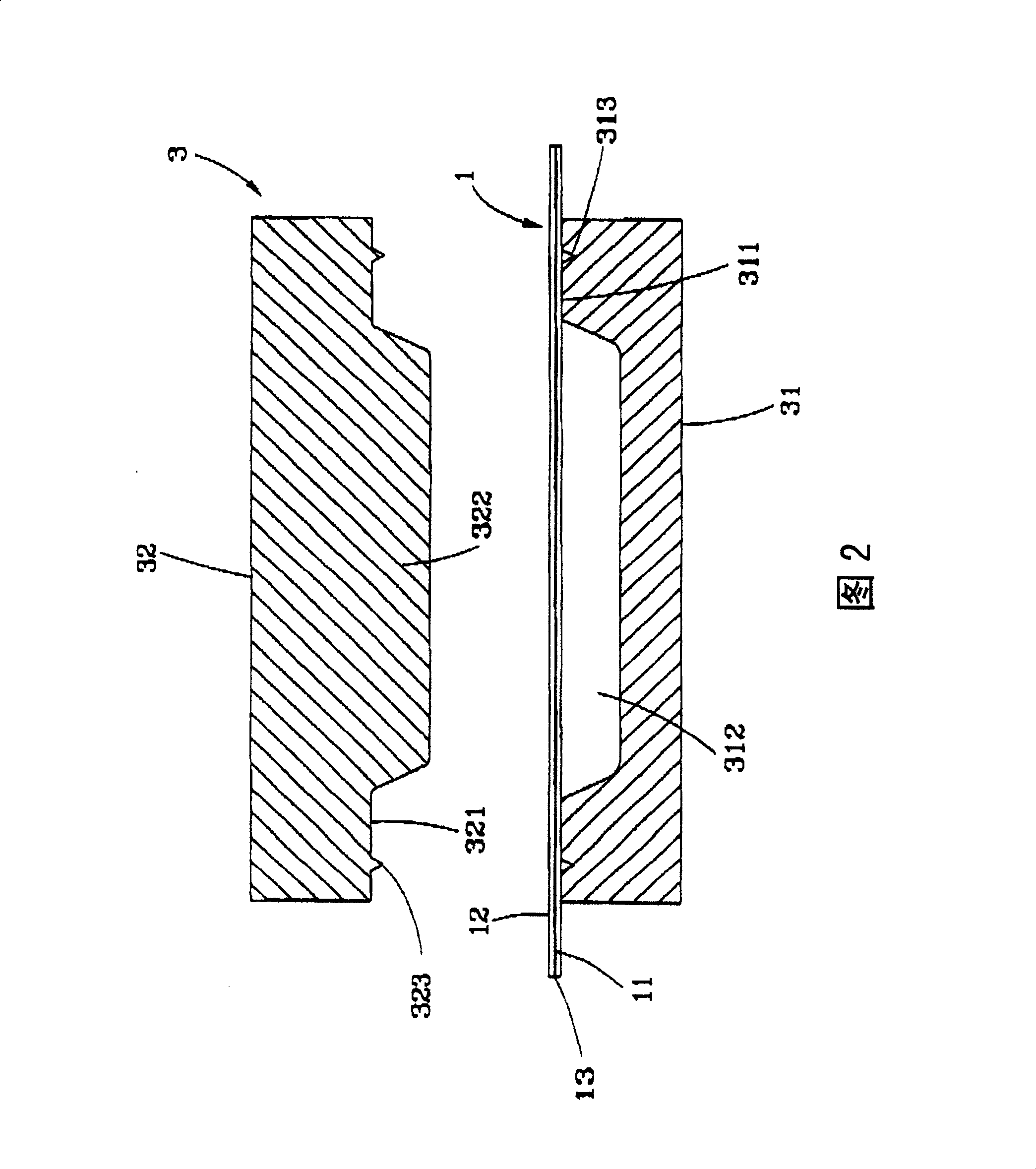

[0028] Please refer to Figures 1 to 3, the manufacturing method of the preferred embodiment of the present invention includes the following steps:

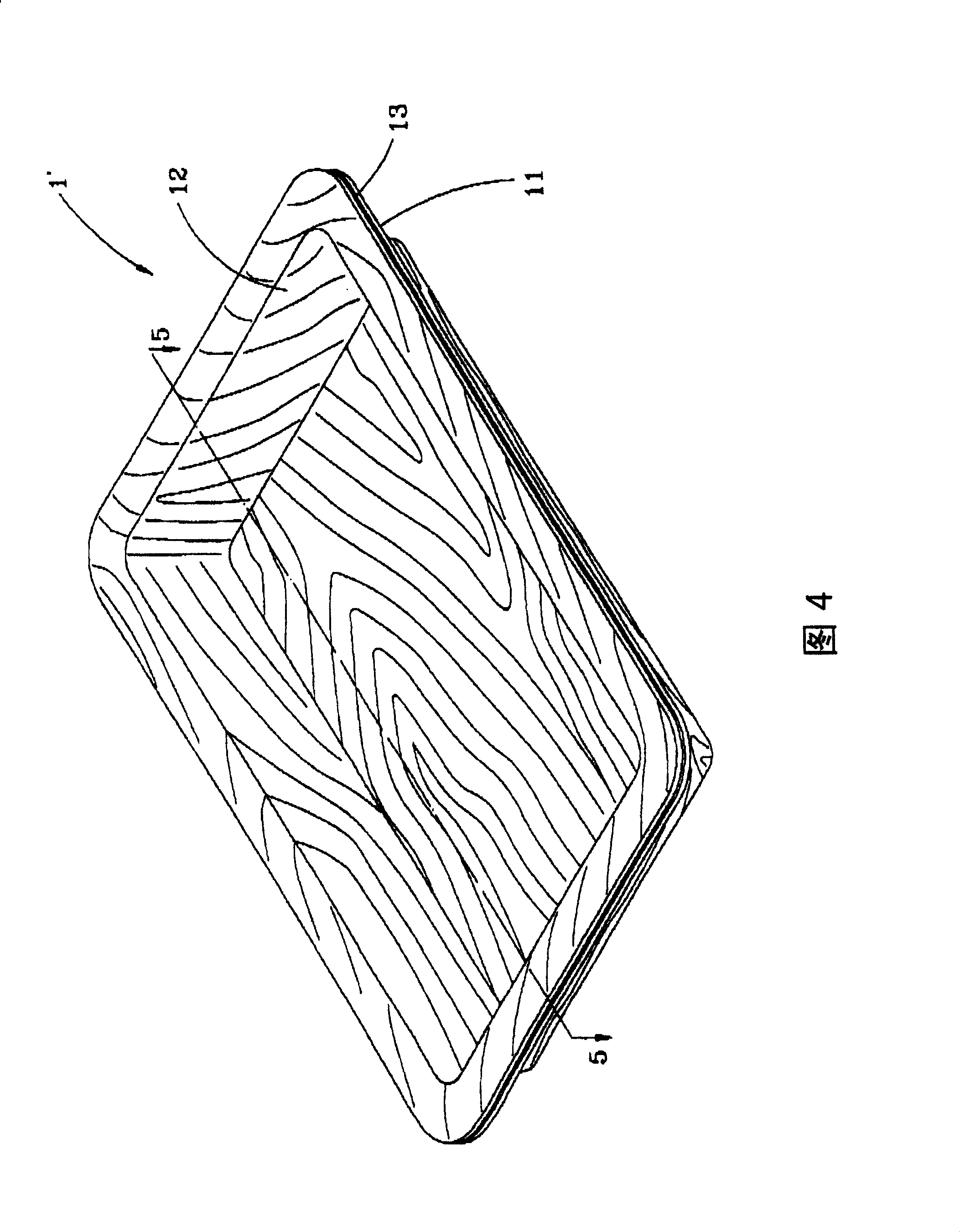

[0029] Step 1: Prepare two wood veneers 11, 12 and a glued film 13. The wood veneers 11, 12 are obtained from at least six-year-old Malacca (Fallcata Albisia) species (about 35 cm in diameter), and the volume is cut into 0.5 mm. thickness, and then moderately dried; the glued film 13 is made of a natural long-fiber material, and is made by coating or soaking edible glue or bio-glue on the upper and lower surfaces, and the long-fiber material is based on The advantage of wood is that it is easy to recycle and takes into account the needs of environmental protection.

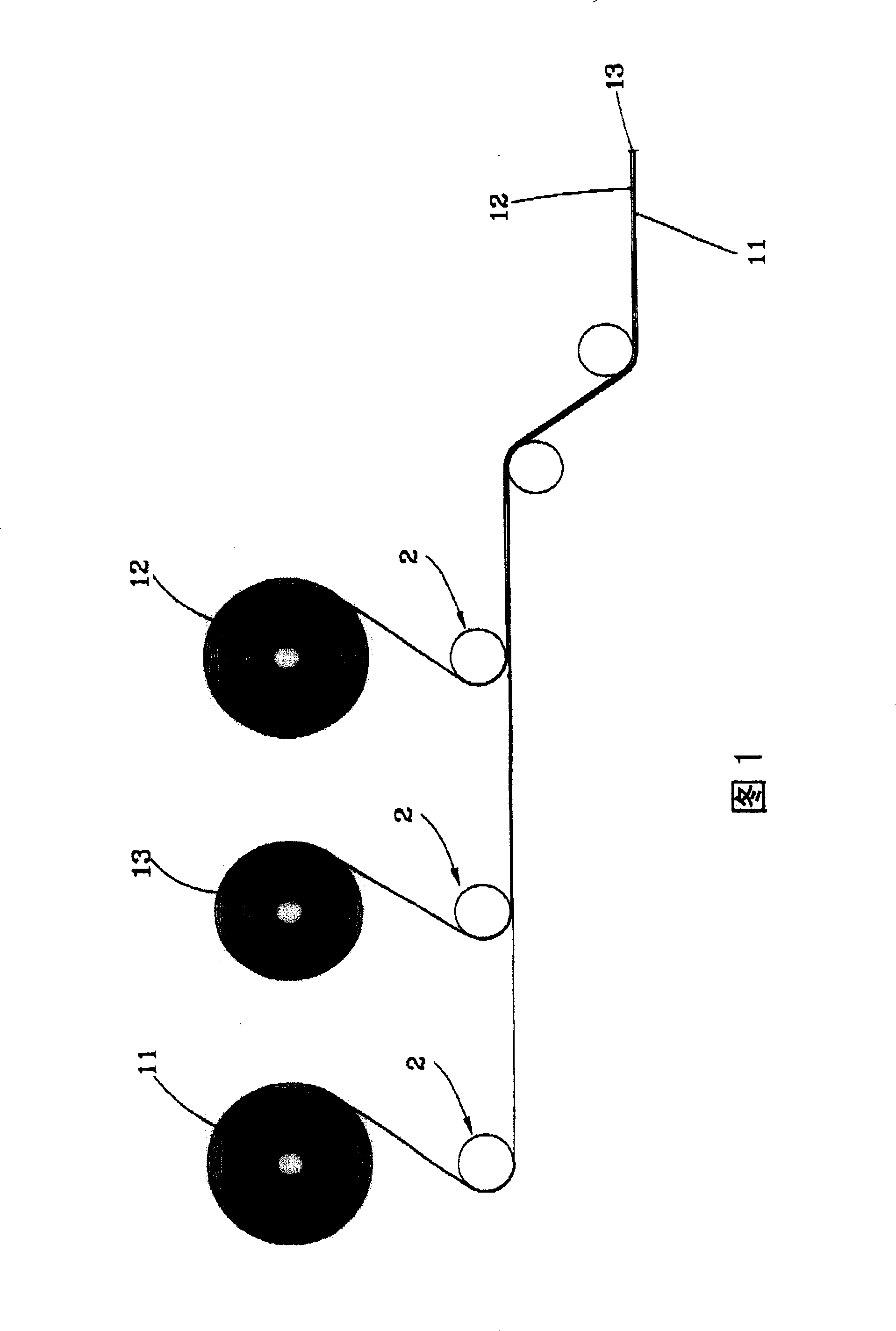

[0030] Step 2: Convey and stack the wood veneers 11, 12 and the glued film 13 with a plurality of rollers 2, so that the glued film 13 is stacked between the two wood veneers 11, 12, referring to Fig. 1, and passing through a cutting machine (Fig. (not shown in the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com